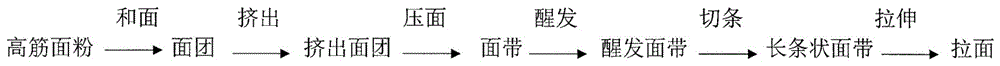

Method for making stretched noodles industrially

A technology of ramen and dough, which is applied in the field of ramen preparation, can solve the problems of time-consuming and labor-intensive, achieve smooth and soft taste, and shorten the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 100g of high-gluten flour and pour it into the kneading cylinder, then add 42g of water to the high-gluten flour, and knead the dough for 6 minutes to form a dough; extrude the mixed dough through an extruder twice to obtain an extruded dough ; Put the extruded dough on a noodle pressing machine with a roll spacing of about 5mm and fold the noodle in the same direction for 10 times to obtain a noodle strip with a thickness of 5mm; Prove in the proofing box for 35 minutes to get the proofing noodle strip; cut the proofing noodle strip into a long strip with a length of 180mm, a width of 15mm and a thickness of 5mm; hold both ends of the long strip with both hands , shake and pull with even force, pull it to a length of 0.8-1m, fold the two ends together and repeat the above-mentioned stretching action again, according to the diameter of the noodles, fold and stretch repeatedly 1-3 times, and finally make the ramen noodles.

Embodiment 2

[0022] Weigh 100g of high-gluten flour and pour it into the kneading cylinder, then add 43g of water to the high-gluten flour, and knead the dough for 7 minutes to form a dough; extrude the mixed dough through an extruder twice to obtain an extruded dough ;Put the extruded dough on a noodle press with a roll spacing of about 10mm and fold the noodle in the same direction for 10 times to obtain a noodle strip with a thickness of 10mm; then put the 10mm noodle strip into a temperature of 25 ℃ and a humidity of 71%. Prove in the proofing box for 30 minutes to obtain the proofing noodle strip; cut the proofing noodle strip into a long strip with a length of 180mm, a width of 15mm and a thickness of 10mm; hold both ends of the long strip with both hands , shake and pull with even force, pull it to a length of 0.8-1m, fold the two ends together and repeat the above-mentioned stretching action again, according to the diameter of the noodles, fold and stretch repeatedly 1-3 times, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com