An intelligent civil engineering waste block sorting device

A sorting device and civil engineering technology, applied in sorting and other directions, can solve the problems of incapable of transferring different waste blocks, low degree of intelligent control, and high labor intensity, so as to facilitate rapid transfer and sorting and separation processing. Work, easy to operate, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

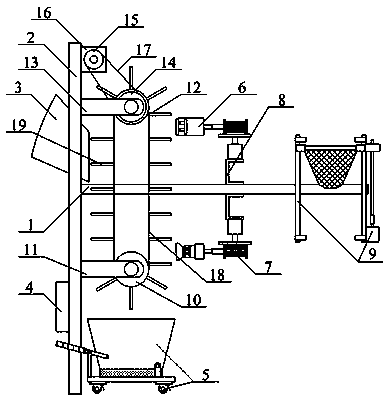

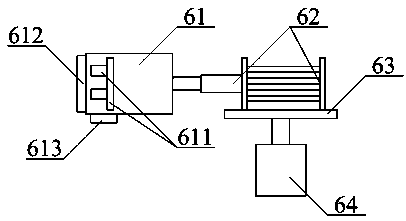

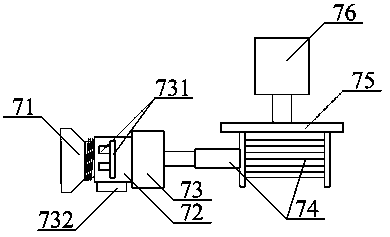

[0058] as attached figure 1 to attach Figure 7 shown

[0059] The present invention provides an intelligent civil engineering waste block classification device, which includes a horizontal bracket 1, a vertical support frame 2, a waste block feeding hopper 3, an intelligent cabinet 4, a waste sorting and moving vehicle 5, and an iron block sorter 6. Block sorting machine 7, U-shaped connecting frame 8, sorting speed shifter 9, driven roller 10, primary wheel frame 11, driving roller 12, secondary wheel frame 13, driven pulley 14, driving Pulley 15, drive motor 16, V-belt 17, conveyor belt 18 and shifting tooth 19, described horizontal bracket 1 horizontal left end bolt is installed in the position of upper five centimeters in the middle of the right side of vertical support frame 2; The block feed hopper 3 runs through the upper left bolt connection of the vertical support frame 2; the intelligent cabinet 4 bolts are installed on the lower left part of the vertical support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com