Boiler flue gas denitration purification system and boiler flue gas denitration purification method

A technology for boiler flue gas and purification system, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc. Consumption and other issues to achieve the effect of saving resources, enhancing mixing, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

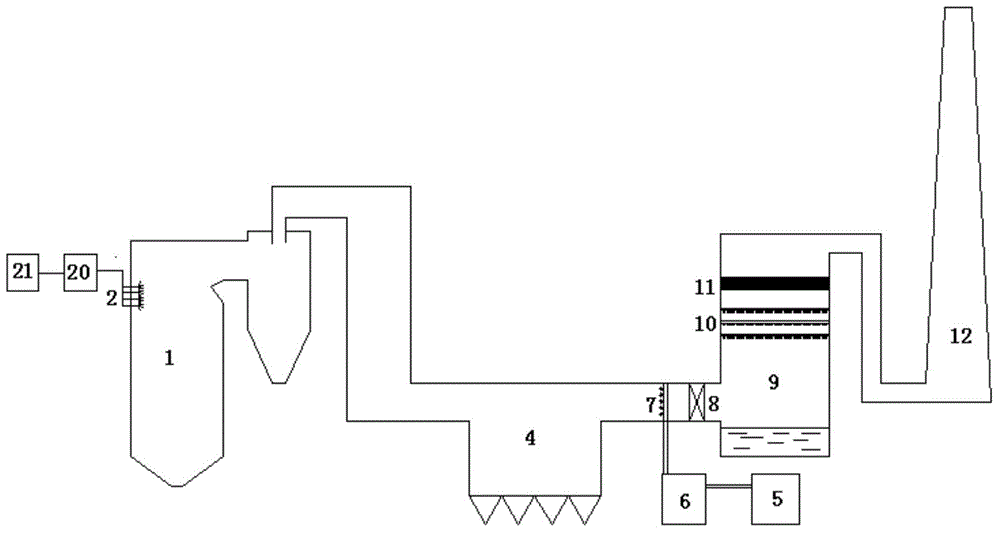

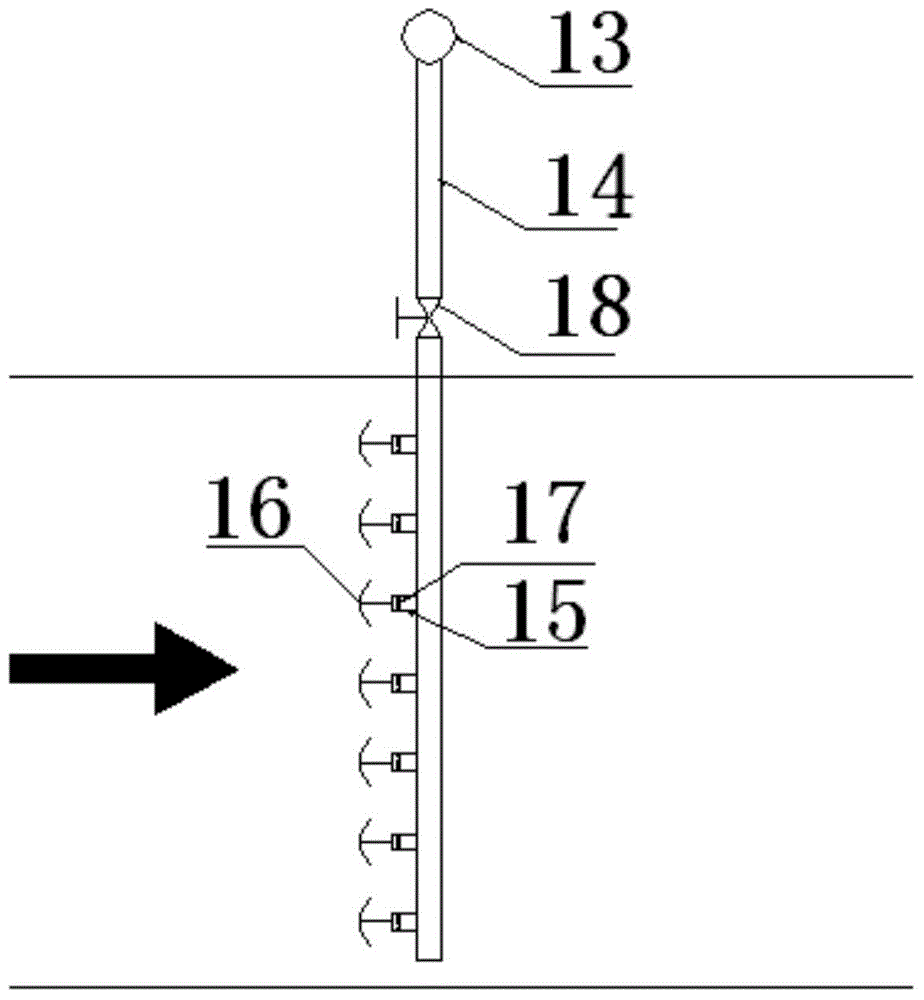

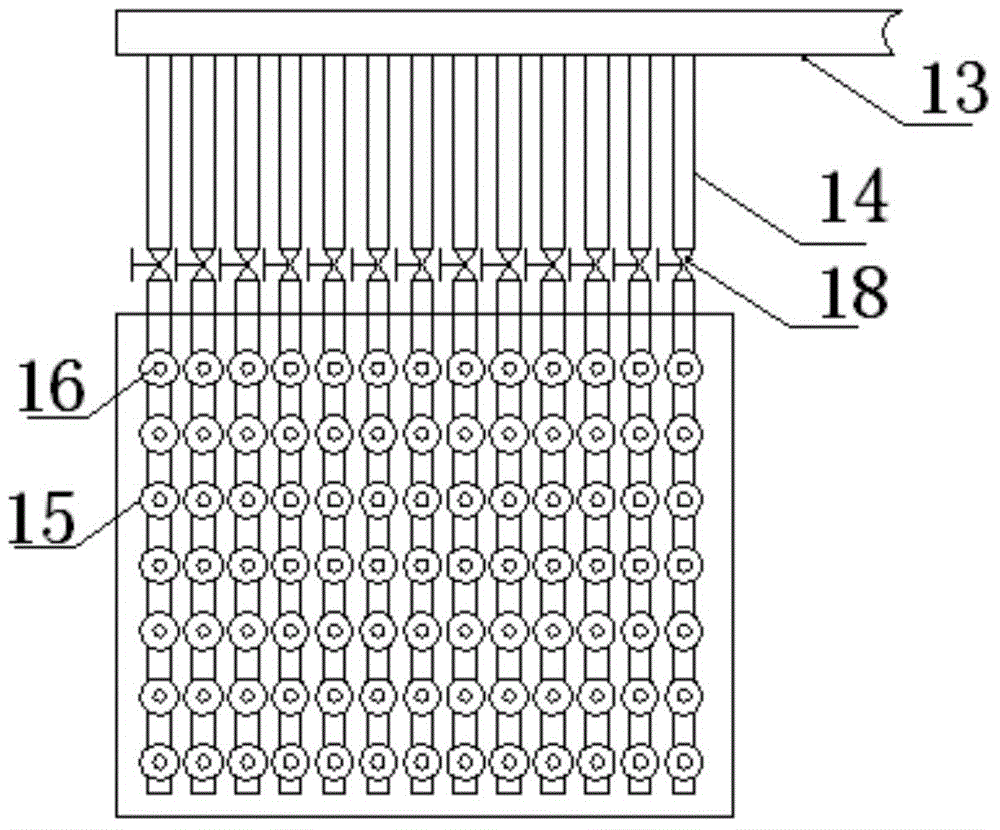

[0039] see figure 1 , a purification system for boiler flue gas denitrification, comprising a circulating fluidized bed boiler 1, a dust collector 4, a desulfurization tower 9 and a chimney 12 connected in sequence, the furnace of the circulating fluidized bed boiler is connected with a denitrification reducing agent injection module, the The deduster 4 is connected to the desulfurization tower 9 through the desulfurization tower inlet flue, and also includes an ozone injection device 7 and a static mixer 9 arranged in the desulfurization tower inlet flue along the flue gas flow direction, and is connected to the ozone injection device 7 The ozone generator 6 and the air separation unit 5 connected with the ozone generator 6.

[0040] In this embodiment, the denitration reducing agent injection module includes a denitration reducing agent storage tank 21, a denitration reducing agent metering device 20 and a denitration reducing agent injection device 2 connected in sequence, ...

Embodiment 2

[0044] Figure 6 It is the second embodiment of the present invention, such as Figure 6 As shown, the difference from Example 1 is that the boiler is a coal-fired boiler 19, an SCR reactor 3 is set between the coal-fired boiler and the dust collector, and a denitration catalyst layer is set in the SCR reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com