Portable fire hose laying vehicle

A fire hose and laying vehicle technology, which is applied in fire rescue and other directions, can solve the problems of difficult hose retraction, difficult laying of hoses, and high quality of single-drum hoses, achieving rapid laying and recycling, saving laying time, Reduce the effect of laying personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

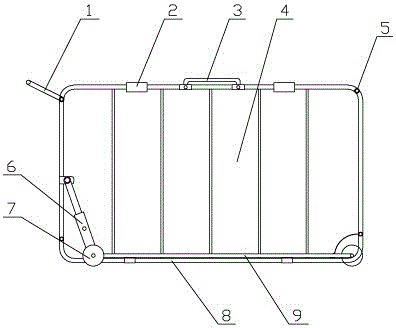

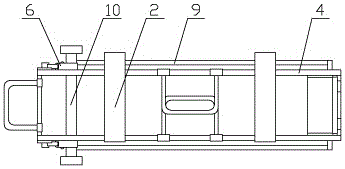

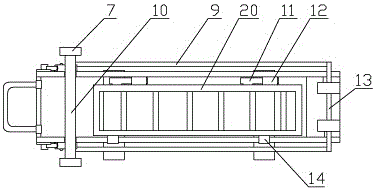

[0023] see Figure 1-Figure 6 , the present invention is a portable fire hose laying vehicle, which has a cuboid car body 4, the top and bottom surfaces of the car body are all arranged in an open structure, and the two sides of the open structure on the bottom surface of the car body are respectively provided with a wheel axle A10 and a wheel axle B13, wherein the wheel shaft B is hinged with one end of the car body, and the other end of the car body rests on the wheel shaft A, and the wheel shaft A and the wheel shaft B are connected together through two connecting rods 9, and the ends of the wheel shaft A and the wheel shaft B are provided with There are rollers 7; both ends of the wheel shaft A are also symmetrically provided with a set of car body jacking devices 6, and the two sets of car body jacking devices are respectively arranged at the front and rear sides of the car body, and the lower ends of the car body jacking devices are hinged. On the axle A, the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com