Ozone catalytic oxidation stirring reactor and sewage treatment method

A technology of ozone catalytic oxidation and stirred reactor, which is applied in the direction of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of high cost of catalytic membrane components, complicated process flow, difficult maintenance and operation, etc. , to achieve the effects of prolonging the contact reaction time, high reaction efficiency, and reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

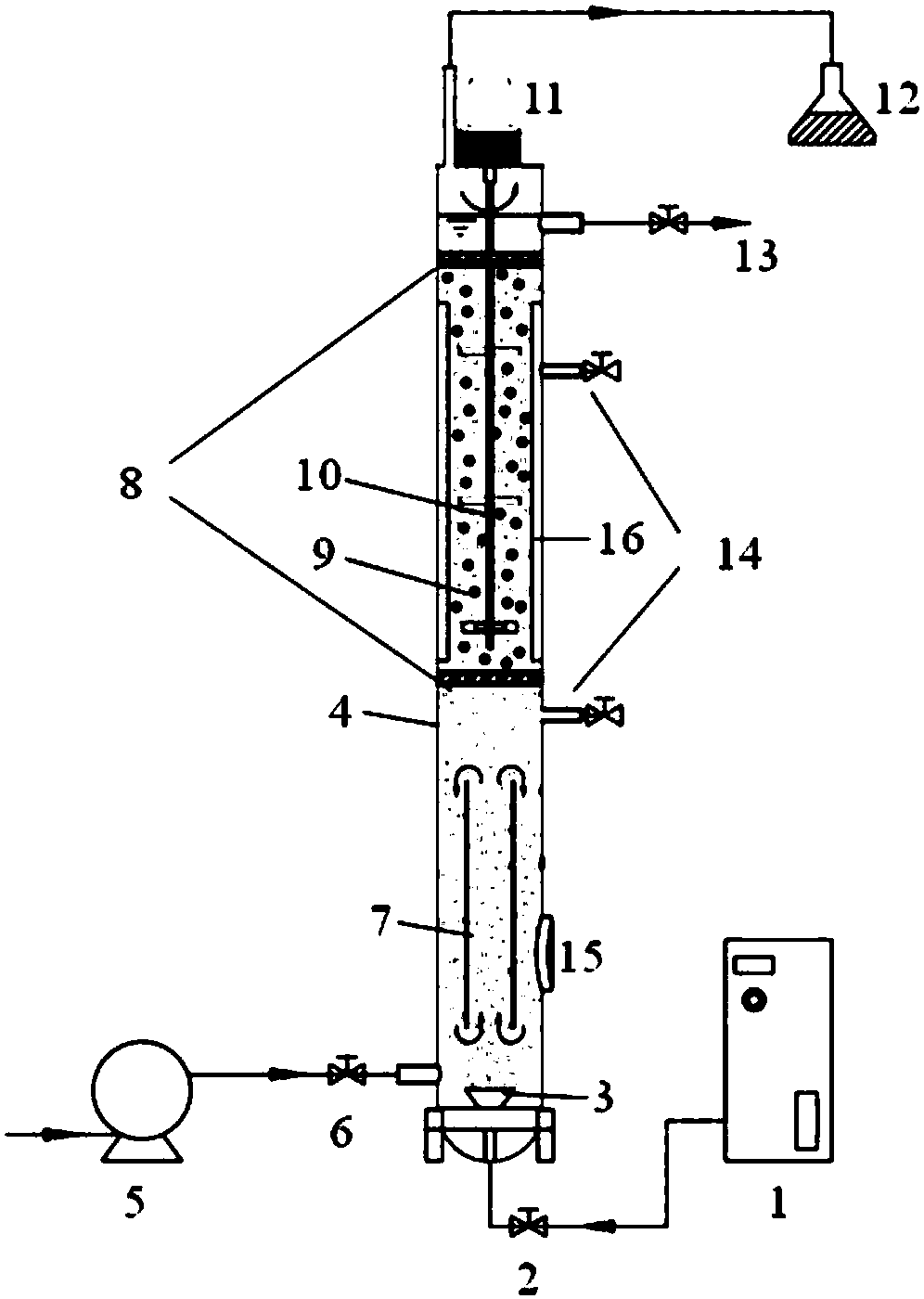

[0056] A new, high-efficiency ozone catalytic oxidation stirred reactor, the ozone reactor is divided into two stages from bottom to top:

[0057] The first-stage reaction zone includes an aeration device and a draft tube;

[0058] The second-stage reaction zone includes a supporting layer, a catalytic packing and a stirring device;

[0059] Wherein, the ozone produced by the ozone generator (1) is carried out in the ozone catalytic oxidation stirred reactor (4) after the gas flow meter (2) adjusts the gas velocity;

[0060] In the first-stage reaction zone, the aeration device (3) is located at the bottom of the ozone reactor, preferably a micro-bubble aeration device, and the bottom of the ozone reactor adopts the aeration device (3) to aerate, and the organic chemical wastewater passes through the flow pump ( 5) Enter the reactor (4) with the valve (6), where the gas and liquid are pre-mixed, and then fully mixed and internally circulated through the guide tube (7), prolon...

Embodiment 2

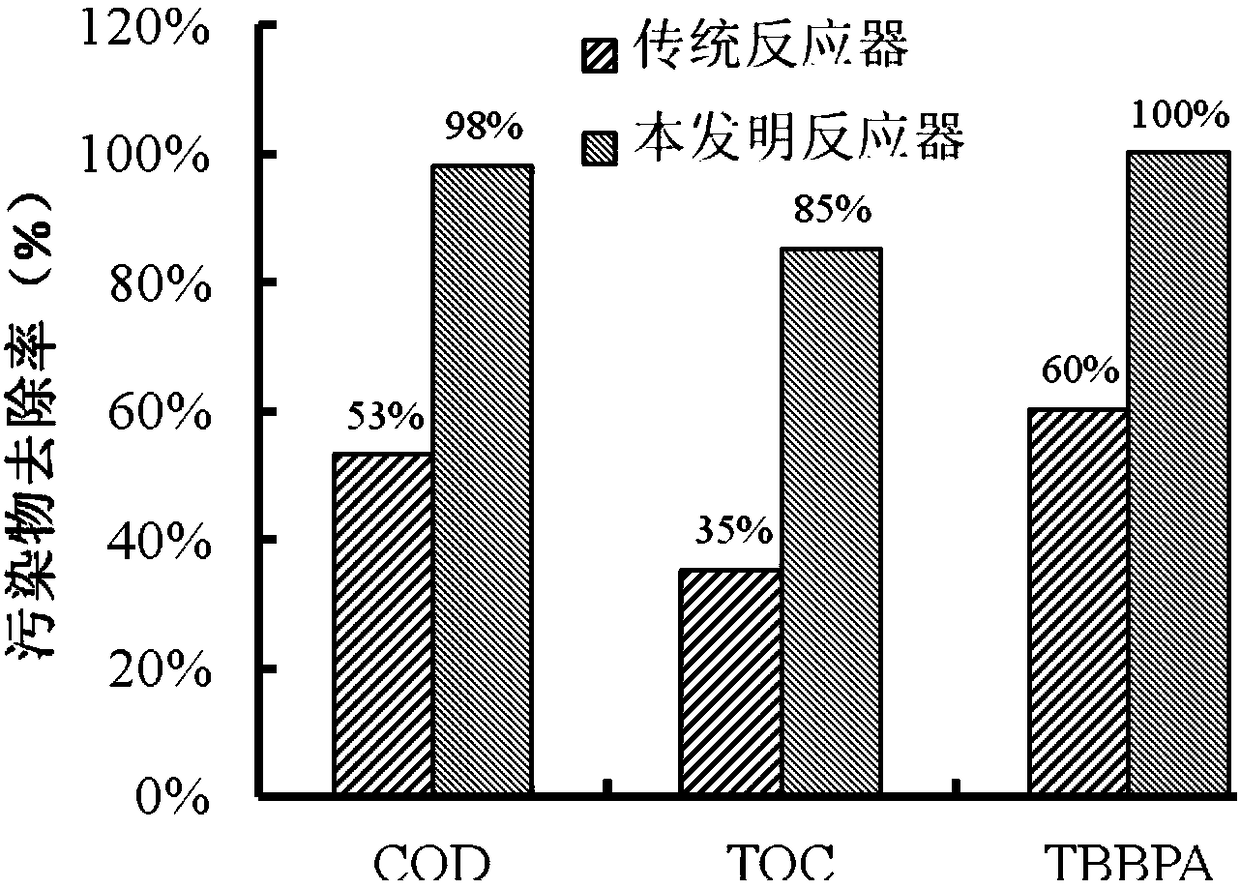

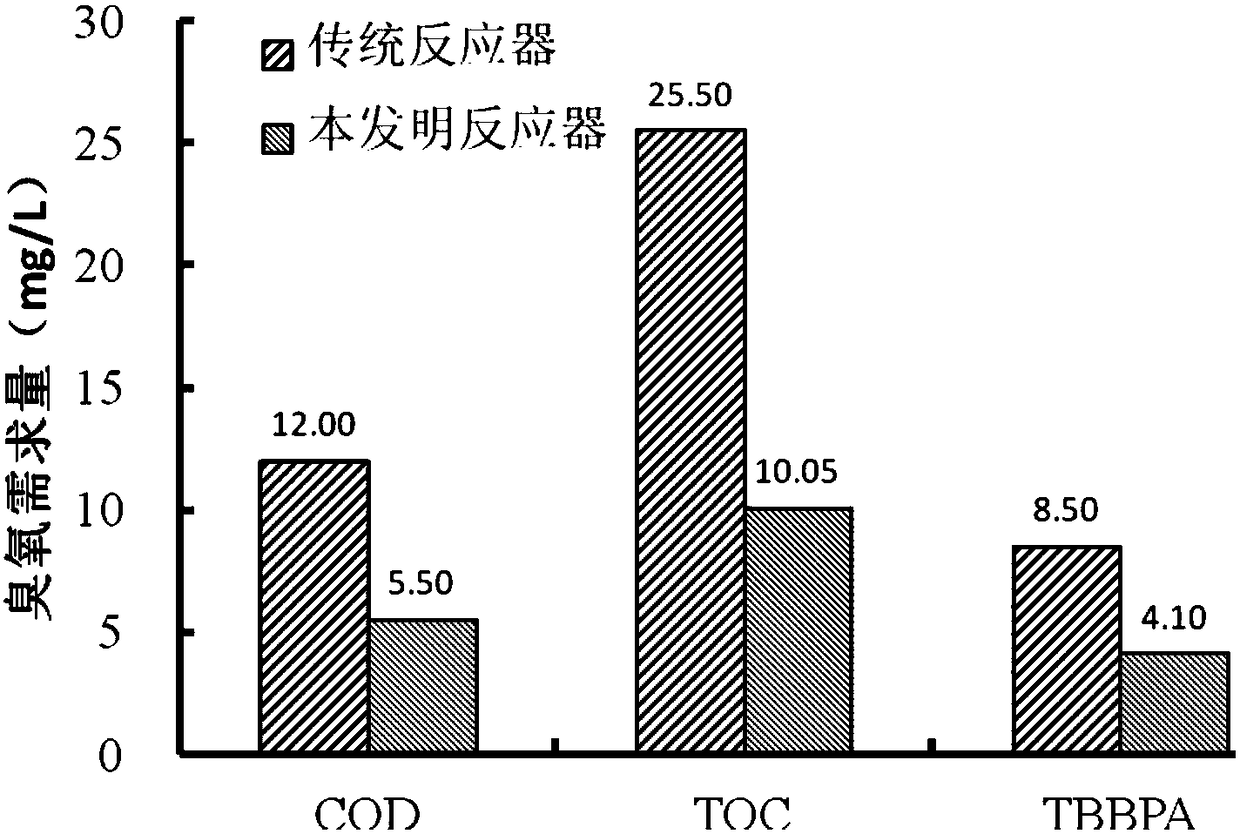

[0065] Taking the electronics industry wastewater as an example (this type of wastewater contains a large amount of inorganic and organic pollutants, such as brominated flame retardant tetrabromobisphenol A), after water quality analysis, the water quality conditions in the actual wastewater are pH 2.5-4, COD 385mg / L, TOC 125mg / L, TBBPA1mg / L, acute toxicity 45TU, chronic toxicity 87TU, use the traditional columnar ozone reactor and the reactor of the present invention to treat this type of industrial wastewater.

[0066] Adopt the device of embodiment 1 to carry out wastewater treatment, wherein, the dosage of ozone is 4mg / L, wastewater pH is 3.0, temperature is 30 ℃, and reaction time is 1h,

[0067] The ozone generated by the ozone generator enters the reactor through the gas flow meter. A microbubble aeration device is installed at the bottom of the reactor. The microbubble aeration is started at the beginning of the reaction. The effective contact area between ozone bubbl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com