Preparation of graphene supported fullerene hybrid and polymer flame retardation application

A fullerene and graphene technology, applied in the field of preparation of graphene hybrid materials, can solve the problems of difficulty in obtaining uniformly dispersed nanoparticles, decreased mechanical properties of composite materials, weak interfacial interaction, etc., and achieves wide application prospects, The effect of easy operation and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

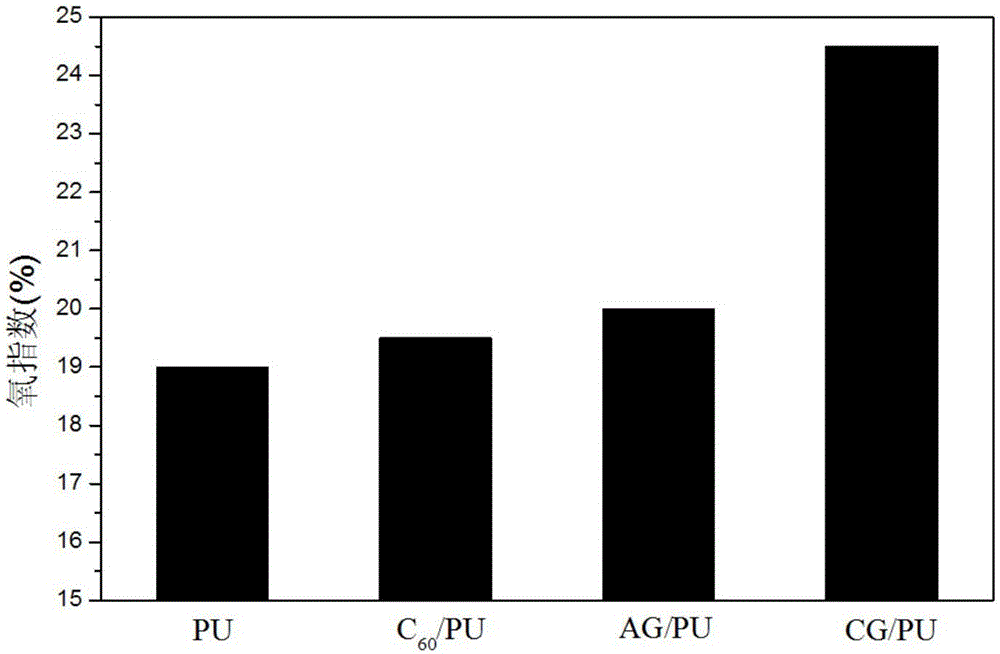

[0032] Implementation example 1, the preparation of fullerene loaded graphene / polyurethane rigid plastic foam

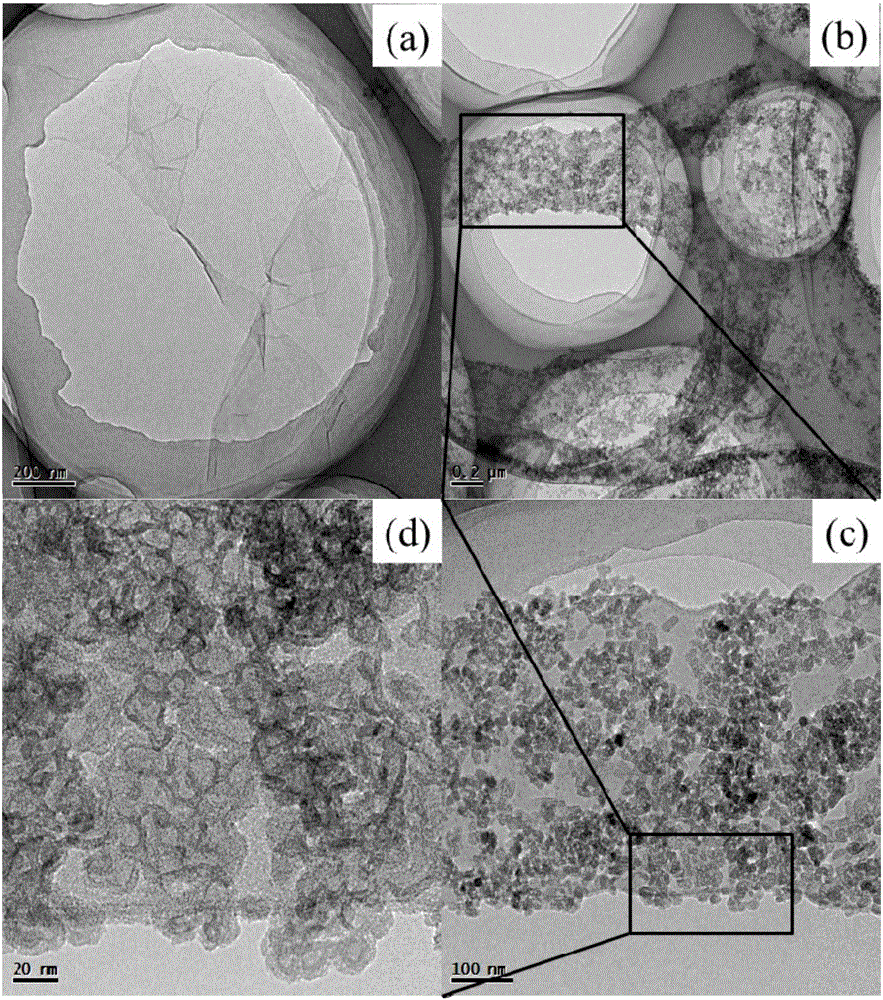

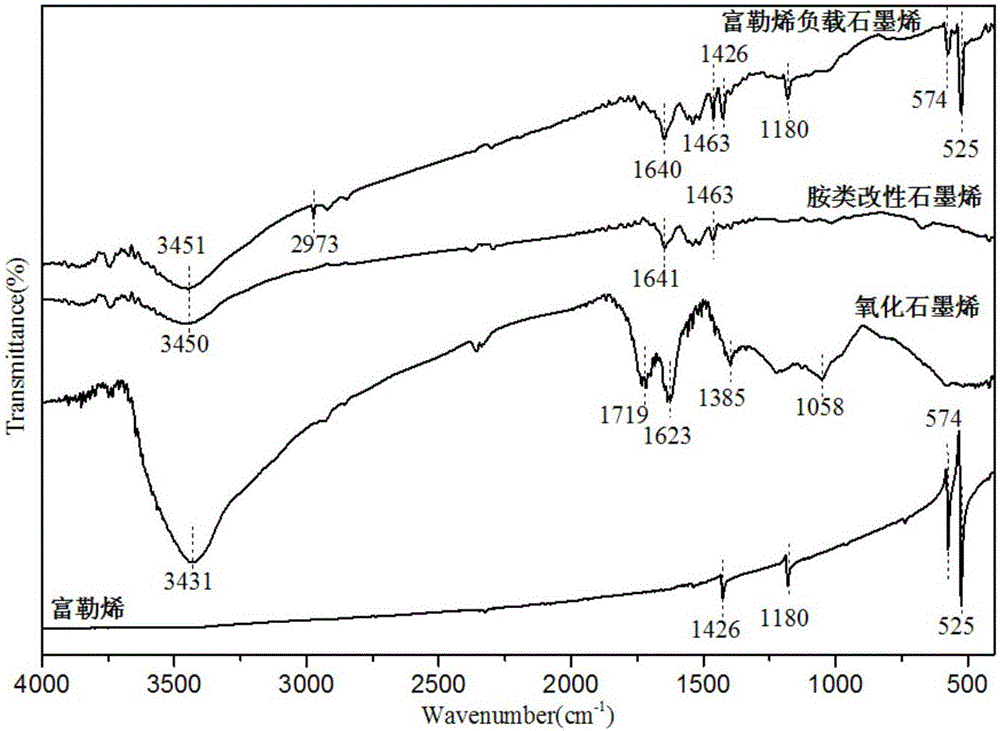

[0033] (1), preparation of fullerene-supported graphene hybrid materials

[0034] a, 50 mg GO was dissolved in 500 ml water, and ultrasonically dispersed until it turned yellow and transparent.

[0035] b. Add 200 mg polyethyleneimine to the above solution, and ultrasonically disperse for 30 minutes after flocs appear.

[0036] c. Heat and stir the mixed solution in a 60°C oil bath for 12 hours. After taking out the solution that turned black, it was centrifuged, washed 5 times with ethanol, and dried under vacuum at 60 °C. Amine-modified graphene is obtained.

[0037] d. Dissolve 150mg of amine-modified graphene in 300ml of DMSO and ultrasonically disperse for 30min.

[0038] e. Take out 300 mg of amine-modified graphene and dissolve it in 350 ml of DMSO-toluene mixed solution (4:3, v / v), and disperse ultrasonically until a purple transparent solution is formed ...

Embodiment 2

[0045] Implementation example 2, the preparation of fullerene loaded graphene / epoxy resin composite

[0046] The fullerene-supported graphene hybrid material was prepared as in step (1) in Example 1.

[0047] The preparation of fullerene-loaded graphene / epoxy resin composites was as follows: 1 g fullerene, 1 g amine-modified graphene and different masses (0.4, 0.6, 0.8 and 1 g) of fullerene-loaded graphene were added to the 100g bisphenol A glycidyl ether ethanol solution, ultrasonic 30min to form a uniform solution. The mixture was heated at 120°C to remove the solvent, and after no obvious bubbles escaped, it was moved into a vacuum oven at 60°C for 30 minutes to be vacuumed. After taking it out, add 23.4g of curing agent diethyltoluenediamine, and vacuum defoam after stirring. After taking it out, pour the mixed liquid into a U-shaped mold preheated at 100°C, put the mold into an oven, and control the curing temperature as follows: 120°C for 1h, 180°C for 2.5h and 190°C f...

Embodiment 3

[0049] Implementation example 3, the preparation of fullerene loaded graphene / unsaturated resin composite material

[0050] The fullerene-supported graphene hybrid material was prepared as in step (1) in Example 1.

[0051] The preparation of fullerene-loaded graphene / unsaturated resin composites is as follows: ultrasonically disperse 1 g of fullerene, 1 g of amine-modified graphene, and 1 g of fullerene-loaded graphene in 30 g of styrene solution to form a uniform Add 0.8g of cobalt naphthenate, 1g of methyl ethyl ketone peroxide and 100g of unsaturated resin to the solution at one time, stir well and pour it into the mold immediately, leave it at room temperature for 8h, and post-cure in an oven at 80°C for 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com