Method for online early warning of strip steel thickness deviation

A strip steel and deviation technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of large errors and lags in manual measurement, achieve timely feedback, solve large errors and lags in manual measurement, and achieve significant implementation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

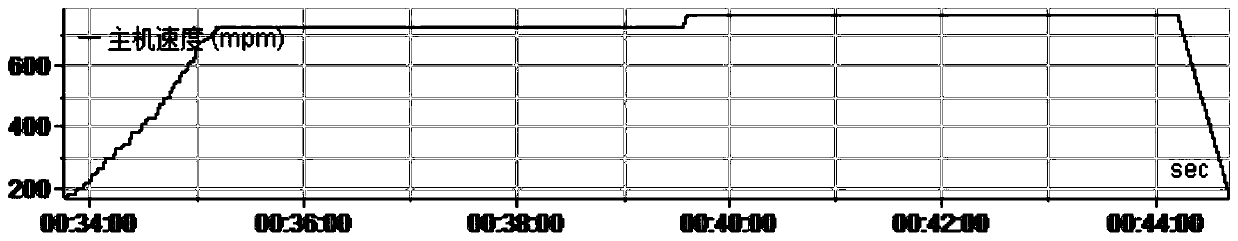

[0043] figure 1 When the host speed v>100mpm, start to calculate and warn;

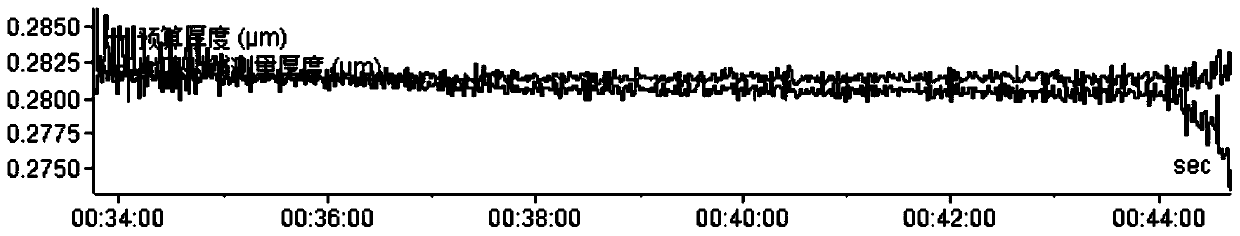

[0044] figure 2 The two curves are respectively the predicted value h of the strip thickness at the exit side 预 Measure the strip thickness h at the exit side 出 ; h 预 and h 出 The two curves are very close, and the steady speed stage fluctuates in the range of 0-3μm;

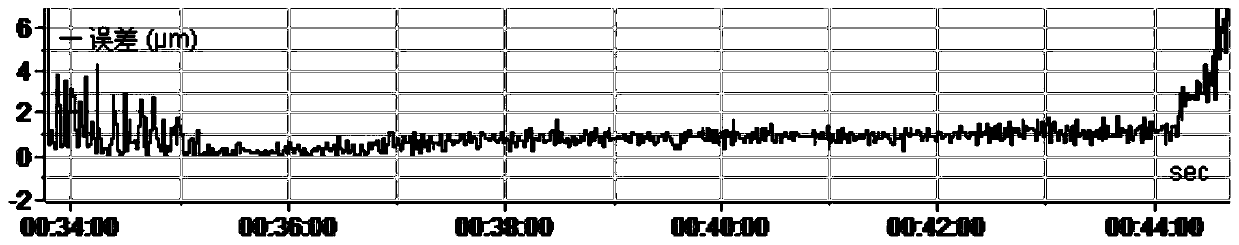

[0045] image 3 is the predicted value h of strip thickness at the exit side 预 Measure the strip thickness h from the exit side 出 The deviation curve of , that is, Δδ=h 预 -h 出 ;The Δδ curve is very straight, fluctuates in the range of 0-3μm in the steady speed stage, and fluctuates in the range of 0-8μm in the acceleration and deceleration stages, and the thickness is within the tolerance range; it can be judged that the thickness of the steel strip is normal;

[0046] Figure 4 It is the alarm curve, because the strip steel thickness control is normal, the alarm value display is always 0, and the curve is the 0 horizontal li...

Embodiment 2

[0048] Figure 5 When the host speed v>100mpm, start to calculate and warn;

[0049] Figure 6 The lower curve is the predicted value h of strip thickness at the exit side 预 , the upper curve is the measured strip thickness h at the exit side 出 ; h 预 and h 出 The two curves are far apart, with an interval of more than 23 μm;

[0050] Figure 7 is the predicted value h of strip thickness at the exit side 预 Measure the strip thickness h from the exit side 出 The deviation curve of , that is, Δδ=h 预 -h 出 ;The Δδ curve fluctuates greatly, fluctuates in the range of 19-22 μm in the steady speed stage, and fluctuates in the range of 18-26 μm in the acceleration and deceleration stages, which is far beyond the 5 μm thickness tolerance range as a whole; it can be determined that the thickness of the strip drifts;

[0051] Figure 8 It is an alarm curve. Because the strip thickness drifts and the control is abnormal, the alarm value is displayed as 1, and the curve is a column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com