Rapid detection reagent, and detection methods thereof

A detection method and detection agent technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as unsatisfactory requirements, and achieve the effects of shortening the detection cycle, simple components, and shortening the detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

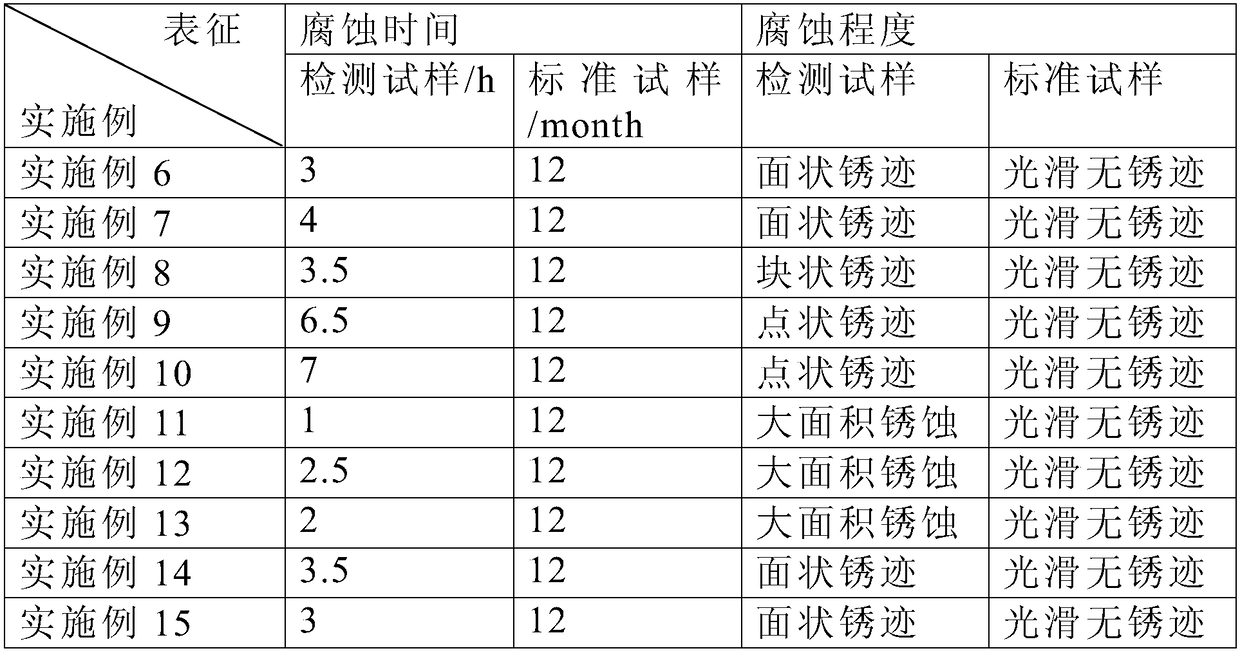

Examples

Embodiment 1

[0034] Detection agent configuration: Weigh raw materials according to the composition of the detection agent, including 500 parts of deionized water, 15 parts of copper chloride solution, 150 parts of acetic acid, 160 parts of hydrochloric acid, 25 parts of ferric chloride solution, 40 parts of potassium chloride solution, chlorine 20 parts of mercuric solution, wherein the concentrations of the components are: copper chloride solution: 10%, acetic acid: 35%, hydrochloric acid: 30%, ferric chloride solution: 8%, potassium chloride solution: 20%, chlorine Mercury solution: 5%.

Embodiment 2

[0036] Detection agent configuration: Weigh raw materials according to the composition of the detection agent, including 100 parts of deionized water, 10 parts of copper chloride solution, 100 parts of acetic acid, 120 parts of hydrochloric acid, 20 parts of ferric chloride solution, 30 parts of potassium chloride solution, chlorine 15 parts of mercuric solution, wherein the concentration of each component is: copper chloride solution: 1%, acetic acid: 10%, hydrochloric acid: 10%, ferric chloride solution: 1%, potassium chloride solution: 10%, chlorine Mercury solution: 0.5%.

Embodiment 3

[0038] Detection agent configuration: Weigh the raw materials according to the composition of the detection agent, including 1000 parts of deionized water, 20 parts of copper chloride solution, 200 parts of acetic acid, 200 parts of hydrochloric acid, 30 parts of ferric chloride solution, 50 parts of potassium chloride solution, chlorine 25 parts of mercuric solution, wherein the concentrations of the components are: copper chloride solution: 20%, acetic acid: 40%, hydrochloric acid: 36%, ferric chloride solution: 12%, potassium chloride solution: 25%, chlorine Mercury solution: 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com