Technique for folding and producing adsorption type napkin paper and device thereof

A folding device and manufacturing process technology, applied to cardboard items, etc., can solve problems such as poor product quality stability, complex folding mechanism structure, and low folding accuracy, and achieve stable product quality, simple structure, and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

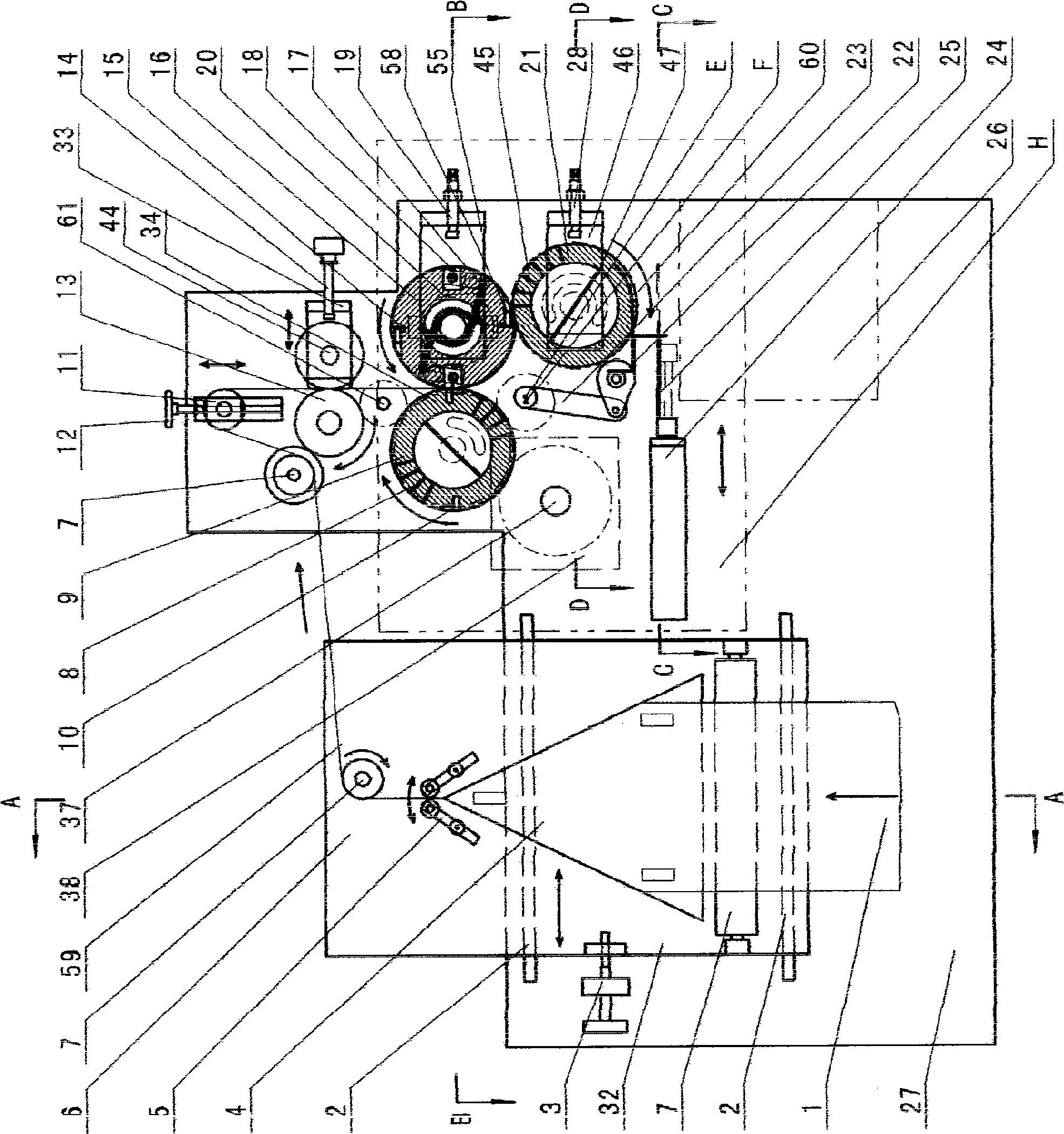

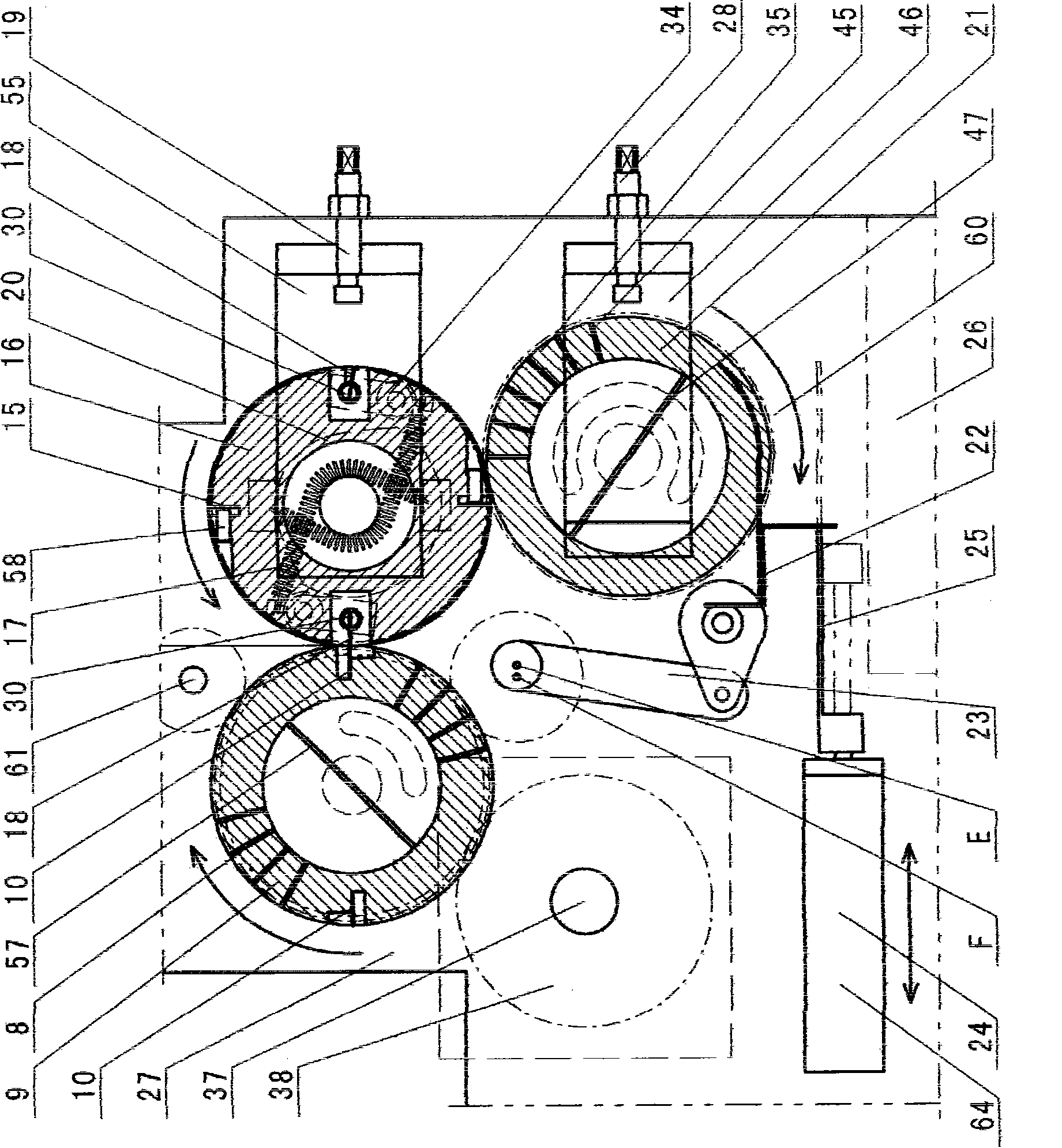

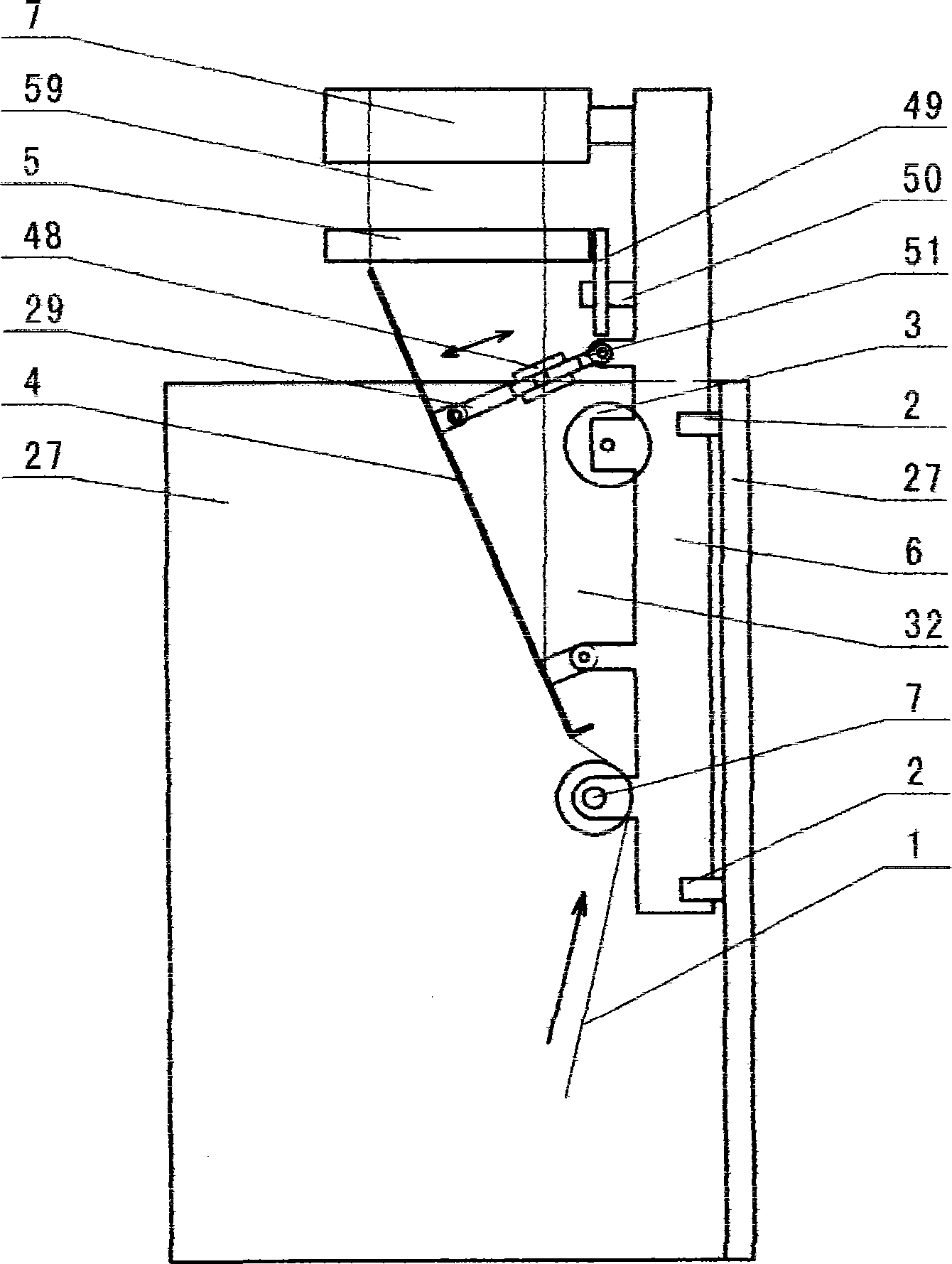

[0024] Follow the accompanying drawings for further details: figure 1 shown, see also figure 2 , image 3 with Figure 4 , the printed napkin 1 is a good napkin printed and embossed in the previous process, and it can also be a blank napkin. Bottom frame 27 is the mounting base of the whole adsorption type napkin folding device, slide rail 2 is installed on the bottom frame 27, and moving plate 6 is supported on the slide rail 2, is the installation basis of whole vertical folding mechanism 32, and vertical folding mechanism 32 is existing It is composed of slide rail 2, horizontal adjustment hand wheel 3, longitudinal folding triangle plate 4, pressure roller 5, moving plate 6, screw rod 29, adjustment rod 48, swing arm 49, swing arm shaft 50 and lower screw rod 51 Longitudinal folding mechanism 32 . In the longitudinal folding mechanism 32, one end of the longitudinal folding triangular plate 4 is hinged on the moving plate 6, and the other end is connected with the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com