Device for integrating ultra-clean emission, desulfurization, denitrification and dedusting of flue gas and process of device

A technology for desulfurization, denitrification, and flue gas, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of popularization and application of the inhibition of ozone oxidation process, short half-life of ozone decomposition, and high operating costs, and achieve the realization of flue gas ultra-high Net emission, high desulfurization, denitrification and dust removal efficiency, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

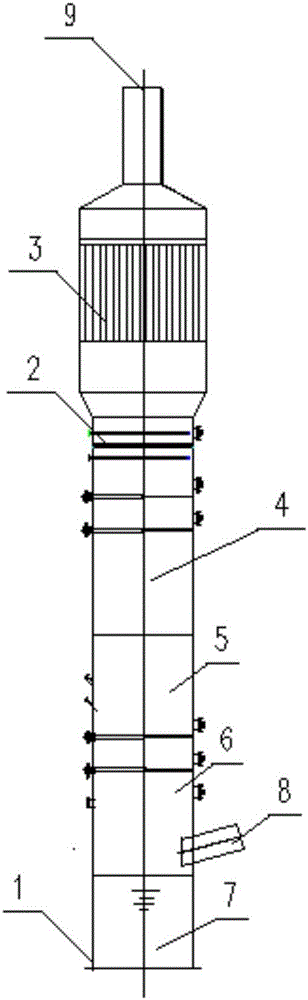

[0035]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] At present, the process of simultaneous wet desulfurization and denitrification is mainly based on the oxidation absorption method, which mainly passes the flue gas through a strong oxidative environment first, and oxidizes NO into NO 2 , and then absorbed by lye, the oxidizing agent mainly used is HClO 3 (NaClO 2 ), O 3 、H 2 o 2 and KMnO 4 etc., the absorption solution is NaOH, MgOH, etc.; and the present invention solves NO x Low oxidation efficiency, or high operating costs, chlorine dioxide (ClO 2 ) is the most oxidizing agent of the present invention, specifically as follows:

[0037] Chlorine dioxide (ClO 2 ) is a yellow-green to orange-yellow gas. It is internationally recognized as a safe and non-toxic green disinfectant with strong oxidizing properties. Its main uses are sterilization, bleaching, deodorization, disinfection, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com