Method for reducing large-size calcium aluminate inclusions in steel

A calcium-aluminate, large-scale technology, applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of elaboration, difficult to float and remove, and achieve the effect of reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

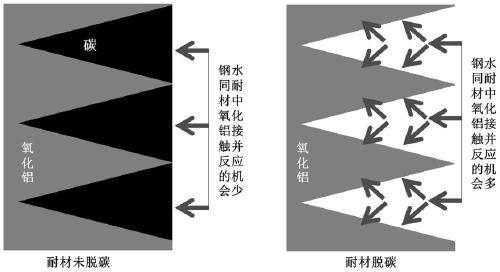

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

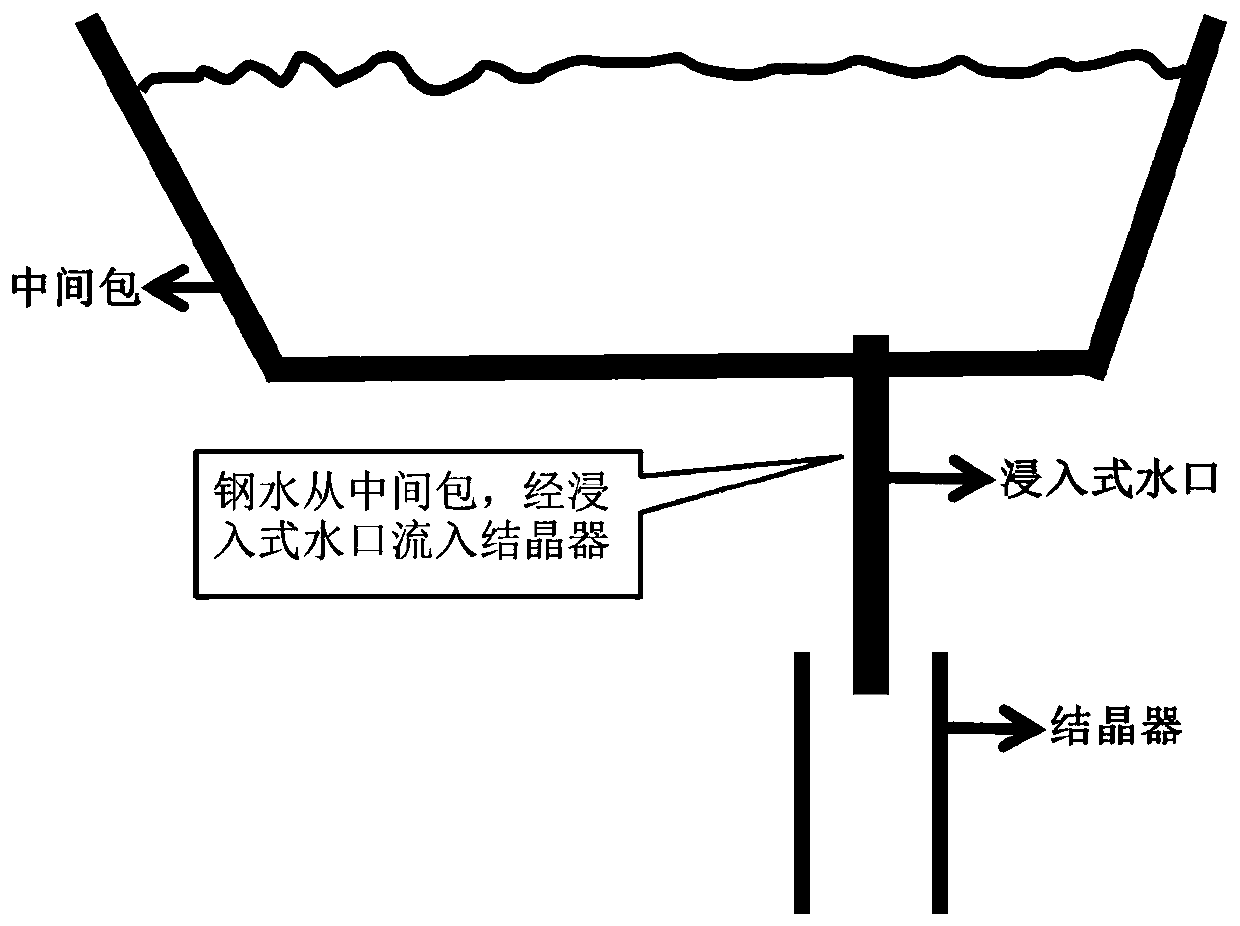

[0030] Choose 8 machines and 8 streams tundish separated on the left and right sides (4 streams on the left and right sides, that is, the left and right tundish have 4 tundish immersion nozzles (Al 2 O 3 -C quality)), under the condition that other process parameters remain unchanged, the left and right tundish immersion nozzles use the same manufacturer (for example, Vesuvius), and the chemical composition of the refractory material is similar to meet the requirements of Al 2 O 3 ≥50%, C≥1% requirements.

Embodiment 1

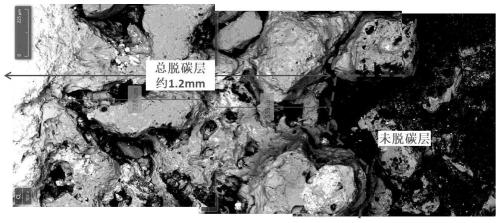

[0031] Example 1: During the test, the total baking time of the left tundish is required to be 5h. First, it is baked for about 1h. It is required that the temperature of the tundish immersion nozzle is maintained at about 100°C within this 1h; then the temperature is rapidly raised to 700°C, and the temperature is increased. Speed 30℃ / min, keep it at 700℃ for 3h; then heat up to 900℃, keep it for about 1h;

Embodiment 2 and comparative example 2

[0037] Use 8 machines and 8 stream tundish separated on the left and right sides (4 streams on the left and right sides, that is, the left and right tundish have 4 tundish immersion nozzles). Under the condition of other process parameters unchanged, the left and right sides The package immersion nozzle uses the same manufacturer (for example, Vesuvius), and the chemical composition of the refractory material is similar to meet the requirements of Al 2 O 3 ≥50%, C≥1% requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com