Ozone catalytic fluidized bed device and method for treating high-concentration organic wastewater difficult to biodegrade

A technology for organic wastewater treatment and refractory biodegradation, which is applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., and can solve the problems of low ozone utilization rate, catalyst hardening, and low organic matter salinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

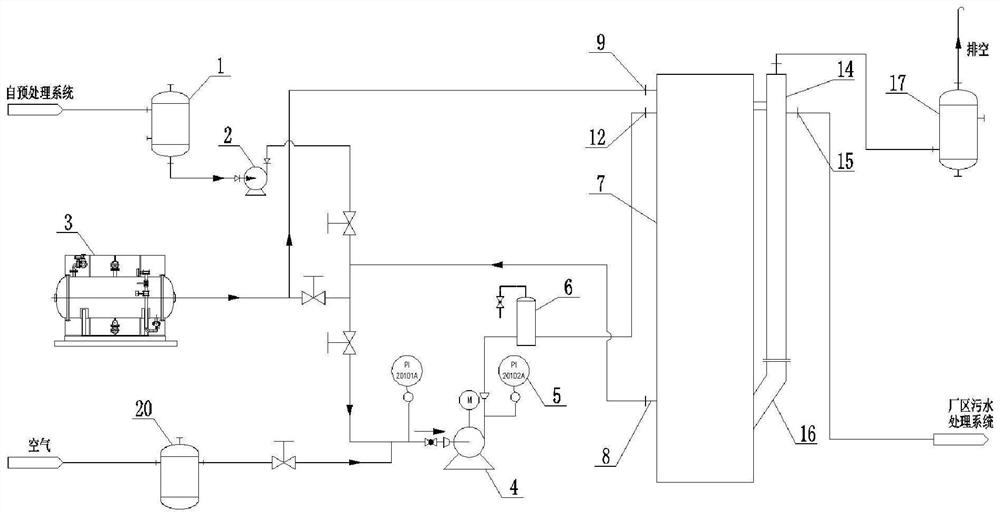

[0047] In all embodiments of the present invention, a kind of ozone catalytic fluidized bed device that is used for the treatment of high-concentration refractory organic waste water is provided, and its structure comprises organic waste water delivery pipeline and dissolved air water delivery pipeline, sewage booster pump 2, Ozone generator 3, dissolved air pump 4, fluidized bed reactor 7 and a plurality of control valves; Ozone generator 3 is used to produce ozone; the ozone to produce dissolved air water; the organic waste water delivery pipeline is set on the upstream of the dissolved air pump 4; the dissolved air water delivery pipeline is set on the downstream of the dissolved air pump 4; Junction, second junction and third junction.

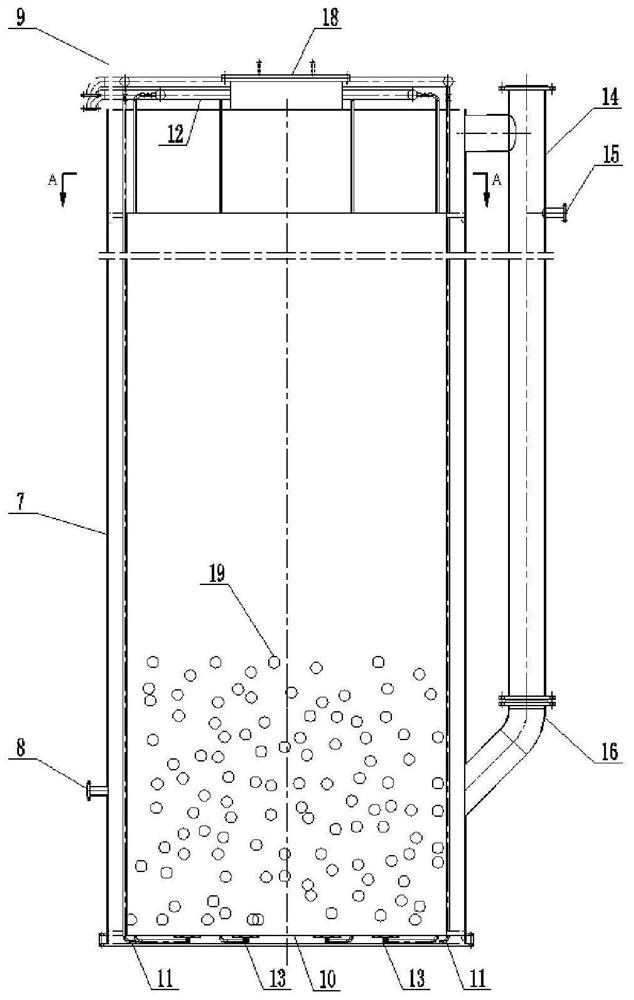

[0048] Such as figure 2 As shown, the top of the fluidized bed reactor 7 is provided with a top dissolved air water distribution pipe 12, and the top dissolved air water distribution pipe 12 communicates with at least one dissolved air w...

Embodiment approach

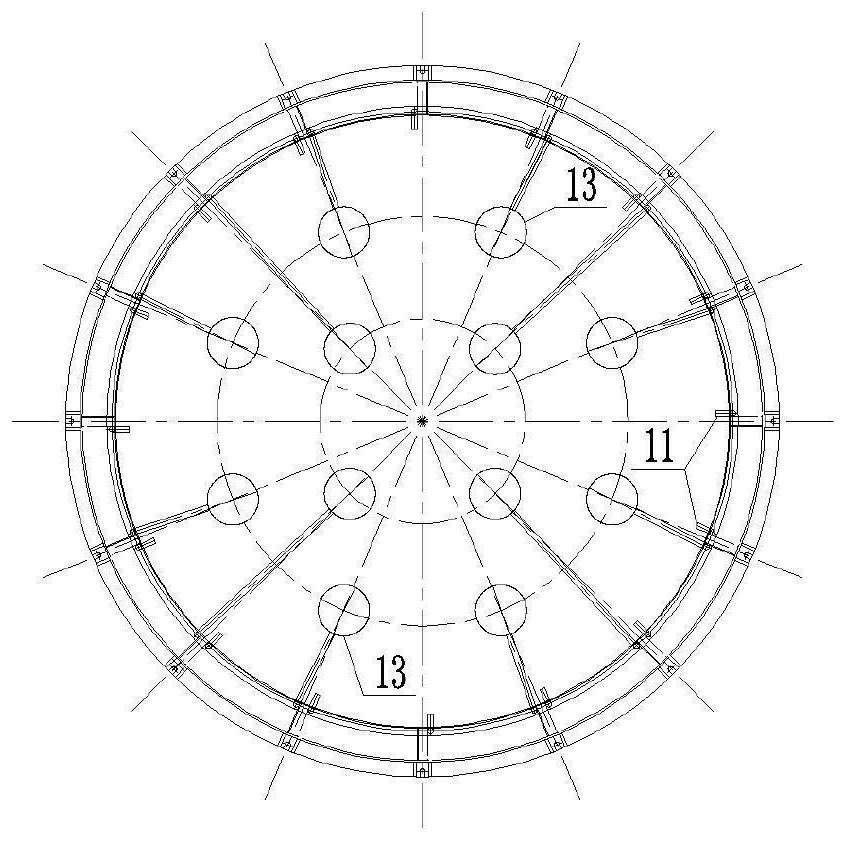

[0059] Such as figure 1 A kind of preferred embodiment of the present invention shown, described ozone catalytic fluidized bed device, comprises the sewage storage tank 1 connected by pipeline, sewage pressurized pump 2, ozone generator 3, dissolved air pump 4, gas-water separator 5. Pressurized tank 6. Fluidized bed reactor 7. Return pipe 8. Ozone gas distribution pipe at the top of the pool 9. Air corridor at the bottom of the fluidized bed 10. Dissolved air water distribution head 11. Top dissolved air water distribution pipe 12. Bottom Ozone gas dissolving head 13, return pipe 14, water outlet 15, return water outlet 16 and tail gas decomposer 17. Wherein the fluidized bed reactor 7 is filled with a granular catalyst 19 . The top of the fluidized bed reactor 7 is provided with a pool top inspection port 18 .

[0060] Wherein the ozone produced by the ozone generator 3, a part passes through the top ozone gas distribution pipe 9 of the pool, connects the bottom ozone diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com