Efficient pipeline anti-corrosion treatment device

An anti-corrosion treatment and high-efficiency technology, which is applied to the surface coating liquid device, spray device, pre-treatment surface, etc., can solve the problems of easily damaged pipelines, low processing efficiency, and high labor operation intensity, etc., to improve work efficiency , prevent damage to the tube body, and facilitate the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

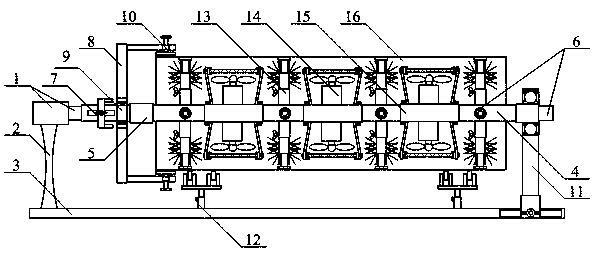

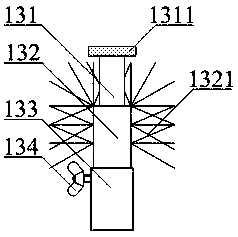

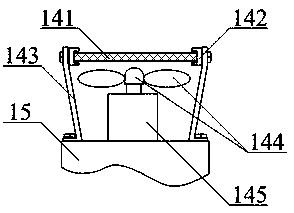

[0040] as attached figure 1 to attach Figure 8 shown

[0041] The invention provides a high-efficiency pipeline anti-corrosion treatment device, which includes a rotating motor 1, a support frame 2, a base 3, a hollow shaft 4, a sleeve coupling 5, an anti-corrosion liquid nozzle structure 6, a sliding block structure 7, and a rotating Disc 8, conventional bearing 9, fast rotary rod structure 10, sliding end plate structure 11, height adjustment auxiliary wheel structure 12, inner wall cleaning structure 13, fast drying machine structure 14, fastening sleeve 15 and pipe body 16, all The rotating motor 1 described above is installed on the upper left part of the base 3 through the support frame 2; one end of the hollow shaft 4 is connected to the sliding block structure 7 through the sleeve coupling 5, and the other end is connected to the sliding end plate structure 11; The sliding end plate structure 11 is arranged on the upper right part of the base 3; the rotating disk 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com