Sealing rubber strip edge cutting machine

A technology of sealing strips and trimming machines, which is applied in metal processing and other directions to achieve high precision, reduce labor requirements, and reduce labor intensity and labor pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

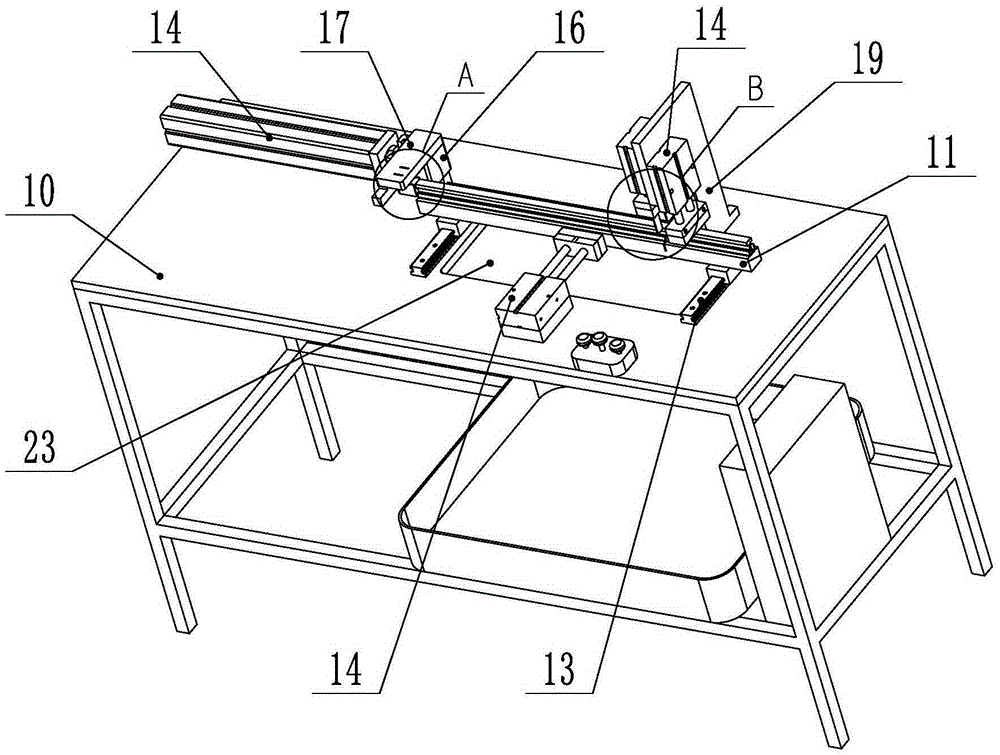

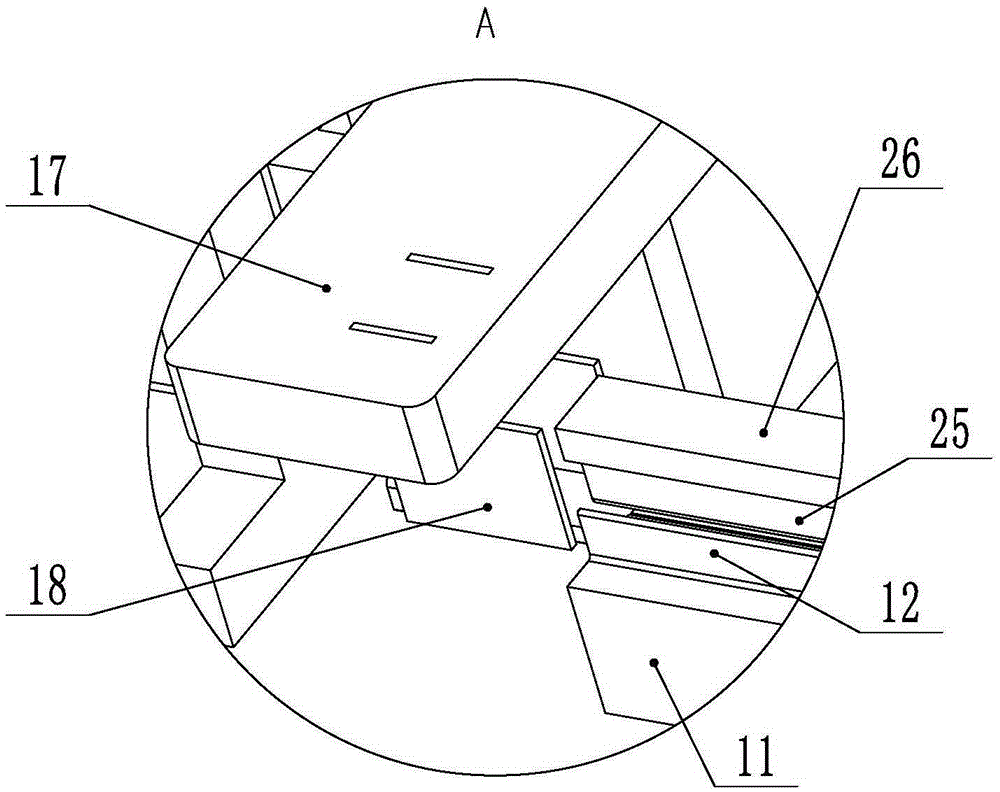

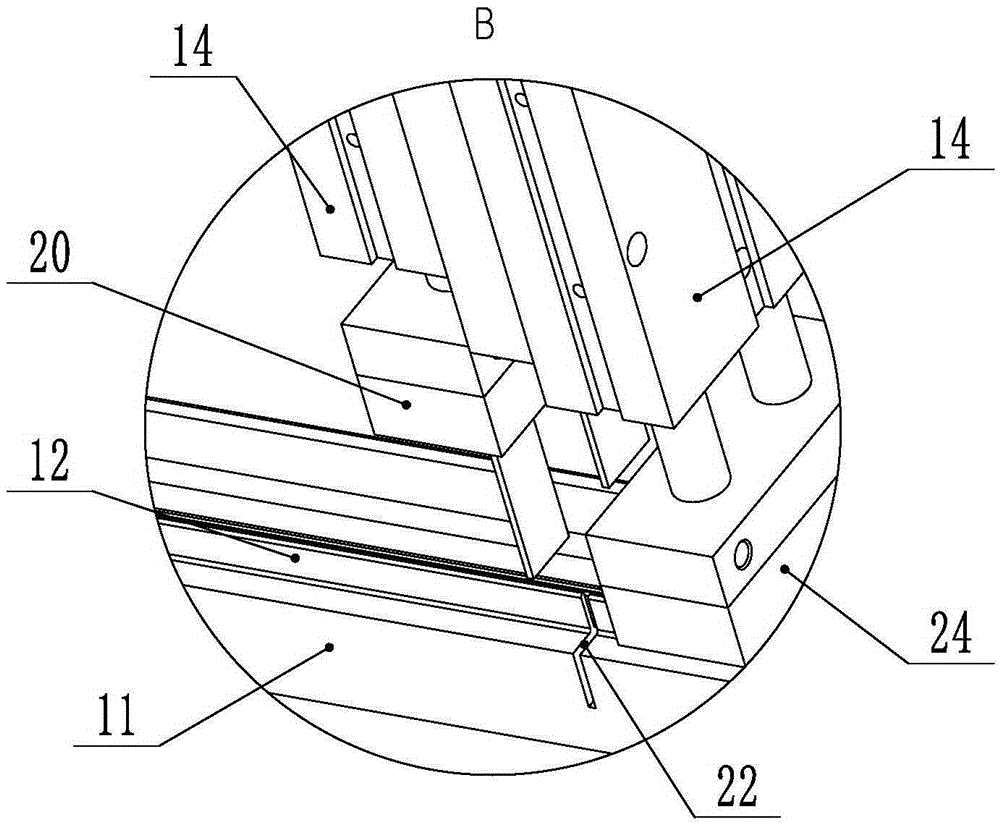

[0023] refer to Figure 1~6 , is a kind of edge cutting machine for sealing rubber strips disclosed by the present invention, comprising a frame 10, on which a fixing seat 11 for fixing the sealing rubber strip is arranged, and on the fixing seat 11, two guides parallel to each other are arranged in the axial direction The plate 12 and the frame 10 are provided with two sliding rails 13 at intervals, and the fixing seat 11 is slid on the two sliding rails 13 and driven by the power device 14 .

[0024] On the frame 10, one side of the fixed seat 11 is provided with a slide rail 15, the direction of motion on the slide rail 15 is perpendicular to the direction of motion on the slide rail 13, and the slide rail 15 is provided with a slide seat 16 driven by a power unit 14 , the sliding seat 16 is provided with a mounting frame 17, and two slitting knives 18 arranged at intervals and parallel to each other are installed on the mounting frame 17. The power unit 14 drives the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com