Tile laying structure in full-automatic ground tile laying device

A fully automatic, floor tile technology, applied in the direction of building structure, construction, etc., can solve the problems of slow tiling efficiency and difficult laying of large bricks, etc., to achieve the effect of reducing labor force and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

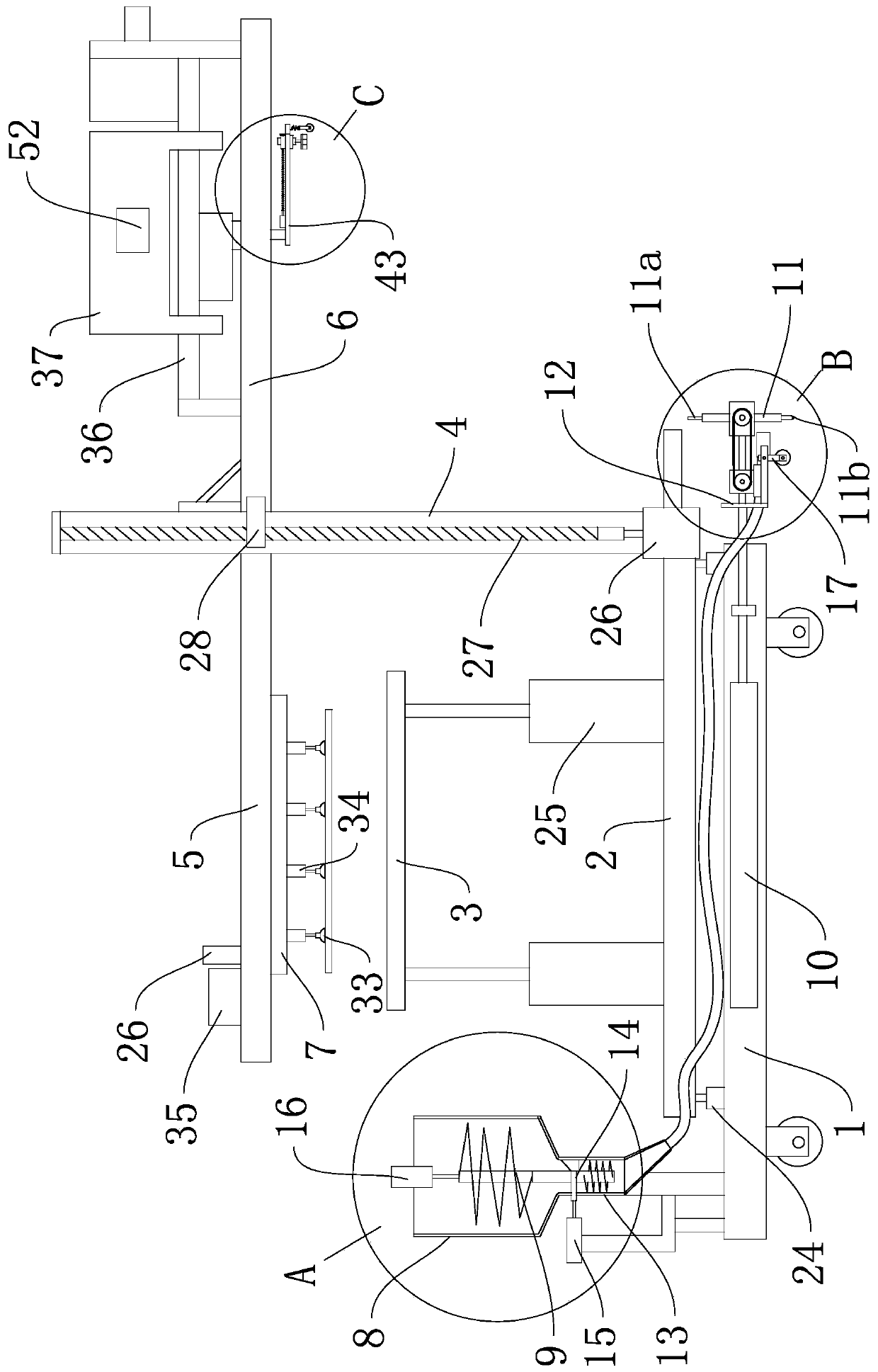

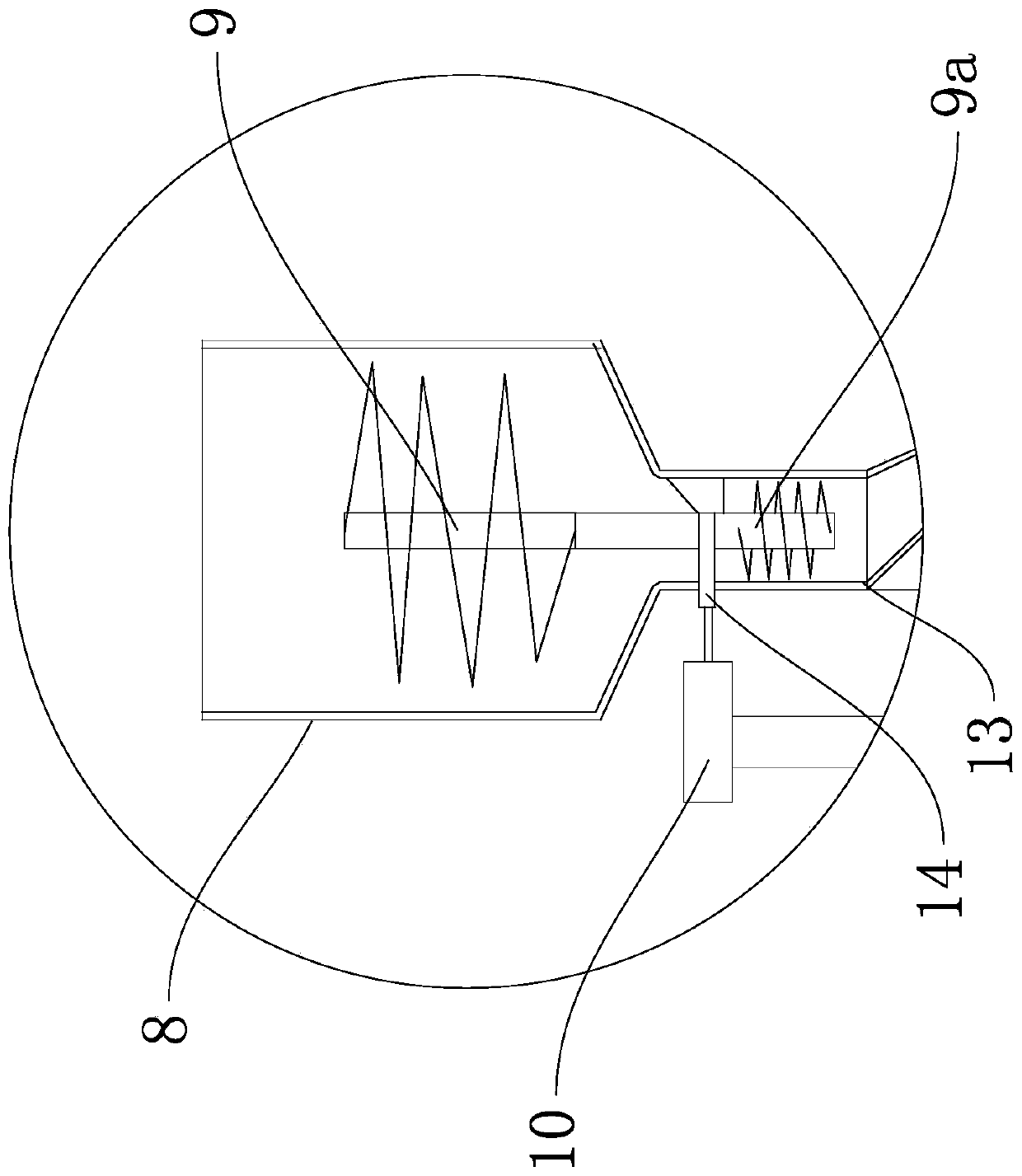

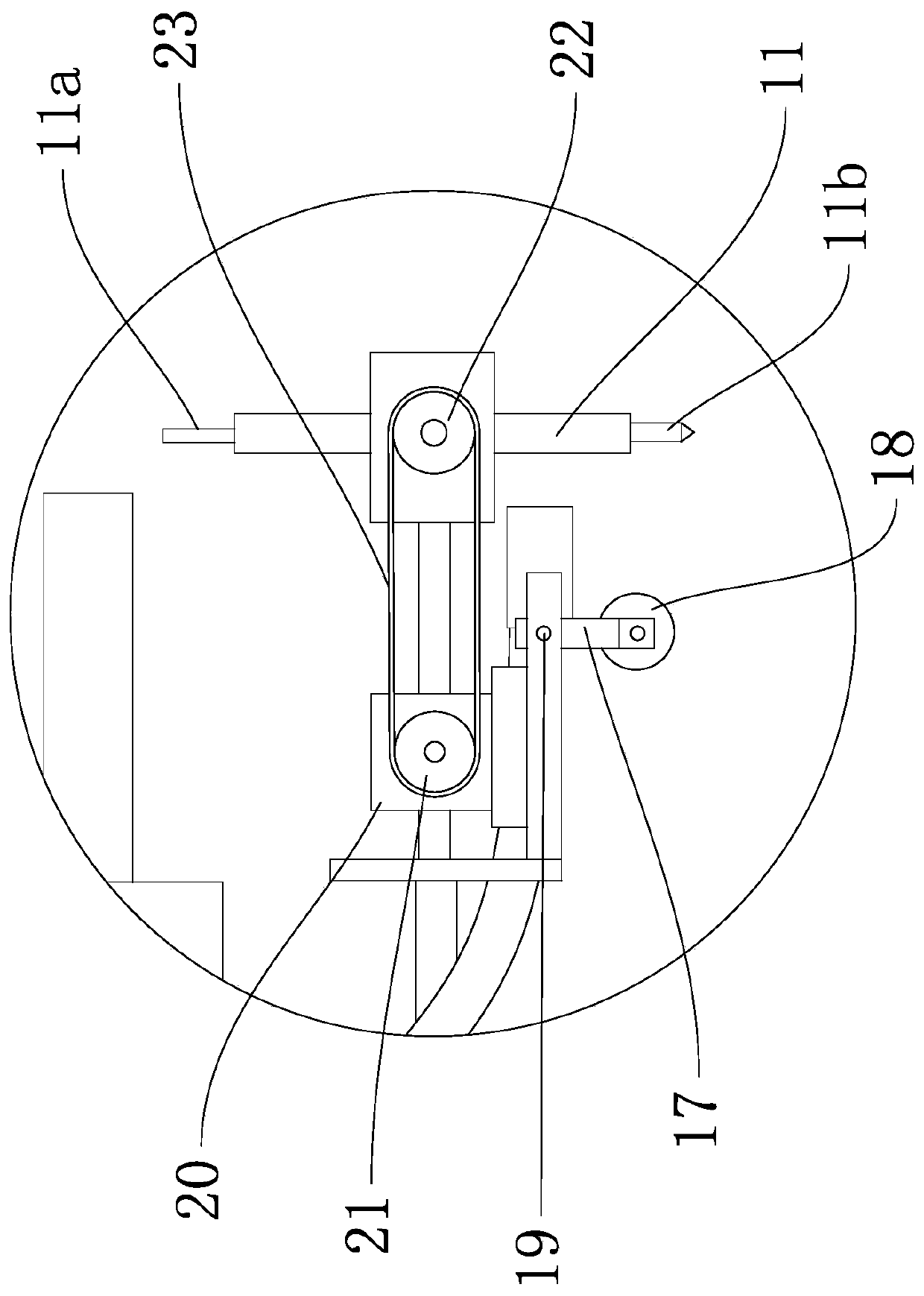

[0029] Such as Figure 1 to Figure 8As shown, a brick laying structure in a fully automatic floor tile laying equipment includes a base 1, and the base 1 is provided with a mobile device capable of moving the base 1. The stirring and paving mechanism to the ground, the base 1 is provided with an adjustment platform 2, and several adjustment components are arranged between the adjustment platform 2 and the base 1, the adjustment components can keep the adjustment platform 2 in a horizontal state, and the adjustment platform 2 is provided with stacking floor tiles The stacking platform 3 and the adjustment platform 2 are also fixed with a vertical guide rail 4, the upper end of the guide rail 4 is fixed with a track 1 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com