A high-toughness anti-split carbon fiber composite wire mandrel and preparation method thereof

A composite material and carbon fiber technology, which is used in the manufacture of cables/conductors, conductors, insulated conductors, etc., to achieve the effect of improving compactness, ensuring deformation resistance, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

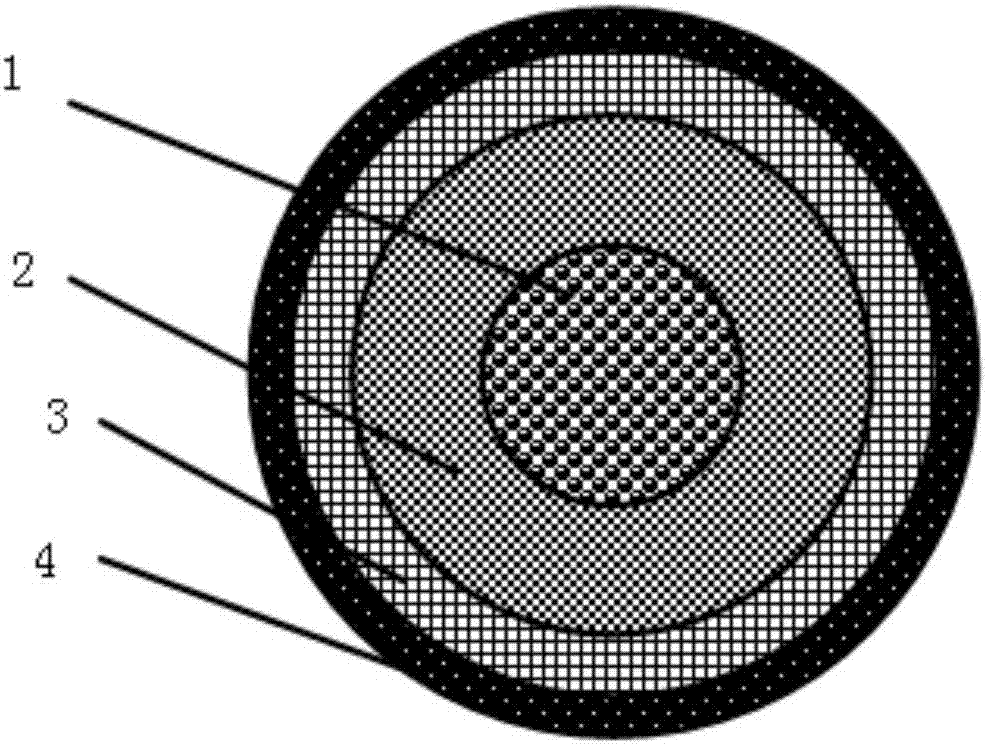

[0047] A highly flexible, split-resistant carbon fiber composite wire mandrel, such as figure 1 As shown, from the inside to the outside, it consists of four parts: a rigid core 1, a flexible layer 2, an anti-split layer 3 and a surface wear-resistant layer 4. The preparation method includes: preparation of rigid core, preparation of flexible layer, preparation of anti-split layer and preparation of surface wear-resistant layer.

[0048] Preparation of rigid core: T300 carbon fiber is used as high-strength reinforcing fiber, M40J is used as high-modulus reinforcing carbon fiber, the mixed mass ratio of high-strength / high-modulus carbon fiber is 10:1, epoxy resin is used as matrix resin, and the resin content is 40% . The resin and reinforcing fiber are formed by pultrusion process, and the diameter of the final formed rigid core is 3mm.

[0049] Preparation of the flexible layer: select S glass fiber as the main reinforcing fiber, mix T700 high-strength carbon fiber, the mix...

Embodiment 2

[0054] The preparation of a highly flexible and anti-split carbon fiber composite wire mandrel includes: the preparation of a rigid core, the preparation of a flexible layer, the preparation of an anti-split layer and the preparation of a surface wear-resistant layer.

[0055] Preparation of rigid core: T700 carbon fiber is used as high-strength reinforcing fiber, M60J carbon fiber is used as high-modulus reinforcing carbon fiber, the mixed mass ratio of high-strength / high-modulus carbon fiber is between 3:1, phenolic resin is used as matrix resin, and the resin content is 30%. The resin and reinforcing fiber are formed by pultrusion process, and the diameter of the final formed rigid core is 6mm.

[0056] Preparation of the flexible layer: choose E glass fiber as the main reinforcing fiber, mix T800 high-strength carbon fiber, the mixed mass ratio of glass fiber and carbon fiber is 4:1, the resin matrix adopts polyurethane modified unsaturated polyester resin, and the content...

Embodiment 3

[0061] The preparation of a highly flexible and anti-split carbon fiber composite wire mandrel includes: the preparation of a rigid core, the preparation of a flexible layer, the preparation of an anti-split layer and the preparation of a surface wear-resistant layer.

[0062] Preparation of rigid core: T800 carbon fiber is used as high-strength reinforcing fiber, M60J carbon fiber is used as high-modulus reinforcing carbon fiber, the mixed mass ratio of high-strength / high-modulus carbon fiber is between 8:1, and unsaturated polyester resin is used as matrix resin. The resin content is 45%. The resin and reinforcing fiber are formed by pultrusion process, and the diameter of the final formed rigid core is 12mm.

[0063] Preparation of the flexible layer: choose E glass fiber as the main reinforcing fiber, mix T300 high-strength carbon fiber, the mixed mass ratio of glass fiber and carbon fiber is 5:1, the resin matrix adopts polyurethane modified epoxy resin, and the content o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com