Remote intelligent automatic bridge crane running system based on virtual reality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with the accompanying drawings.

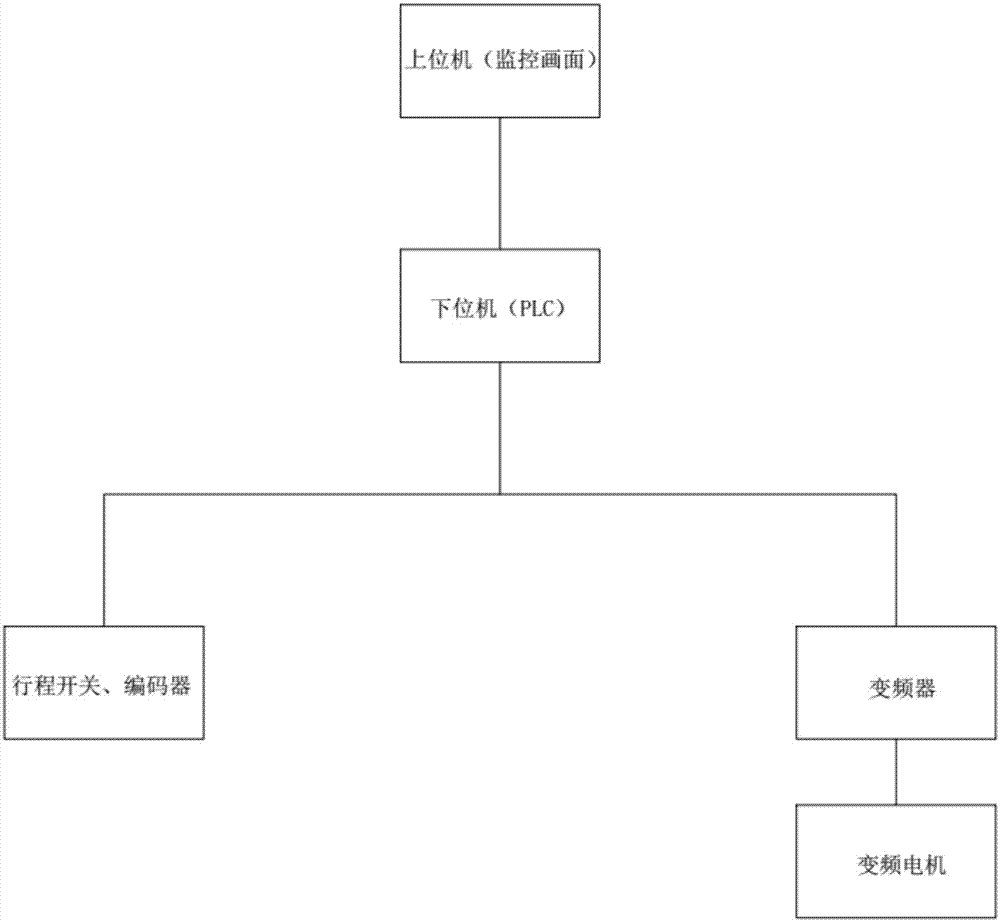

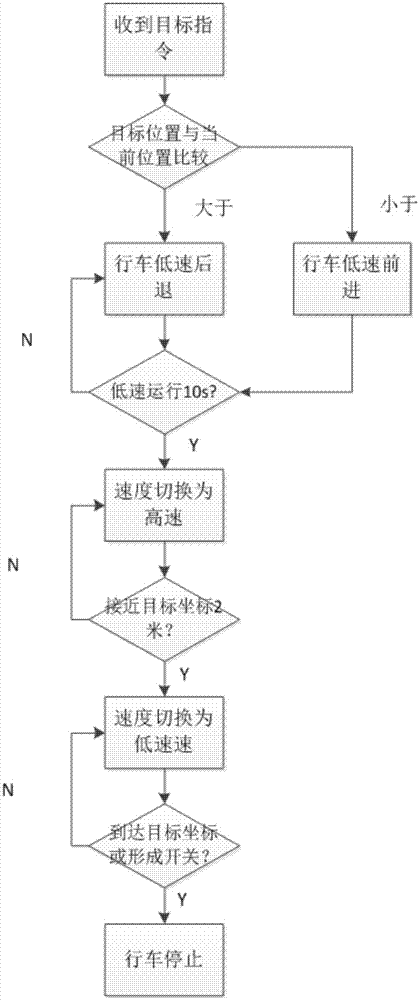

[0022] refer to figure 1 As shown, one embodiment of the present invention is a remote intelligent automatic operation system based on virtual reality. As shown in the figure, the system includes a host computer and a lower computer (that is, a programmable logic controller, figure 1 PLC shown in ), travel switch, encoder, frequency converter and variable frequency motor, based on the various components in the aforementioned system, the specific connection methods and uses are as follows:

[0023] The first is the upper computer, which is connected to the programmable logic controller through the network, and is used for the upper computer to call the 3D monitoring software according to the size of the site building, and build a 3D model of the driving and the site where the driving is located; the aforementioned 3D model can be directly obtained through the market. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com