Preparation method of novel AB adhesive film

A new type of adhesive film and technology, applied in the direction of adhesives, adhesive types, films/sheets without carriers, etc., can solve problems such as the inability to convey the photosensitive effect of screen fingerprints, the inability to perfectly fit curved screens, and the failure of screen fingerprint unlocking, etc. , to achieve the effect of good appearance, sensitive unlocking effect and good compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

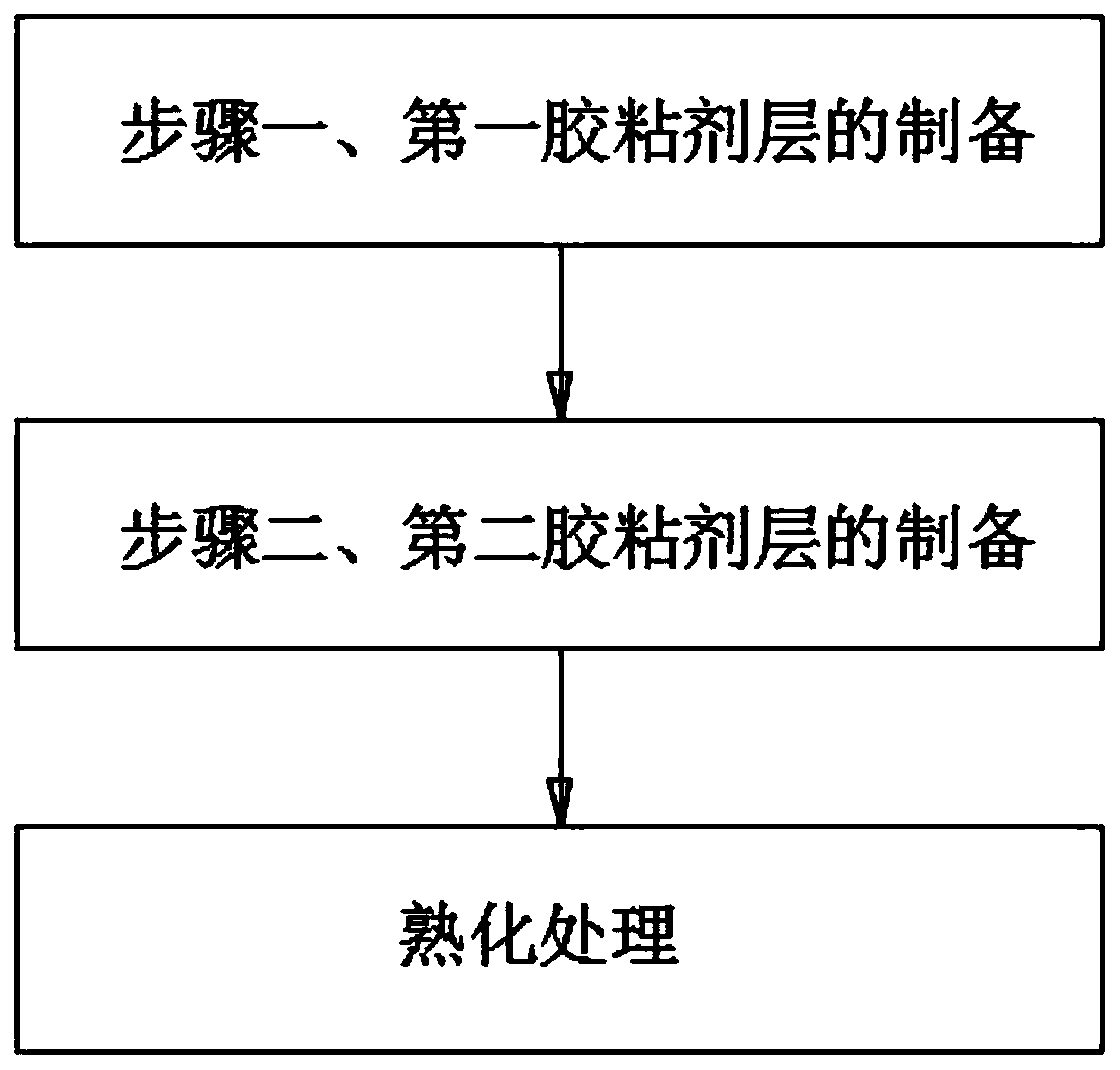

[0032] The preparation method comprises the following steps:

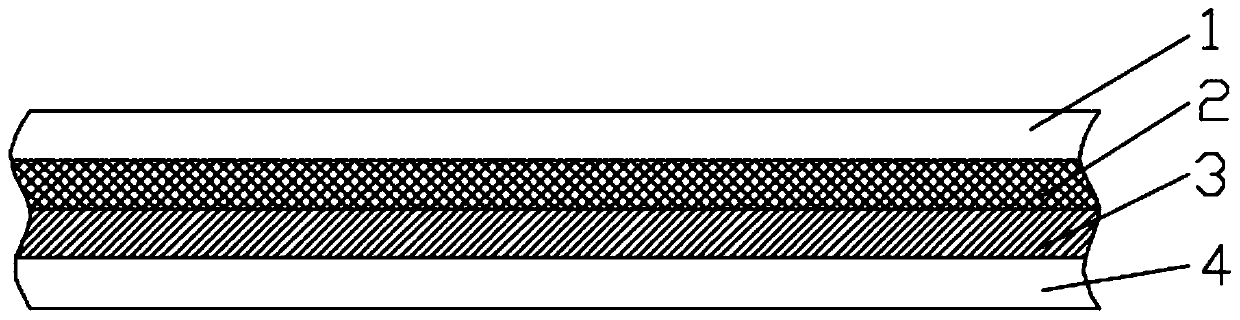

[0033] Step 1. Preparation of the first adhesive layer: After fully stirring the acrylic adhesive solution used for preparing the first adhesive layer 2, filter it with a filter screen of 10-40 μm, and use dimples, comma shafts or slits on the coating machine Coated on the first release layer 1 by extrusion, after drying in a four-section oven, it was bonded and rolled with the engineering film (organic silicon release film) to obtain the first adhesive layer 2, and the first adhesive Layer 2 is pasted on the lower side of the first release layer 1;

[0034] Step 2. Preparation of the second adhesive layer: After fully stirring the prepared second adhesive layer 3 silicone adhesive solution evenly, filter it with a filter screen of 10-40 μm for use. Peel off the above-mentioned engineering film (organic silicon release film), on the prepared first adhesive layer 2, use the comma shaft or slit extrusion on the coat...

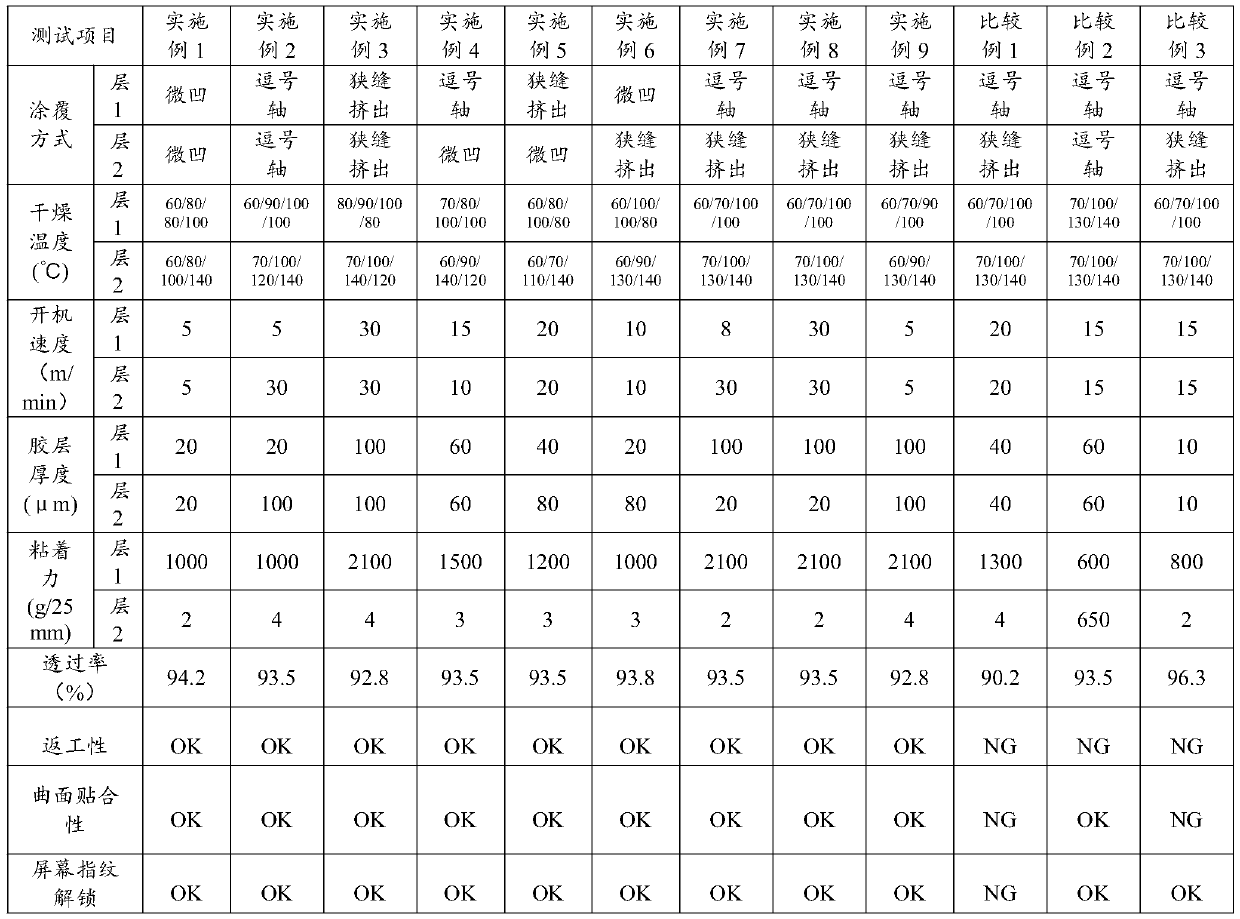

Embodiment 1

[0041] 1) Preparation of the first adhesive layer 2:

[0042] Coat the prepared acrylic adhesive with dimples on the surface of the 50 μm fluorine release film, that is, the first release layer 1. The thickness of the coating is 20 μm. Drying in a special oven, starting at a speed of 5m / min, after drying is complete, it will be bonded and rolled with the engineering film (organic silicon release film);

[0043] 2) Preparation of the second adhesive layer 3:

[0044] Peel off the above-mentioned engineering film (organic silicon release film), and apply the prepared silicone adhesive on the surface of the first adhesive layer 2 with dimples. The thickness of the coating is 20 μm. Dry in a four-section oven at 140°C with a starting speed of 5m / min. After drying is complete, it is bonded and wound with a 50μm fluorine release film, that is, the second release layer 4 .

[0045] Place the above-prepared product in an oven at 40°C for 2 days to mature to obtain the final stable p...

Embodiment 2

[0047] 1) Preparation of the first adhesive layer 2:

[0048] Coat the prepared acrylic adhesive with a comma shaft on the surface of the 75 μm fluorine release film, namely the first release layer 1, with a coating thickness of 20 μm. Drying in a special oven, the starting speed is 30m / min, after drying is complete, it is bonded with the engineering film (organic silicon release film) for winding;

[0049] 2) Preparation of the second adhesive layer 3:

[0050] Peel off the above-mentioned engineering film (organic silicon release film), and apply the prepared organic silicon adhesive on the surface of the first adhesive layer 2 with a comma axis. The thickness of the coating is 100 μm. Dry in a four-section oven at 140°C with a starting speed of 30m / min. After drying is complete, it will be bonded and rolled with a 50μm fluorine release film, that is, the second release layer 4 .

[0051] Put the above-prepared product in an oven at 40°C for 3 days for aging to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com