Patents

Literature

105results about How to "Resolve lag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

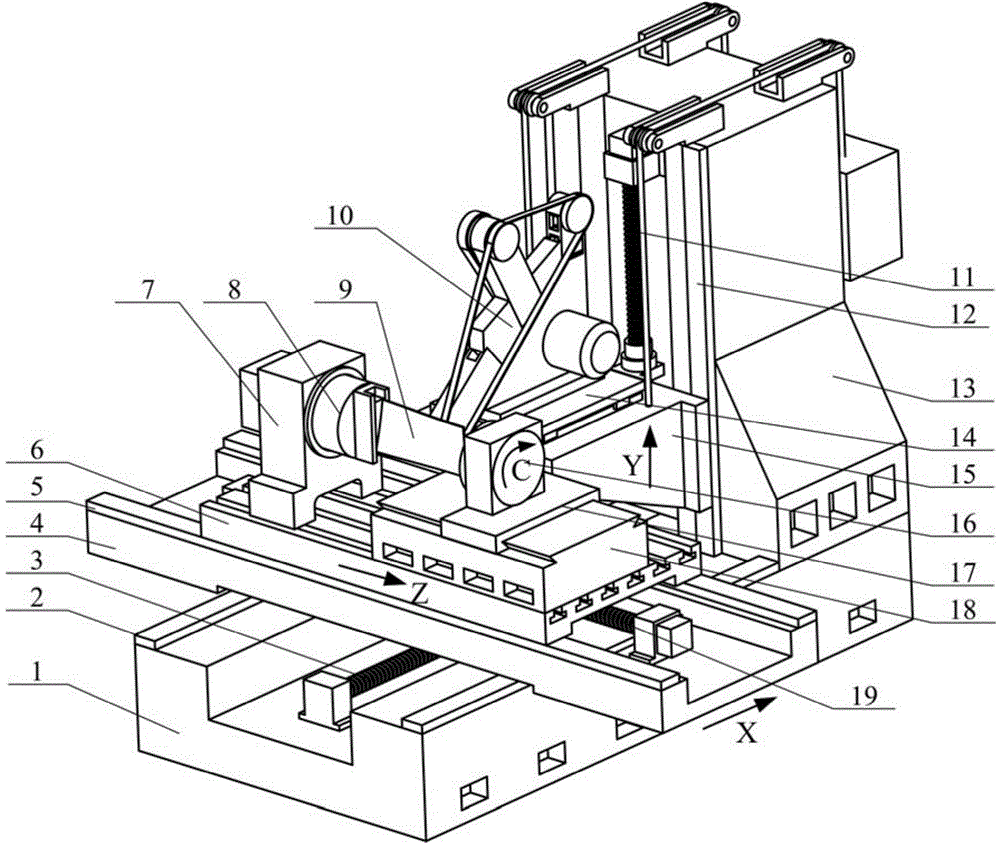

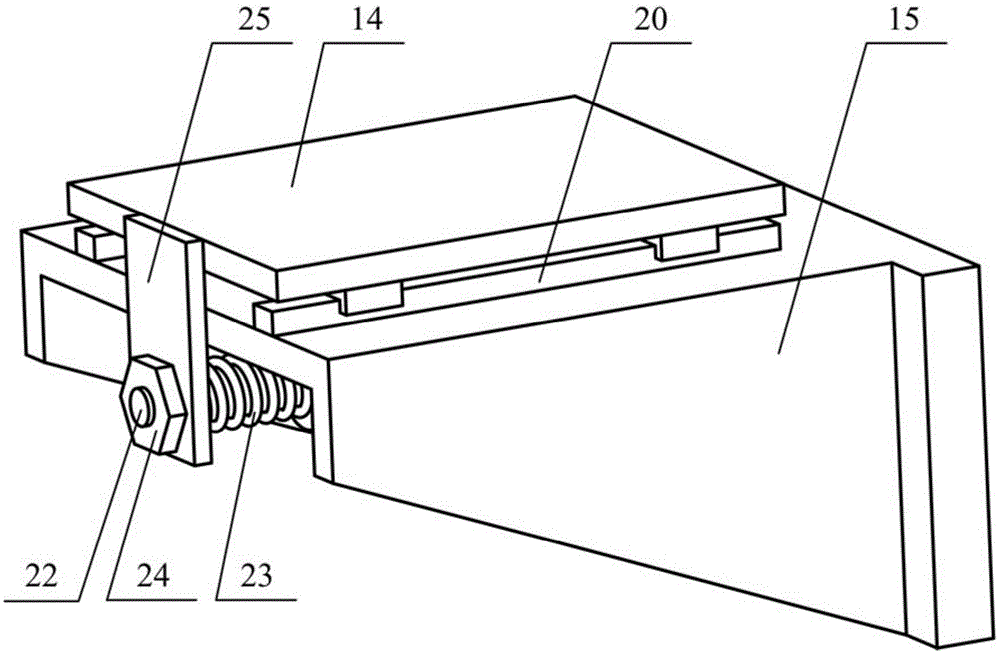

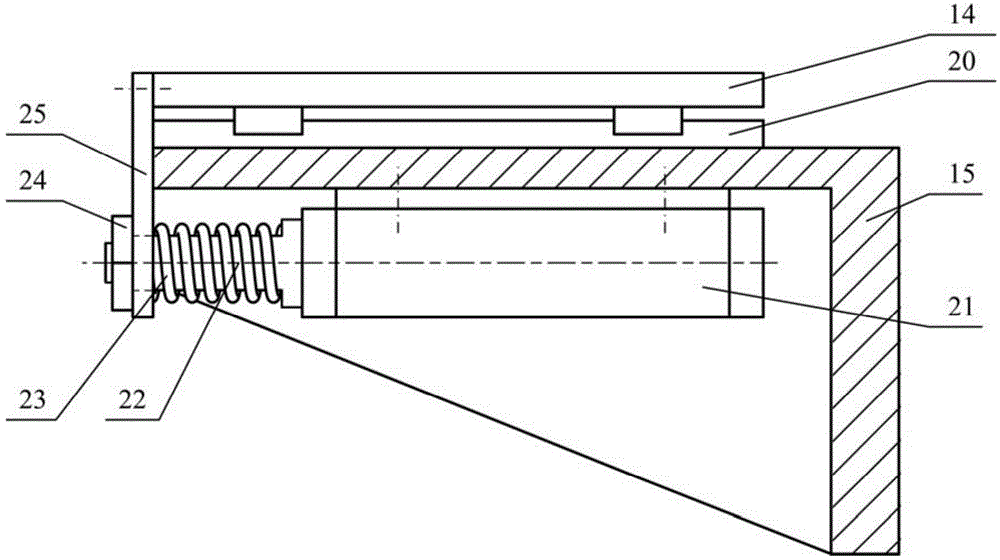

Self-adaption profile modification blade abrasive belt polishing machine tool

ActiveCN104440474ARealize the effect of polishing contact pressure compensationReduce performance pressureGrinding drivesBelt grinding machinesContact pressureCompensation effect

The invention discloses a self-adaption profile modification blade abrasive belt polishing machine tool, comprising a machine tool body, an X-axis carriage, an X-axis carriage, a C-axis rotary table, a Y-axis sliding block, an abrasive belt polishing head component, an air cylinder, and the like, wherein a pressure compensation element is in series connection between the abrasive belt polishing head component and the air cylinder to cooperate with the air cylinder to form a polishing contact pressure. During machining, the polishing machine tool performs interpolation feed according to an ideal polishing track; due to the existence of a blade profile error (or waveness), the polishing contact point deviates from the ideal polishing track in a pressure shaft direction, and the acting pressure of the pressure compensation element changes along with the deviation, so as to realize the polishing contact pressure compensation; the pressure compensation element can utilize a constant-pressure type gas bearing with oppositely arranged air cushions, and realizes the polishing contact pressure compensation effect by utilizing a pressure balance function to the oppositely arranged air cushions. The self-adaption profile modification blade abrasive belt polishing machine tool has the advantages that the response speed of pressure compensation is increased, the self-adaption modification on the profile error (or waveness) during blade polishing machining is realized, and the profile precision is improved.

Owner:XI AN JIAOTONG UNIV

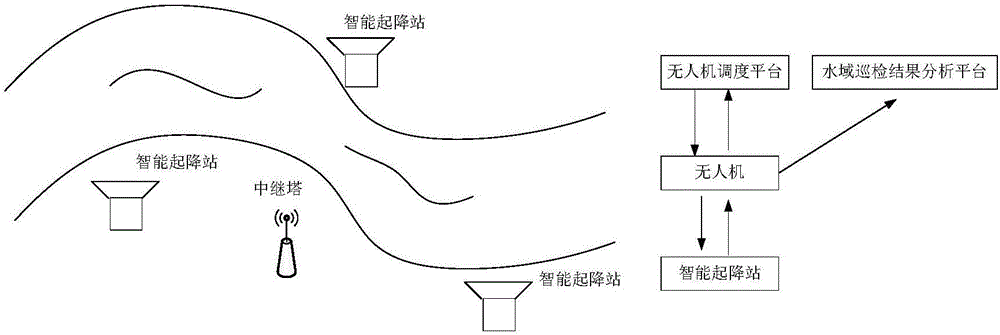

Water area automatic routing inspection system and method based on unmanned aerial vehicle

ActiveCN106774427AResolve lagComplete monitoringPosition/course control in three dimensionsAutomatic routingUncrewed vehicle

The invention discloses a water area automatic routing inspection system and method based on an unmanned aerial vehicle. The system partially comprises a ground control center, an intelligent take-off and landing station and the unmanned aerial vehicle, wherein the ground control center comprises an unmanned aerial vehicle dispatching platform and a water area routing inspection result analysis platform; the unmanned aerial vehicle dispatching platform is used for selecting vehicle types of the unmanned aerial vehicle; the water area routing inspection result analysis platform receives and stores the water area routing inspection data and analyzes the water area features through water area routing inspection data; the intelligent take-off and landing station comprises a data transmission module and an autonomous cruising module; the data transmission module is used for receiving data sent by the unmanned aerial vehicle in real time, and sending the data to the ground control center; the autonomous cruising module is used for using a non-manual method for changing a power supply battery of the unmanned aerial vehicle in the process of executing the water area routing inspection task by the unmanned aerial vehicle; the unmanned aerial vehicle cruising function is executed.

Owner:SHANDONG UNIV +1

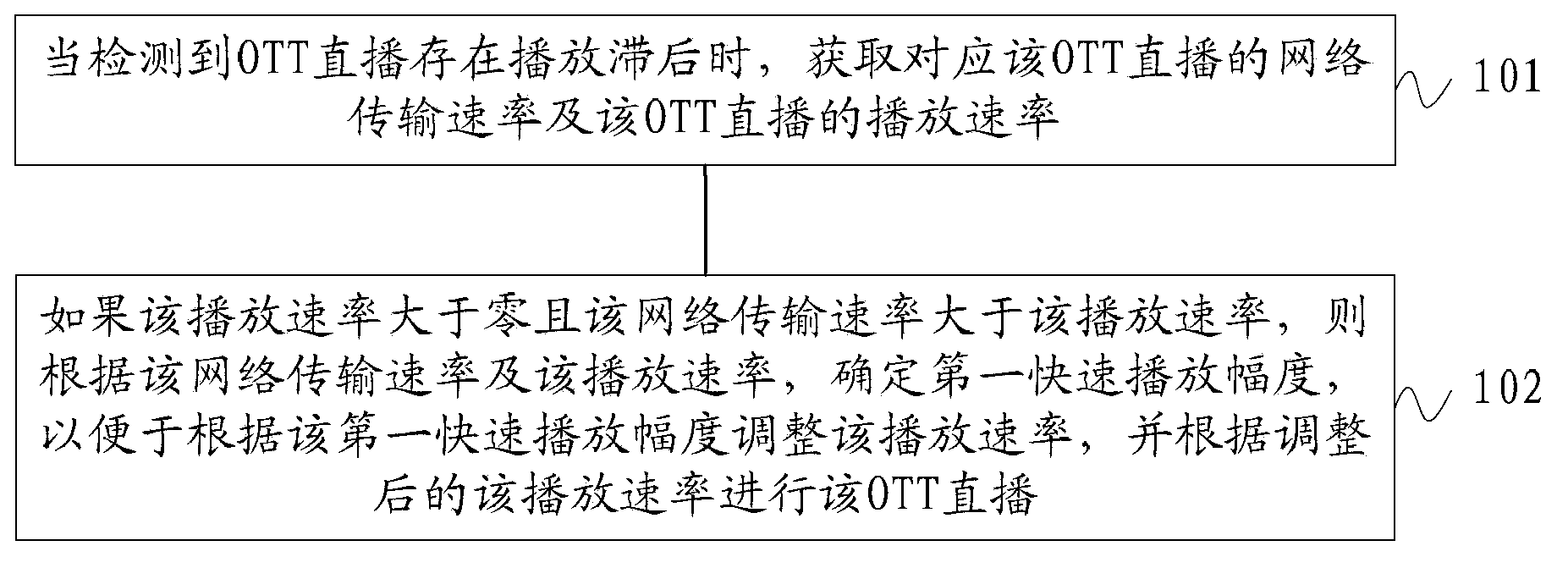

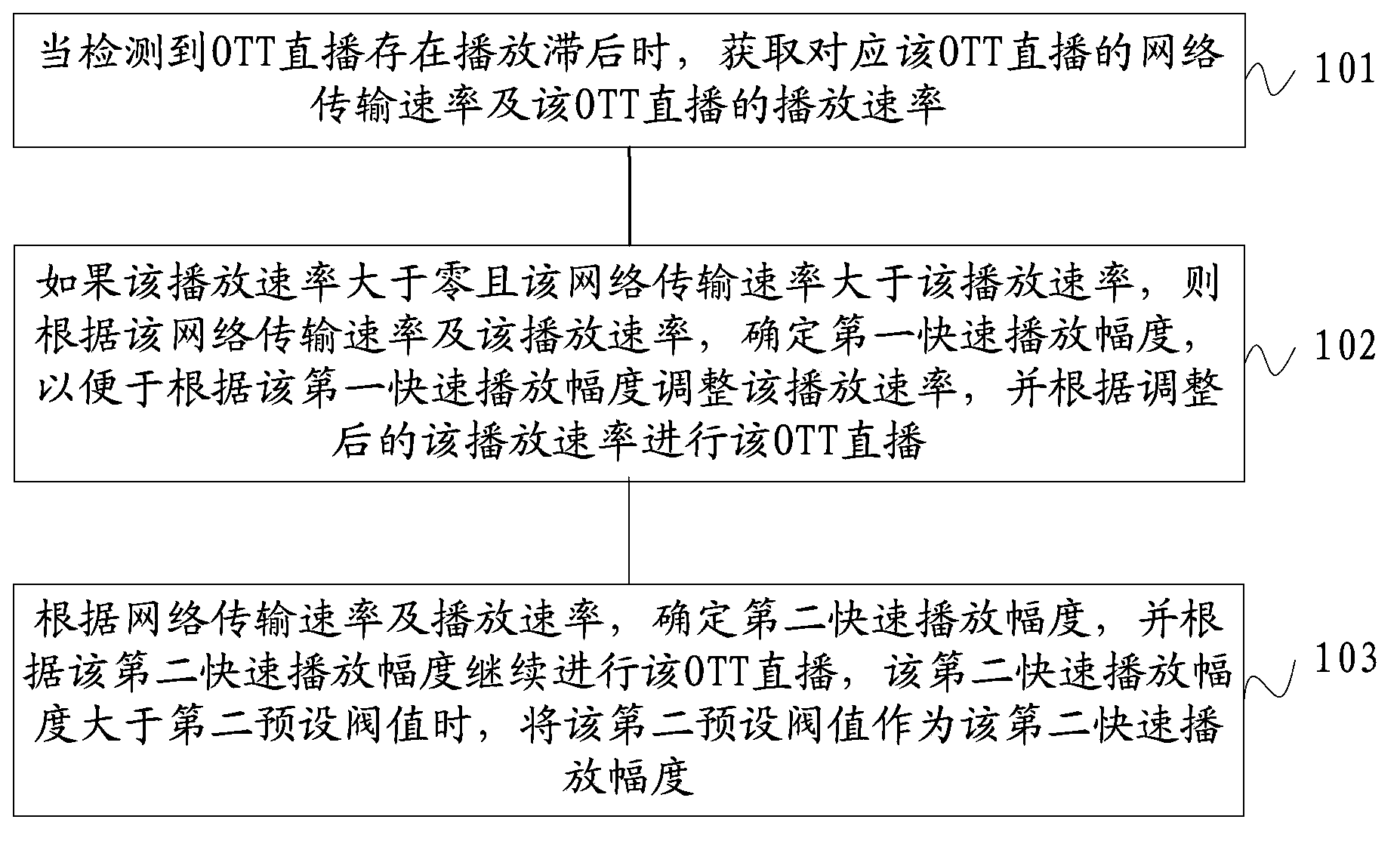

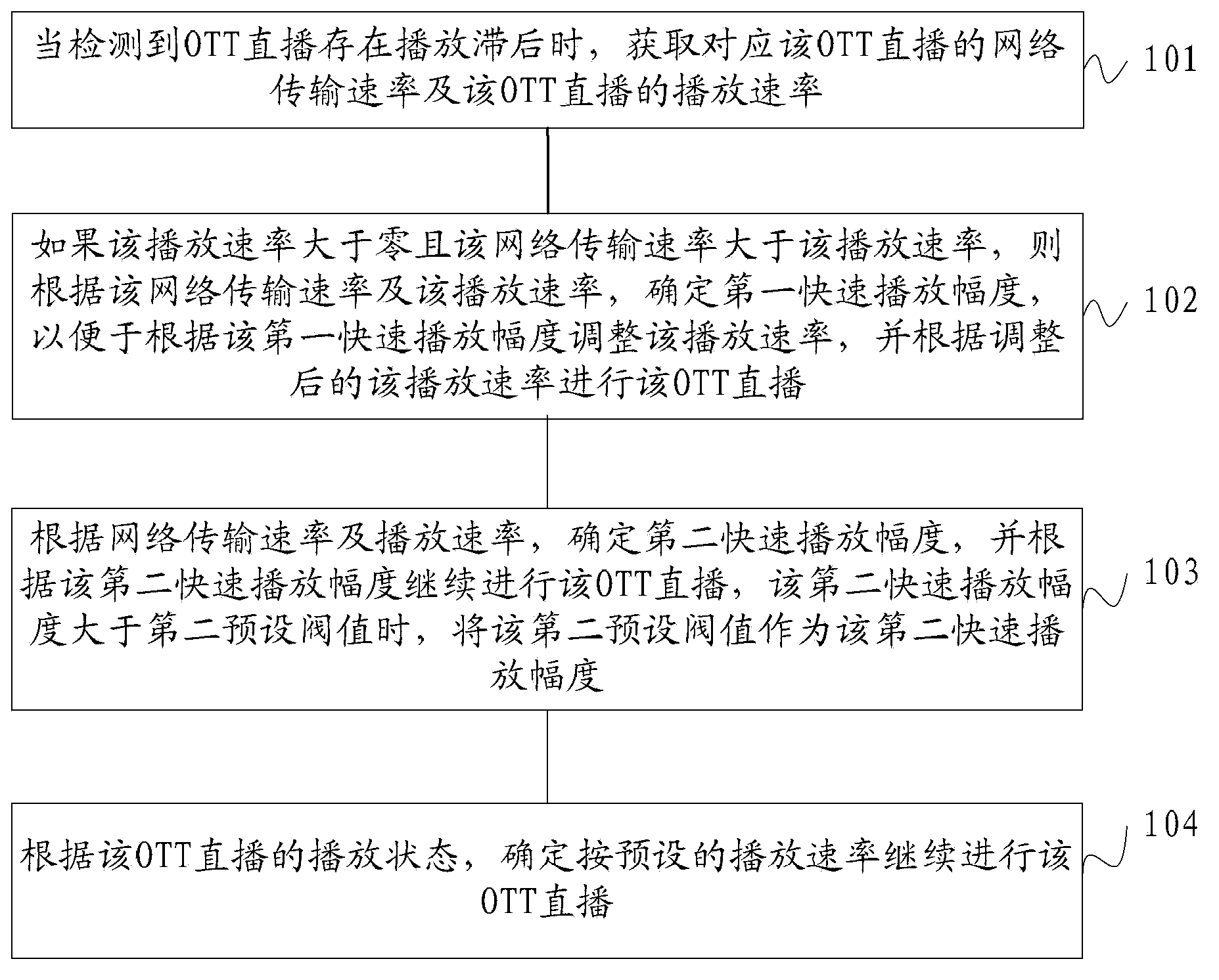

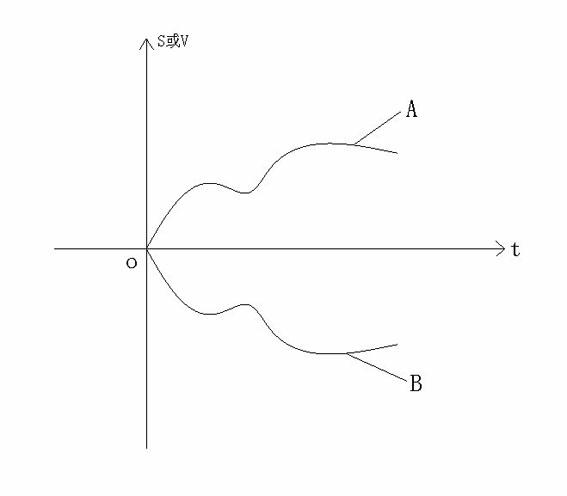

Method, device and system of OTT (Over The Top) live broadcast

ActiveCN104079955AResolve lagImprove continuitySelective content distributionThe InternetComputer science

An embodiment of the invention discloses a method, a device and a system of OTT (Over The Top) live broadcast for enhancing continuity of the OTT live broadcast so as to improve user experience. The method comprises the following steps of: when the OTT live broadcast is detected to have play lag, obtaining a network transmission rate corresponding to the OTT live broadcast and play speed of the OTT live broadcast; if the play speed is greater than zero and the network transmission rate is greater than the play speed, determining a first quick play range according to the network transmission rate and the play speed so as to facilitate adjusting the play speed according to the first quick play range and carrying out the OTT live broadcast according to the adjusted play speed. The embodiment of the invention is mainly applied to the field of Internet, the quick play range can be adjusted according to the network transmission rate and the play speed, the lag of the OTT live broadcast is repaired, jump of a content of the OTT live broadcast is avoided and the continuity of the OTT live broadcast is enhanced, so that the user experience is improved.

Owner:HUAWEI TECH CO LTD

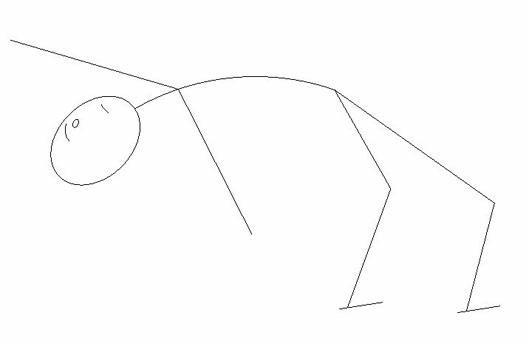

Human-machine interaction control method and application thereof

ActiveCN102541260AEasy to controlEfficient use ofInput/output for user-computer interactionDesign optimisation/simulationInteraction controlMan machine

The invention provides a human-machine interaction control method and an application thereof. The method is characterized in that a user implements user-permissible micro-actions so as to control a self role in a virtual environment to implement corresponding virtual permissible actions, and comprises the following steps of: 1) creating a self role in a virtual world; 2) implementing micro-actions by a user when the body of the user does not leave a position at which the user is located; 3) tracking and identifying the micro-action implementation of the user, and ensuring that when the user implements any micro-actions, the body of the user does not leave the position at which the user is located; and 4) amplifying the self role so as to implement the micro-actions of the user. By using an 'action amplification system' introduced in the invention, all functions or abilities endowed by the integral virtual world can be realized under the condition that the body of a user has no displacement phenomenon or has a mini-displacement phenomenon, so that the user is only at a same control position in a whole course in the virtual world; and meanwhile, the implementation of a situation that the moving parts of the user are consistent with the moving parts of a person in the virtual world is facilitated, so that the user is easy to master.

Owner:漳州市阿思星谷电子科技有限公司

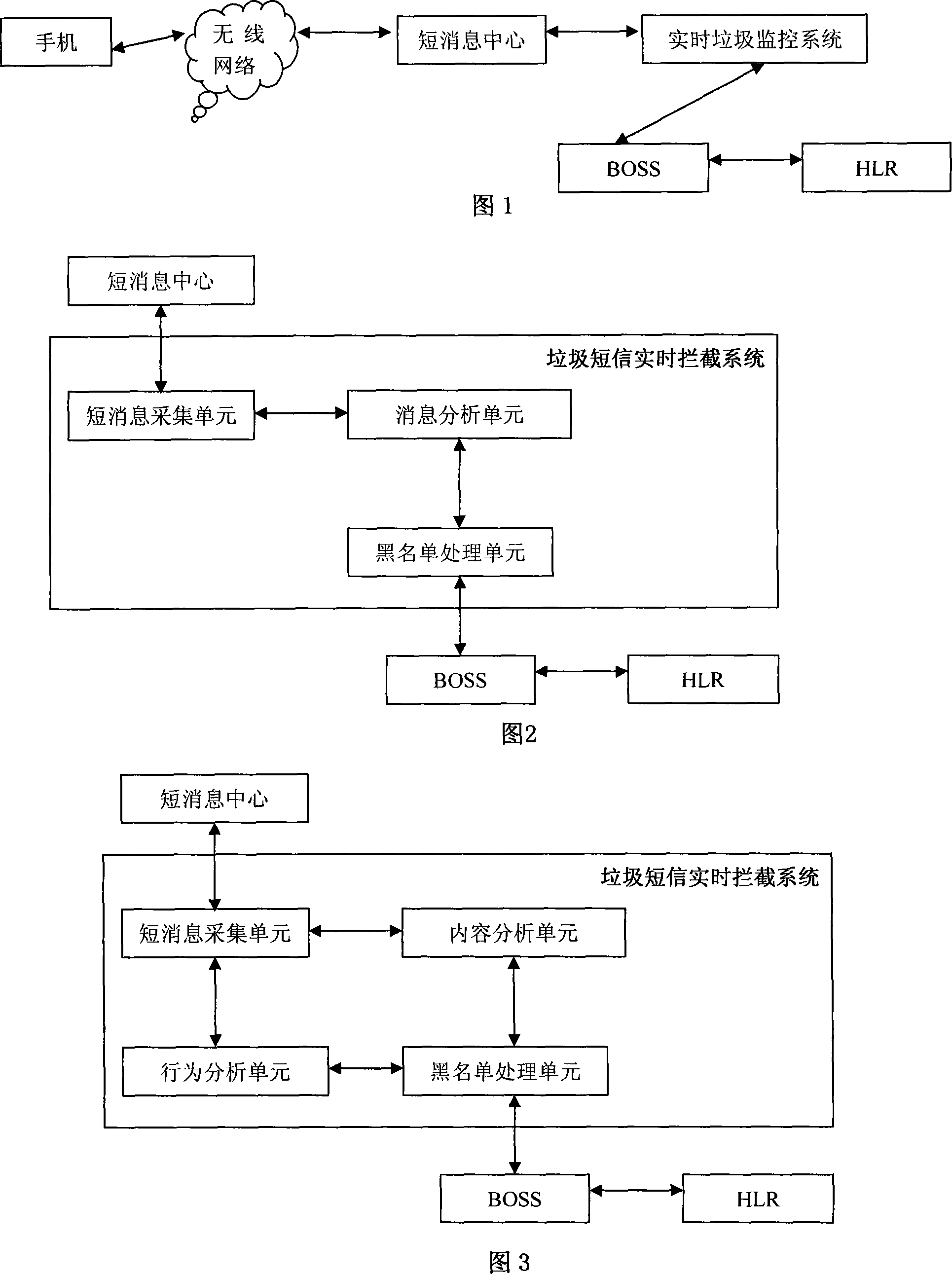

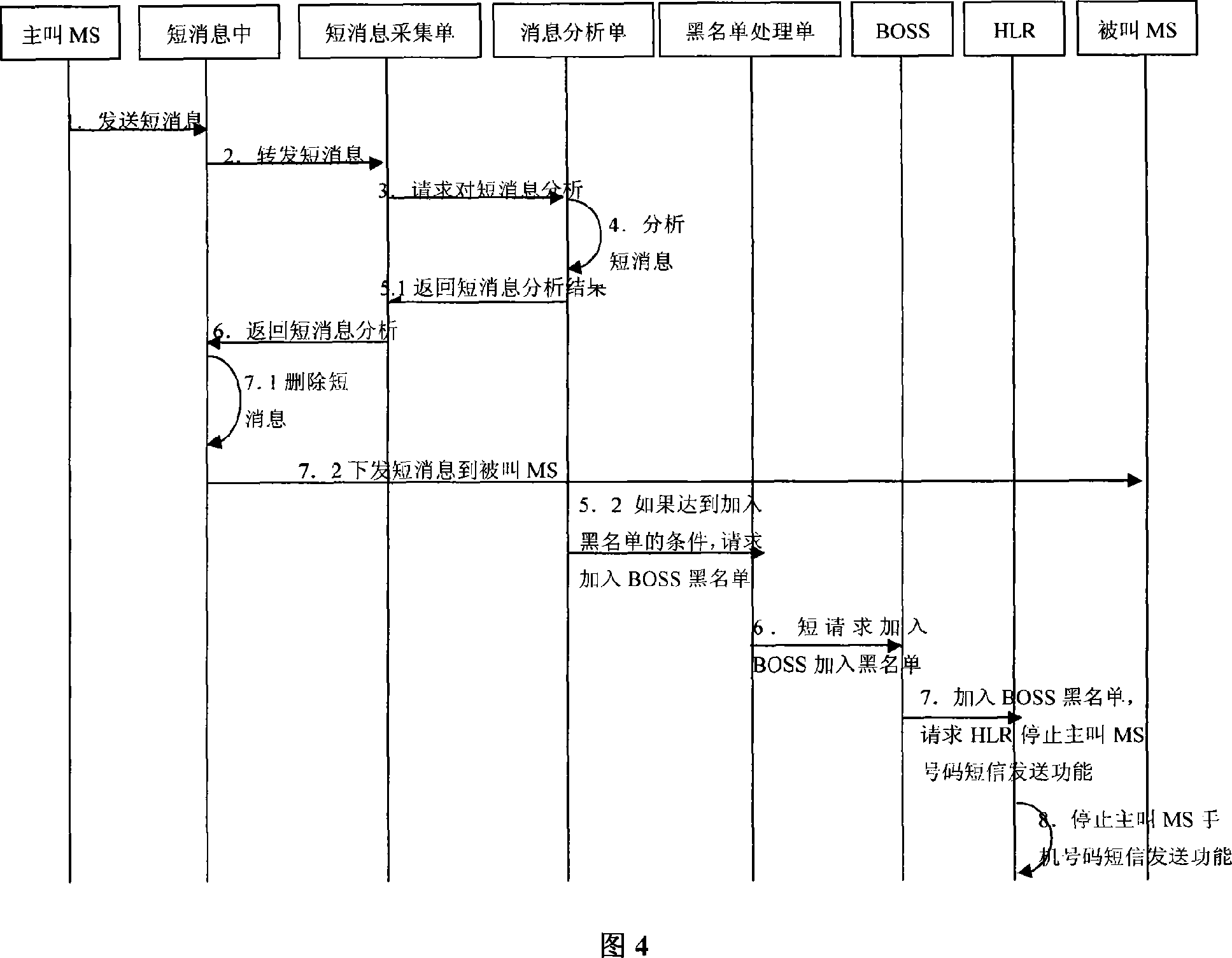

A spam real time interception method and system

InactiveCN101150762AResolve lagHigh speedRadio/inductive link selection arrangementsAutomatic exchangesReal time analysisHit ratio

The invention provides a realtime interception method of spam short messages and a system, the method adopts a realtime monitoring mode, that is a spam short message realtime interception system participates in control of a short message scheduling process. A short message sends short messages which are submitted by attribution users to the spam short message realtime interception system to analyze in realtime. The spam short message realtime interception system adopts methods of flow monitoring, keyword filtration and hit ratio, judges illegal messages or messages illegal users, sends the analysis result to BOSS, the BOSS notifies HLR to stop short message sending function of users.

Owner:CHINA MOBILE GROUP JIANGSU

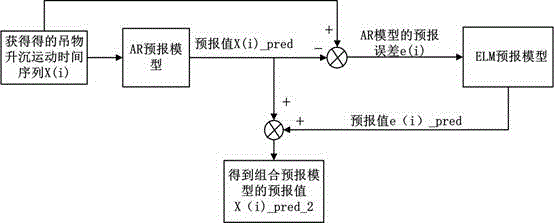

Ship crane heaving compensation method based on hanger heaving motion forecast

InactiveCN104817019AResolve lagImproving the Prediction Accuracy of Heave DisplacementLoad-engaging elementsCranesLearning machineCoordinate change

The invention relates to deck lifting equipment, and belongs to the field of offshore operation and maritime affair guarantee in ocean engineering. A heaving compensation method comprises a measuring device, a forecasting device, a control device and a hydraulic driving device. A hydraulic winch in the hydraulic driving device is mounted on a crane upper car; a drum of the hydraulic winch is wound with a lifting rope; and the lifting rope is connected with a hanger through a fixed pulley fixed at the top end of a lifting arm. The measuring device obtains the heaving displacement of the hanger by the coordinate change according to measured values of all sensors; the forecasting device adopts an autoregression and extreme learning machine combined forecasting model to forecast the heaving displacement of the hanger; and the control device performs the compensation operation for an input handle signal, a heaving displacement forecasted value and a length change quantity of the lifting rope, and outputs a control signal to the hydraulic driving device so as to control the heaving motion of the hanger. The heaving compensation method can effectively solve the lag problem of the measuring device and the hydraulic driving device in the compensation control, and prominently improve the heaving compensation precision.

Owner:XIANGTAN UNIV

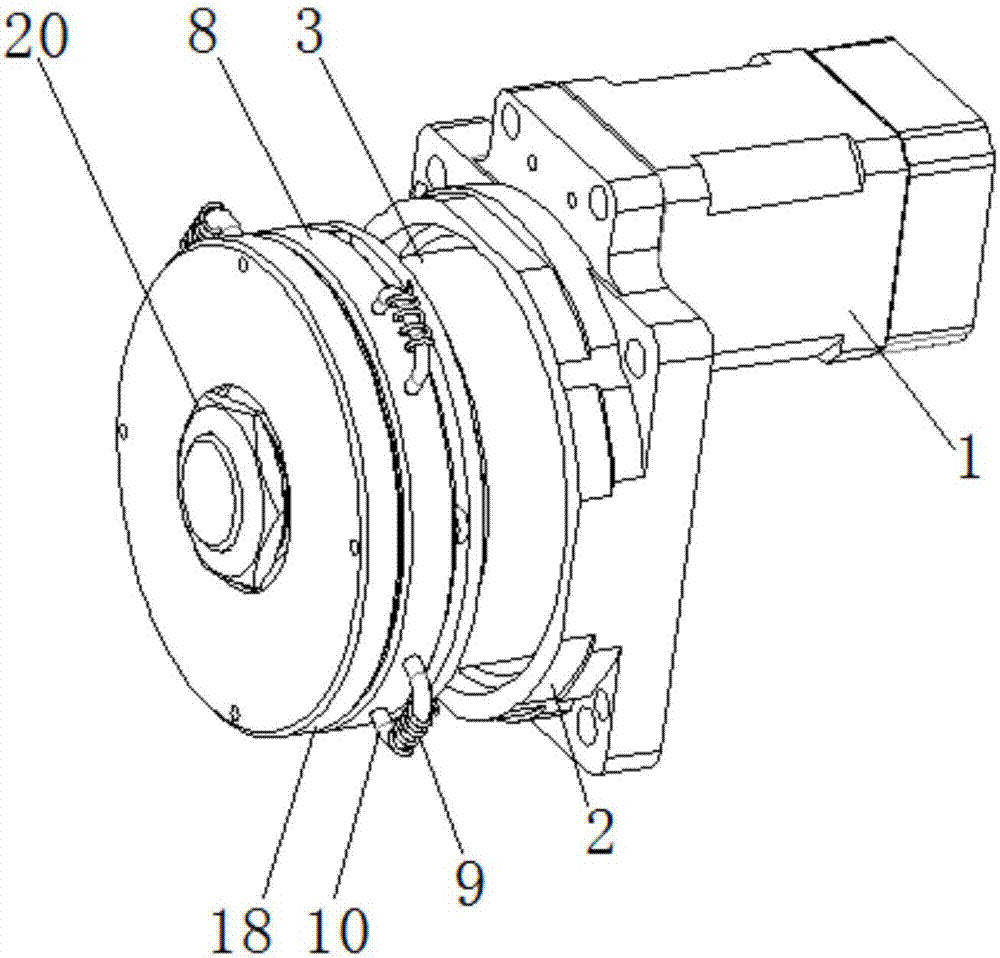

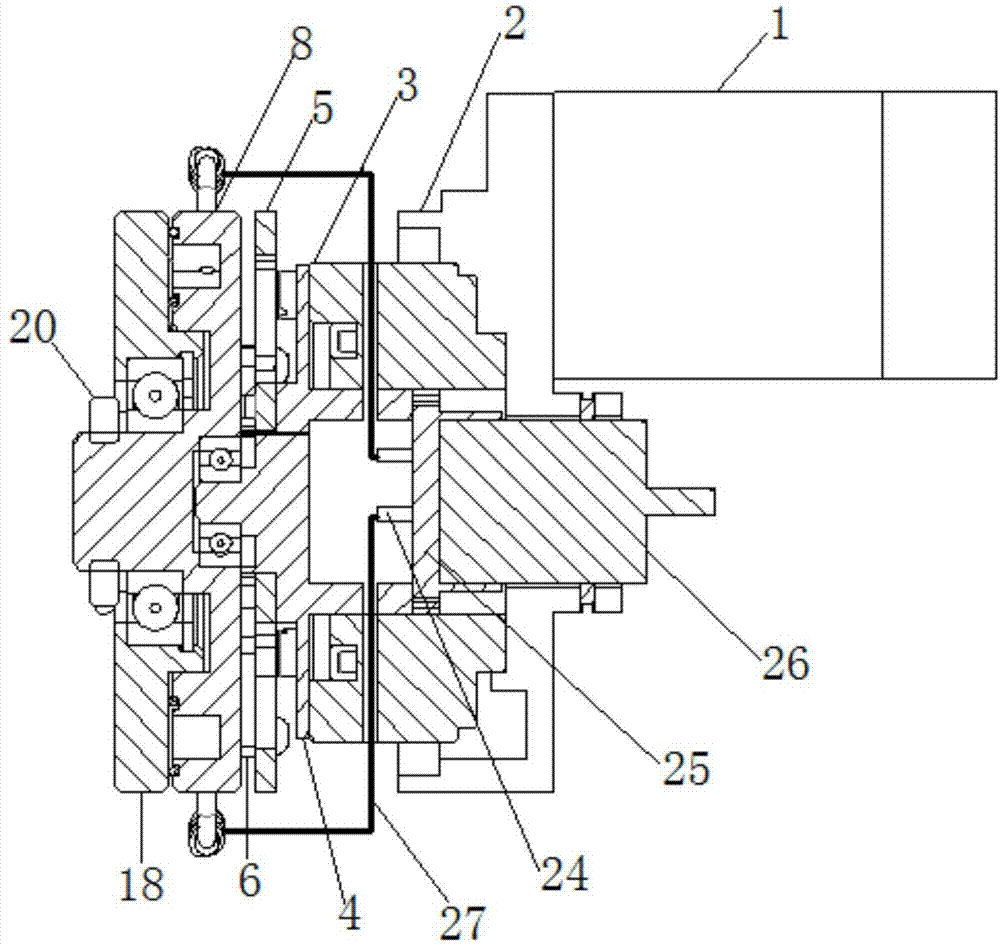

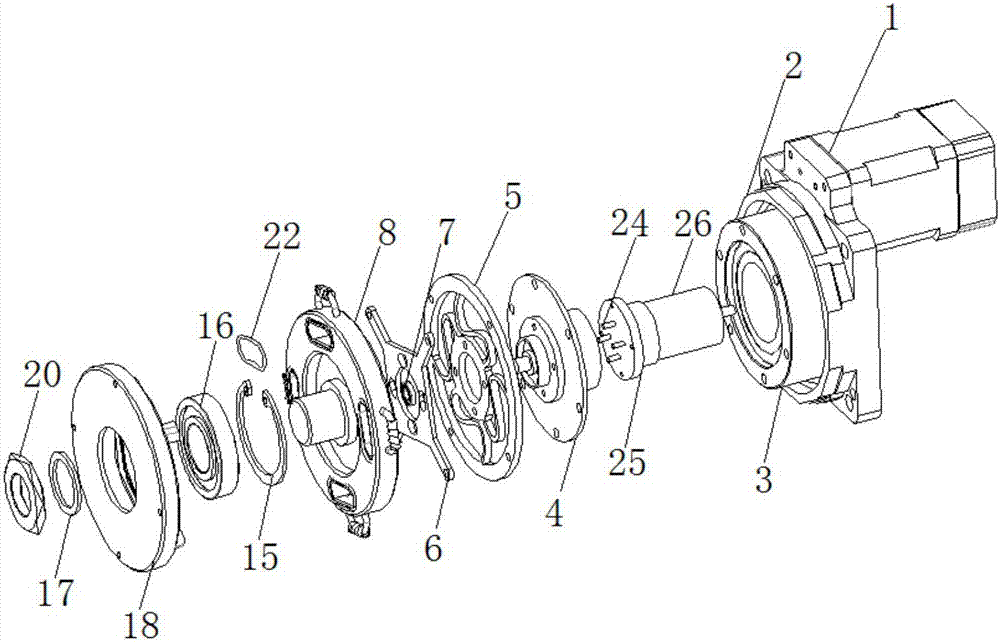

Flexible driver with controllable damping and used for robot joint

ActiveCN107571255AImprove flexibilityTo achieve the purpose of controllable dampingProgramme-controlled manipulatorJointsMagnetorheological fluidSacroiliac joint

The invention discloses a flexible driver with controllable damping and used for a robot joint. The existing flexible driver is lag in drive response, and uncontrollable in flexibility. The inner ringof a hollow rotary platform of the flexible driver disclosed by the invention is driven by an external force, and drives an electric brush rotor and an output disc to rotate; an inner rotary disc comprises a disc body and a central stud; the inner ring of a planar torsional spring is fixed to an output disc, and the outer ring of the planar torsional spring is fixed to a cross support frame and the disc body; an outer rotary disc is born on the central stud, and compressed with an end surface opposite to the disc body, and a compression force is adjusted by an adjustment device; 2-4 grooves are formed in a part close to the edge, of the disc body; a magnetorheological fluid is injected into each groove; two fluid through holes are formed in the bottom of each groove, and the outer ends ofthe two fluid through holes are communicated by a pipeline; each pipeline is wound with a coil; and cylindrical bodies as many as the grooves are arranged on the inner end surface of the outer rotarydisc, and each cylindrical body is embedded in the corresponding groove and divides the groove into two cavities. The flexibility of the flexible driver disclosed by the invention is effectively improved, and a controllable movement flexibility degree is achieved.

Owner:HANGZHOU DIANZI UNIV +1

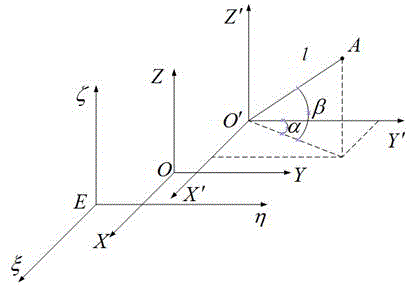

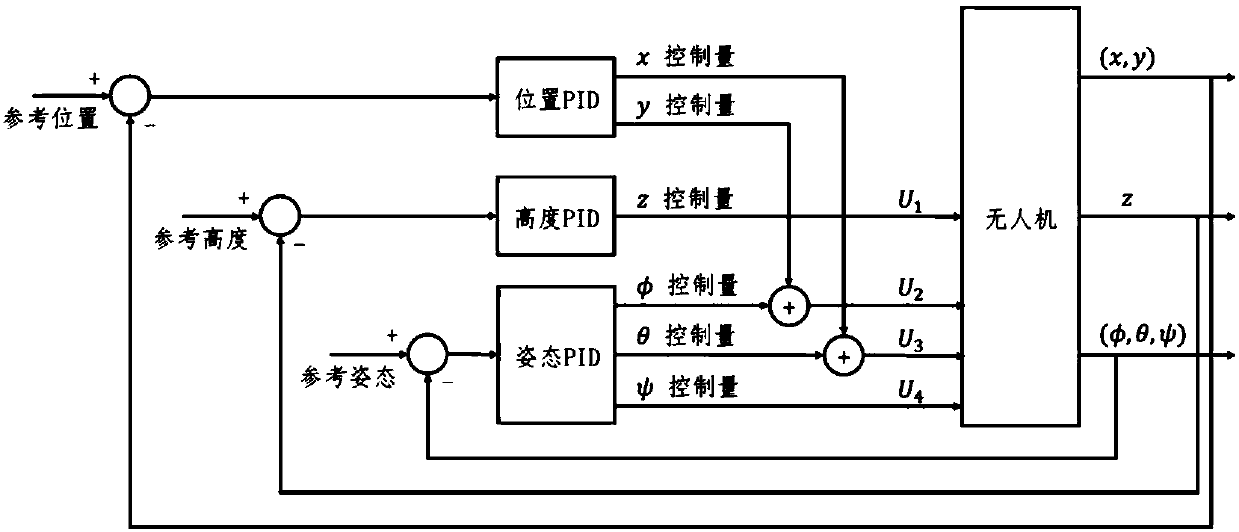

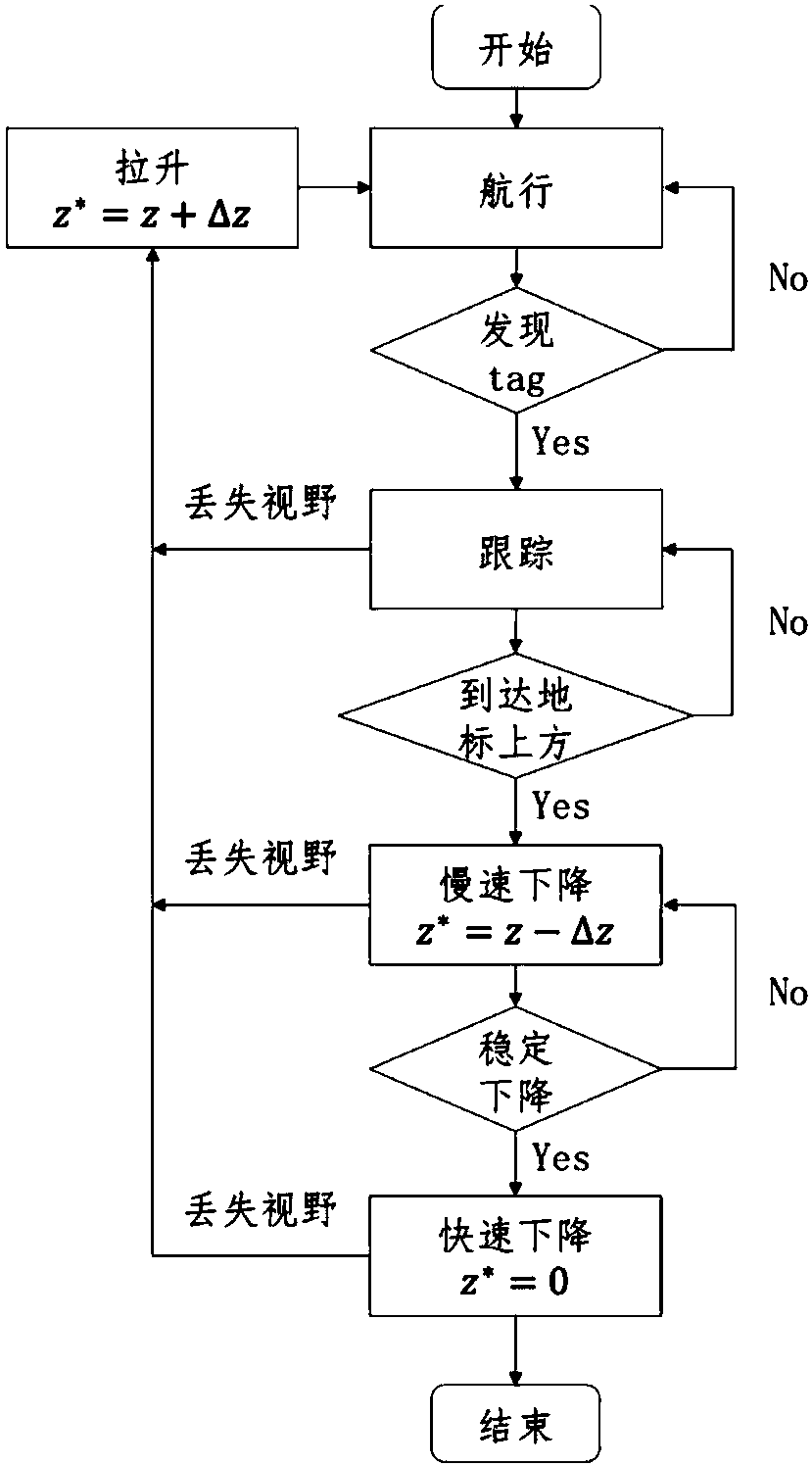

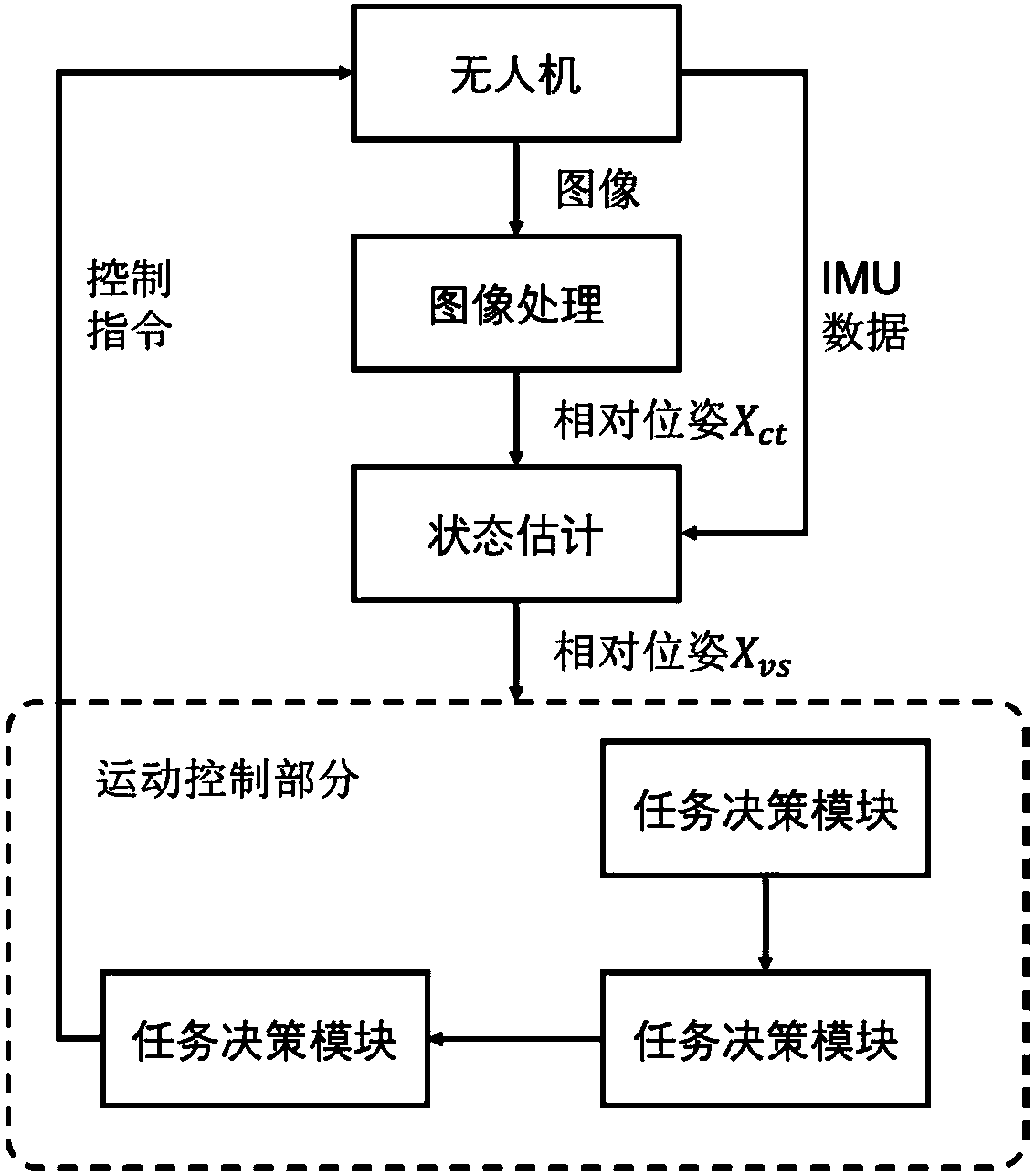

Unmanned aerial vehicle staged autonomous landing method based on visual information fusion

ActiveCN108594848ALower technical barriersLow costPosition/course control in three dimensionsVision basedInformation capture

The invention relates to an unmanned aerial vehicle staged autonomous landing method based on visual information fusion. The method includes the following steps of 1) landmark making: taking a corresponding target landing point on the unmanned ship as a landmark, attaching an AprilTags label to the landmark, and adjusting the angle of the unmanned aerial vehicle camera; 2) image processing: according to the parameter information of the camera and the image information captured by the camera, acquiring the relative pose Xct between the camera and the landmark when the landmark is found; 3) information fusion: performing information fusion on the relative pose Xct between the camera and the landmark and the measurement data of the IMU, and acquiring the real-time relative pose Xvs of the unmanned ship under the unmanned aerial vehicle reference system; 4) motion control: ensuring flight stability and path tracking according to the real-time relative pose Xvs in a nested control mode, atthe same time, landing by adopting a staged landing method. Compared with the prior art, the method has the advantages of being effective and real-time, avoiding lag, and being stable and safe.

Owner:SHANGHAI JIAO TONG UNIV

Man-machine interaction control method and application thereof

ActiveCN103207667AEasy to controlIncrease activity timeInput/output for user-computer interactionGraph readingInteraction controlMan machine

The invention provides a man-machine interaction control method and application thereof. A user controls a self-role in a virtual environment to implement corresponding virtual permissible action by implementing user permissible micro-action. The method includes the steps: 1) creating the self-role in a virtual world; 2) executing the micro-action by the user without leaving the position of the body of the user; 3) tracking and identifying the micro-action executed by the user with the body not leaving the position of the user when the user executes optional micro-action; and 4) amplifying the self-role to execute the micro-action of the user. By the aid of an 'action amplifying system', the user can realize all functions or abilities endowed by all virtual worlds without displacement of the body or only by tiny displacement of the body, the user stays at the same control position in the whole process of the virtual worlds, moving parts of the user are consistent with those of persons in the virtual worlds, and the user easily uses the method.

Owner:漳州市阿思星谷电子科技有限公司

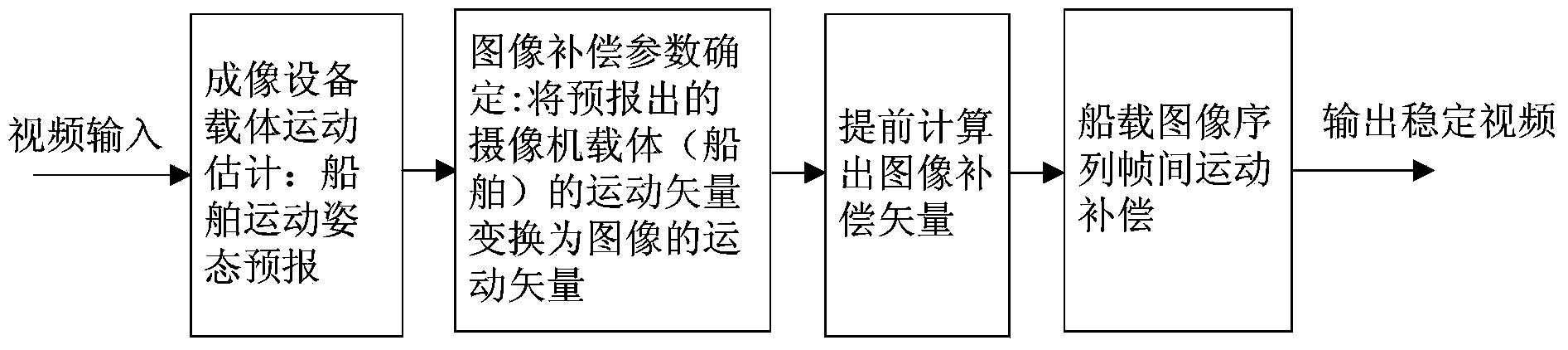

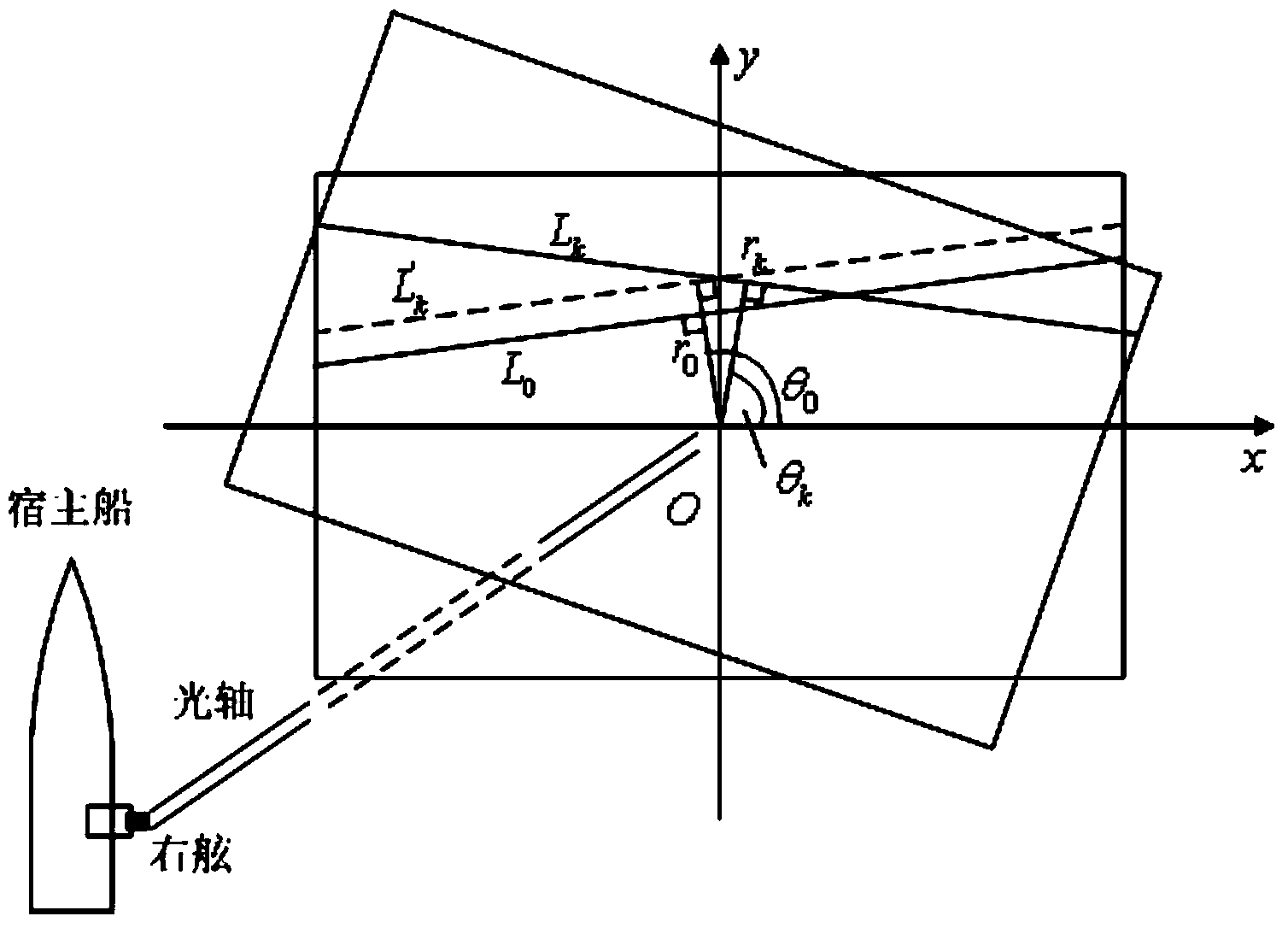

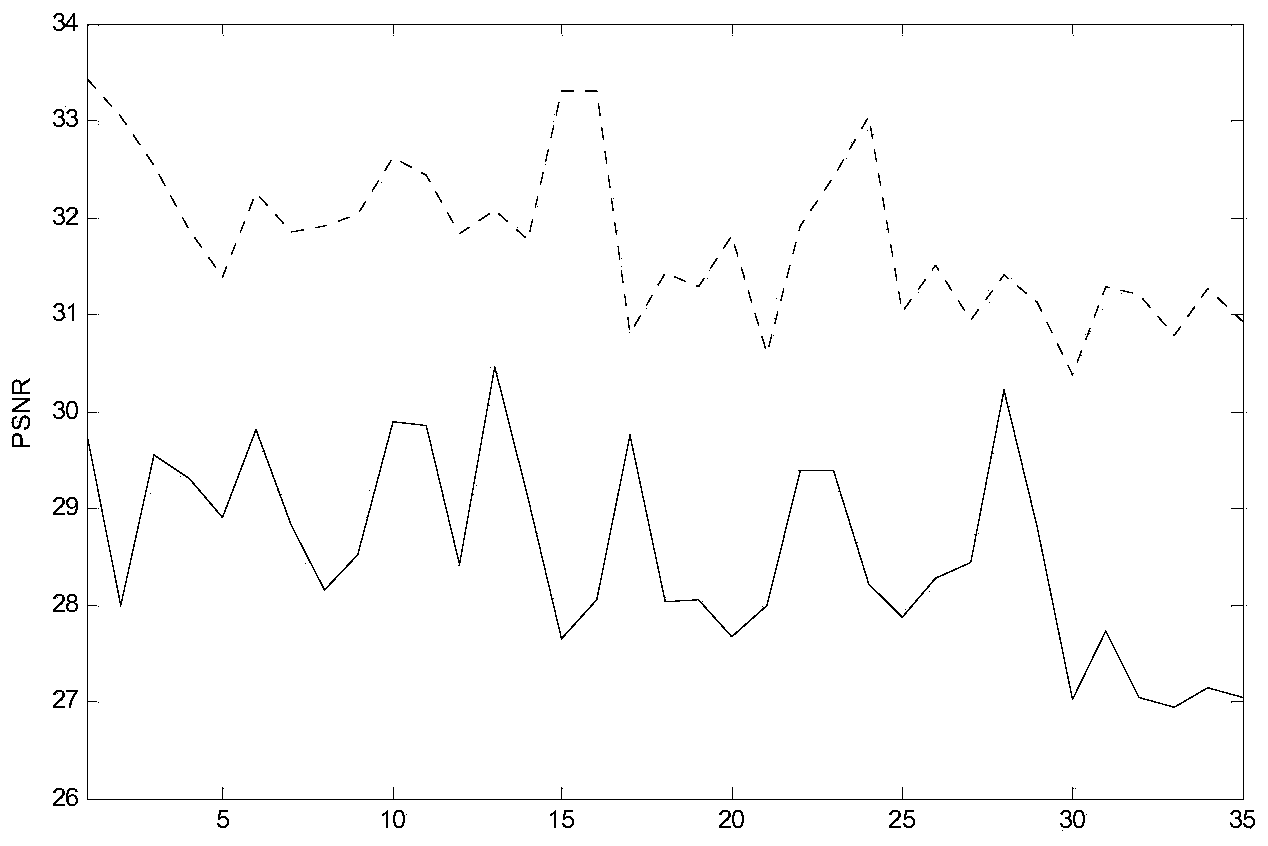

Shipborne video image stabilization method based on ship motion posture prediction

InactiveCN103516960AImprove real-time performanceResolve lagTelevision system detailsColor television detailsMotion vectorLeast squares support vector machine

The invention relates to a shipborne video image stabilization method based on ship motion posture prediction. The method is characterized in that a ship motion posture prediction method based on a least squares support vector machine (Least squares support vector machine, LSSVM) of particle swarm optimization (Particle swarm optimization, PSO) is provided to predict the ship motion posture, so as to acquire ship motion vector prediction data; according to the ship motion vector prediction data, the motion vector data of images are calculated; the image compensation vector is calculated in advance; and motion compensation is carried out on the images frame by frame. According to the method, a particle swarm optimization algorithm is introduced to carry out parameter selection on the least squares support vector machine; the ship motion posture prediction accuracy is improved; the image motion vector estimation accuracy is improved; the video image stabilization quality is improved; the image compensation vector is calculated in advance; the real-time of an image stabilization algorithm is enhanced; and the problem of lag, which is caused due to the fact that the traditional method estimates the image motion vector according to a fluctuated video, is solved.

Owner:HARBIN ENG UNIV

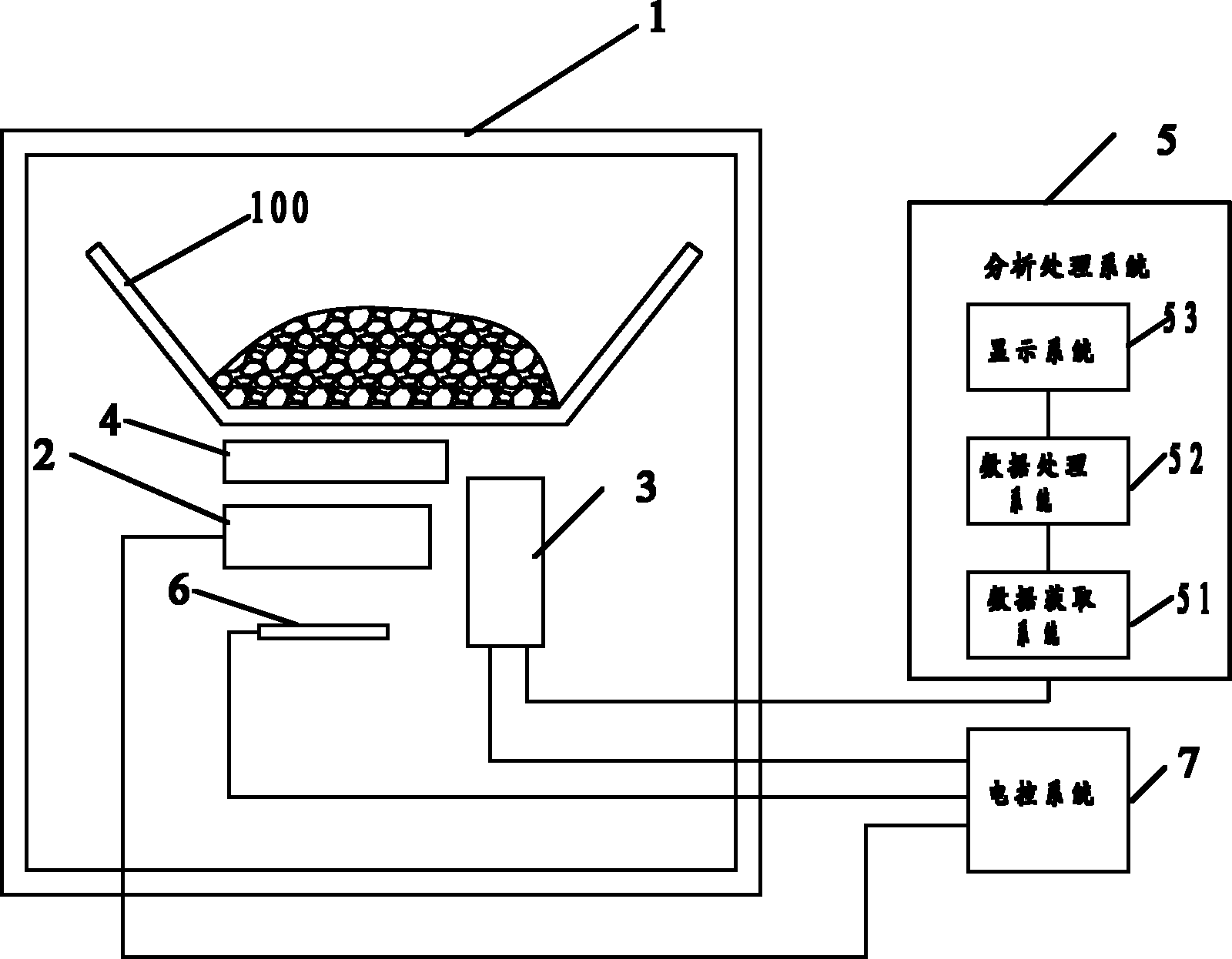

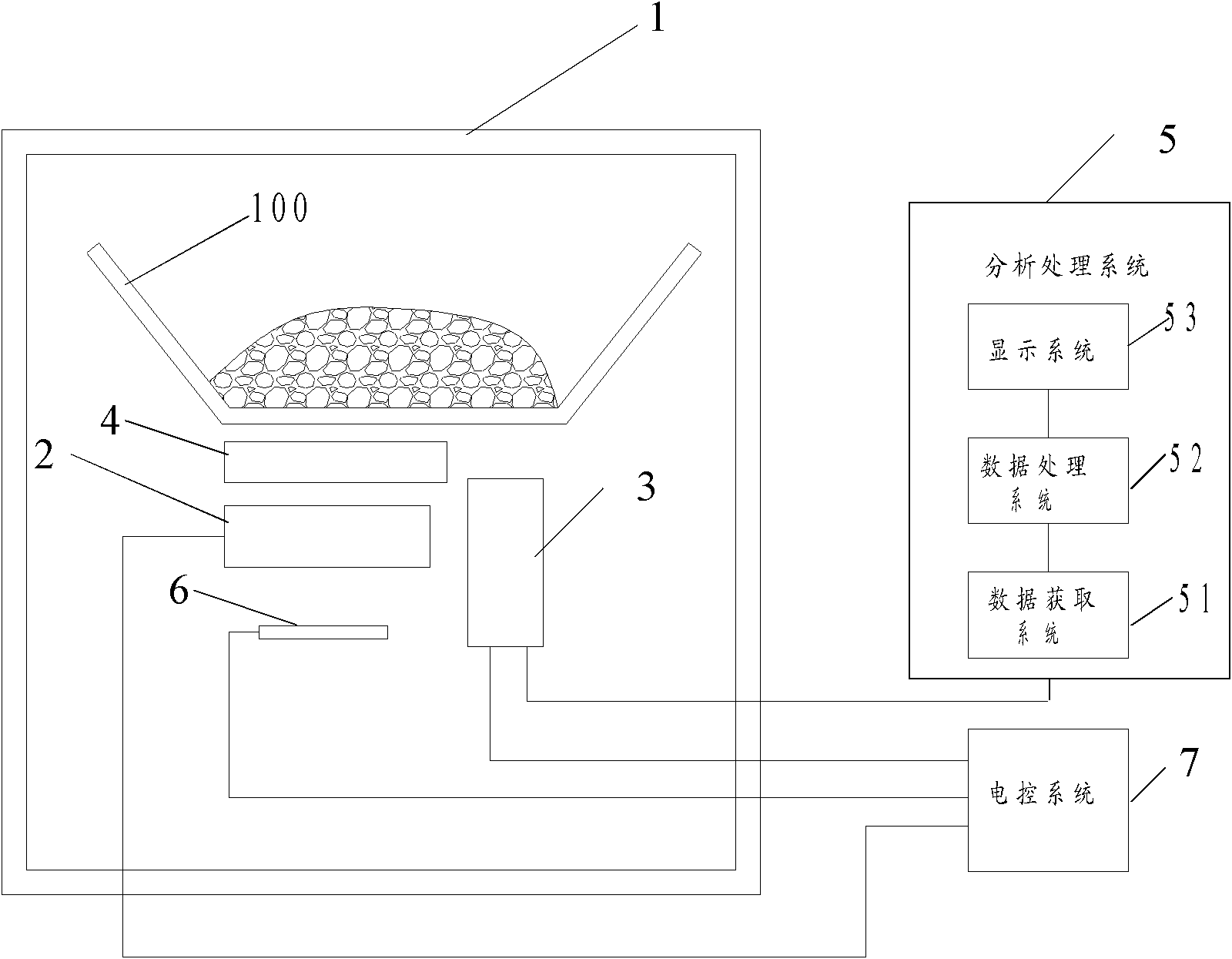

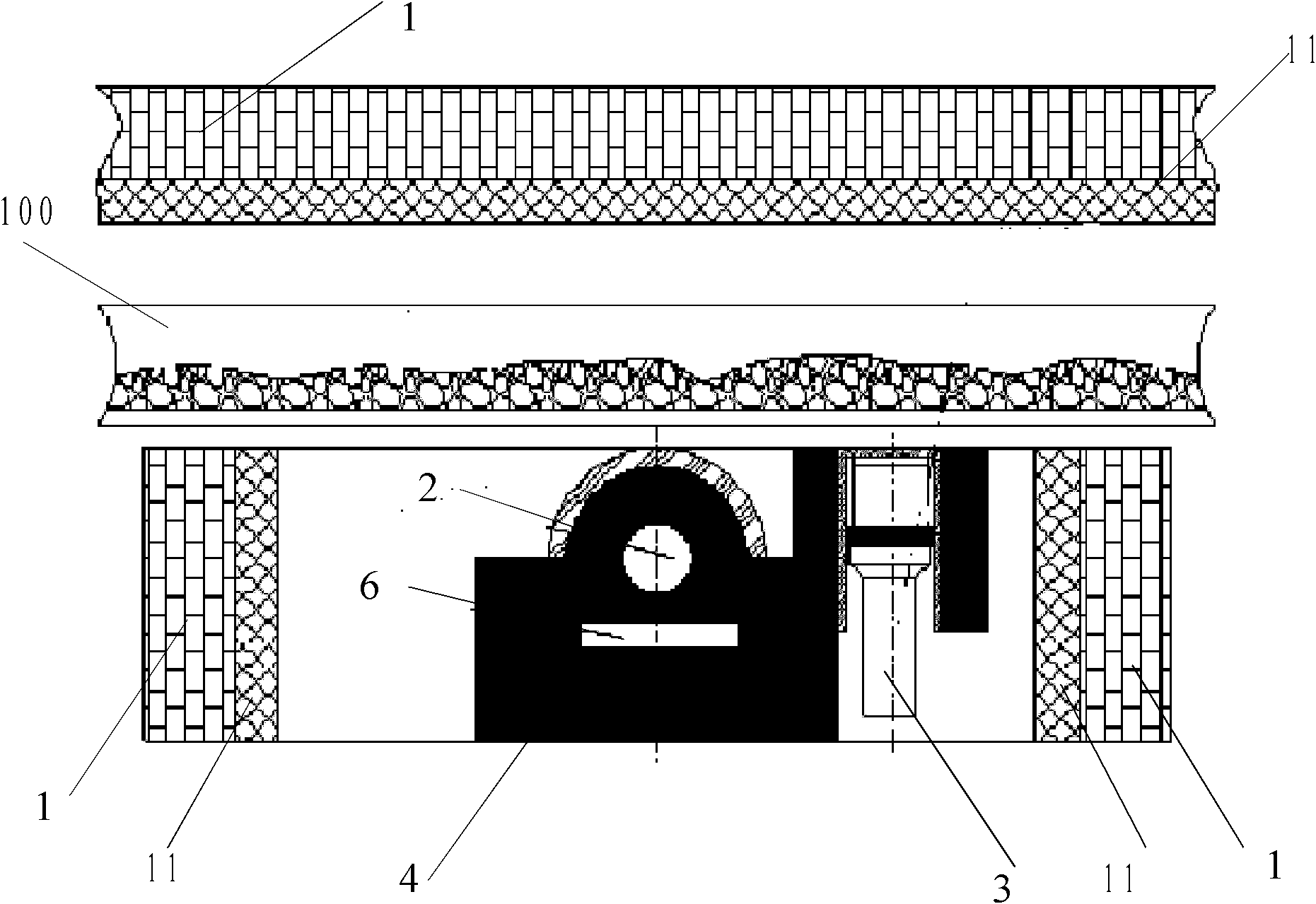

Method for detecting coal quality composition on conveying belt and device thereof

InactiveCN102095741AResolve lagReduce mistakesMaterial analysis by transmitting radiationAnalysis dataEngineering

The invention provides a method for detecting coal quality composition on a conveying belt and a device thereof; the device comprises a shielding case arranged on the conveying belt, a neutron generator and a gamma-ray detector, and an analysis processing system, wherein a closed space is formed in the shielding case, and the inner side of the shielding case is provided with a neutron reflector; the neutron generator and the gamma-ray detector are arranged inside the shielding case and positioned below the conveying belt, and neutron slowed bodies are filled among the conveying belt, the neutron generator and the gamma-ray detector; the analysis processing system is arranged outside the shielding case and is connected with the gamma-ray detector, and is used for obtaining the signals output by the gamma-ray detector to carry out energy spectrum analysis and calculate the content of coal quality composition and industrial analysis data. Through the embodiment of the invention, neutron activation prompt fission gamma-ray technology is adopted without sampling and sample making processes, and the content of coal quality composition can be obtained in time; therefore, the problem that the coal quality analysis data is hysteretic is solved.

Owner:CHANGSHA KAIYUAN INSTR

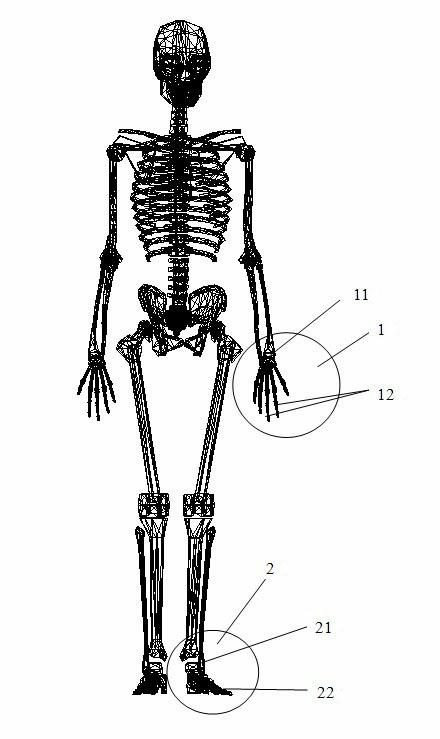

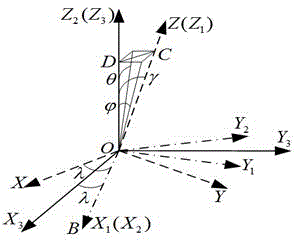

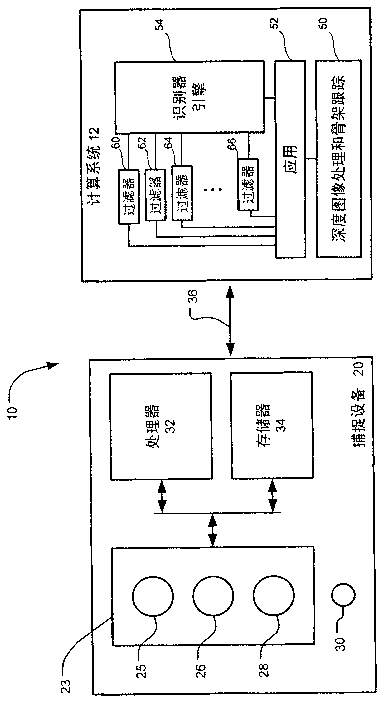

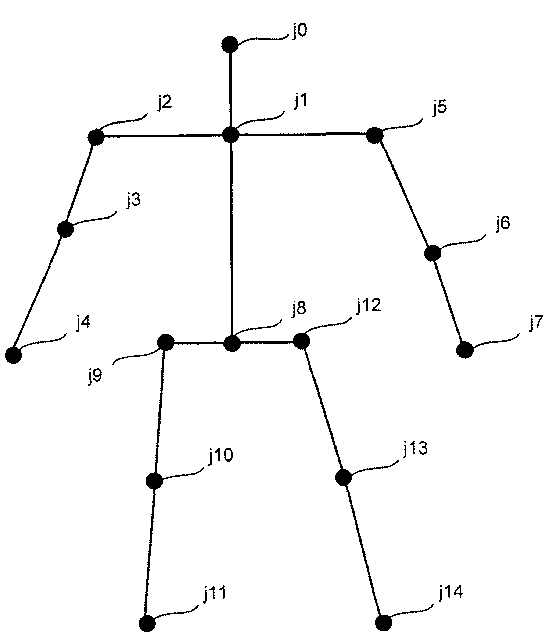

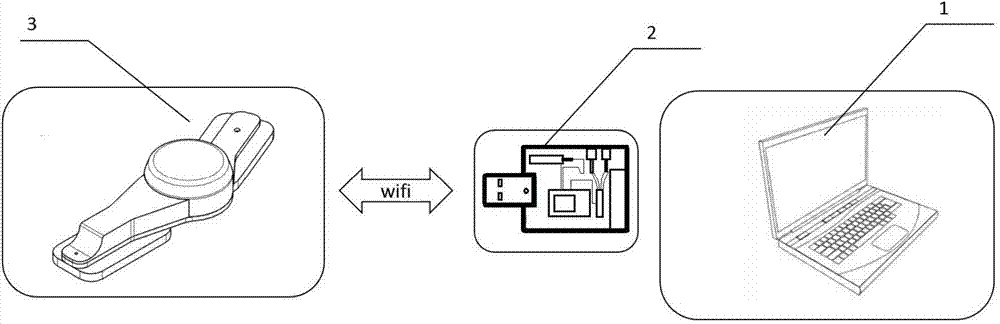

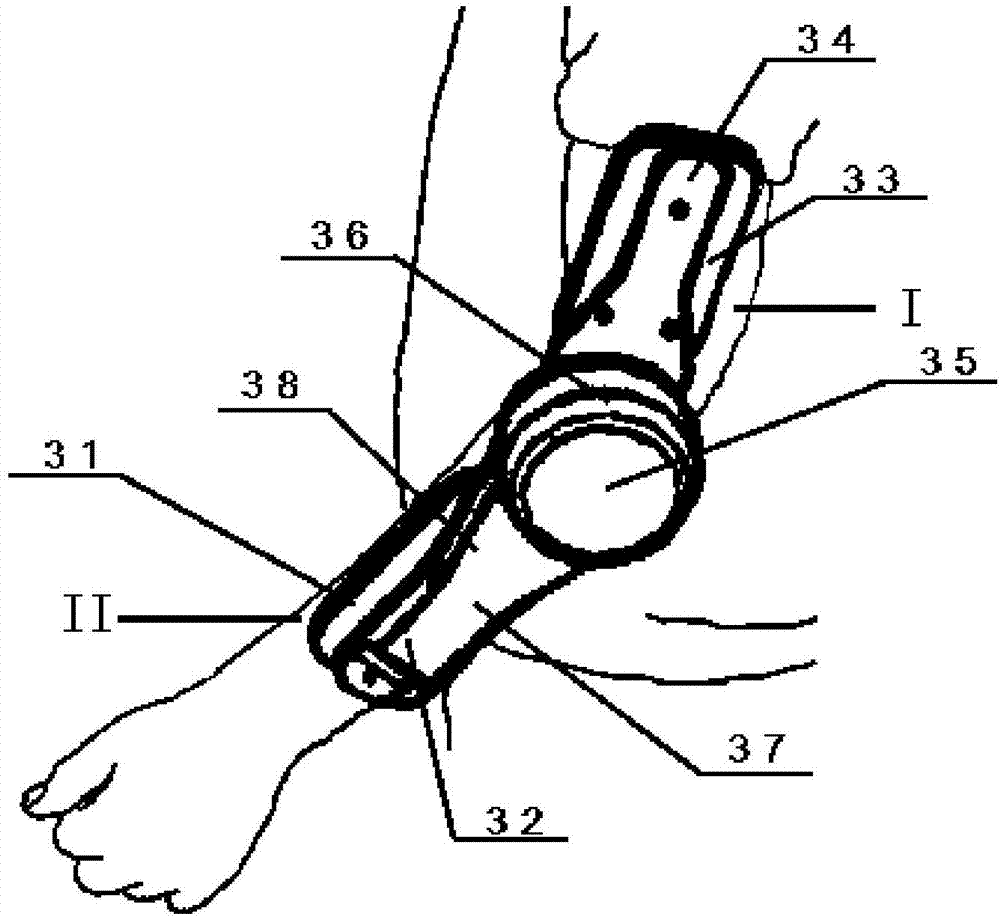

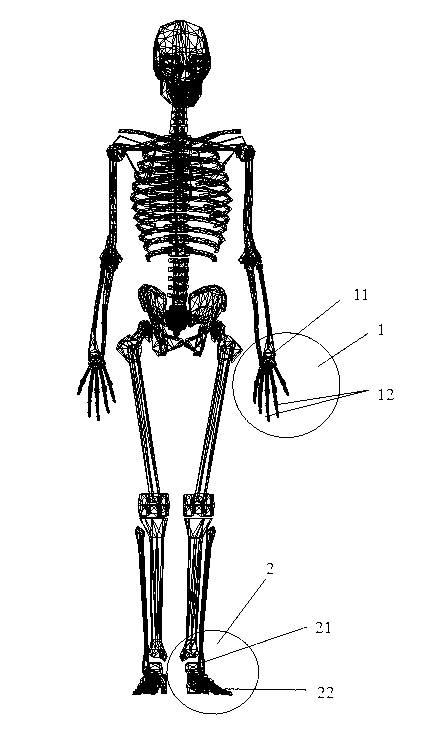

Wearable smart ring capable of capturing three-dimensional postures of four limbs of human body

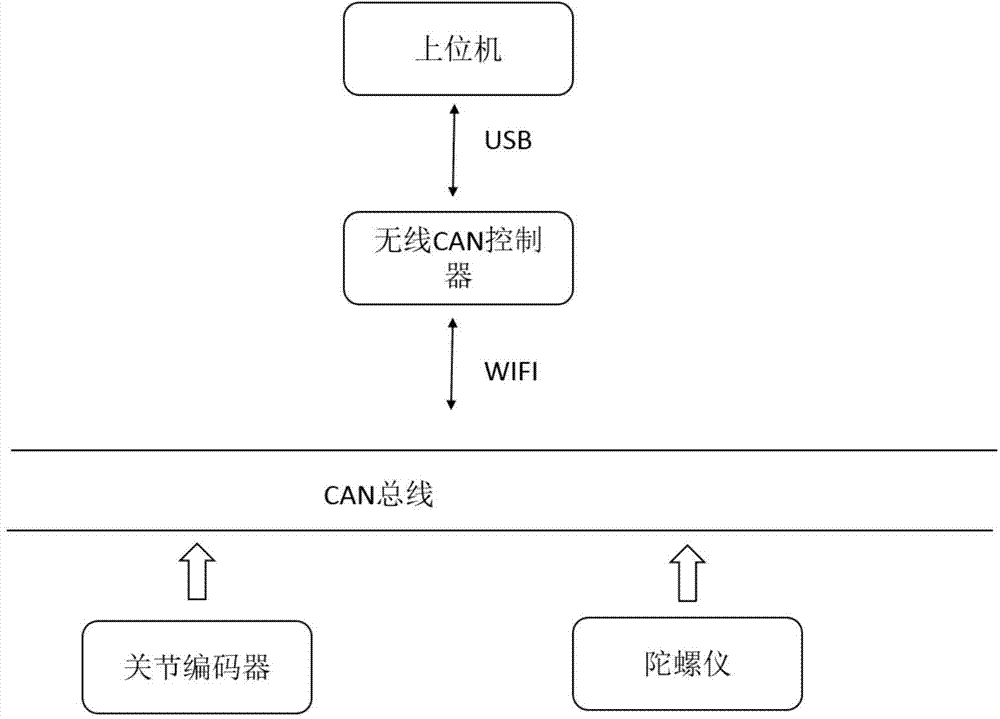

InactiveCN104771175AEasy to fixAccurate measurementDiagnostic recording/measuringSensorsHuman bodyGyroscope

The invention provides a wearable smart ring capable of capturing three-dimensional postures of the four limbs of a human body. The wearable smart ring comprises a joint wearable fixing device worn at a joint position of a human body, wherein an upper connecting rod fixing block and a lower connecting rod fixing block are respectively fixed on an upper connecting rod and a lower connecting rod at the joint position of the human body; an upper connecting rod shaft is connected with the upper connecting rod fixing block; the lower connecting rod shaft is connected with the lower connecting rod fixing block; a joint encoder is used for detecting the joint rotating angle of the human body, a flange is connected with the upper connecting rod shaft, and a rotating shaft is connected with the lower connecting rod shaft; an upper connecting rod gyroscope is used for detecting the spacial rotating direction at the upper connecting rod of the human body; and a joint fixing device end wireless CAN bus is connected with the joint encoder and the upper connecting rod gyroscope respectively and used for transmitting signals of the upper connecting rod gyroscope and signals of the joint encoder. The wearable smart ring has the characteristics of accurate joint angle measurement, precise and timely angle reading, high adaptability, long transmission distance, real-time transmission and the like and effectively solves the problem of data reading delay.

Owner:SHANGHAI JIAO TONG UNIV +1

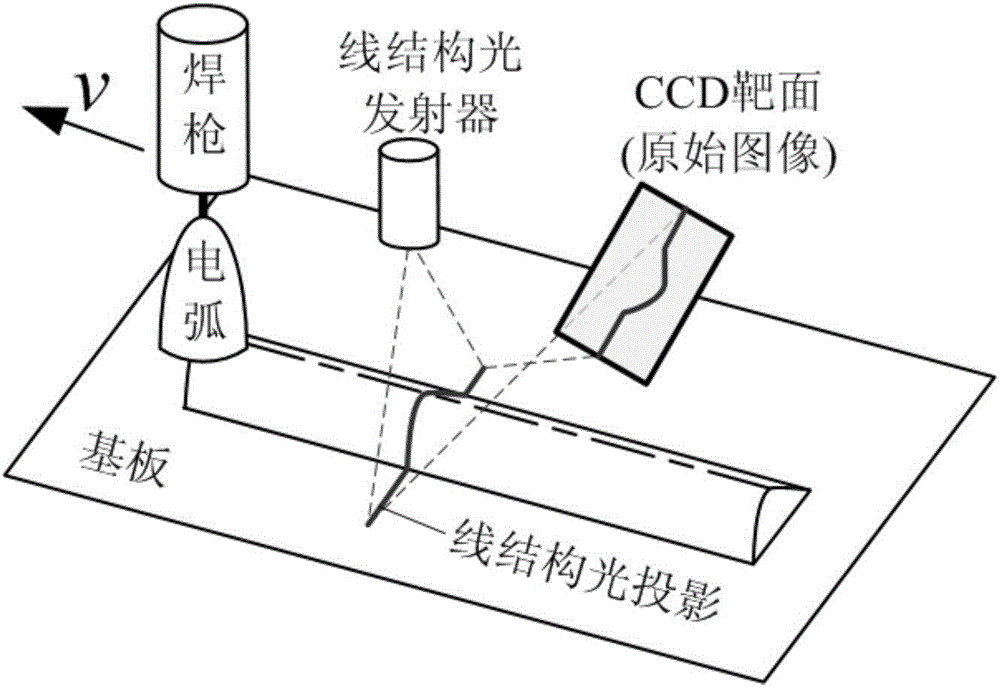

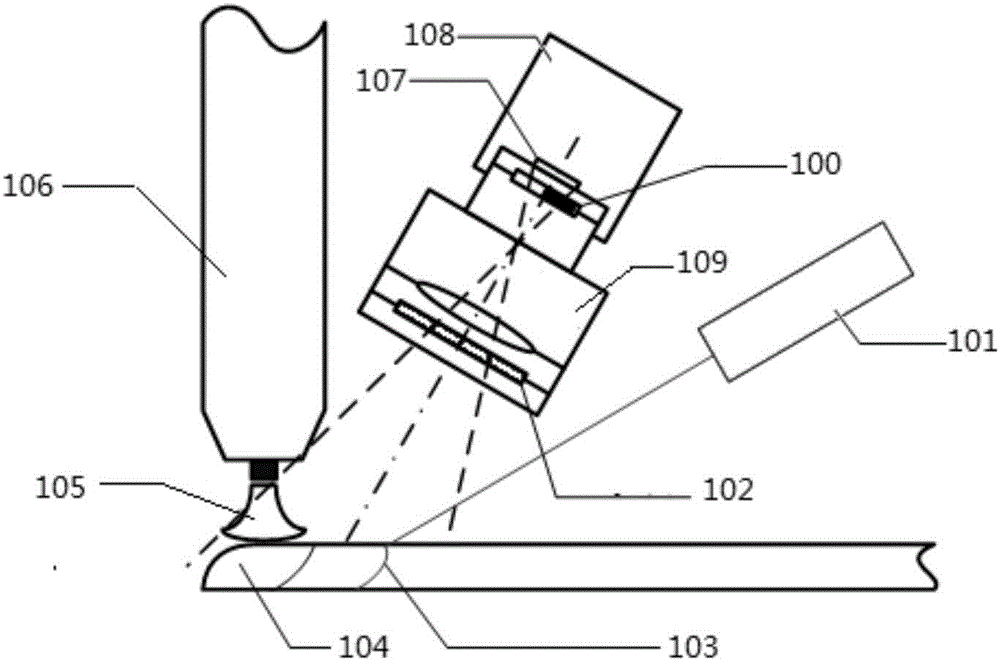

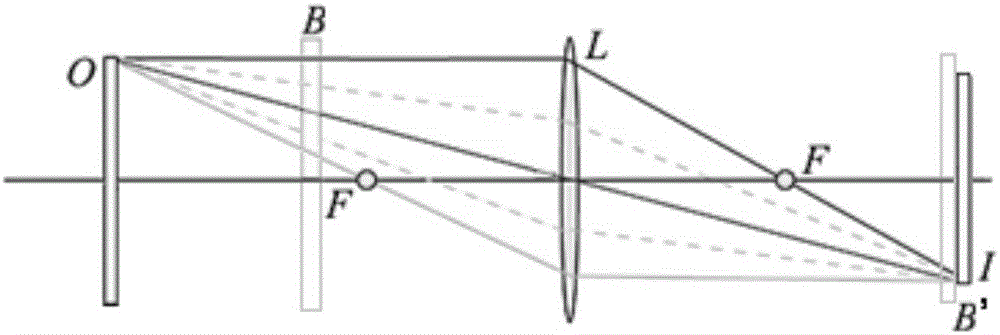

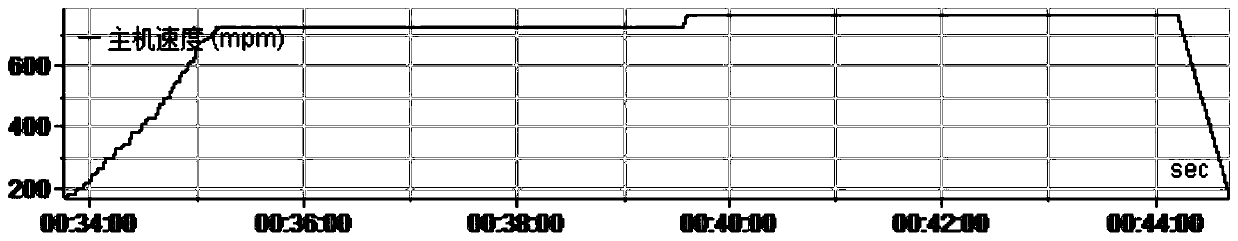

Weld bead dimension zero-lag real-time detection device for arc additive manufacturing and real-time detection method

A weld bead dimension zero-lag real-time detection device for arc additive manufacturing and a real-time detection method belong to the field of intelligent additive manufacture and are intended to solve the problem that the prior art is unable to provide zero-lag detection for weld bead width and height. The weld bead dimension zero-lag real-time detection device comprises a zonal dimming element, a linear-structure optical generator, an optical filter plate, a CCD (charge coupled device) camera and a head; the head is mounted at the front end of an imaging target face of the CCD camera, the optical filter plate is mounted at the inner front end of the head, a laser stripe emitted by the linear-structure optical generator is cast to the rear of a molten bath, the laser stripe and the molten bath are spaced, a welding torch is vertically disposed right above the molten bath, electric arc generated by the welding torch is positioned at the upper end of the molten bath, and the zonal dimming element is mounted between the imaging target face of the CCD camera and the head. The weld bead dimension zero-lag real-time detection device and the real-time detection method are used for arc additive manufacture and are also suitable for arc welding.

Owner:HARBIN INST OF TECH

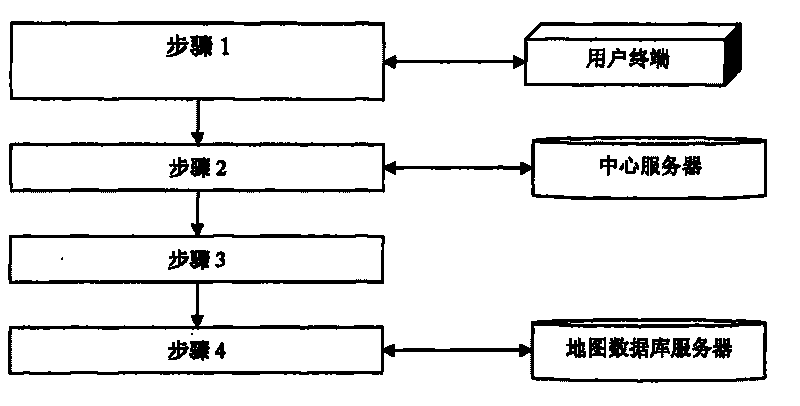

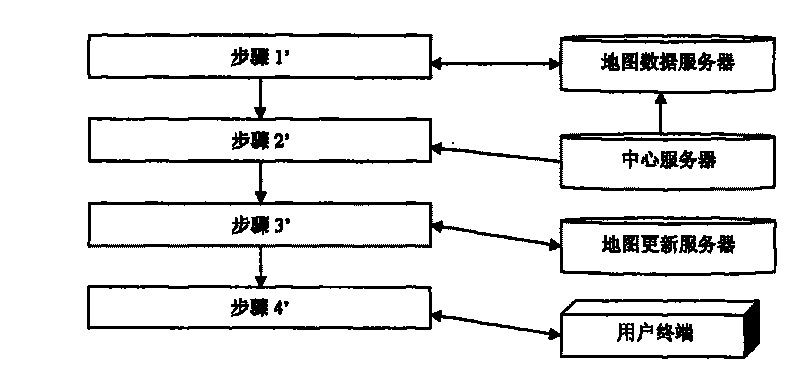

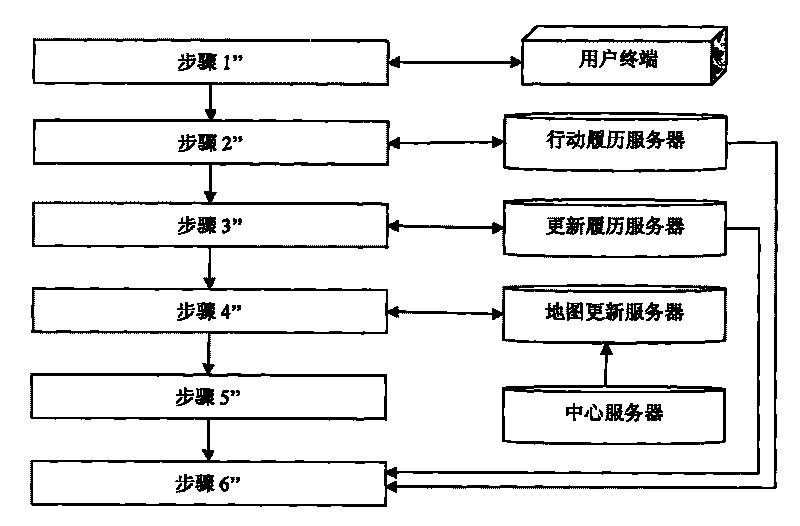

Bidirectional Delta information updating method of navigation electronic map

InactiveCN101713657AAddress information lagIncrease interactionInstruments for road network navigationSpecial data processing applicationsData providerElectronic map

The invention provides a bidirectional Delta information updating method of a navigation electronic map, which comprises a bidirectional updating of a map databank of a map data provider and a map databank of a user terminal. The bidirectional Delta information updating method is characterized in that geographic information differences and modified Delta information are converted into Delta data through a map element unique identification code, the databank of the map data provider can be modified in time, and the Delta information can be released directly or sent to the user terminal according to a user requirement in order to ensure the map databank of the user terminal to update in time. By directly providing Delta information modification, the invention solves the problems of unidirectional batch updating which is only provided by a manufacturer to customers, inflexible updating content which is generally aiming at certain area with monoblock updating, high cost and over-long time on map format conversion, and the like in the traditional navigation electronic map, and ensures the map data provider to acquire the Delta information in time and release the Delta information to the map user.

Owner:DMG INFOTECH +1

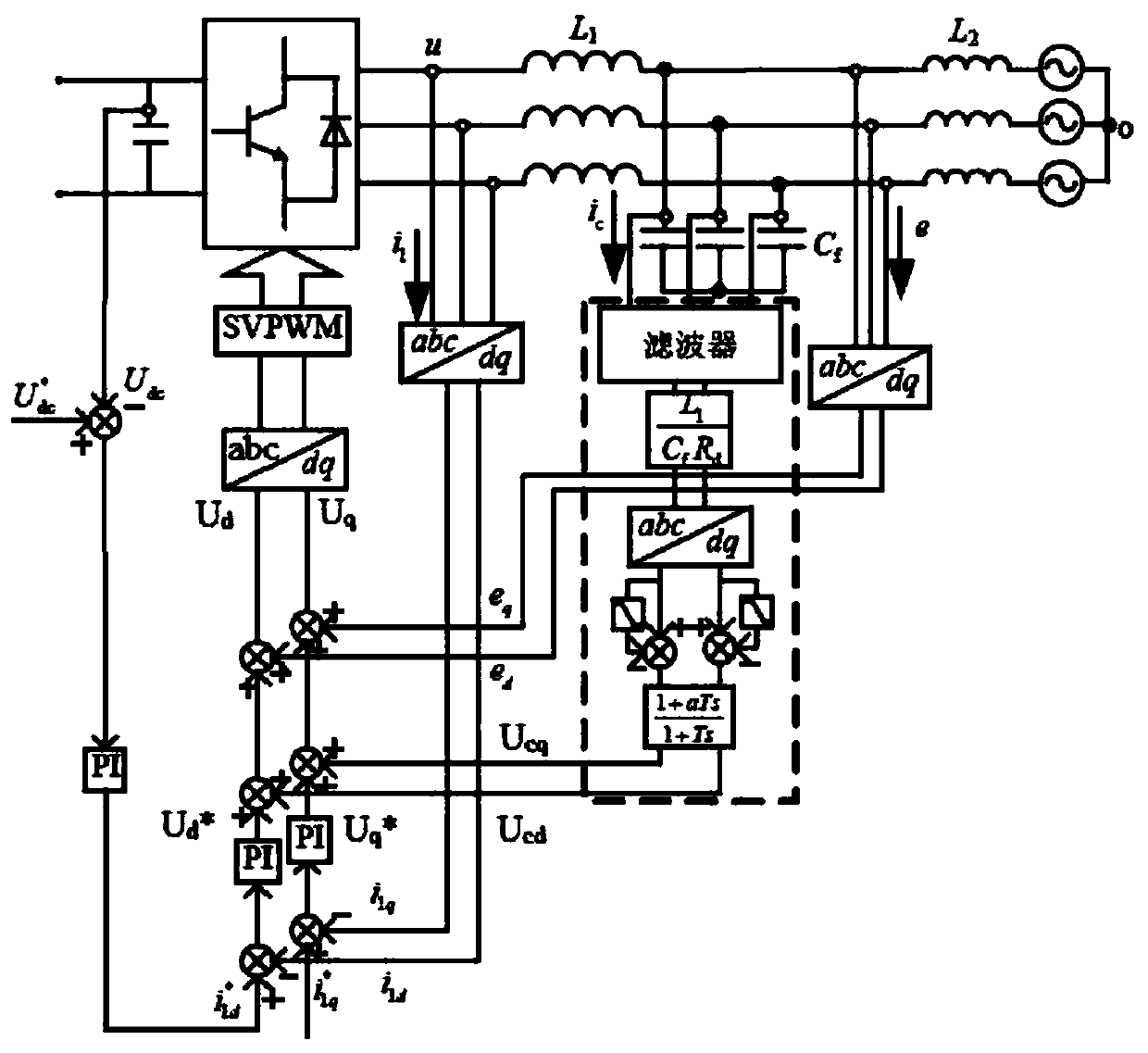

Active damping resonance control method for energy storage converter

InactiveCN110380416AResolve lagImprove adaptabilitySingle network parallel feeding arrangementsHarmonic reduction arrangementHysteresisCapacitance

The invention discloses an active damping resonance control method for an energy storage converter and aims to improve an active damping control method in the prior art. A grid-connected controller utilizes a proportional-integral PI control method, a voltage loop and current loop double closed-loop path is utilized, vector transformation is utilized to convert an AC quantity into a DC quantity for adjustment; correspondingly, the proportional link output of a channel is fed back through the filter capacitor current, the AC quantity is converted into the DC quantity through vector transformation, an advanced compensation controller is utilized, and compensation control for the hysteresis caused by sampling delay and digital control is performed. The advanced compensation controller is utilized for compensation control for the hysteresis caused by sampling delay and digital control, and a sampling aliasing and lag problem in practical industrial applications is solved. The method is advantaged in that a problem of resonance suppression from the single-machine resonant frequency to multi-machine resonant frequency wide frequency range existing in the whole system after multiple inverters are connected in parallel is solved, effective suppression of harmonics is achieved, the harmonic content is reduced, and adaptability to the wide frequency range is improved.

Owner:NARI TECH CO LTD +1

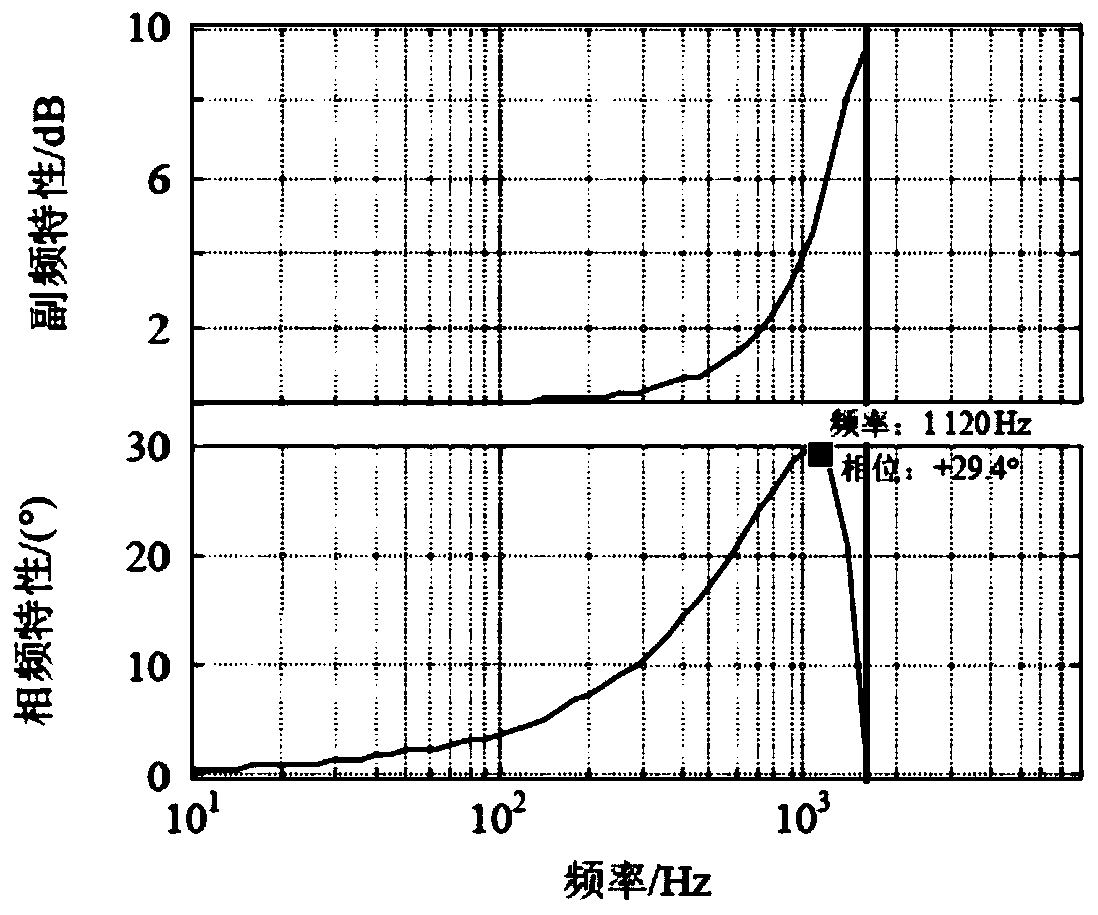

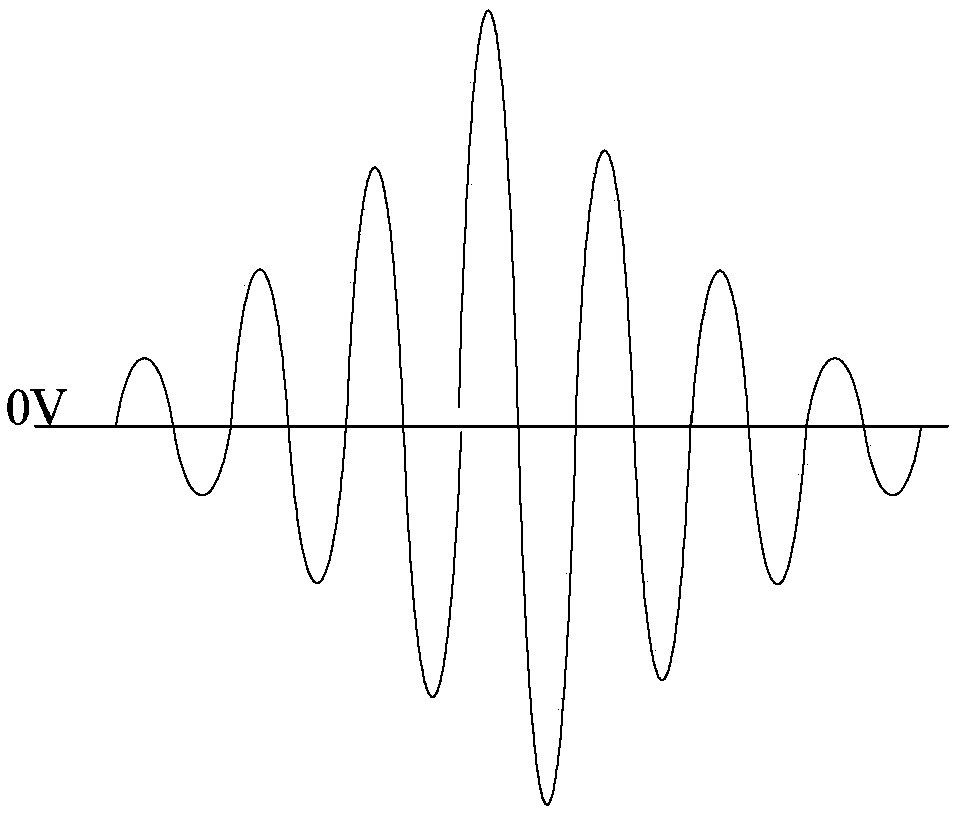

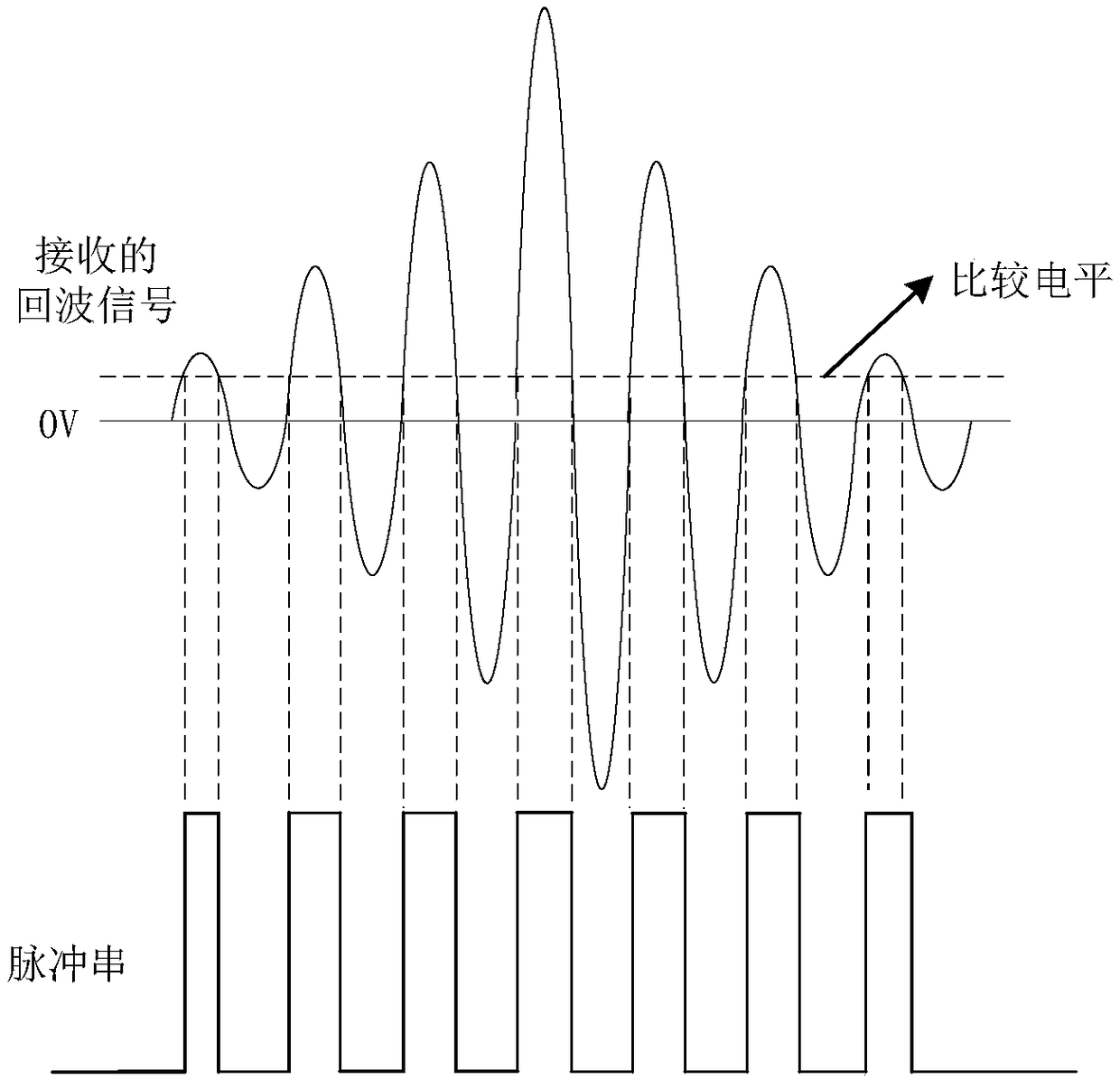

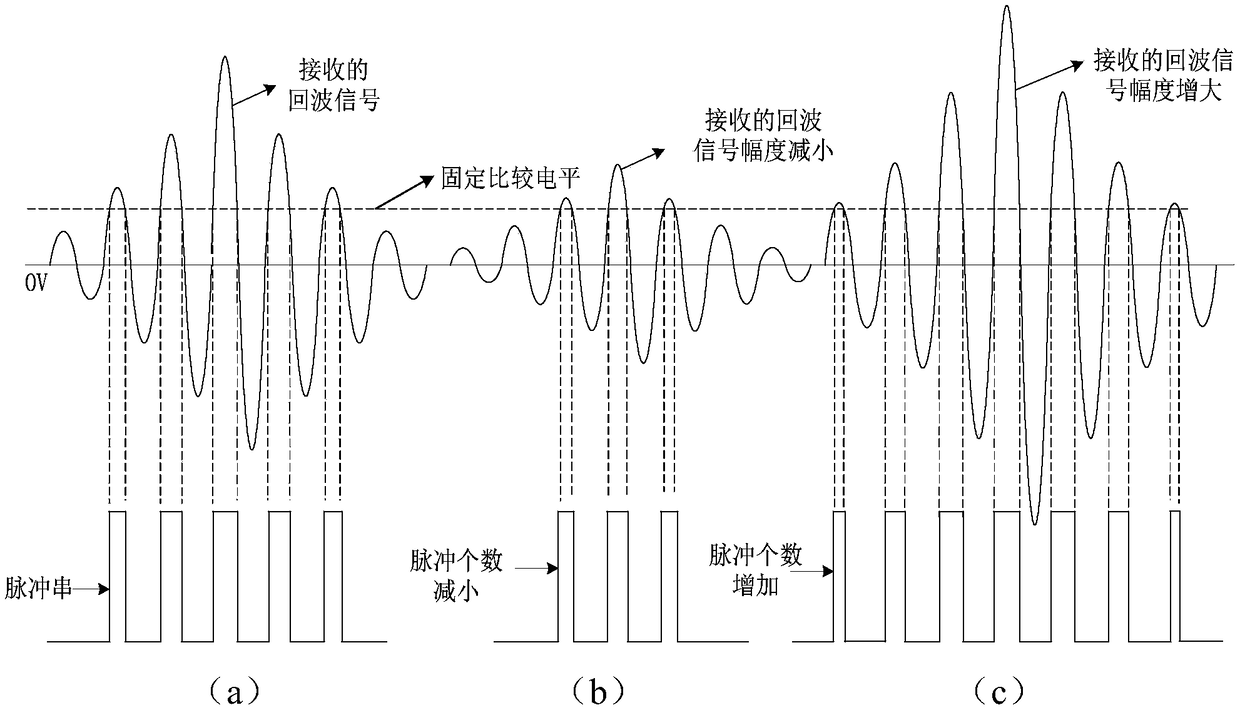

Echo signal detection circuit of adaptive ultrasonic wave

ActiveCN109186693AAccurate detectionSolve the wave jump problemVolume/mass flow measurementUltrasound attenuationMain channel

The invention discloses an echo signal detection circuit of an adaptive ultrasonic wave, wherein an echo signal docked by a pre-channel circuit is amplified and filtered, and a main channel circuit performs re-amplification processing and zero-crossing comparison to generate a main channel signal containing an interference pulse; an auxiliary channel circuit pre-receives the signal for peak detection and obtains a comparison level through attenuation according to a certain proportion, the official received signal is subjected with trigger comparison with the comparison level to generate a first pulse-sequence signal, a strobe signal is generated according to the falling edge of the first pulse for an AND-operation with the main channel signal, and a second pulse-sequence signal is output to trigger a timing module to stop timing to obtain a time difference. By adopting a peak detection circuit and cooperating with a working mode of two consecutive times of signal reception and transmission, the echo signal detection circuit provided by the invention dynamically tracks the pre-received signal and flexibly adjusts the comparison level, which solves the pulse-sequence skipping problem. In addition, the strobe signal is functioned to avoid the effect of the noise pulse of the main channel on the time measurement, and the main channel uses a zero-crossing comparator to solve the problem of phase lead or lag in the quarter period of the pulse sequence.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

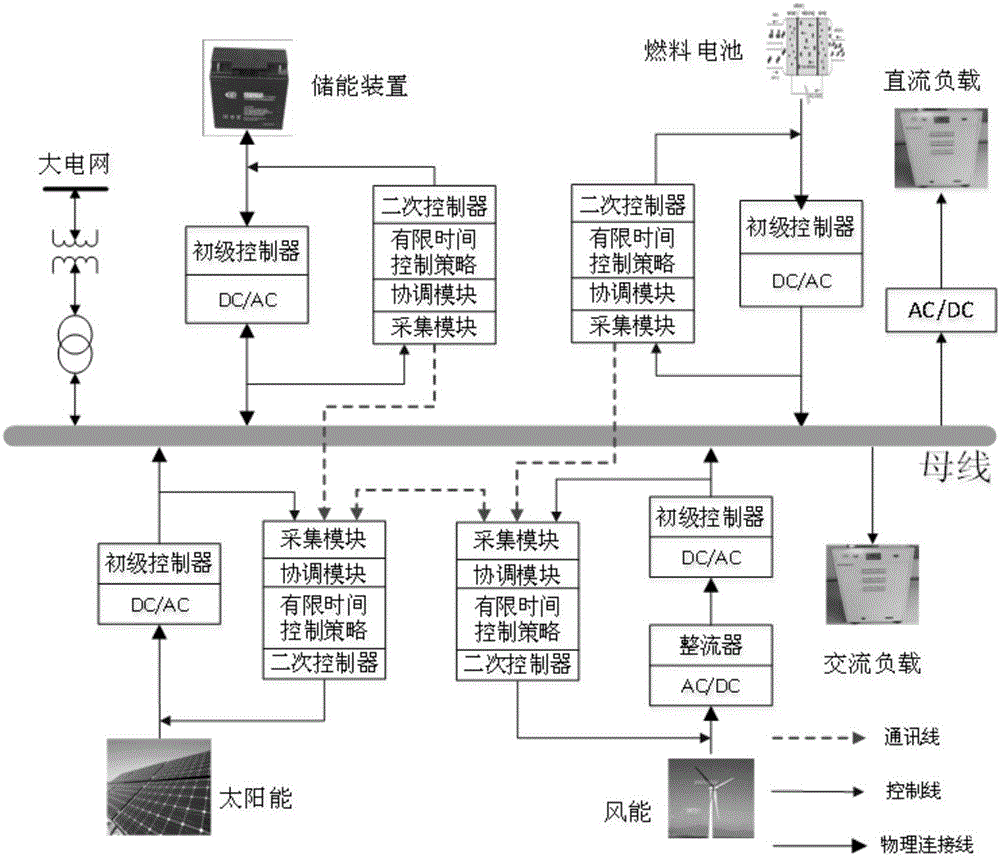

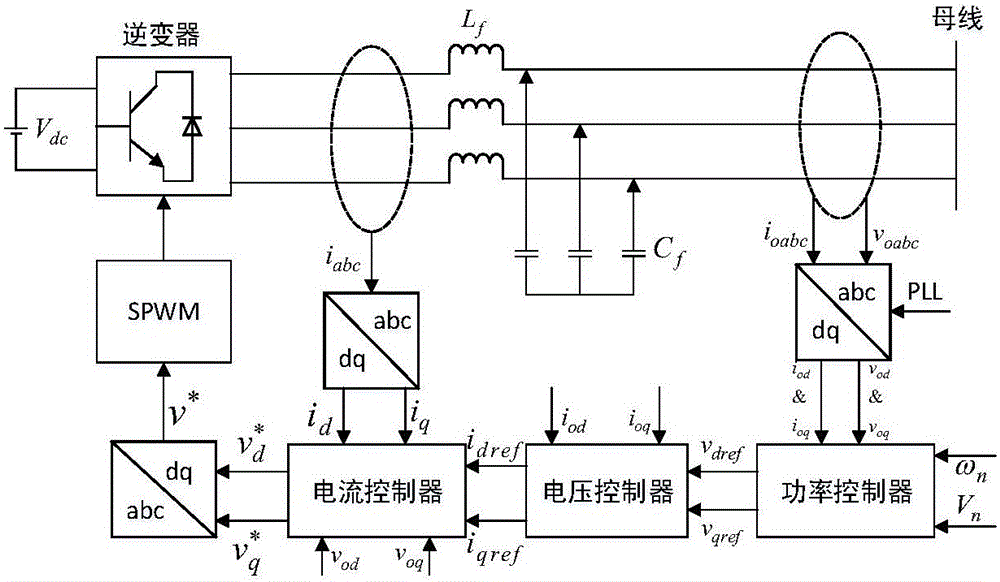

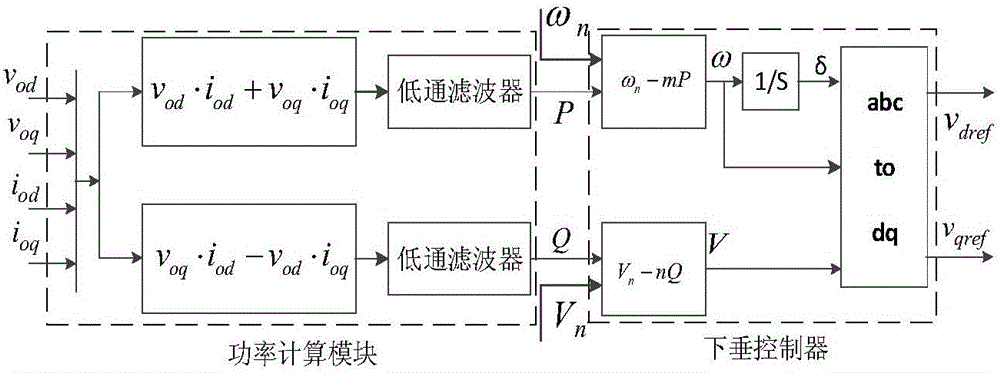

Microgrid distributed finite time control method based on communication lag

InactiveCN105896613AResolve lagSatisfy the plug-and-play featureAc-dc conversionEnergy industryMicrogridCurrent voltage

The invention discloses a microgrid distributed finite time control method based on a communication lag. The microgrid distributed finite time control method comprises the following steps of acquiring an output current voltage of an inverter end and an input current voltage of a load end by a voltage / current acquisition module, and outputting the output current voltage and the input current voltage to a primary controller of the voltage / current acquisition module, a secondary controller of the voltage / current acquisition module and a secondary controller of a neighboring power generation unit; processing the voltage current information of the secondary controllers and the voltage current information of a neighboring node by the secondary controller, and generating voltage and frequency reference information of the primary controller; generating a sinusoidal pulse width modulation (SPWM) wave by the primary controller through power calculation, droop control and voltage current control according to the reference information given by the secondary controllers, and controlling the output voltage of an inverter. In actual secondary control of a microgrid, the communication lag will necessarily exist, and by the method, the lag problem can be effectively solved.

Owner:CHONGQING UNIV

Tracking method of hot rolling basic automation control data security timeliness

InactiveCN102637008AGuaranteed integrity and reliabilityIncreased integrity and reliabilityProgramme control in sequence/logic controllersMemory addressData acquisition

The invention provides a tracking method of hot rolling basic automation control data security timeliness, and the method is used for transmitting steel strip information of production completion to a local database accurately in real time and transmitting the steel strip information to a remote database in the Ethernet synchronously. The technical scheme of the invention is as follows: a data acquisition device is equipped with dual network cards; one of the network cards is connected with a memory mapped network and the network card and the memory mapped network are set as a network section; the other network card is connected with a third layer of Ethernet and the network card is set as a three-layer Ethernet section; an acquisition program in the data acquisition device establishes an external variable of Profibus; the external variable corresponds to a PLC (Programmable Logic Controller) unit address, in such a way, the data acquisition program shares one same memory address; data of finished products in the PLC memory can be stored into the local database through a memory mapped network data acquisition program; lost data can be found from the local database by using a communication interrupt data retransmission mechanism; the lost data can be added into a temporary memory; and a retransmission program is triggered manually till the data is transmitted into the remote database safely.

Owner:WEIER AUTOMATION CO LTD TANGSHAN IRON & STEELGRP

Method and system for layered control of vehicle mode decoupling, and media

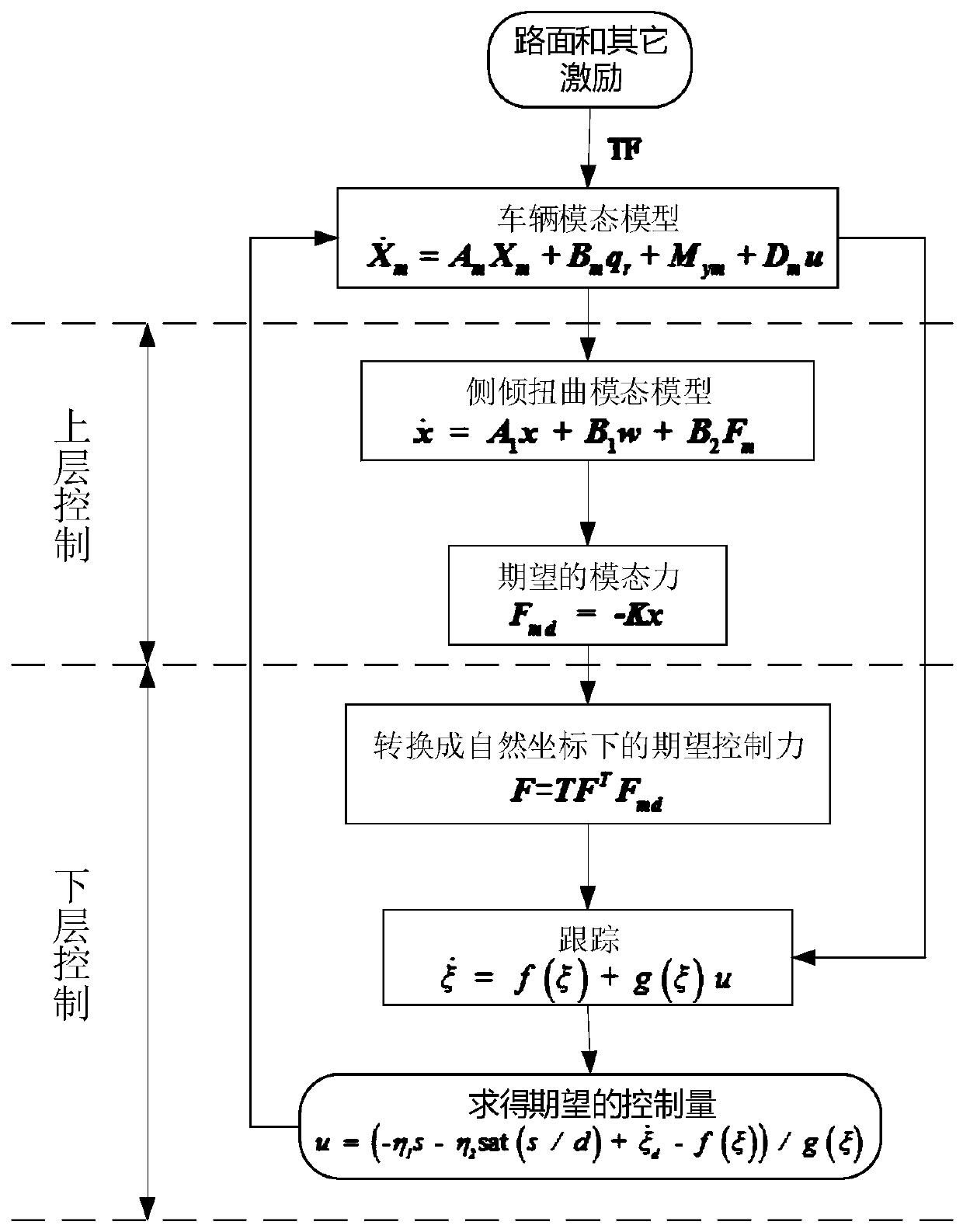

ActiveCN110712491AResolve interferenceSolve nonlinear problemsResilient suspensionsReference modelingControl system

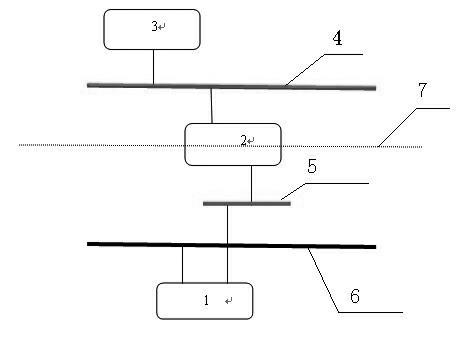

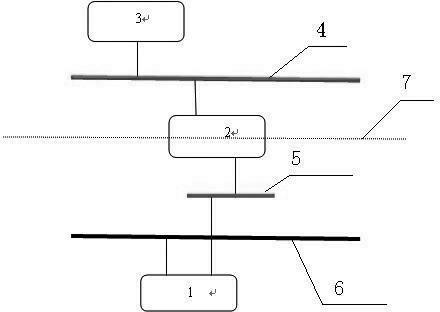

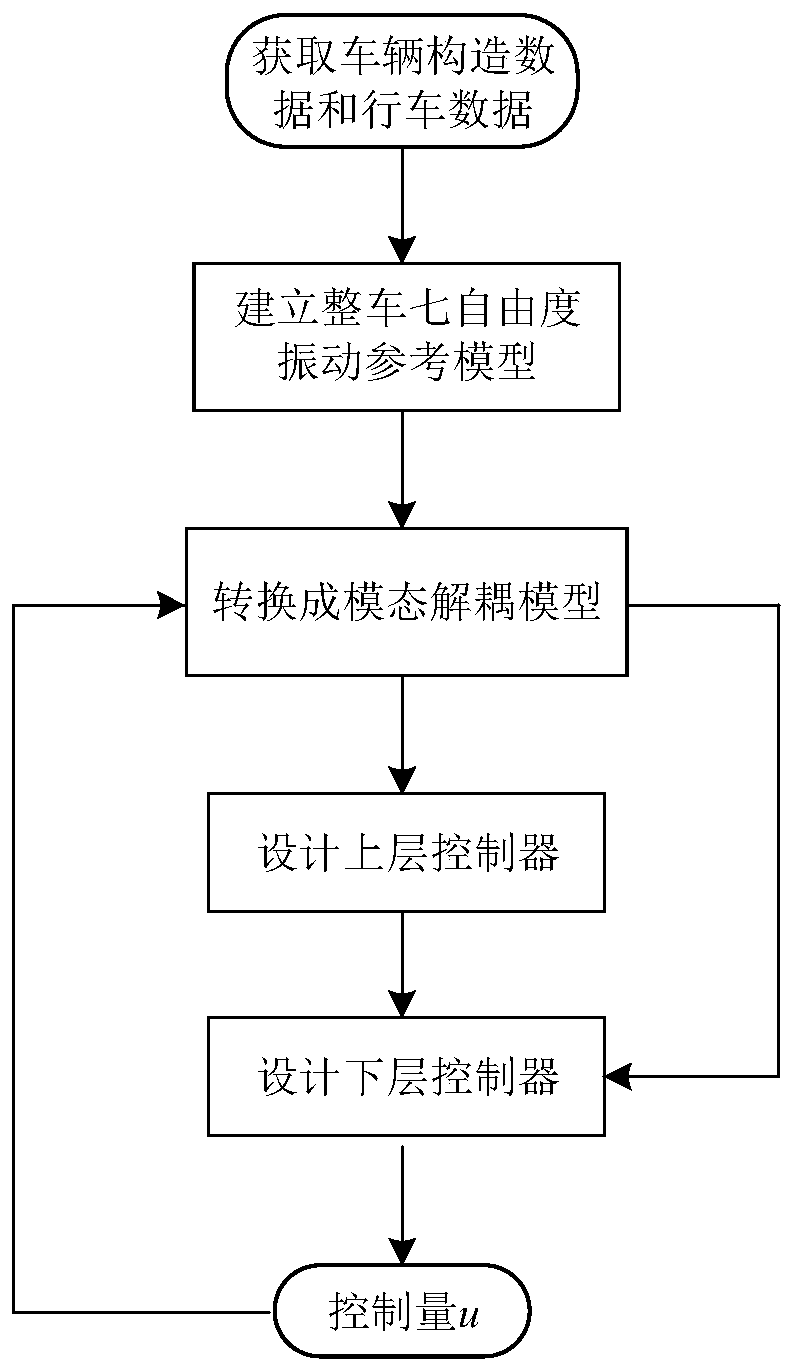

The invention discloses a method and system for layered control of vehicle mode decoupling, and media. The method comprises the following implementation steps of acquiring construction data and driving data of a vehicle, establishing a vehicle seven-degree-of-freedom vibration reference model and converting the vehicle model by using a model conversion matrix TF to obtain a new seven-degree-of-freedom mode decoupling equation used for expressing the vehicle model as a decoupled mode coordinate equation, obtaining desired model control force according to a control target through an upper controller based on the new seven-degree-of-freedom mode decoupling equation, and tracking the obtained desired model control force through a lower controller in combination with a specific suspension actuator system model. The method can decouple several modes of the vehicle from one another, can effectively improve the overall control quality, is beneficial to reducing the complexity of a control system, can be used for researching vehicle motion, analyzing complex vehicle models, and solving the problems of multi-interference, non-linearity, hysteresis, uncertainty and strong coupling during vehicle motion.

Owner:HUNAN UNIV

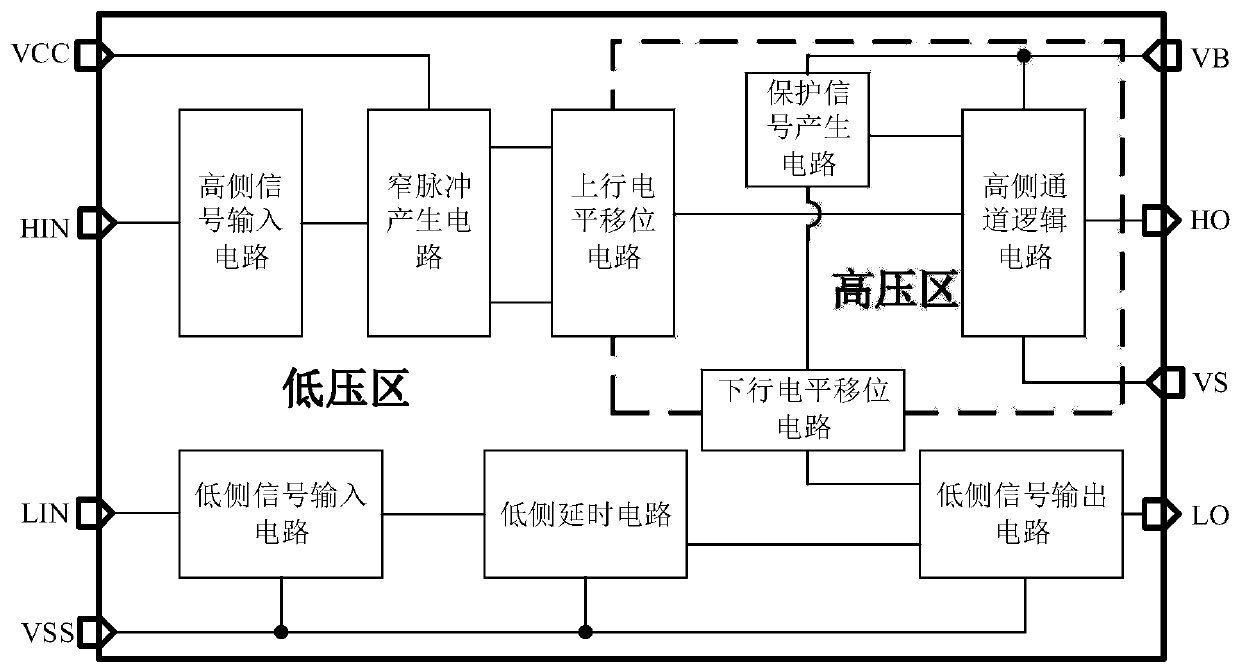

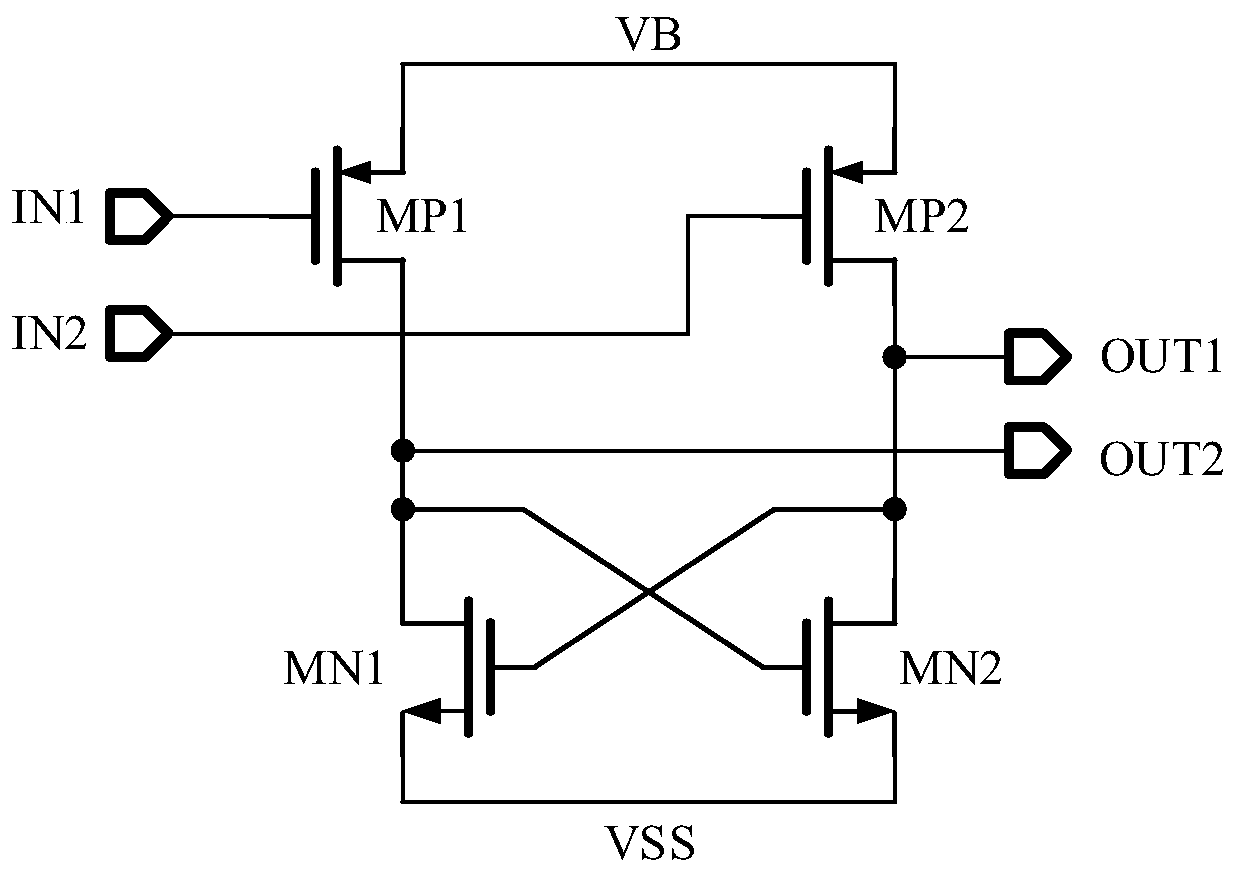

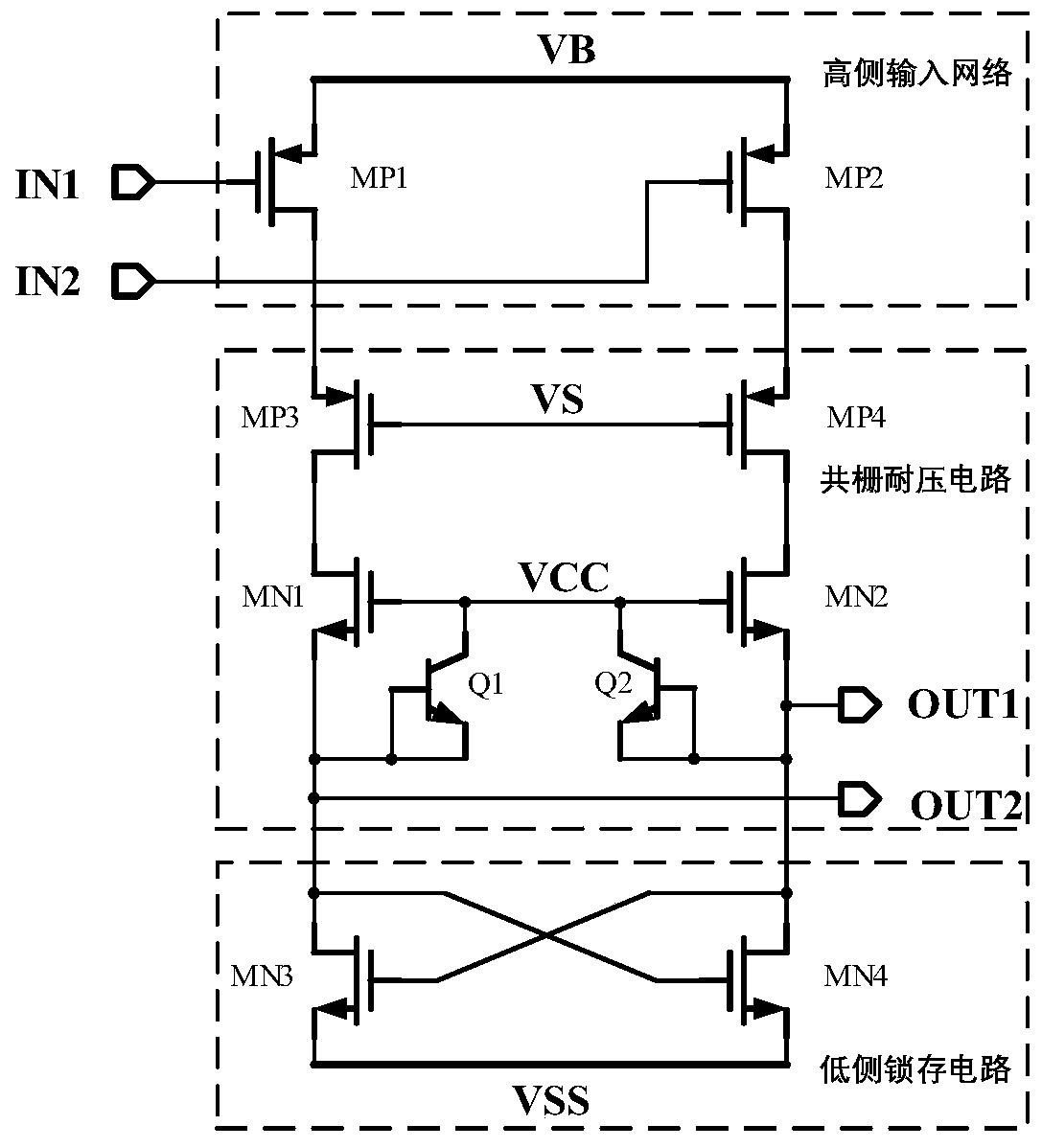

Fast downlink level shift circuit with low working voltage

PendingCN110601690AIncrease grid voltageGood temperature characteristicsReliability increasing modificationsLogic circuits coupling/interface using field-effect transistorsVoltage rangeTransmission delay

The invention discloses a fast downlink level shift circuit with low working voltage. An MOS tube is used as a linear resistor to replace a simple resistor in the 20181084311 application, and two paths of feedback loops composed of PMOS tubes are adopted. When a PMOS tube needs to output a low level, a branch for outputting a low-side low level VSS is conducted; the transmission process of reducing the output level to the low level is accelerated, the transmission delay caused by increasing the resistance is reduced, the delay of the level shift circuit is effectively reduced, the problem thatthe signal is too lagged is solved, and the downlink level shift circuit can work quickly. The HVIC protection module can be applied to the signal conversion process from a high side level to a low side level in an HVIC, more complete transmission of various protection signals can be ensured in a larger working voltage range, and the HVIC protection module can better adapt to different working environments at a higher working speed, so that an HVIC circuit is better protected, and the protection efficiency of the protection module is improved.

Owner:无锡安趋电子有限公司

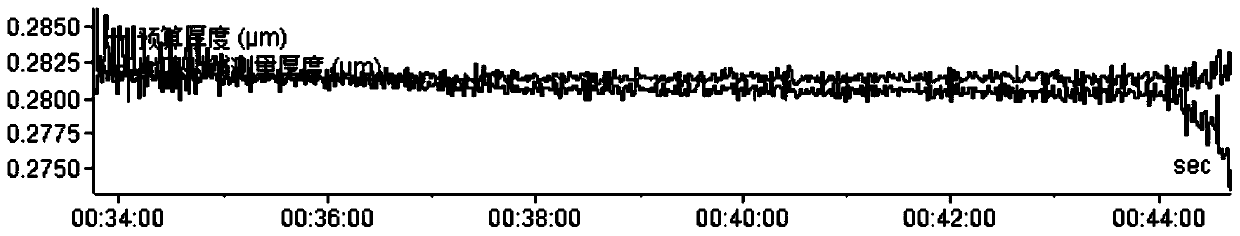

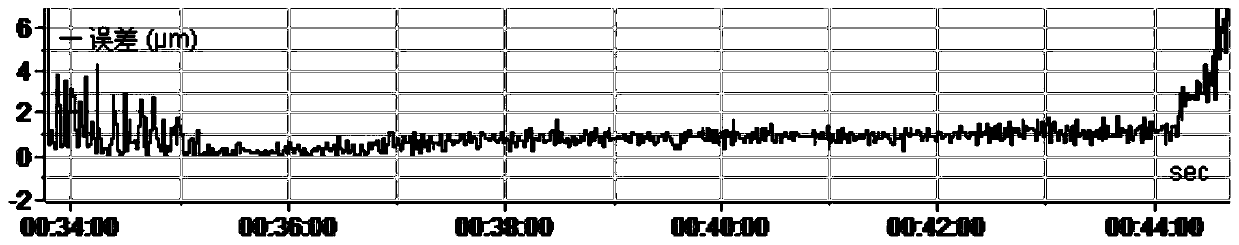

Method for online early warning of strip steel thickness deviation

InactiveCN110548769ATimely feedbackSolve the large error and lag of manual measurementRoll mill control devicesMeasuring devicesWaste generationExit side

The invention discloses a method for online early warning of strip steel thickness deviation. The method for the online early warning of the strip steel thickness deviation includes: using a thicknessgauge for collecting data of the strip steel thickness measured on an exit side and the strip steel thickness measured on an entry side, calculating out a predicted value h<prediction> of the strip steel thickness on the exit side, comparing the predicted value h<prediction> of the strip steel thickness on the exit side with the strip steel thickness h<exit> measured on the exit side, and when the deviation Delta, equal to difference value between the h<prediction> and the h<exit>, exceeds the strip steel thickness tolerance range, sending out an alarm for the strip steel thickness h<exit> measured on the exit side. The method for the online early warning of the strip steel thickness deviation realizes online timely actual thickness prediction and early warning beforehand, is simple and easy to implement and timely in feedback, not only solves the problem that manual measurement is large in error and hysteretic, but also completely eradicates loss caused by waste generation when thickness tolerance of continuous batch steel strips exceeds standards, and is remarkable in implementation effect.

Owner:武汉钢铁有限公司

Method for controlling human-machine interaction and application thereof

ActiveCN103019386ASuitable for a wide range of peopleIncrease activity timeInput/output for user-computer interactionGraph readingVirtual worldData science

The invention provides a method for controlling human-machine interaction and an application thereof. A user controls a self-character in a virtual environment to implement a corresponding virtual permissible action by performing a user permissible micro-action. The method comprises the following steps of: (1) creating a self-character in a virtual world; (2) enabling the user to perform a micro-action without leaving the position of the user; (3) tracing and identifying the performance of the micro-action by the user, and enable the user to perform any micro-action without leaving the position of the user; and (4) amplifying the self-character to execute the micro-action of the user. Due to the adoption of an action amplifying system introduced by the invention, the user can realize all functions or capabilities given by the entire virtual world without moving or by moving slightly, the user can keep at the same operating position in the entire virtual world, meanwhile the consistence of the moving part of the user with a character moving part in the virtual world can be realized conveniently, and the user can comprehend easily.

Owner:漳州市阿思星谷电子科技有限公司

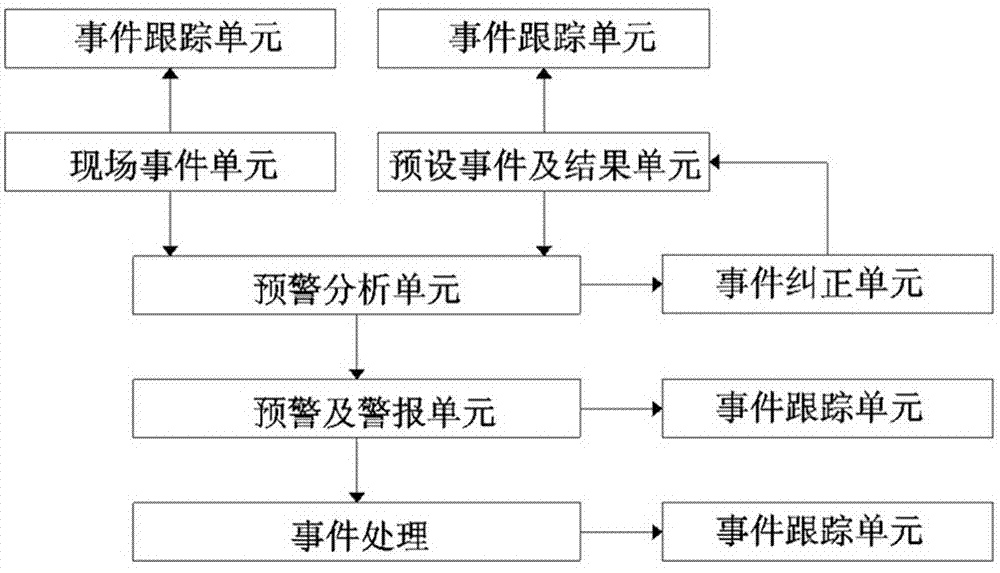

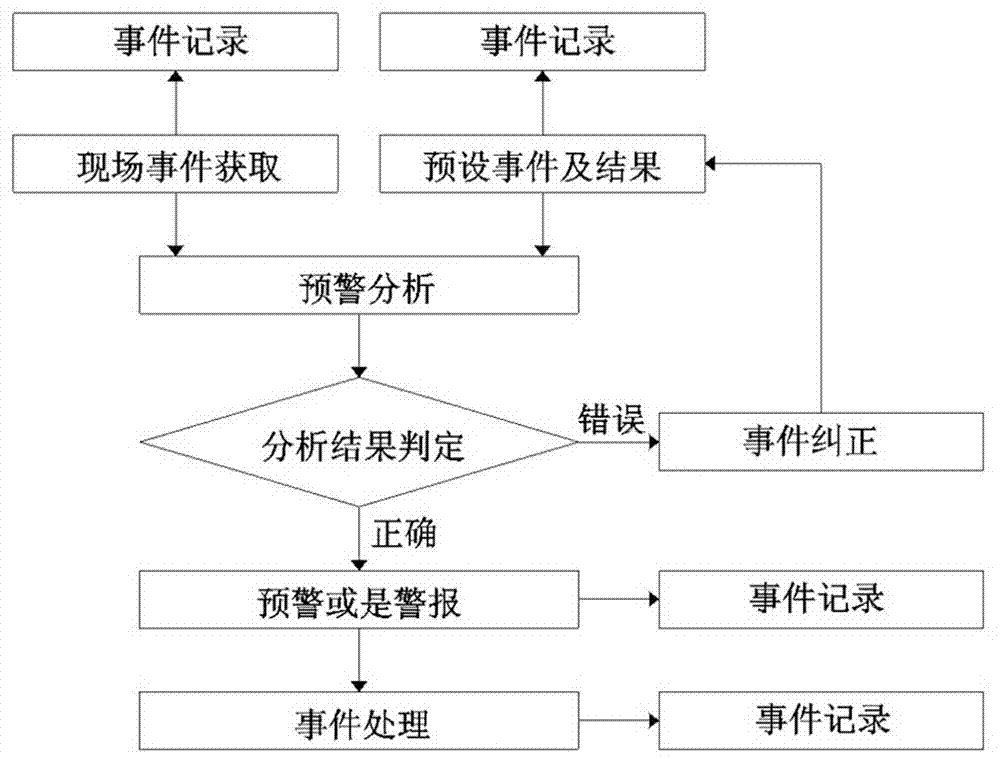

Production accident early warning analysis system and method

InactiveCN104123474AAdd Analysis StatisticsReduce accidentsData processing applicationsSpecial data processing applicationsFalse alarmData acquisition

The invention discloses a production accident early warning analysis system and method. The system comprises a site event unit, a preset event and result unit, an early warning analysis unit, an early warning and alarm unit, an event correction unit and an event tracking unit. The site event unit is used for obtaining site data from a site data acquisition device and conducting simulation to generate site events; the preset event and result unit is used for conducting statistic on preset events and preset event results; the early warning analysis unit is used for comparing the site events with the preset events to obtain analysis results; the early warning and alarm unit is used for sending early warning signals or alarm signals; the event correction unit is used for analyzing reasons for false alarms and correcting the preset events and the preset event results; the event tracking unit is used for forming real-time records of all event information so as to ensure that the event information can be traced back. According to the technical scheme, the production accident early warning analysis system can ensure that a production site is in a controllable and controlling state all the time, and can issue early warning information in real time so that preventive measures can be taken in time, accident potentials can be eliminated, and accidents can be effectively prevented or reduced.

Owner:WUKUN STEEL

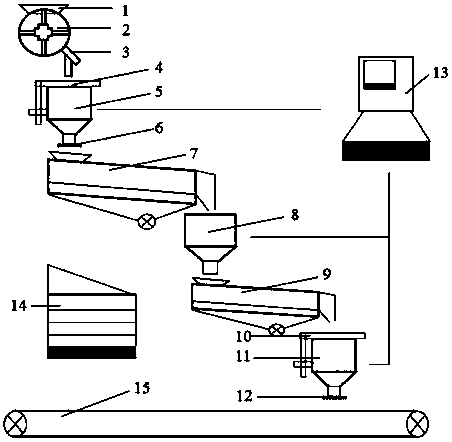

Manufactured sand production quality informatization monitoring system based on grain friction

PendingCN110132783AFully automatedRealize online monitoringWeighing by removing componentPermeability/surface area analysisInformatizationFineness modulus

The invention discloses a manufactured sand production quality informatization monitoring system based on grain friction. The manufactured sand production quality informatization monitoring system isformed by seven portions including a sampling module, a screening module, a morphology analysis module, a grading analysis module, a data processing and information uploading module, a remaining material recovery module and a dedusting module. By adopting the system, the fineness modulus, the stone powder content, the outflow time and the clearance rate of manufactured sand can be monitored in real time, key technical indexes including the outflow time and the clearance rate of specific particle-size manufactured sand can also be monitored, functions of real-time online monitoring and ultra-limit alarm of the quality of the manufactured sand in a production process are realized, and timely effective criteria can be provided for production quality control of the manufactured sand.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

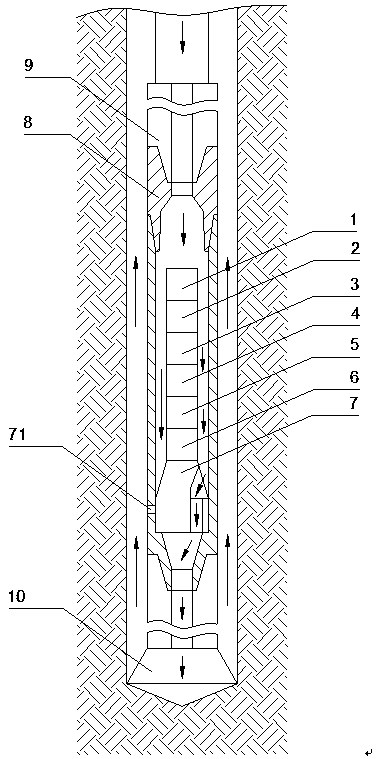

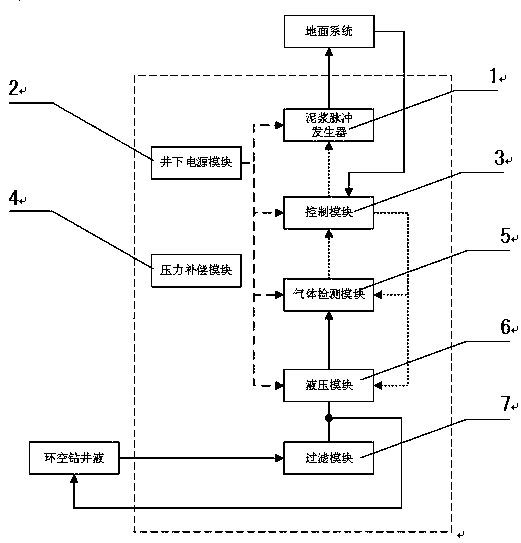

Downhole while-drilling gas-logging testing device

The invention provides a downhole while-drilling gas-logging testing device comprising a hydraulic module, a gas detecting module, a control module and a mud impulse generator. Through moving of a piston in the hydraulic module, annulus drilling fluid flows into the hydraulic module, the gas detecting module measures the content of methane gas in the annulus drilling fluid, and the concentration of the methane gas in a stratum is determined according to the measurement value; gas concentration data are transmitted to the control module, the control module processes the data transmitted by thegas detecting module and transmits the data needing to be uploaded to a ground system to the mud impulse generator, and the mud impulse generator converts data signals needing to be uploaded to the ground system into mud impulse signals and transmits the mud impulse signals to the ground system; and the ground system interprets the mud impulse signals and then obtains the uploaded data. Accordingto the downhole while-drilling gas-logging testing device, downhole gas parameter detection can be achieved in real time and online, and the accuracy of a tested result is improved.

Owner:中石化石油工程技术服务有限公司 +2

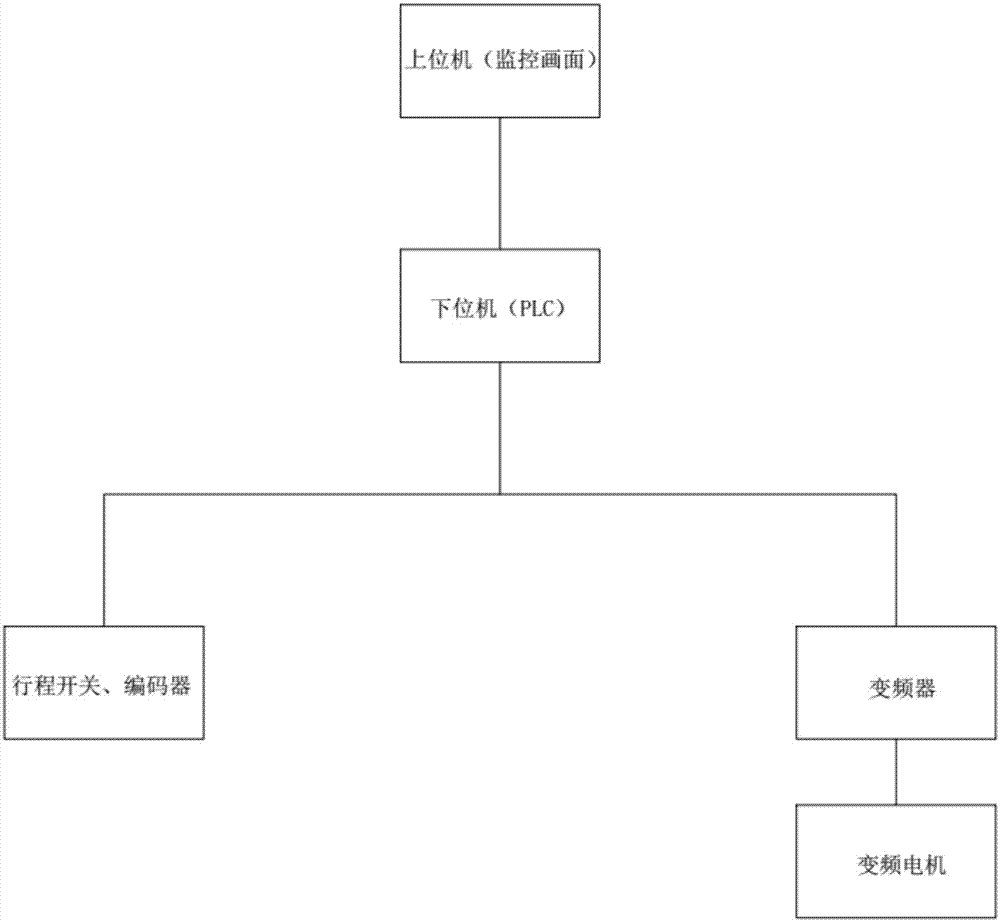

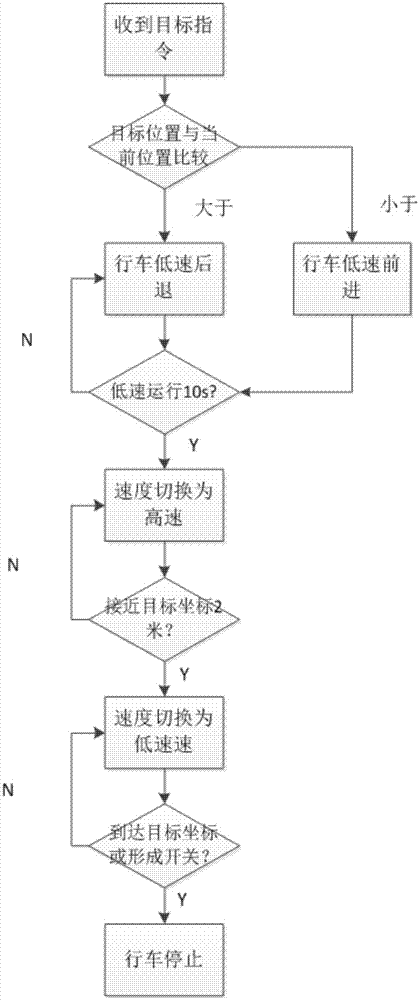

Remote intelligent automatic bridge crane running system based on virtual reality

InactiveCN107247438AAvoid security issuesAvoid health hazardsControl safety arrangementsImage data processingHealth riskAutomatic control

The invention discloses a remote intelligent automatic bridge crane running system based on virtual reality, which belongs to a bridge crane control system. The system includes an upper computer, a lower computer (a programmable logic controller, PLC shown in Figure 1), a travel switch, an encoder, a frequency converter, and a variable-frequency motor. The upper computer accesses the programmable logic controller through a network, and is used for calling 3D monitoring software according to the size of a building on the site and building a 3D model of a bridge crane and the site where the bridge crane is located. 3D modeling in virtual reality is introduced as a bridge crane running monitoring mode, and the running state of a bridge crane is automatically controlled by the programmable logic controller through the bridge crane running monitoring mode. Thus, the precision of bridge crane running control is enhanced, and the running state of a bridge crane can be monitored in an all-round manner. The dangerous airspace is avoided, and safety and health risks to operators caused thereby are avoided. An operation-oriented work mode of operators is changed into a monitoring-oriented work mode, and the labor intensity of operators is reduced.

Owner:NANJING JIANLEI POWER TECH CO LTD

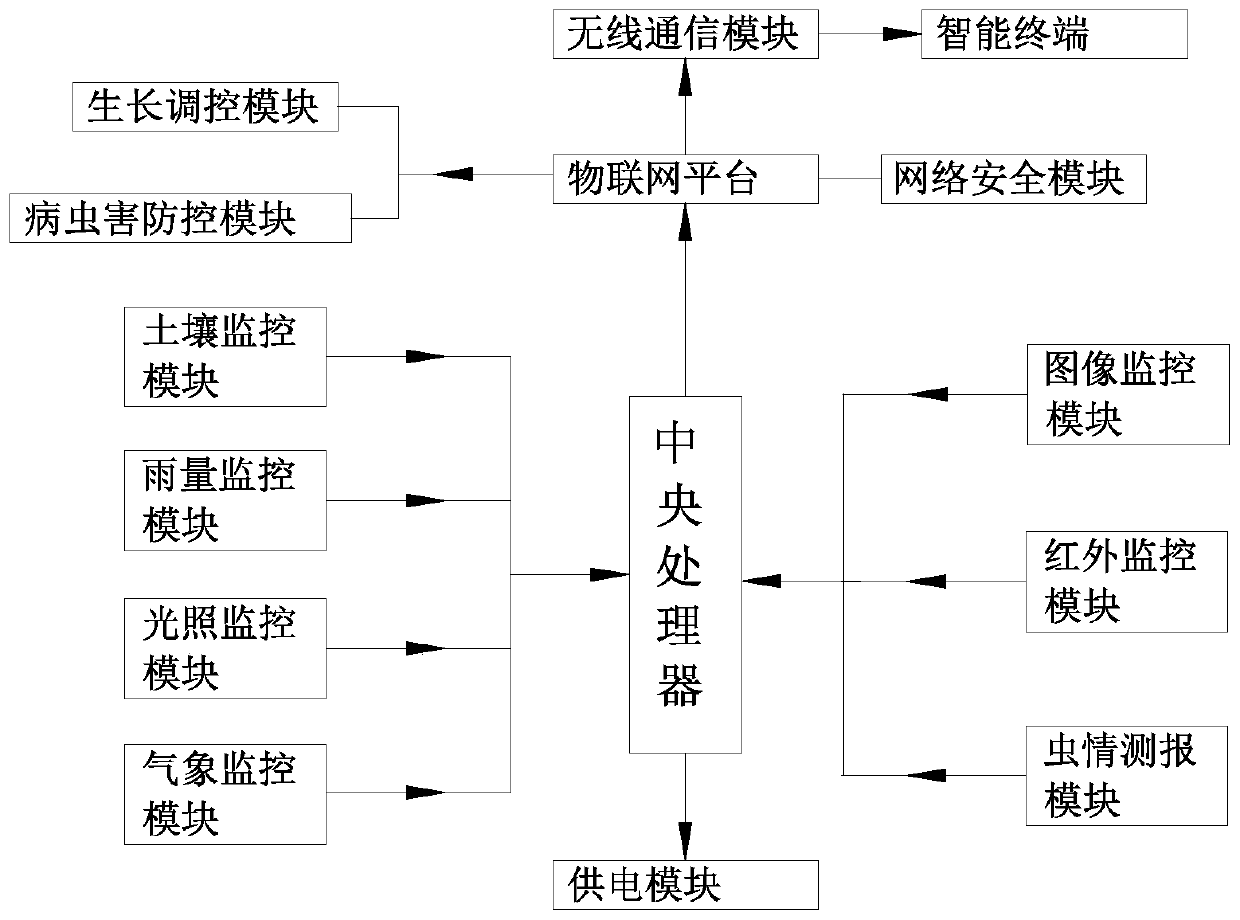

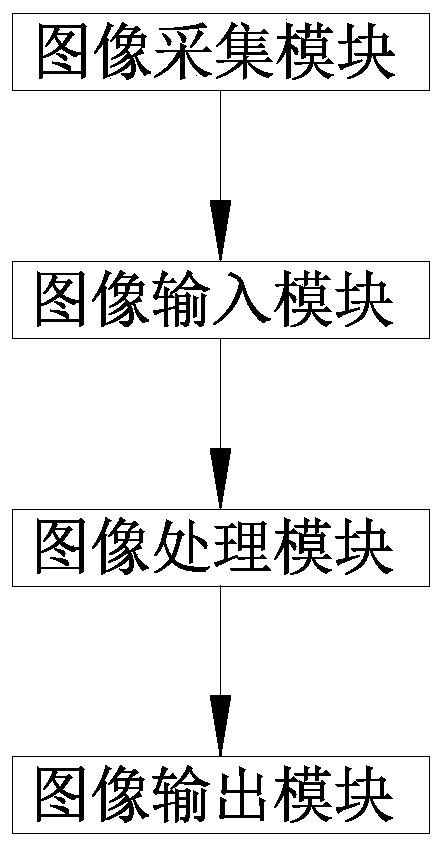

Agricultural pest and disease and growth condition prediction, prevention and control Internet of Things and method

InactiveCN111026200AReal-time regulation of growth conditionsResolve lagSimultaneous control of multiple variablesAgricultural scienceThe Internet

The invention discloses an agricultural pest and disease and growth condition prediction, prevention and control Internet of Things, and relates to the field of agriculture. The agricultural pest anddisease and growth condition prediction, prevention and control Internet of Things comprises a central processing unit, an Internet of Things platform and an intelligent terminal, wherein the Internetof Things platform is connected with the intelligent terminal, a growth regulation and control module, a pest and disease prevention and control module and a network security module. The invention further discloses a prediction, prevention and control method adopting the agricultural pest and disease and growth condition prediction, prevention and control Internet of Things. In order to solve theproblem that traditional agricultural pest and disease and growth condition prediction, prevention and control have certain lag and errors, collected data is obtained through the central processing unit and analyzed to obtain agricultural pest and disease condition and growth condition data, and the data is transmitted to the Internet of Things platform. The growth regulation and control module and the disease and pest prevention and control module are operated through wireless communication between the Internet of Things platform and the intelligent terminal, agricultural growth conditions are regulated and controlled in real time, and plants are accurately watered, fertilized and sprayed with pesticides.

Owner:QINGDAO AGRI UNIV

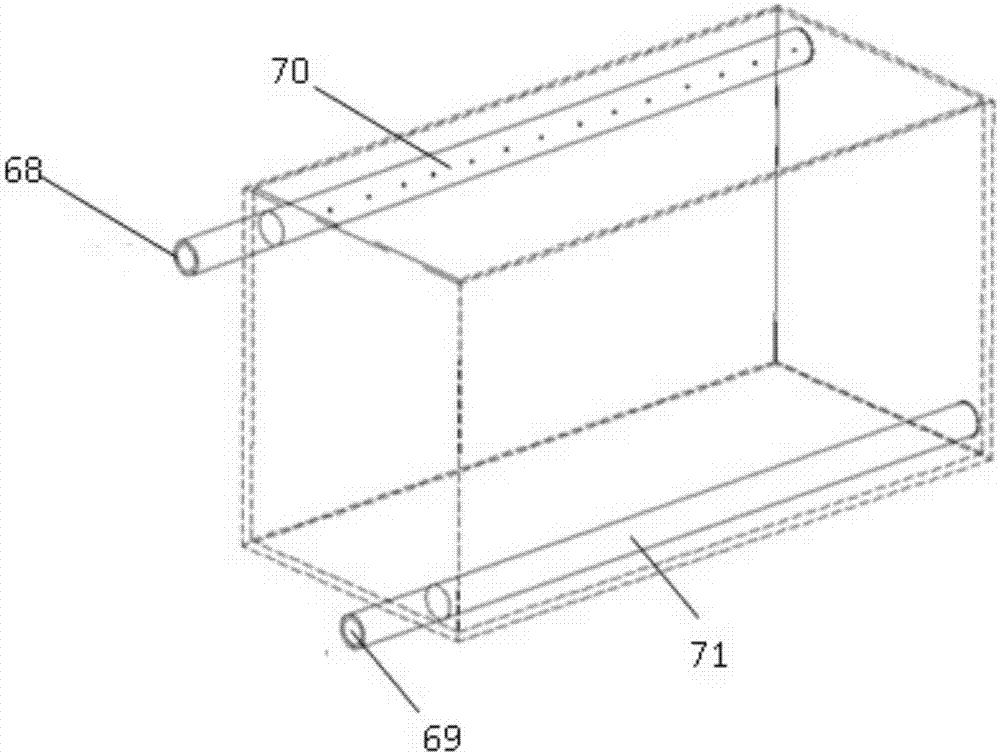

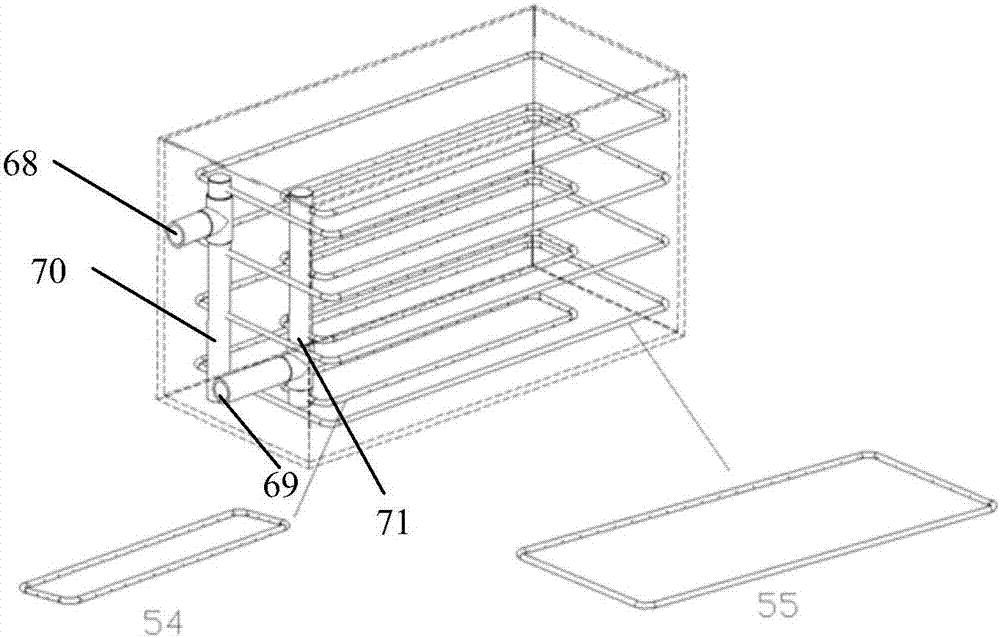

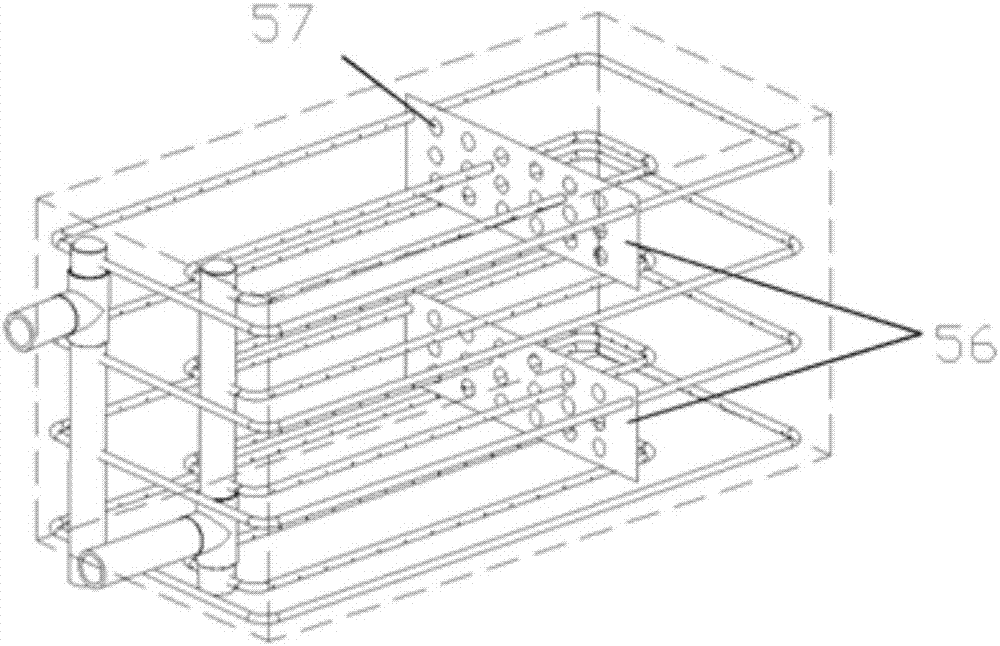

Electrolyte storage tank, redox flow battery, box-type redox flow battery system and charge-discharge control method of redox flow battery

ActiveCN107195942ASpeed up the flowIncrease profitReactant parameters controlRegenerative fuel cellsRedoxEngineering

The invention discloses an electrolyte storage tank, a redox flow battery, a box-type redox flow battery system and a charge-discharge control method of redox flow battery. A ring tube I and a ring tube II are arranged in the electrolyte storage tank, wherein the ring tube II communicates with an electrolyte return hole, the ring tube I communicates with an electrolyte output, the annular perimeter of the ring tube I is not equal to the annular perimeter of the ring tube II, and a plurality of liquid holes are formed in tube walls of both of the annular tube I and the annular tube II. By a multi-layer ring tube structure in the storage tank, an electrolyte flowing dead zone of an electrolyte in the storage tank is greatly reduced, the flowing of the electrolyte is more uniform, and the utilization of the electrolyte is effectively improved; and moreover, since the longitudinal distance between the electrolyte output and the electrolyte return hole is reduced, the problem of SOC lag is effectively solved, and the SOC monitoring accuracy of the redox flow battery is improved.

Owner:DALIAN RONGKE POWER

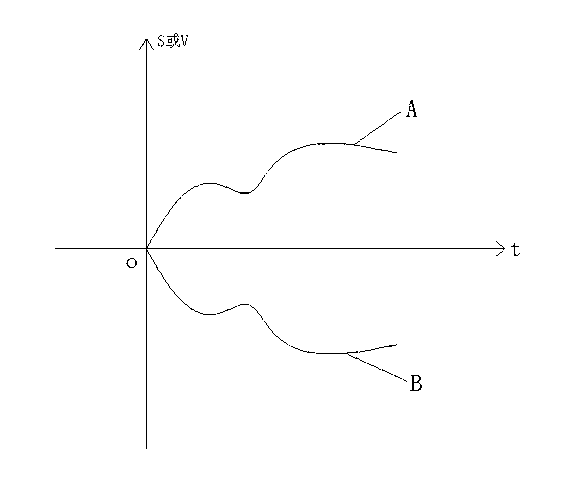

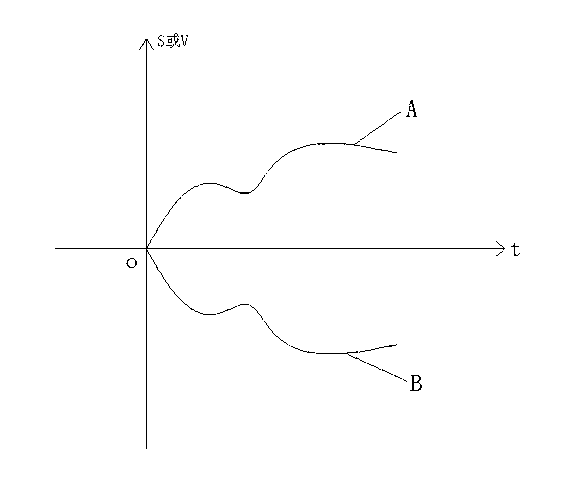

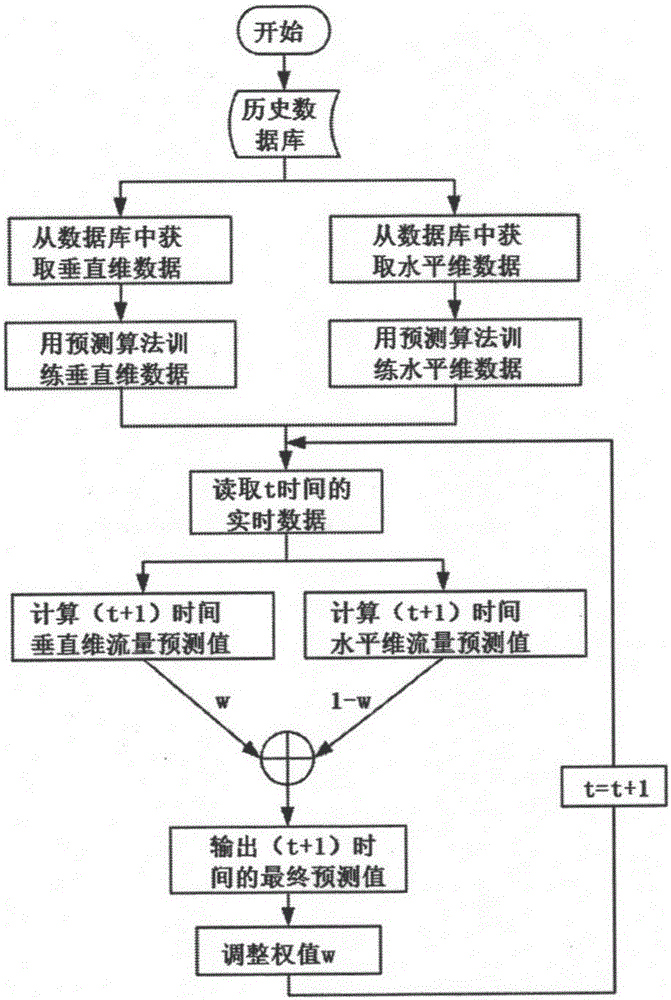

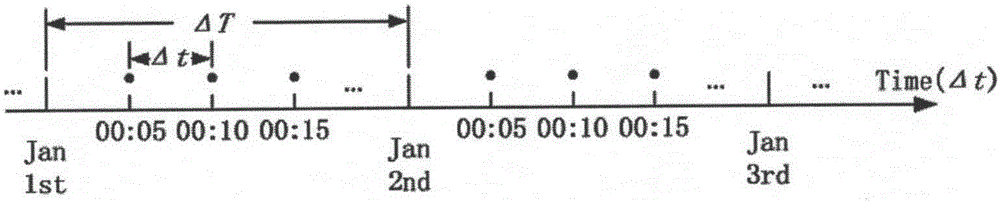

Stock trend prediction method based on 2-dimension flow prediction

The invention relates to a stock trend prediction method based on 2-dimension flow prediction. The stock trend prediction method is characterized in that historical data is extracted, prediction is carried out in the horizontal and vertical time points, and the predicted results are combined to obtain the final prediction data. The stock trend prediction method is advantageous in that the one-step lagging problem in 1-dimension prediction can be effectively solved.

Owner:SHANGHAI DIANJI UNIV

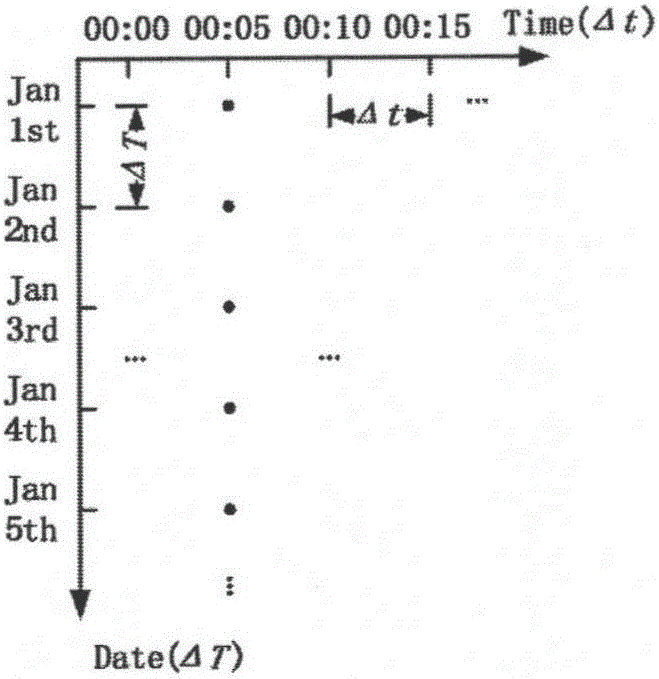

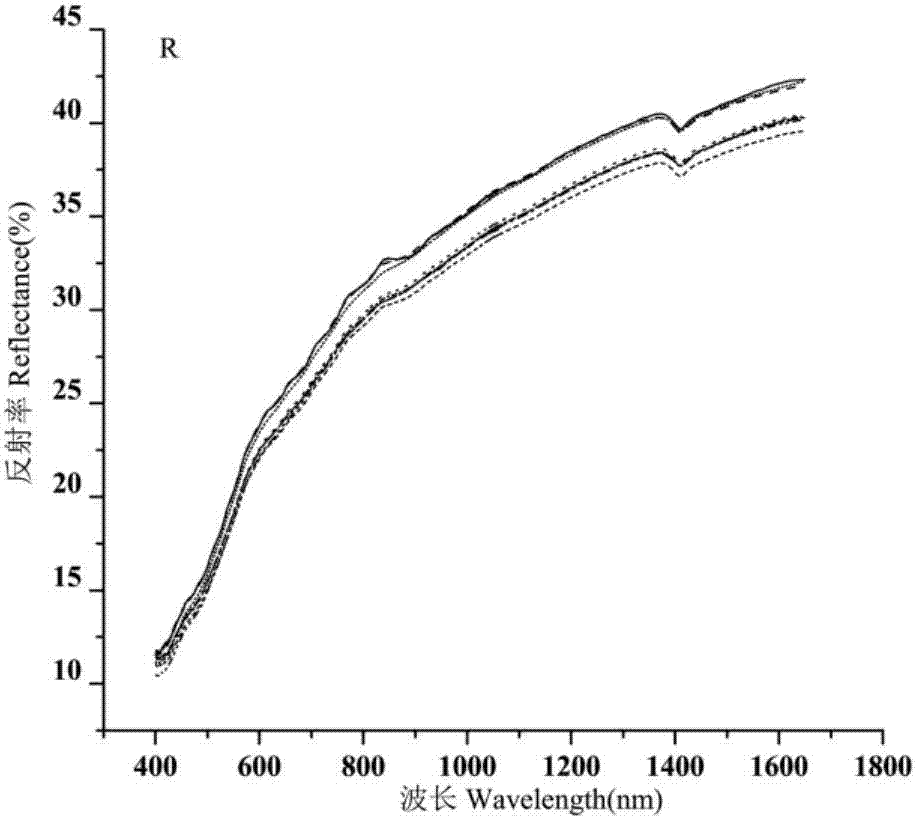

Method for determining content of nitrate ions in secondary saline soil with near infrared spectrum

InactiveCN107505283AReduce waiting timeSave time and costMaterial analysis by optical meansInfraredRelational model

The invention discloses a method for determining a content of nitrate ions (NO3<->) in secondary saline soil with a near infrared spectrum. The method comprises the following steps: determining the content of NO3<-> of a secondary saline soil sample by using a chemical analysis method; carrying out pretreatment by adopting a soil sample spectrum, establishing a relation model of different variable full-waveband spectrums and content of NO3<-> on the basis of partial least squares (PLSR), and selecting an optimum spectral transformation form; selecting a characteristic waveband of the NO3<-> by adopting an interval partial least squares (iPLS) under the selected spectral transformation, and acquiring a model with the optimum precision, i.e. the relation spectral model of the NO3<-> in the secondary saline soil by virtue of cross verification by utilizing PLSR regression on the basis of the selected characteristic waveband. According to the method, the near infrared spectrum data of the secondary saline soil sample with unknown concentration is determined, the data is preprocessed and substituted in the relation spectral model, and the content of the NO3<-> in the unknown soil sample can be directly obtained.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com