Tracking method of hot rolling basic automation control data security timeliness

A basic automation and data control technology, which is applied to the program control and electrical program control of the sequence/logic controller, can solve the problems of data tracking confusion, data blockage, data misalignment, etc., to solve data lag and improve product quality , Increase the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

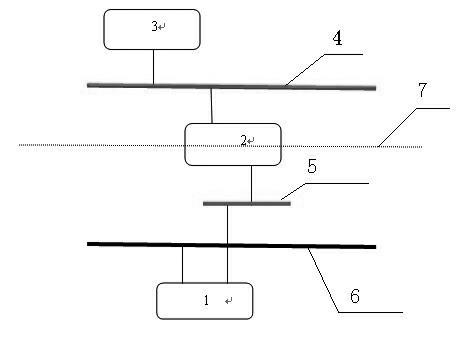

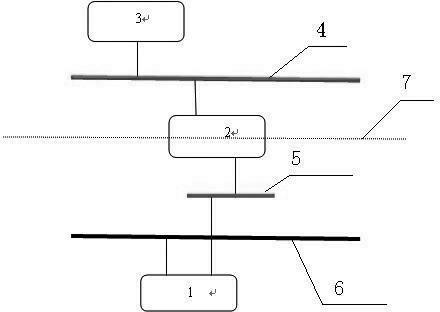

[0010] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0011] The dotted line in the figure is divided into two network segments up and down.

[0012] A tracking method for hot-rolling basic automation control data safety and timeliness, using a three-layer structure, the first layer is Profibus DP network and programmable controller PLC, the second layer is memory image network and data acquisition machine, the third layer , is the Ethernet and the remote database; the programmable controller PLC on the first floor is connected to the Profibus DP network, and the programmable controller PLC is connected to the memory image network through the DP card; the data acquisition machine on the second floor is equipped with dual network cards, of which One network card is connected to the memory image network, and the network card and the memory image network are set to the same network segment, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com