Preparation method of partial glyceride

A technology of glycerides and triglycerides, which is applied in the field of preparation of some glycerides, can solve the problems of poor mutual solubility of reaction substrates, slow reaction speed, long reaction time, etc., and achieve conversion rate, product separation efficiency, and fast reaction speed , the effect of fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

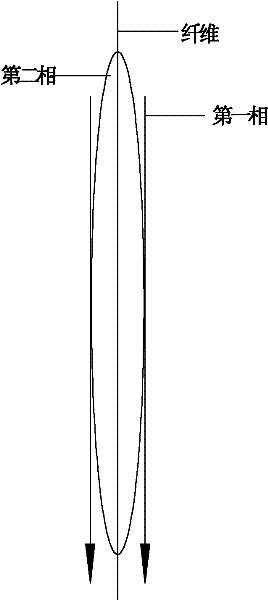

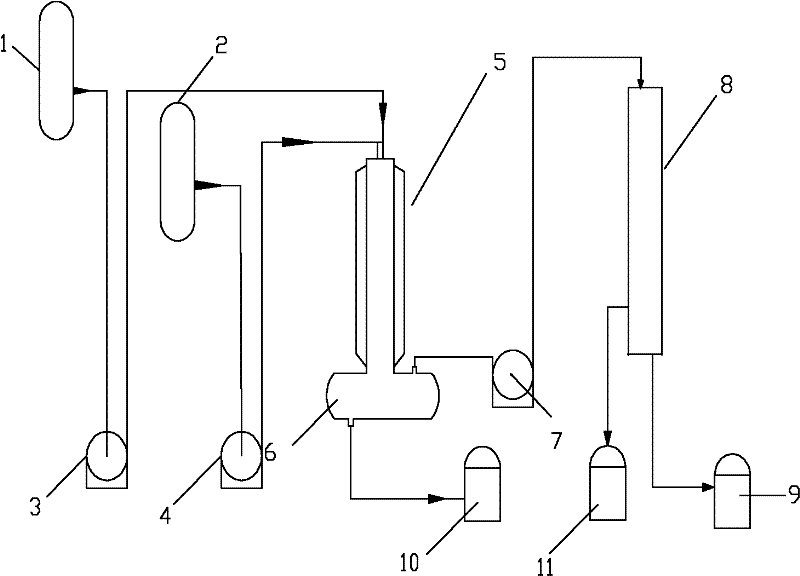

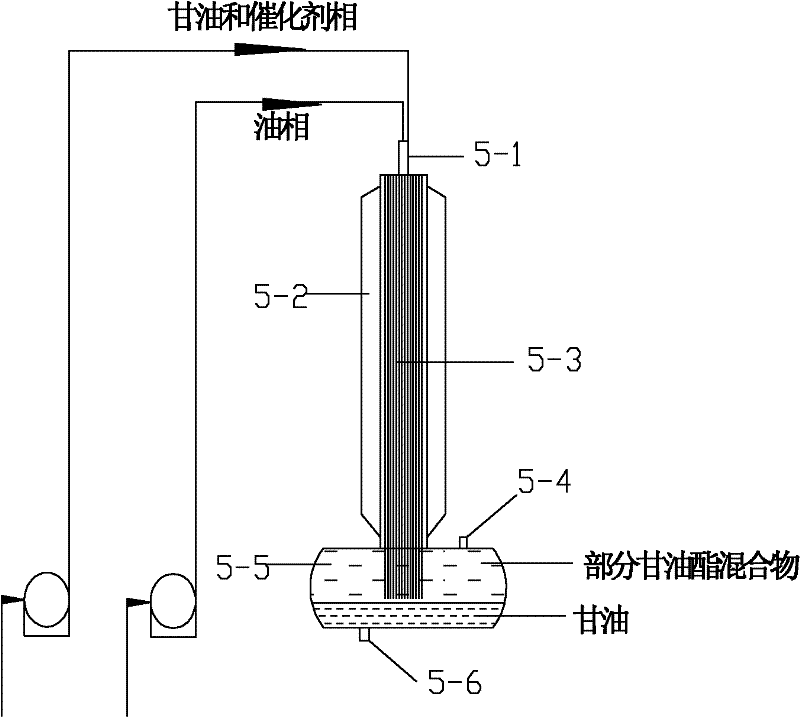

[0035] Example 1: The basic catalyst KOH is completely dispersed in glycerin to form a glycerol catalyst mixture. The quality of catalyzer is 0.1% of oil weight, and soybean oil and alcohol phase are preheated respectively, and control glycerin phase and oil phase mol ratio are 3: 1, pump into fiber reactor with metering pump (the diameter of glass fiber is 12 μ m, In a reactor with a length of 40 cm and an inner diameter of 3 cm), the reaction temperature is controlled at 150° C., and the residence time of the reaction materials in the reactor is 15 min. Sampling and analyzing the reaction conversion ratios of monoglyceride and diglyceride from the outlet of the reactor were 25% and 40%, respectively.

Embodiment 2

[0036] Example 2: Completely disperse the basic catalyst NaOH in glycerin to form a glycerol catalyst mixture. The quality of catalyzer is 0.2% of oil weight, and rice bran oil and alcohol phase are preheated respectively, and control glycerin phase and oil phase mol ratio are 4: 1, pump into fiber reactor with metering pump (the diameter of glass fiber is 12 μ m, In a reactor with a length of 70 cm and an inner diameter of 3 cm), the reaction temperature is controlled at 180° C., and the residence time of the reaction materials in the reactor is 22 min. Sampling and analyzing the reaction conversion ratios of monoglyceride and diglyceride from the outlet of the reactor were 30% and 50% respectively.

Embodiment 3

[0037] Embodiment 3: basic catalyst Ca(OH) 2 Completely dispersed in glycerin, the quality of catalyst is 0.1% of oil weight, and cottonseed oil and glycerin phase are preheated respectively, control glycerin phase and oil phase molar ratio to be 5: 1, pump into fiber reactor (stainless steel The diameter of the fiber is 8 μm, the length of the reactor is 30 cm, and the inner diameter is 3 cm), the reaction temperature is controlled at 200° C., and the residence time of the reaction materials in the reactor is 20 min. Sampling and analyzing the reaction conversion ratios of monoglyceride and diglyceride from the outlet of the reactor were 38% and 40%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com