Ultralow-temperature ultra-clean flue gas exhausting system and method for thermal power plant

A discharge system and thermal power plant technology, applied in the direction of separation methods, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of secondary pollution from gypsum rain, white smoke from chimneys, etc., to alleviate white smoke and reduce energy Effect of waste and reduction of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

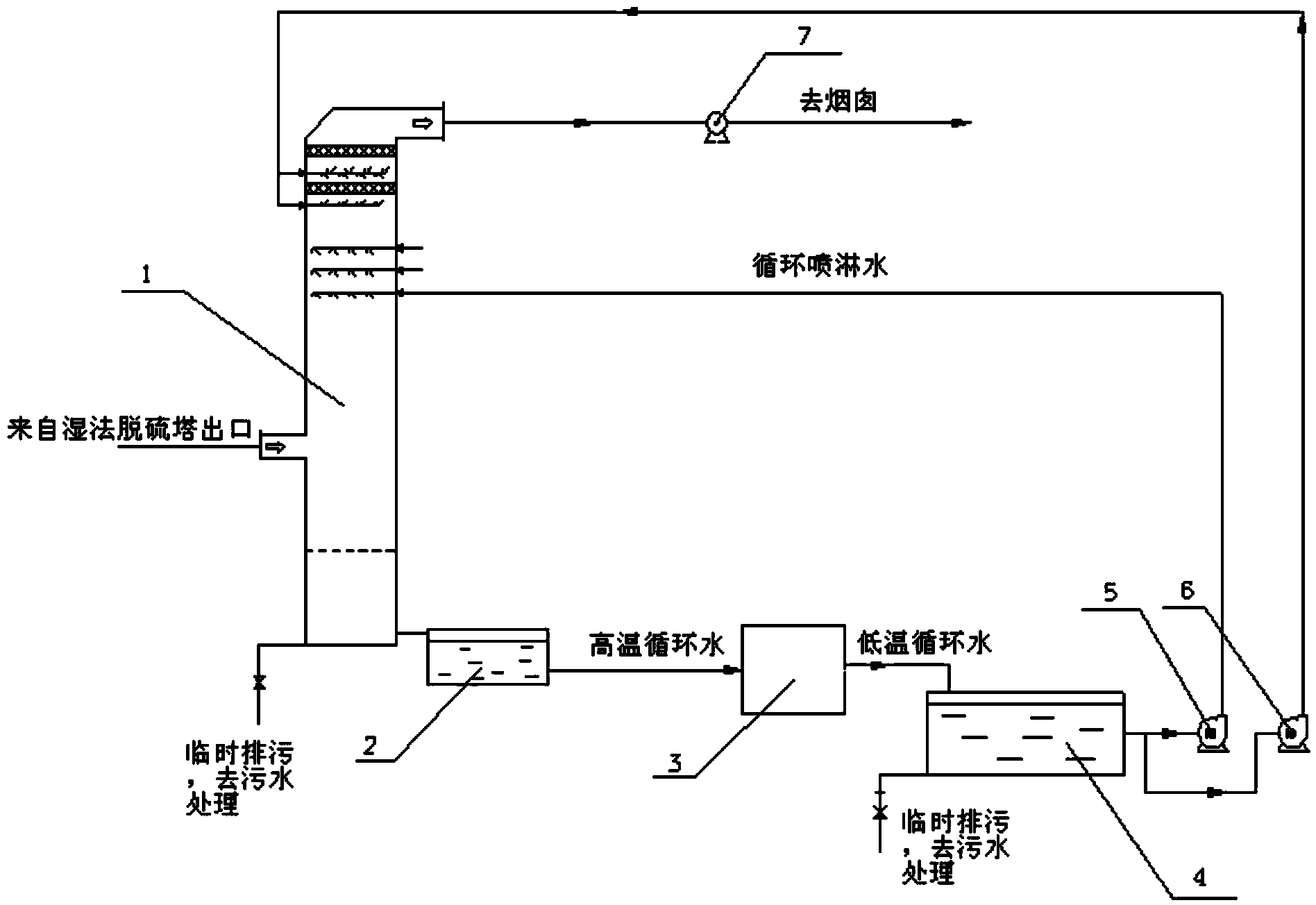

Embodiment 1

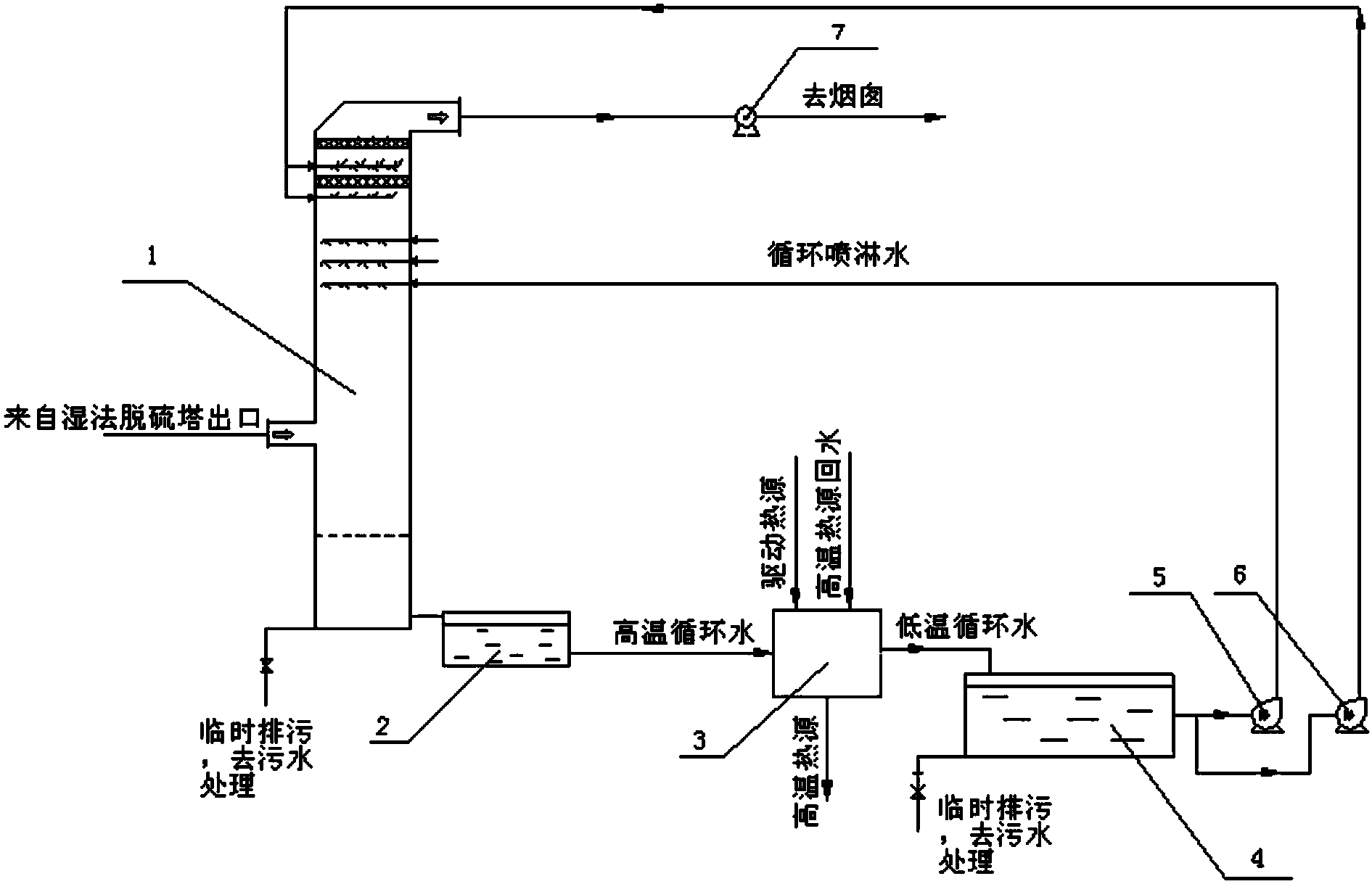

[0032] Such as figure 2As shown, the heat exchange system 3 of this embodiment is an absorption heat pump. The driving heat source of the absorption heat pump comes from the low-pressure cylinder extraction of the steam turbine of the thermal power plant, and the return water of the heat network is used as the working medium of the high-temperature heat source of the absorption heat pump. The discharge method is as follows: the wet flue gas from the outlet of the wet desulfurization tower of the thermal power plant enters through the flue gas inlet of the heat exchange scrubber 1, walks from bottom to top in the heat exchange scrubber 1, and the circulating cooling water is atomized through multi-layer nozzles After walking from top to bottom, the flue gas and the atomized circulating cooling water contact countercurrently in the heat exchange scrubber 1, and a strong heat and mass transfer process occurs, the flue gas is cooled by the circulating cooling water, and the water ...

Embodiment 2

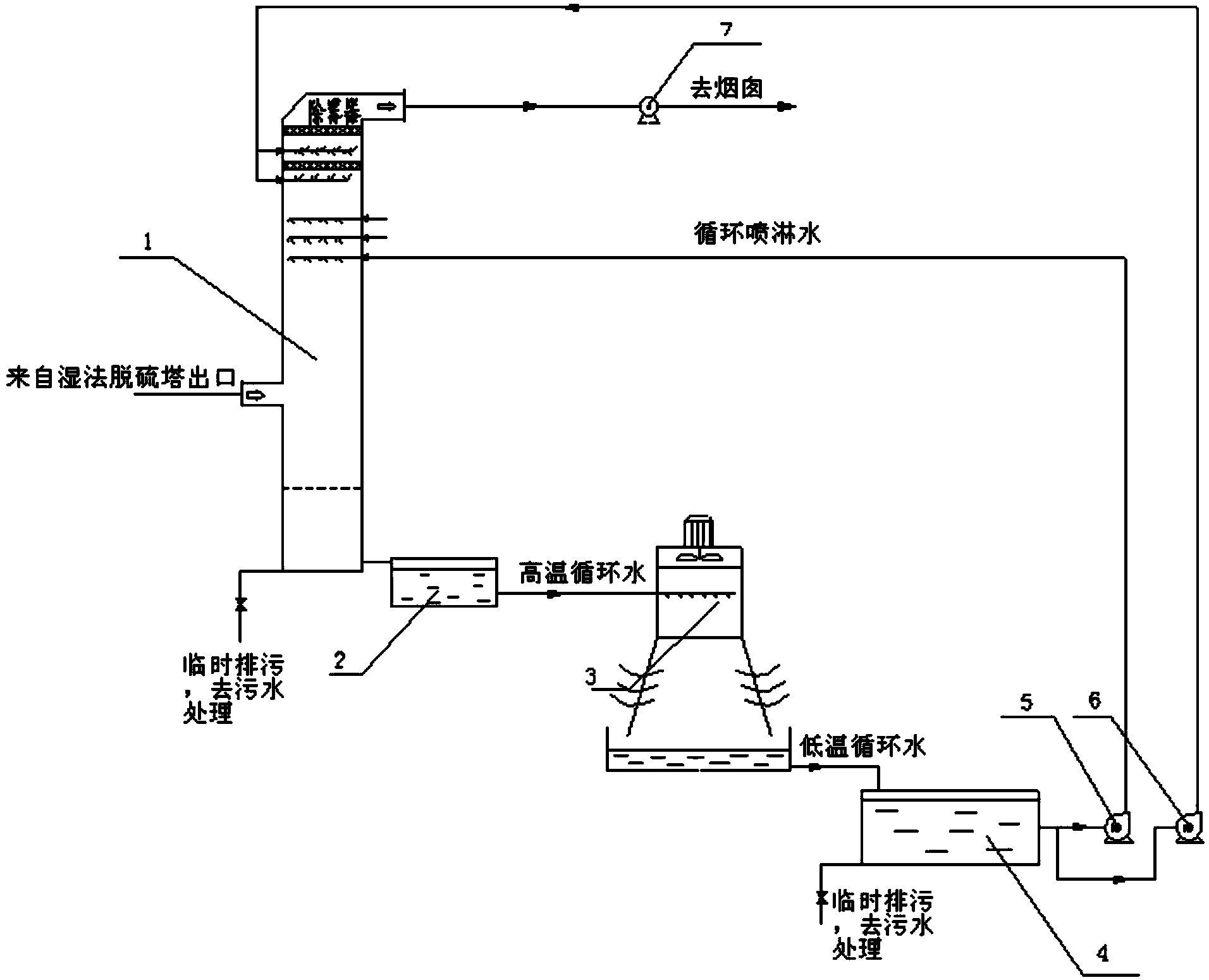

[0034] Such as image 3 As shown, the heat exchange system 3 of this embodiment is a cooling tower. The discharge method is as follows: the wet flue gas from the outlet of the wet desulfurization tower of the thermal power plant enters through the flue gas inlet of the heat exchange scrubber 1, walks from bottom to top in the heat exchange scrubber 1, and the circulating cooling water is atomized through multi-layer nozzles After walking from top to bottom, the flue gas and the atomized circulating cooling water contact countercurrently in the heat exchange scrubber 1, and a strong heat and mass transfer process occurs, the flue gas is cooled by the circulating cooling water, and the water vapor in the flue gas condenses Afterwards, a large amount of condensed water enters the circulating cooling water, the sensible heat of the flue gas and the latent heat of vaporization of the water vapor are absorbed by the circulating cooling water, and the cooled flue gas continues upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com