Automatic solid phase extraction equipment

A technology of extraction equipment and solid-phase extraction column, which is applied in the field of automatic solid-phase extraction equipment, can solve problems such as poor liquid addition accuracy, lower test results, and easy volatilization of reagents, so as to improve separation speed, improve working environment, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

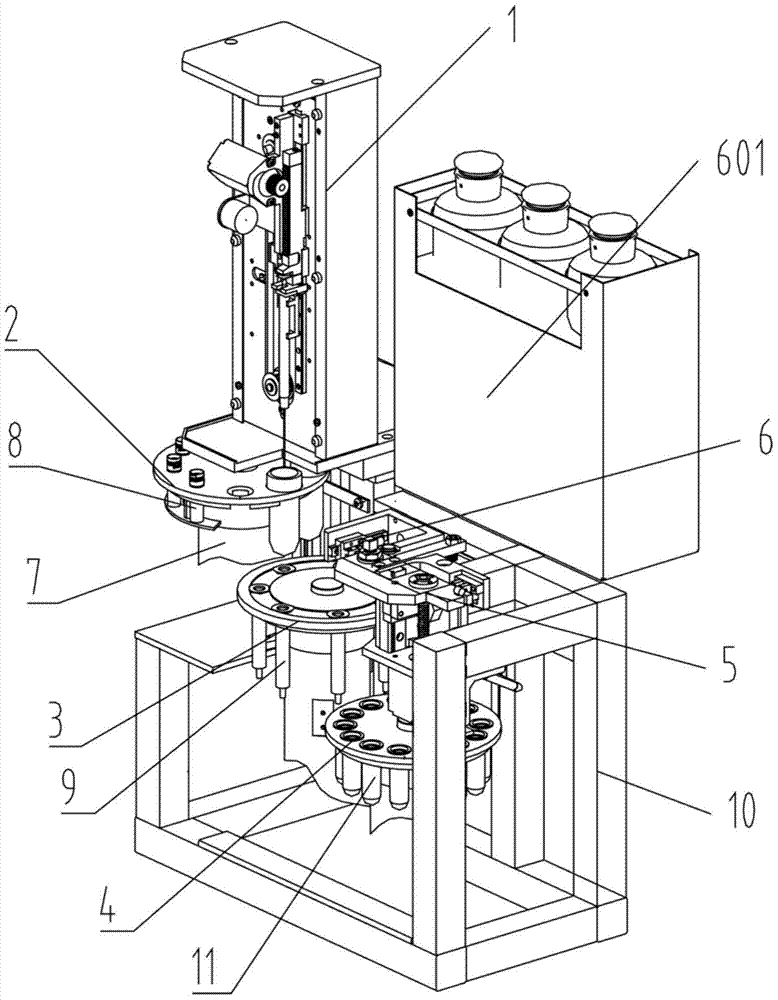

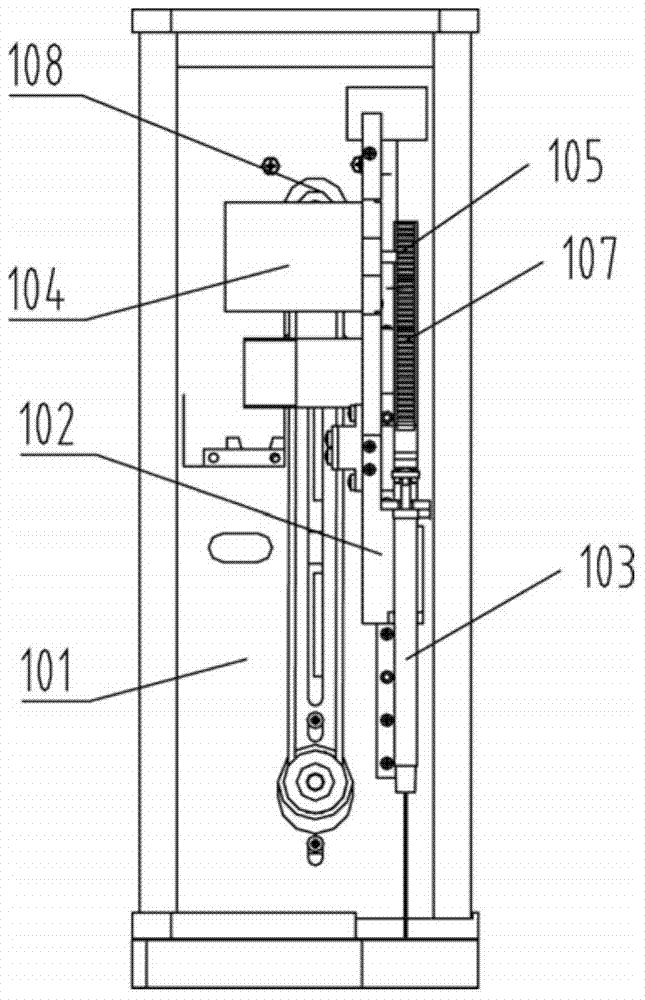

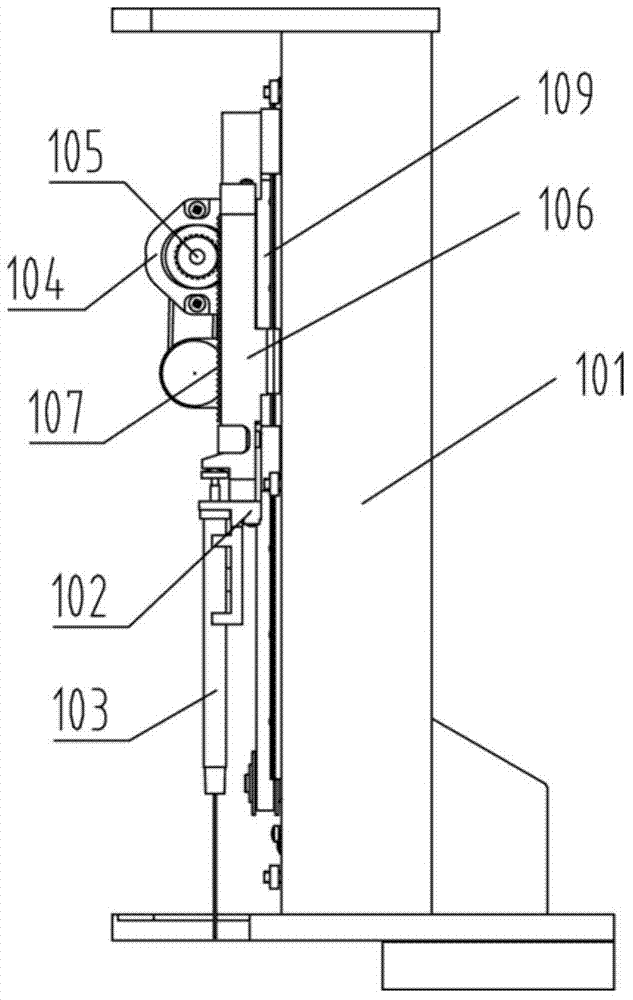

[0042] Such as Figures 1 to 8 As shown, the automatic solid-phase extraction equipment of the present invention includes: a frame 10, a sampling device 1, a sample turntable 2, an extraction column turntable 3, a liquid addition device 6, a pressurizing device 5, an extract solution turntable 4 and a control device (not shown).

[0043] The frame 10 is welded with alloy materials. The sample carousel 2, the extraction column carousel 3 and the extract carousel 4 are arranged in order from high to low, and are respectively installed on the frame 10 through the rotating bracket 7, so that the sample carousel 2, the extraction column carousel 3 and the extract carousel 4 can be rotated horizontally. The outer circumference of the extraction column turntable 3 is provided with a plurality of extraction column support holes 301 for supporting the solid phase extraction column 9. The solid phase extraction column 9 is a prior art, and is placed on the extraction column support ho...

Embodiment 2

[0056] This embodiment is basically the same as Embodiment 1, except that the moving mechanism of the liquid adding device is not limited to the swing assembly, and can be any mechanism capable of moving the liquid adding head to a position above the solid phase extraction column.

Embodiment 3

[0058] This embodiment is basically the same as Embodiment 1, the difference is that the liquid feeding device of this embodiment includes a liquid feeder, a liquid feeding head and a positioning mechanism, the liquid feeder is connected to the liquid feeding head through a pipeline, and the liquid feeding head passes through The positioning mechanism is arranged above the hole of the extraction column holder. When working, the turntable of the extraction column rotates, turning the solid phase extraction column to the bottom of the liquid filling head, and the liquid supplier injects solvent into the solid phase extraction column through the liquid filling head, and continues the solid phase extraction column to the bottom of the gas filling head, Moving down, the gas source injects pressurized gas into the solid phase extraction column to complete the extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com