Self-adaption profile modification blade abrasive belt polishing machine tool

A self-adaptive, abrasive belt technology, applied to abrasive belt grinders, grinding machine parts, grinding machines, etc., can solve problems such as errors and achieve the effect of increasing the removal amount of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structural principle and working principle of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the actual structure of the present invention is not limited to the following embodiments.

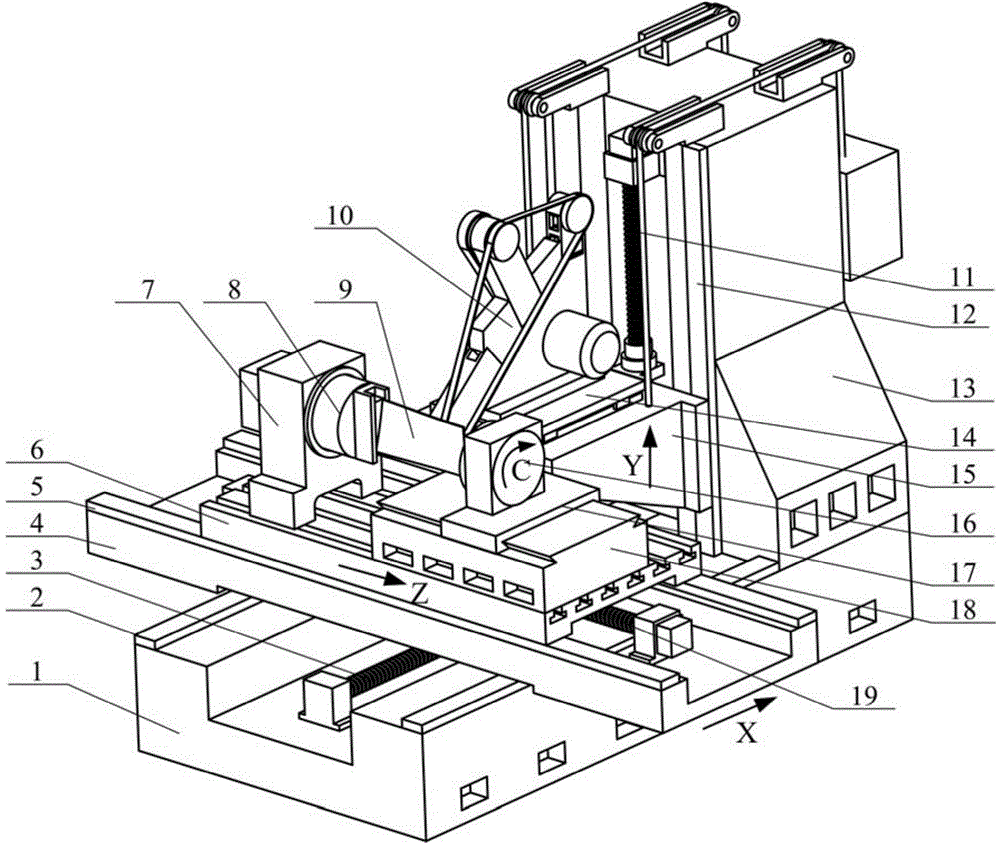

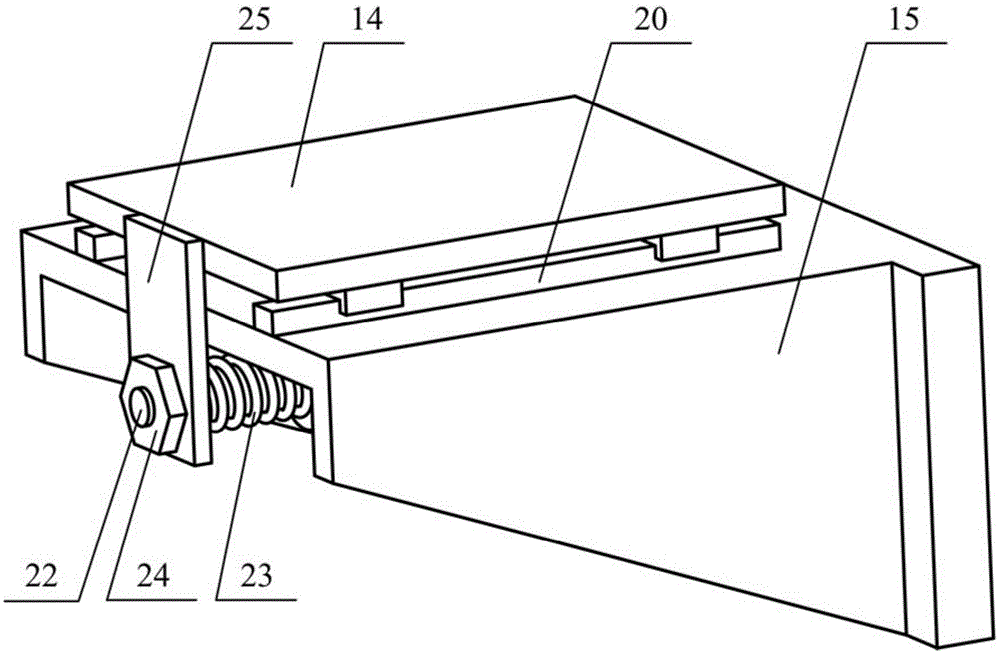

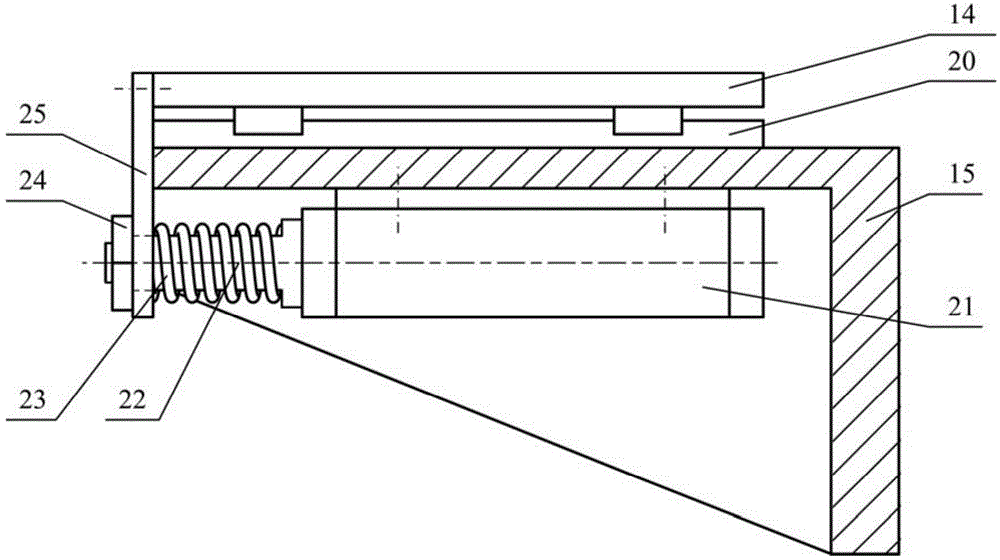

[0027] see Figure 1~3 , a self-adaptive blade abrasive belt polishing machine tool of the present invention, comprising a bed 1, a column 13, an X-axis carriage 4, a Z-axis carriage 6, a C-axis turntable 7, a top seat 16, and a Y-axis slider 15 , Pressure shaft slide plate 14, pressure shaft guide rail 20 and abrasive belt grinding head part 10.

[0028]Among them, the X-axis carriage 4 is guided by the X-axis guide rail 2 installed on the bed 1, and driven by the X-axis screw transmission part 3 installed in the bed 1, and can move horizontally along the front and rear directions. The upper end of the plate 4 is installed with the Z-axis guide rail 5 along the direction perpendicular to the X-axis, and the Z-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com