Full automatic control method and system for blast furnace pulverizing systems

A technology of pulverizing system and blast furnace, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of high equipment operation rate, operator error, high consumption of coal and electricity per ton, and high gas consumption, so as to eliminate artificial The effect of operating errors, reducing wear and tear of mechanical parts, and reducing power consumption and gas consumption per ton of coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

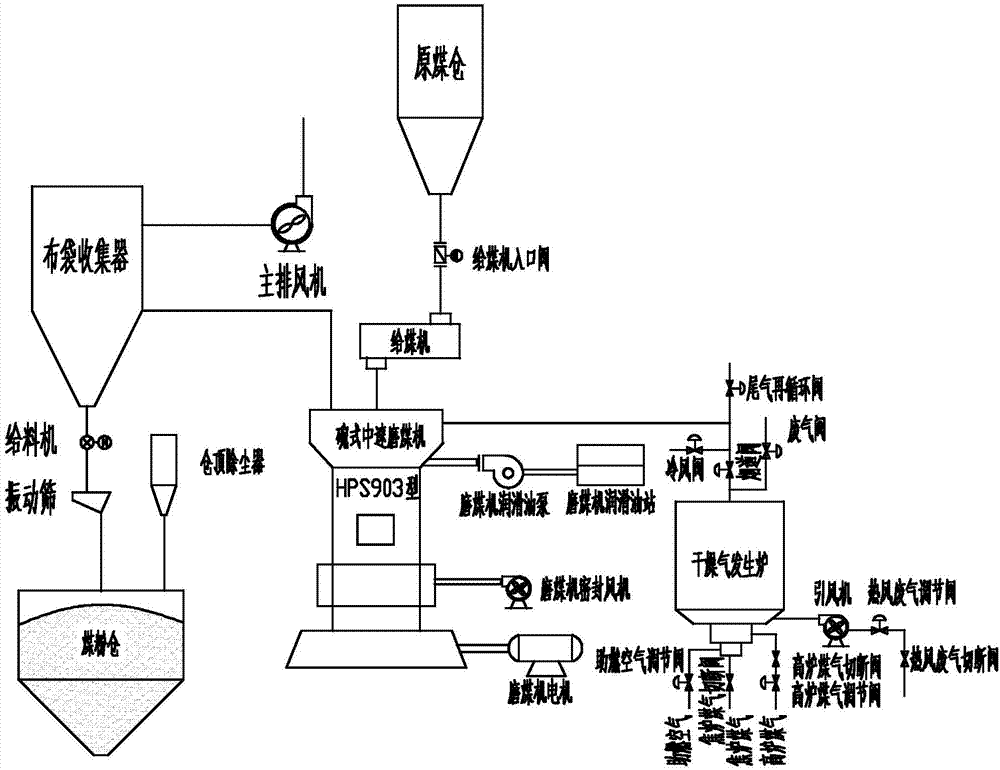

[0029] figure 1 It is a common process flow diagram of blast furnace coal injection pulverization system. The pulverization system is mainly composed of dry gas generator (referred to as drying furnace), induced draft fan, coal feeder, coal mill, main exhaust fan, cloth bag collector and various valves. components.

[0030] Taking the control of the pulverizing system of No. 3 blast furnace of Nangang as an example, with a volume of 2000m3, two pulverizing systems are set up. Each pulverizing system uses a 35t / h medium-speed coal mill. Burn the furnace, use the induced draft fan to mix the waste flue gas of the hot blast stove for drying, and collect the short-process process using high-concentration bag collection.

[0031] The automatic control method of the blast furnace pulverizing system is as follows:

[0032] (i) Preparation and activation

[0033] Start judgment:

[0034] Before starting the pulverizing system, check the current hourly coal injection volume and p...

Embodiment 2

[0046] The fully automatic control system of the blast furnace pulverizing system includes:

[0047] (1) Preparation and start-up unit: used to perform the start-up operation of the pulverizing system;

[0048] The preparation and initiation unit consists of two parts:

[0049] Startup judging unit: By detecting the amount of coal injected in the current hour and the amount of pulverized coal stored in the pulverized coal bin, it is determined to start a single pulverizing system or all pulverizing systems according to the set conditions. Specifically: when it is detected that the amount of powder stored in the coal powder bin is greater than 8 hours and the hourly coal injection amount is less than the design value of the coal mill, start a single pulverizing system, otherwise start all pulverizing systems;

[0050] Start control unit: start each equipment of the pulverizing system according to the set conditions. specifically is:

[0051] When it is detected that ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com