Downhole while-drilling gas-logging testing device

A gas logging, logging and testing device technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of information lag, loss, and inability to reflect the relevant information of the downhole drill bit in real time, so as to solve the information lag and improve the accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

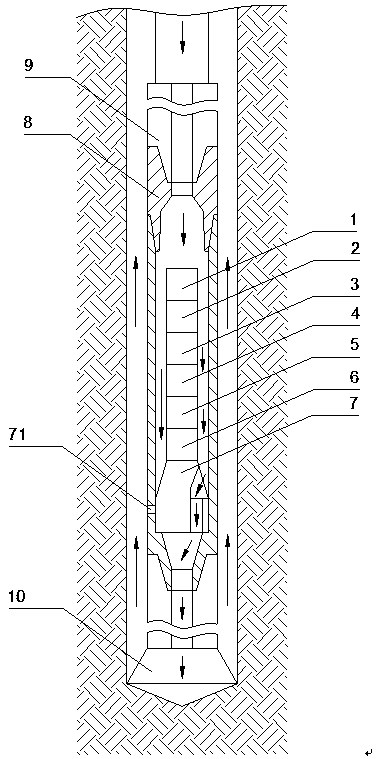

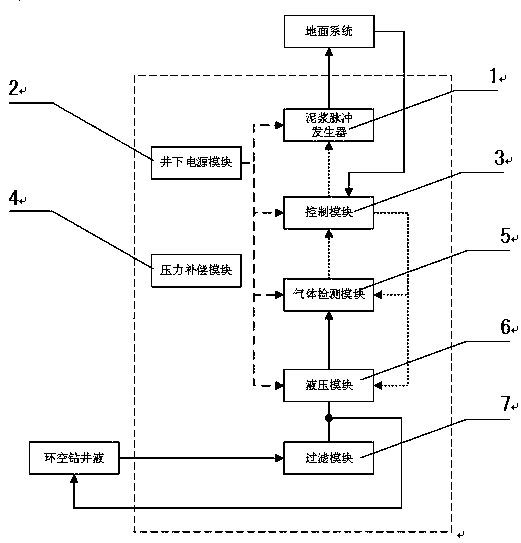

[0016] Such as figure 1 and figure 2 as shown, figure 1 It is the structural diagram of the downhole gas logging while drilling and mud logging testing device of the present invention, figure 2 It is the schematic diagram of the downhole gas logging while drilling testing device. The downhole gas logging while drilling test device includes a mud pulse generator 1 , a downhole power supply module 2 , a control module 3 , a pressure compensation module 4 , a gas detection module 5 , a hydraulic module 6 and a filter module 7 .

[0017] The filter module 7 is used to remove cuttings in the annular drilling fluid, so as to prevent large particles from entering the hydraulic system and causing serious damage to hydraulic cylinders and hydraulic valves....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com