Method for detecting coal quality composition on conveying belt and device thereof

A conveyor belt and coal quality technology, applied in the field of coal quality detection, can solve the problems of coal quality analysis data lag and inability to feed back coal quality information in time, and achieve the effect of reducing errors and solving data lag

Inactive Publication Date: 2011-06-15

CHANGSHA KAIYUAN INSTR

View PDF4 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In view of this, the present invention provides a method and device for detecting the coal quality composition on the conveyor belt, which solves the problem that the coal quality analysis data is lagging behind and the coal quality information cannot be fed back in time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

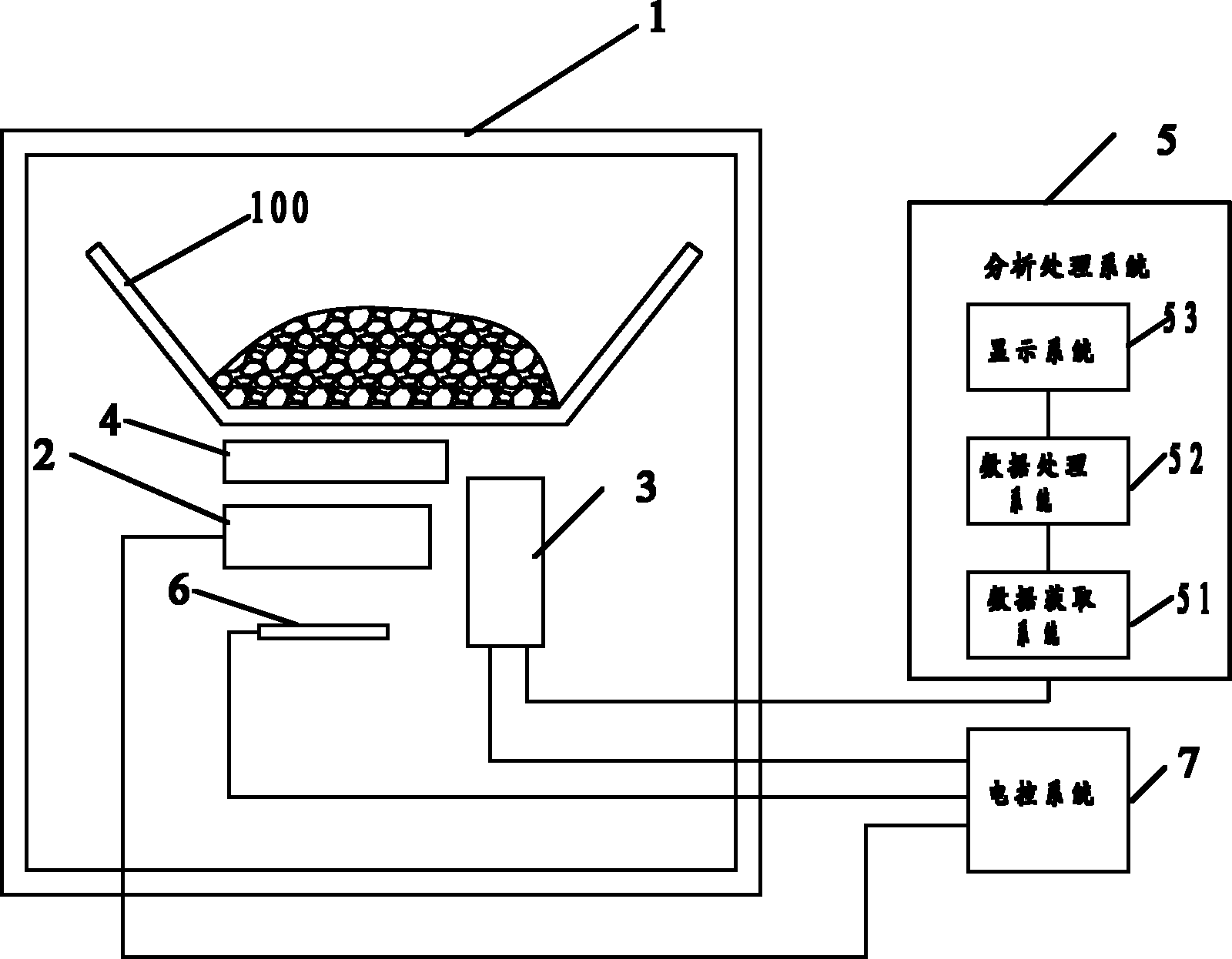

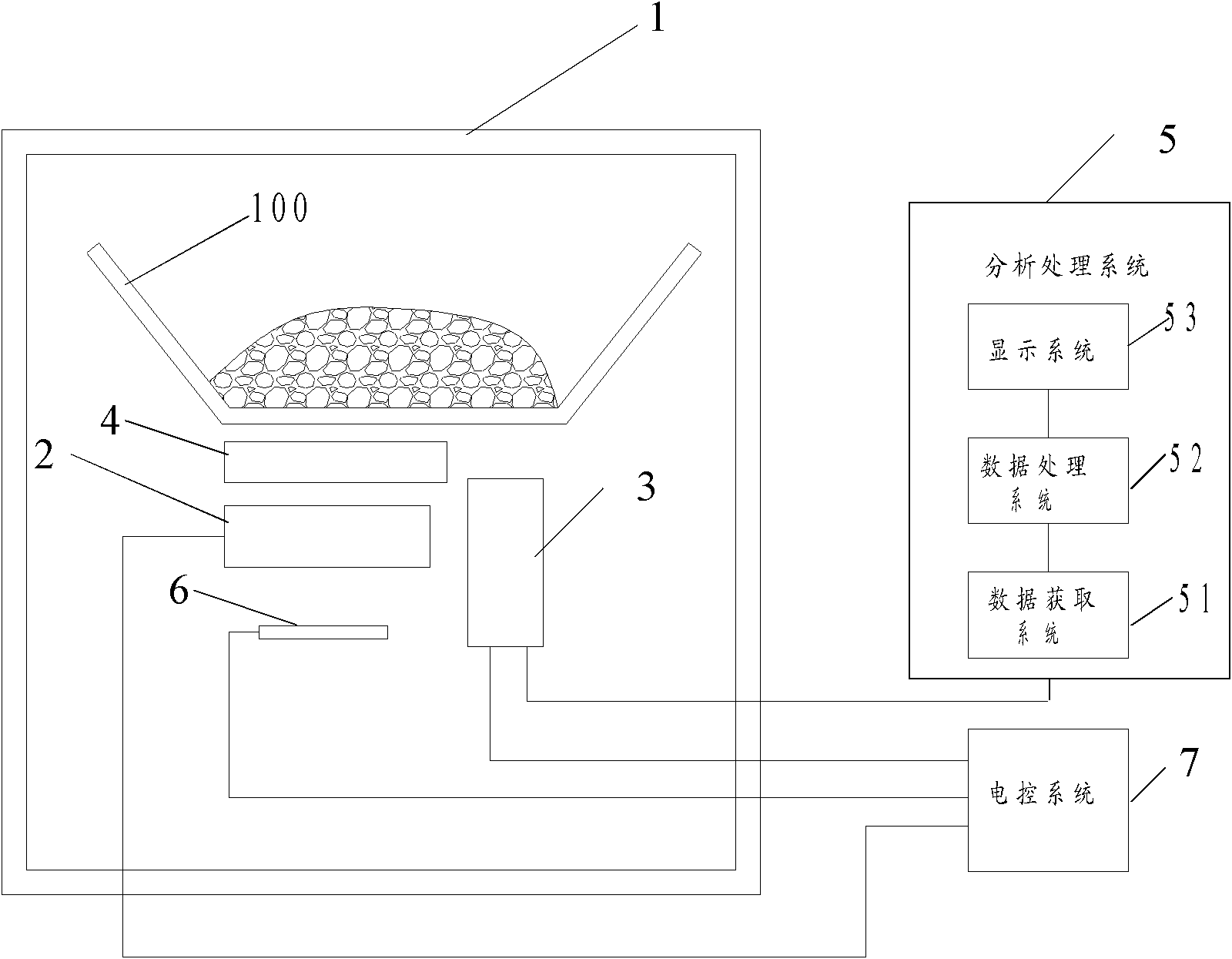

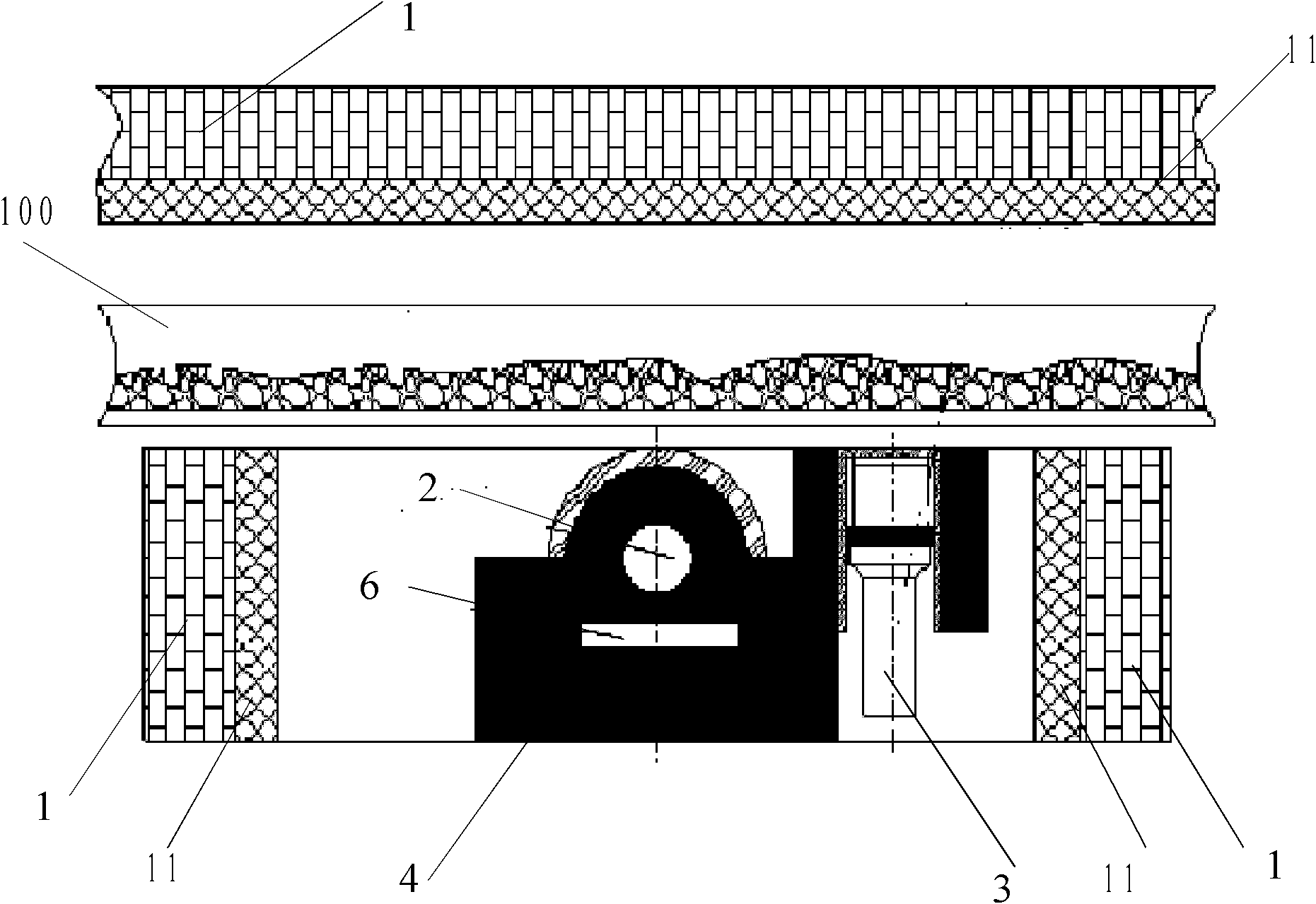

The invention provides a method for detecting coal quality composition on a conveying belt and a device thereof; the device comprises a shielding case arranged on the conveying belt, a neutron generator and a gamma-ray detector, and an analysis processing system, wherein a closed space is formed in the shielding case, and the inner side of the shielding case is provided with a neutron reflector; the neutron generator and the gamma-ray detector are arranged inside the shielding case and positioned below the conveying belt, and neutron slowed bodies are filled among the conveying belt, the neutron generator and the gamma-ray detector; the analysis processing system is arranged outside the shielding case and is connected with the gamma-ray detector, and is used for obtaining the signals output by the gamma-ray detector to carry out energy spectrum analysis and calculate the content of coal quality composition and industrial analysis data. Through the embodiment of the invention, neutron activation prompt fission gamma-ray technology is adopted without sampling and sample making processes, and the content of coal quality composition can be obtained in time; therefore, the problem that the coal quality analysis data is hysteretic is solved.

Description

A method and device for detecting coal components on a conveyor belt technical field The invention relates to the technical field of coal quality detection, in particular to a method and device for detecting coal quality components on a conveyor belt. Background technique At present, coal-fired thermal power plants are mostly operated extensively, and the coal quality is not precisely configured. It is common for the coal quality to be inconsistent with the boiler design, which not only reduces the combustion efficiency of the boiler, but also seriously affects the safety of the boiler operation. Insufficient boiler output, reduced thermal efficiency, reduced pulverizing capacity, coking and ash accumulation on the heating surface of the boiler caused by changes in coal types, and boiler accidents caused by changes in coal quality are also common. The change of coal types has become an issue that affects the safety of coal-fired units in thermal power plants. It is one of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N23/09

Inventor 罗建文张乐

Owner CHANGSHA KAIYUAN INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com