An industrial flue gas membrane dust collector

A dust-collecting desulfurizer, industrial flue gas technology, applied in separation methods, chemical instruments and methods, electrode structures, etc., can solve the problems of huge investment in operating costs, no investment, small desulfurization device systems, etc., and achieve high-efficiency dust-collecting desulfurization , Low operating cost, and the effect of expanding the contact reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

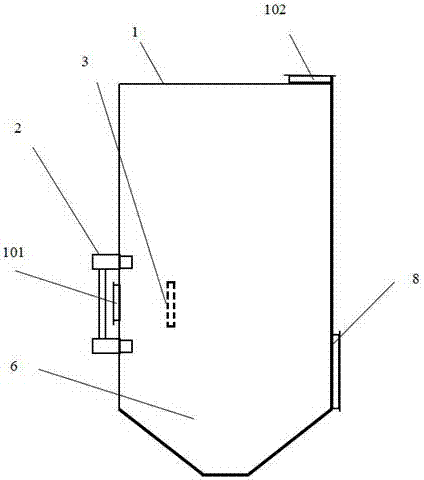

Embodiment 1

[0028] refer to figure 1 , this embodiment includes a housing 1, the housing 1 is vertically arranged, the side of the housing 1 is provided with an air inlet 101, the top of the housing 1 is provided with an exhaust port 102, and the housing 1 is provided with 4 negatively charged film bubbles Dispenser 2, the negatively charged film bubble dispenser 2 is fixed on the housing 1 by bolts, the 4 negatively charged film bubble dispensers 2 are evenly distributed, the housing 1 is provided with a flow stabilizer 3, and the flow stabilizer 3 is located in the intake air Directly in front of the mouth 101, the lower part of the housing 1 is a dust collecting bucket 6, and the middle and lower part of the housing 1 is provided with an inspection door 8.

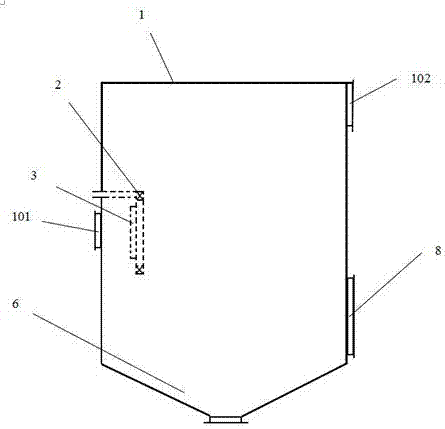

Embodiment 2

[0030] refer to figure 2 The only difference between this embodiment and Embodiment 1 is that the number of negatively charged film bubble applicator 2 is one, and the negatively charged film bubble applicator 2 is fixed on the current stabilizer 3 in the casing 1 by bolts. All the other are with embodiment 1.

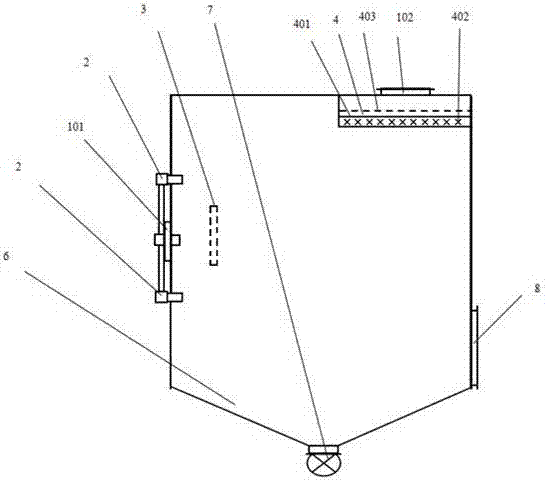

Embodiment 3

[0032] refer to image 3 , the difference between this embodiment and Embodiment 1 is only that: the number of negatively charged film bubble dispensers 2 is 6, and the 6 negatively charged film bubble dispensers 2 are fixed on the housing 1 at the end of the air inlet 101 by bolts; A filter element 4 is also fixed at the end near the exhaust port 102 in the body 1, and the filter element 4 includes a frame 401, and the frame 401 is fixed at the end near the exhaust port 102 in the housing 1, and a filter screen 402 and a soot cleaner are fixed on the frame 401 403; the lower part of the dust collecting bucket 6 is fixedly connected with the slag discharge conveyor 7. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com