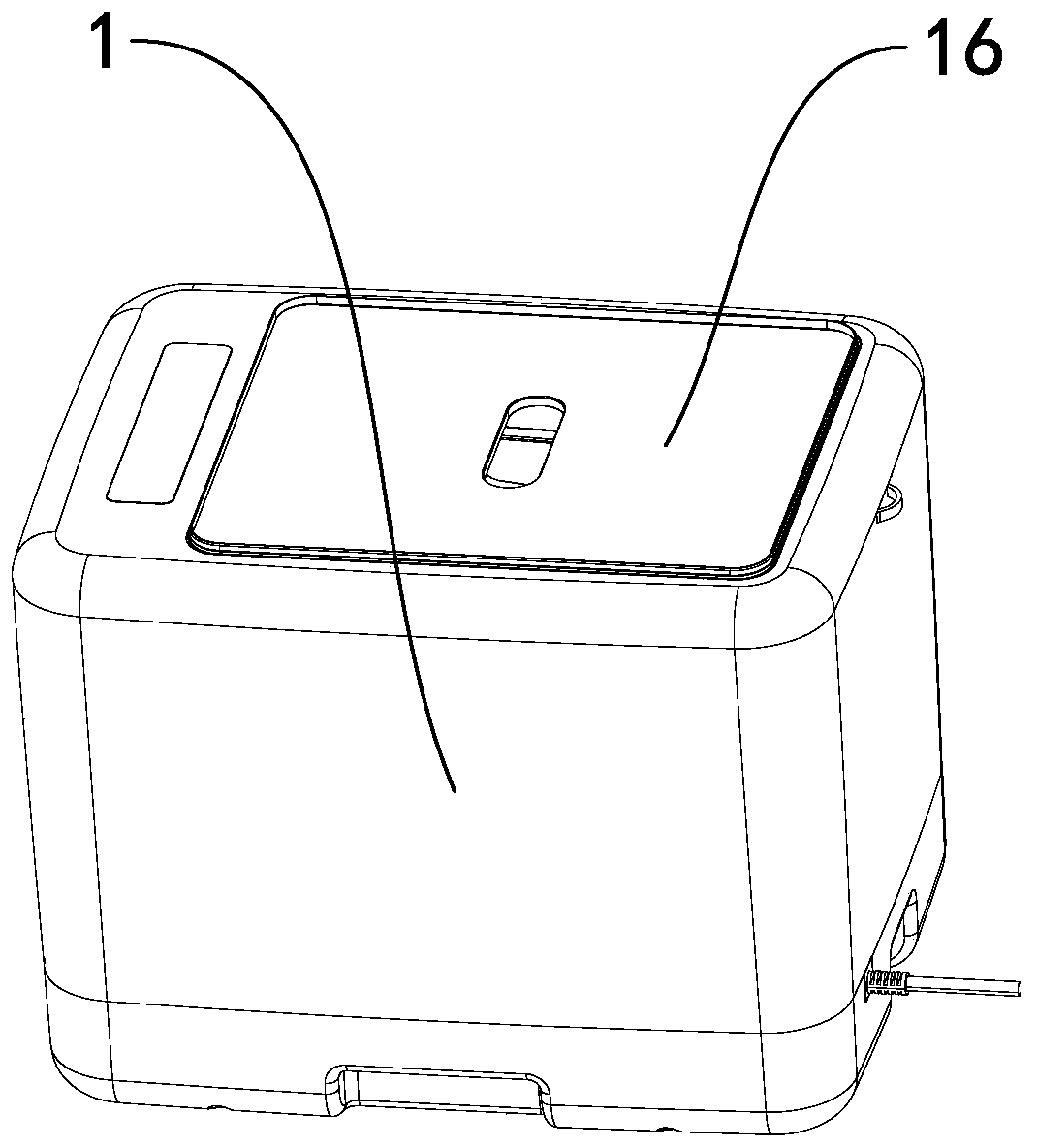

Independent fruit and vegetable cleaning machine

A fruit and vegetable cleaning machine, an independent technology, applied in the field of cleaning machines, can solve the problems of high volume and large occupied space of the fruit and vegetable cleaning machine, and achieve the effect of small occupied space, reasonable structure arrangement, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

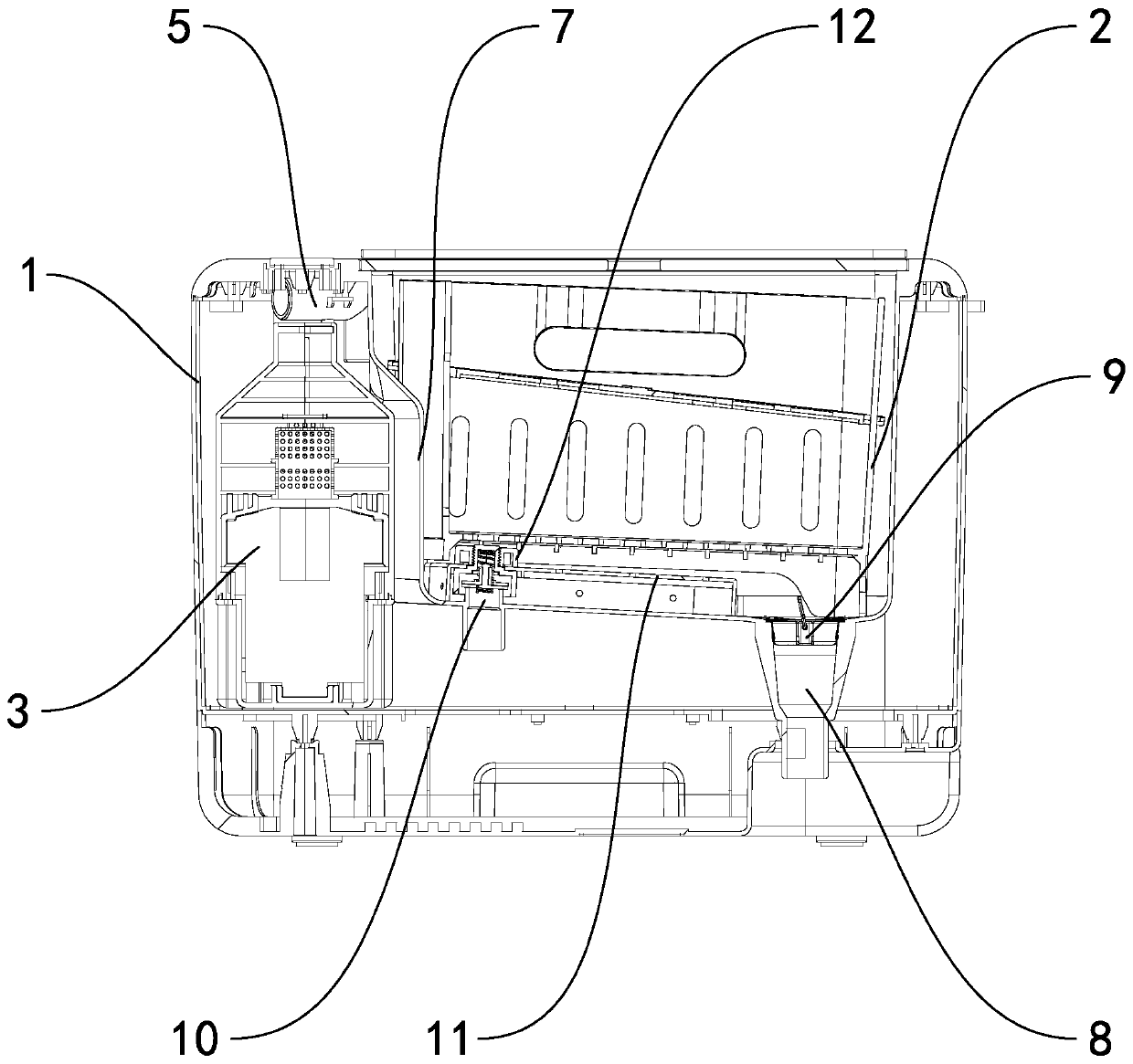

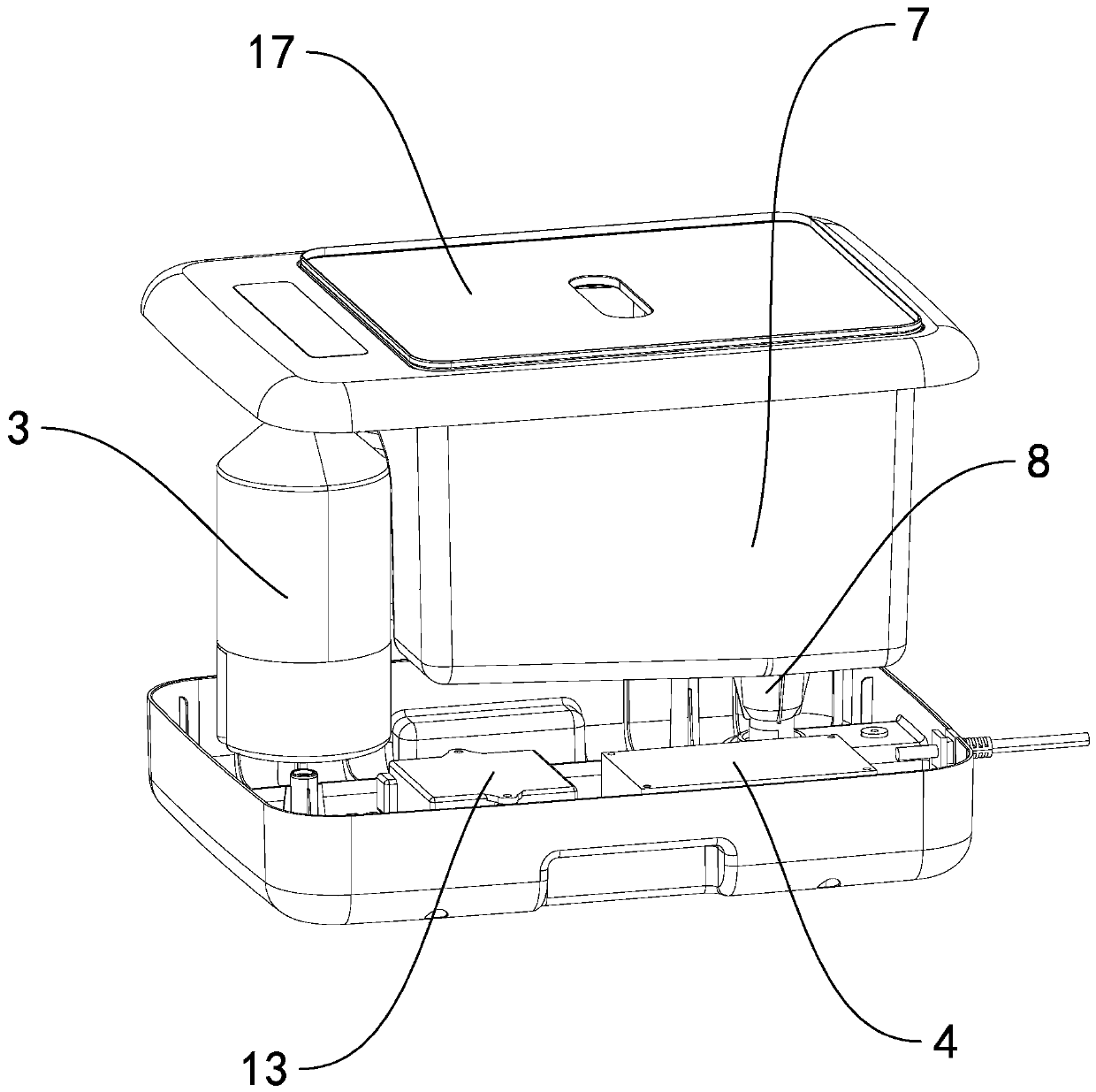

Embodiment 1

[0092] see Figure 14 ~ Figure 16 shown;

[0093] The present invention is an aeration pan, which is installed on the inner bottom wall of the cleaning chamber, and the aeration pan includes an aeration pan body 301, which is connected with an air inlet 313 on the inner bottom wall of the cleaning chamber 312. Inner cavity 302, and the aeration pan body 301 is distributed with a plurality of aeration holes 303 communicating with the inner cavity 302; the aeration pan body 301 includes a top wall 304 connected with the top wall 304 and extending downwards The side wall 305, the lower end of the side wall 305 is open and attached to the inner bottom wall of the cleaning chamber 312, the inner cavity 302 is formed between the inner wall of the aeration pan body 301 and the inner bottom wall of the cleaning chamber 312, The aeration holes 303 are arranged on the top wall of the aeration pan body 301 . The aeration pan body 301 is provided with a connecting hole 307 for connectin...

Embodiment 2

[0097] see Figure 17 ~ Figure 18 shown;

[0098]The present invention is an aeration pan, and the aeration pan body 301 is provided with a avoidance hole 308 that allows the ultrasonic cleaning unit to contact the cleaning liquid in the cleaning chamber 312 . A liquid passage 309 is provided between the inner wall of the avoidance hole 308 and the cleaning chamber 312, and the lower end of the inner wall of the avoidance hole 308 is provided with a plurality of second water leakage holes 310 communicating with the inner cavity 302. The second water leakage The hole 310 is used to make the water in the inner chamber 302 flow to the drain of the cleaning chamber 312 through the second water leakage hole 310 and the liquid passage 309 . The avoidance hole 308 is also called a reserved hole, which is an installation area for the installation of the ultrasonic cleaning unit; the setting of the avoidance hole 308 on the aeration disc body 301 can make the ultrasonic cleaning unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com