A kind of composite hydrogen evolution electrode with copper and cobalt loaded on three-dimensional nickel foam and its preparation method

A technology of hydrogen evolution electrode and nickel foam, which is applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the problems of expensive precious metals, etc., and achieve the effects of simple operation, small environmental impact, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

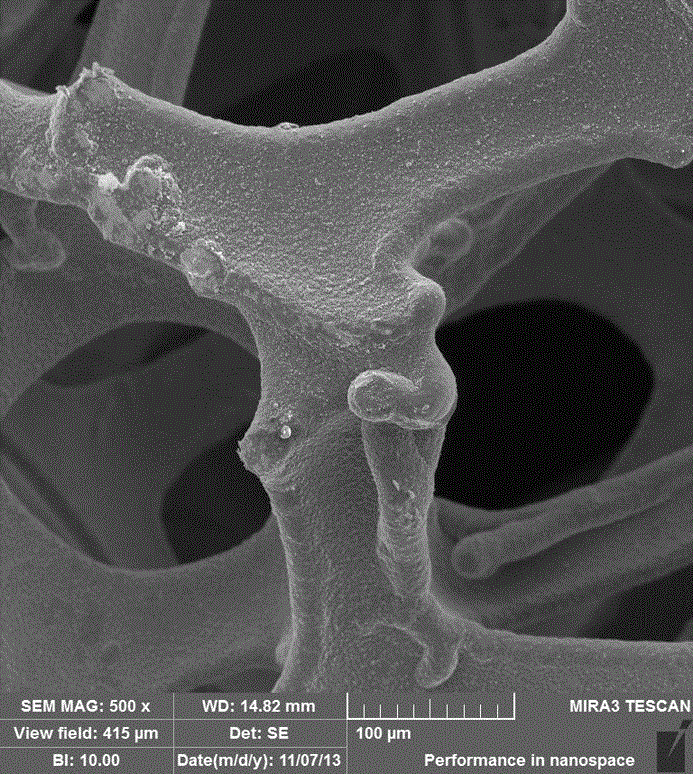

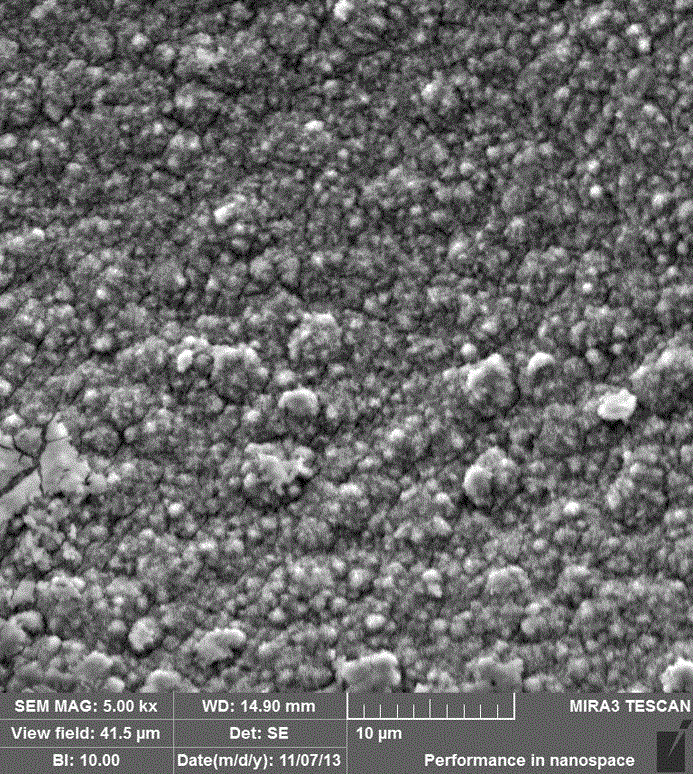

Image

Examples

Embodiment 1

[0033] A preparation method of a three-dimensional nickel foam supported copper and cobalt composite hydrogen evolution electrode is carried out according to the following steps:

[0034] a. Degrease and degrease the three-dimensional nickel foam in acetone for 1 minute, clean it with ultrapure water, then acidify and activate it in an 18wt.% hydrochloric acid solution, and finally place it in ultrapure water for 4 minutes with ultrasound;

[0035] b. Put the three-dimensional nickel foam treated in step a into the copper pyrophosphate solution, or a mixture of one or two of the copper pyrophosphate solution, potassium pyrophosphate solution, and ammonium citrate solution, with the copper sheet as the anode , The three-dimensional nickel foam is the cathode, and the current density is 0.01A / cm 2 Use a multifunctional pulse electroplating power supply for electrodeposition for 500s at a current of 500 s;

[0036] c. Clean the three-dimensional nickel foam on which copper is electroche...

Embodiment 2

[0041] A preparation method of a three-dimensional nickel foam supported copper and cobalt composite hydrogen evolution electrode is carried out according to the following steps:

[0042] a. Degrease and degrease the three-dimensional nickel foam in acetone for 1 minute, clean it with ultrapure water, then acidify and activate it in an 18wt.% hydrochloric acid solution, and finally place it in ultrapure water for 5 minutes with ultrasound;

[0043] b. Put the three-dimensional nickel foam treated in step a into a copper sulfate pentahydrate solution, or a mixture of one or more of copper sulfate pentahydrate solution and biuret solution, sodium hydroxide solution, and glycerin, With copper sheet as anode and three-dimensional nickel foam as cathode, the current density is 0.03A / cm 2 Use a multi-function pulse electroplating power supply for electro-deposition for 600 s at a current

[0044] c. Clean the three-dimensional nickel foam on which copper is electrochemically deposited in s...

Embodiment 3

[0049] A preparation method of a three-dimensional nickel foam supported copper and cobalt composite hydrogen evolution electrode is carried out according to the following steps:

[0050] a. Degrease and degrease the three-dimensional nickel foam in acetone for 1 minute, wash with ultrapure water, then acidify and activate it in 18wt.% hydrochloric acid solution, and finally place it in ultrapure water for 7 minutes;

[0051] b. Put the three-dimensional nickel foam treated in step a into the mixed solution of copper sulfate pentahydrate and boric acid, with the copper sheet as the anode and the three-dimensional nickel foam as the cathode, at a current density of 0.05A / cm 2 Use a multi-function pulse electroplating power supply to electrodeposition for 700s at a current of 700s;

[0052] c. Clean the three-dimensional nickel foam on which copper is electrochemically deposited in step b with ultrapure water, and then sonicate it in ultrapure water for 7 minutes;

[0053] d. Put the thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com