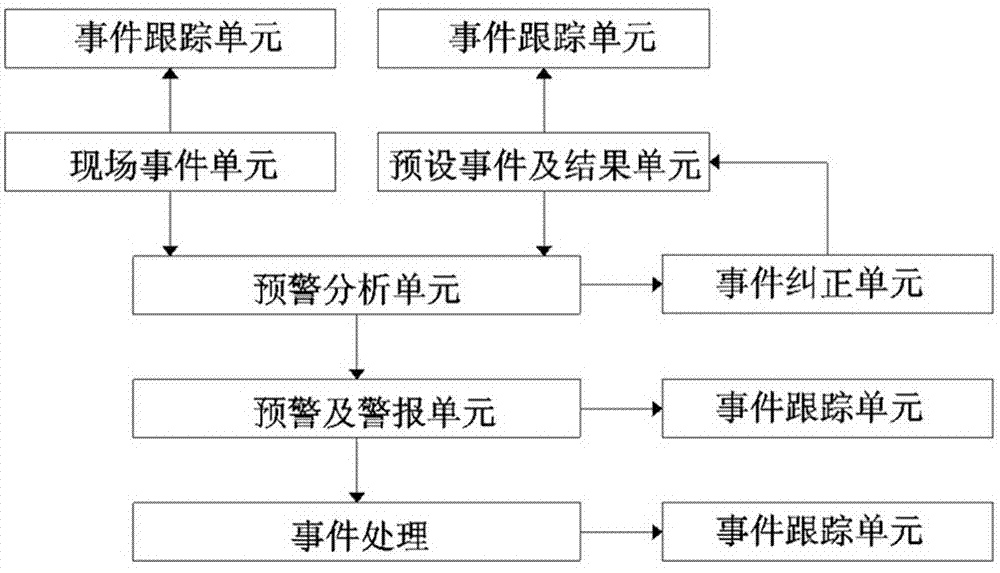

Production accident early warning analysis system and method

A technology for early warning analysis and accidents, applied in manufacturing computing systems, special data processing applications, instruments, etc., can solve the problems of accident site damage, lack of early warning mechanisms, and lack of guidance information to prevent accidents, ensure traceability, Increase the effect of analysis statistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

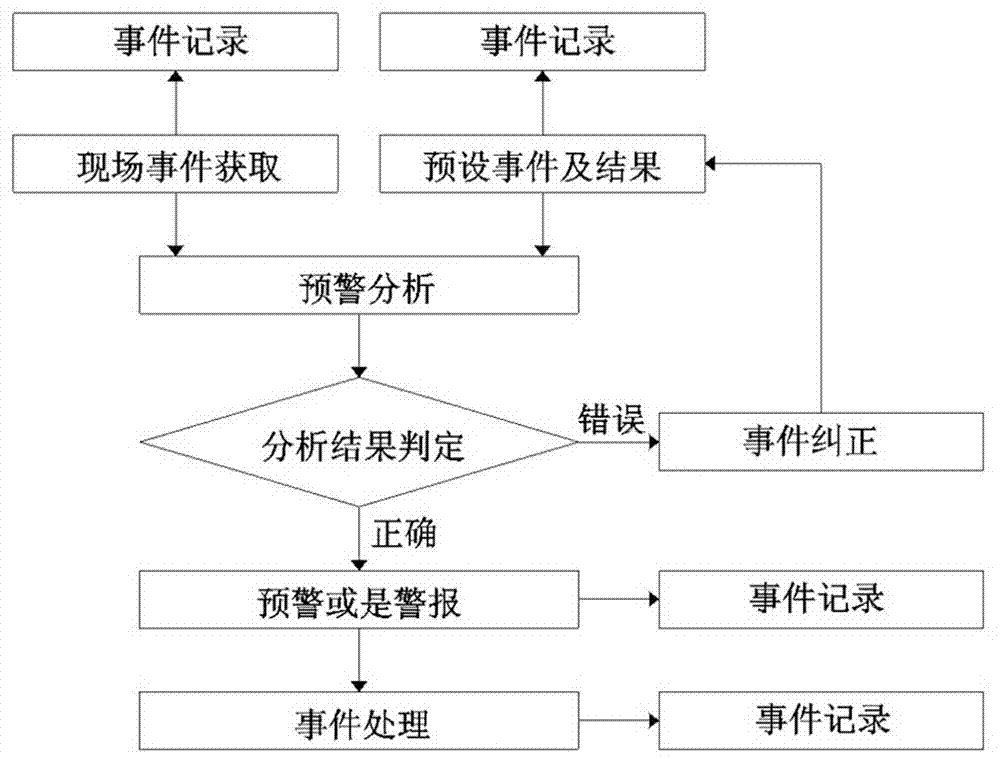

Embodiment 1

[0043] On-site events obtained by the on-site event unit from the on-site data acquisition equipment: the operator increased the amount of coal injection, which caused the temperature to rise too fast;

[0044] Similar preset events and their resulting preset event results are counted in the preset event and result unit, and the preset event result is: the quality of molten iron is affected;

[0045] The early warning analysis unit compares the on-site event with the preset event, finds out the similar preset event, and obtains the result of the preset event, that is, the result that the on-site event may cause: the quality of molten iron is affected; the quality of molten iron is affected The degree of harm that may be caused, the scope of influence, the size of the influence, the loss of personnel and property, etc. are divided into multiple levels;

[0046] The early warning and alarm unit sends out early warning signals or alarm signals in different levels according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com