Patents

Literature

31 results about "Black band" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

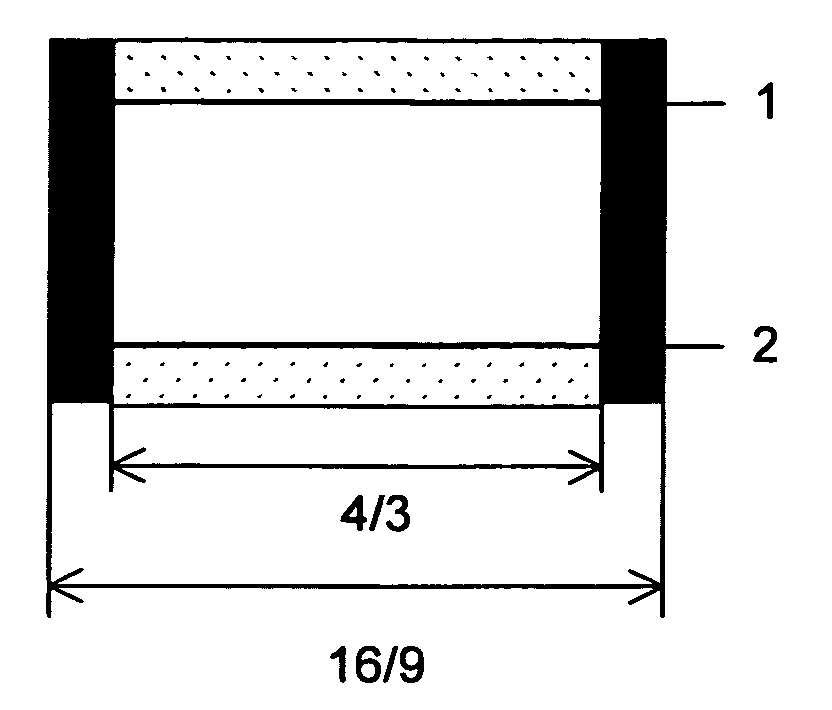

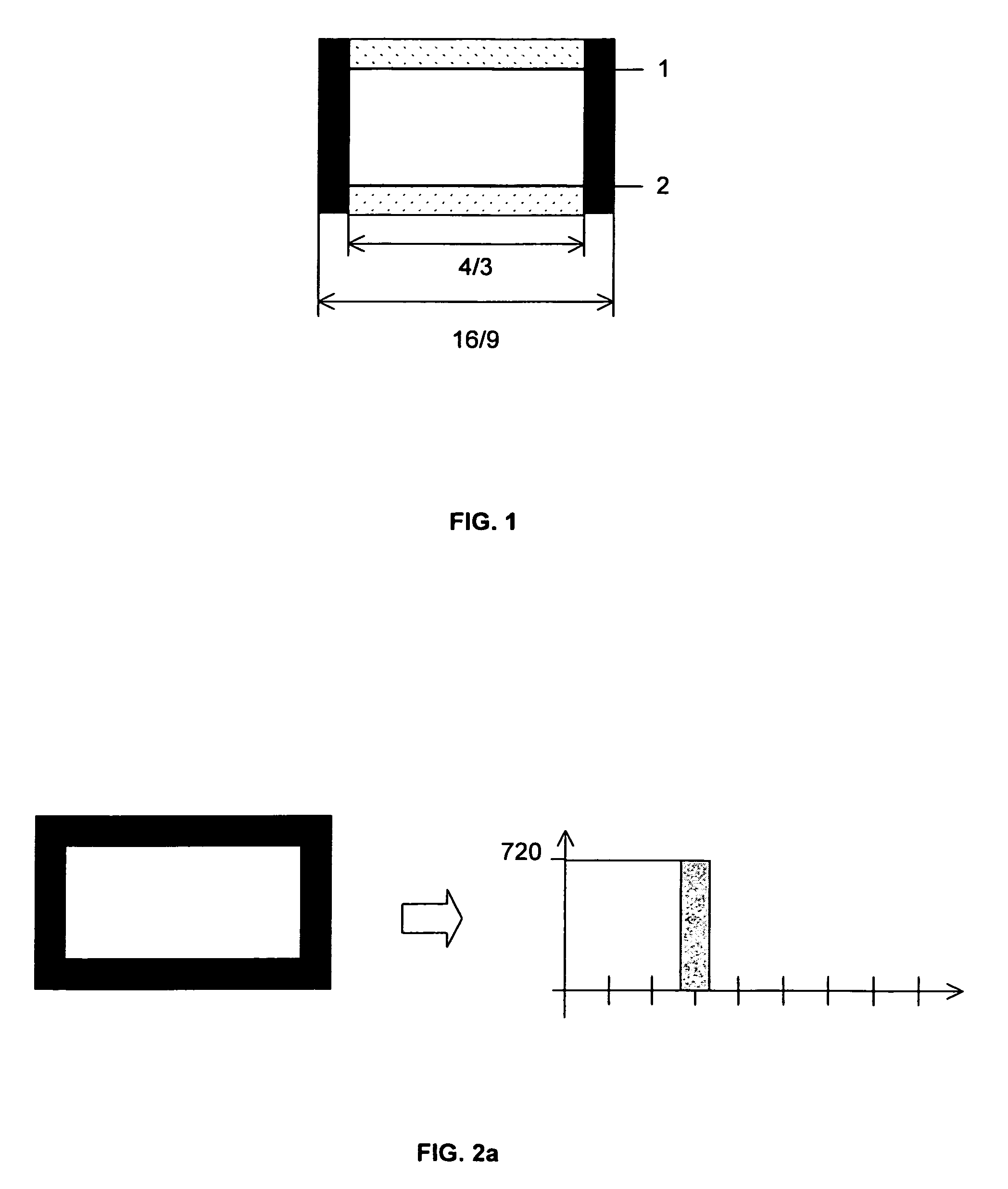

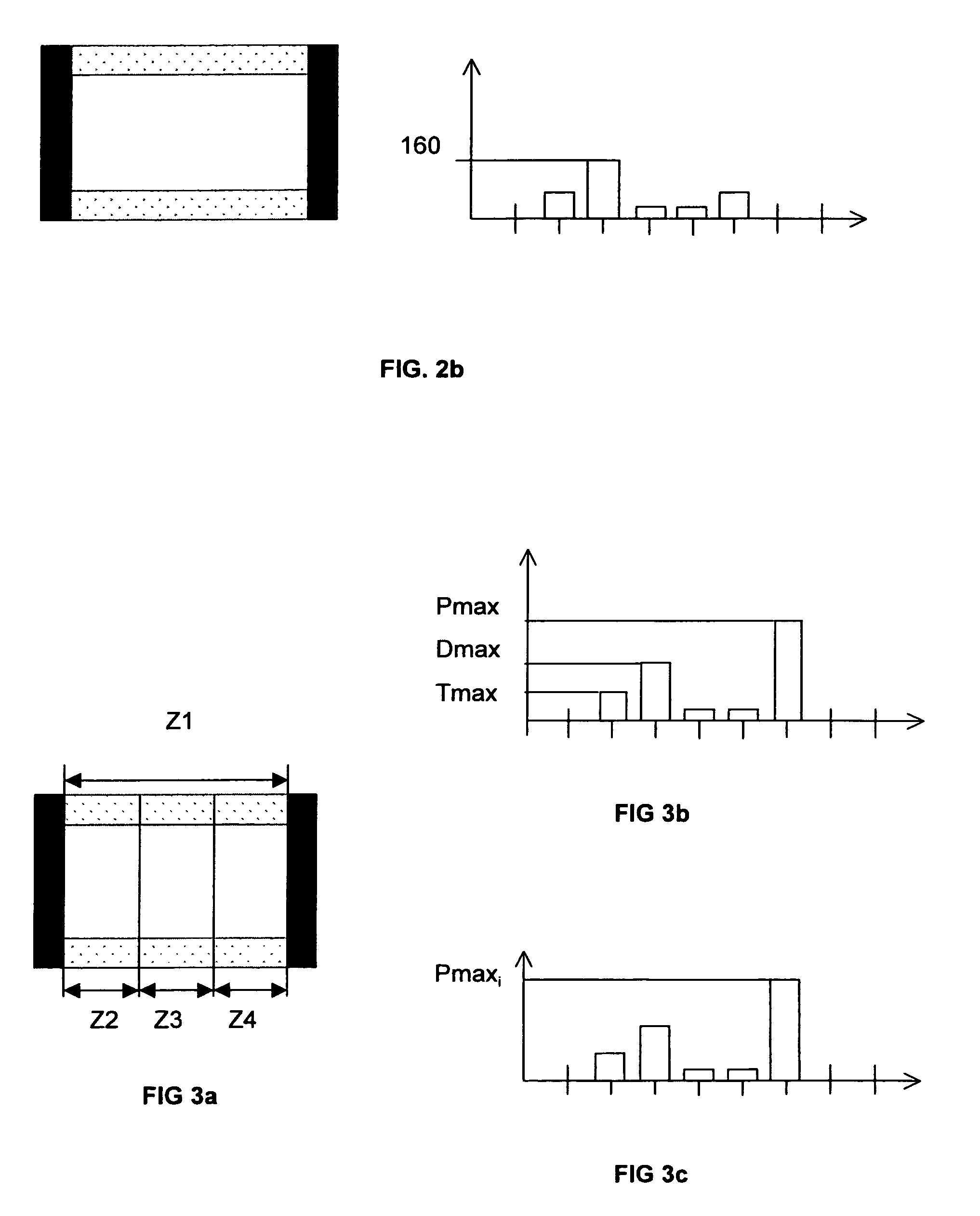

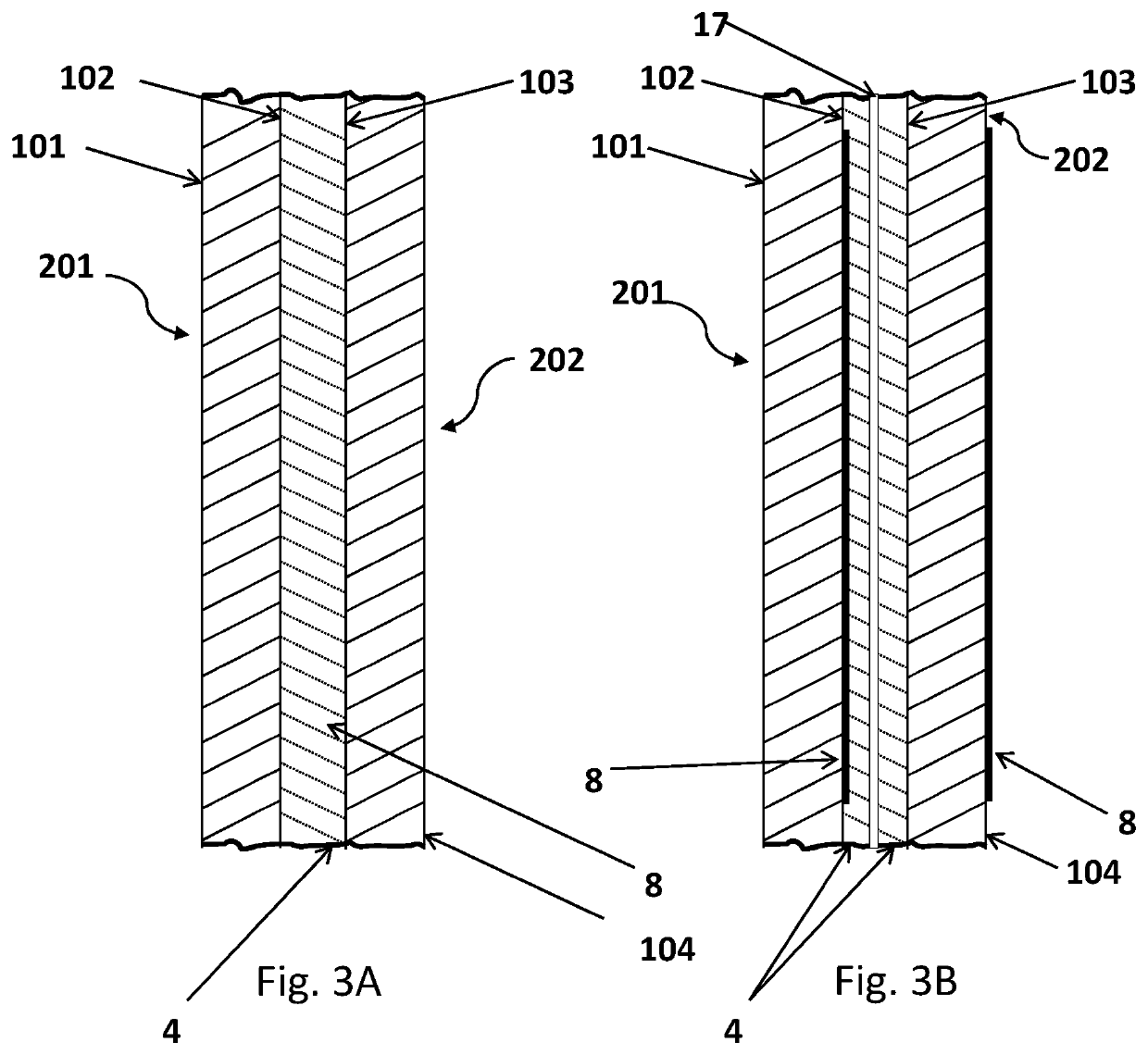

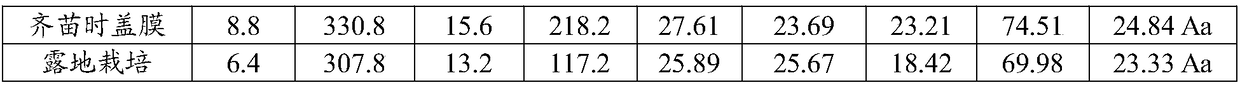

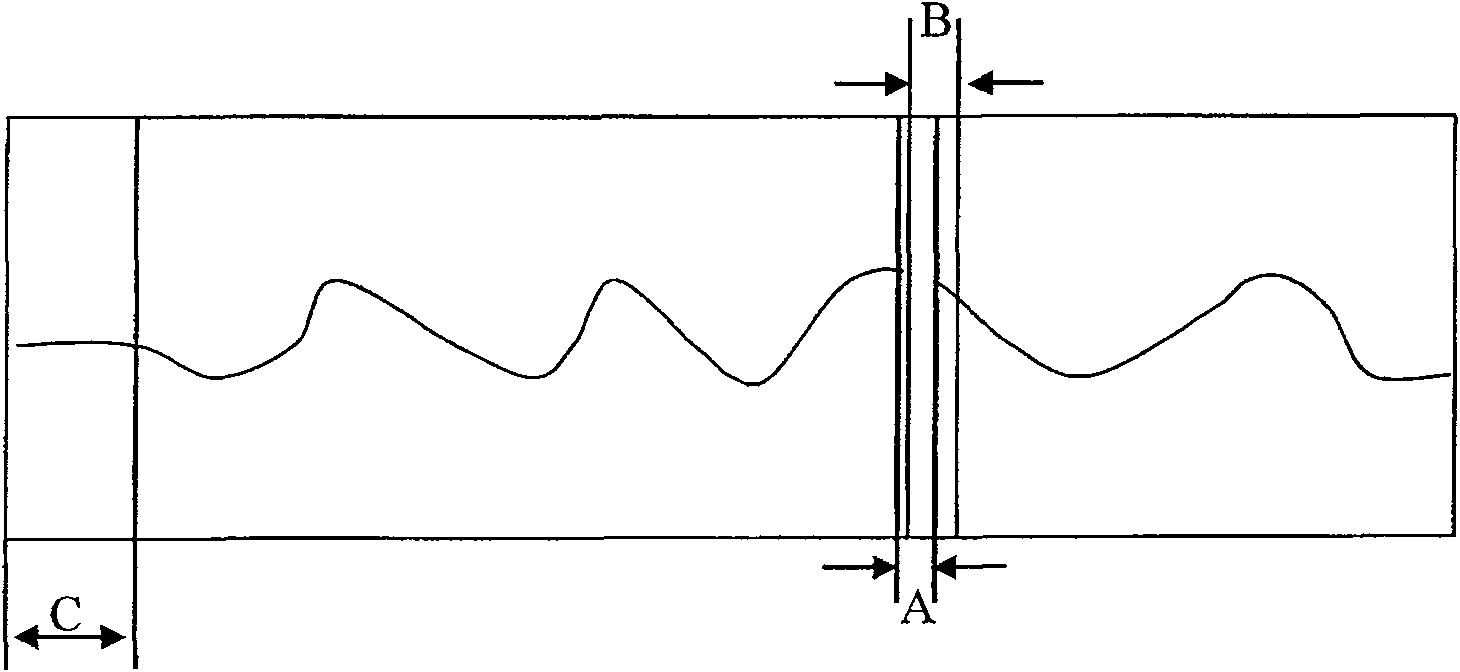

Process for detecting black bars in a video image

InactiveUS6947097B1Reliable detectionTelevision system detailsTelevision system scanning detailsPattern recognitionComputer graphics (images)

A process for detecting black bands in a video image within a luminance range corresponding to low luminance values comprises the steps of: calculating, for each line situated in a location in which a black band can be expected to be found if present in said video image, a value relating to a maximum number of occurrences of points having the same luminance value; averaging said value over said lines in said location; calculating a threshold dependent on said average; and, comparing said value relating to said maximum number of occurrences obtained for a new line with said threshold. Applications relate, for example, to the detection of the “letterbox” format.

Owner:INTERDIGITAL MADISON PATENT HLDG

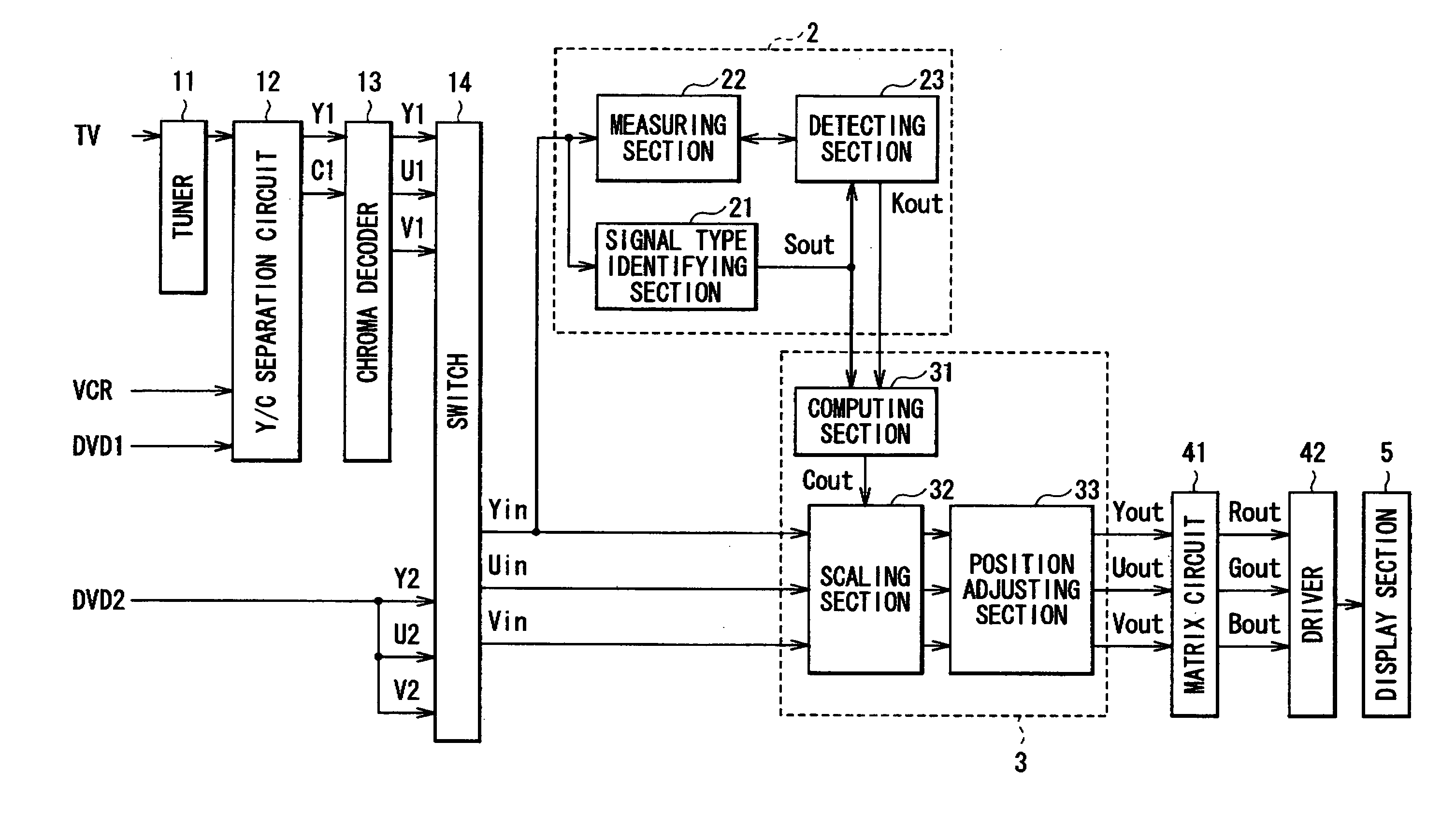

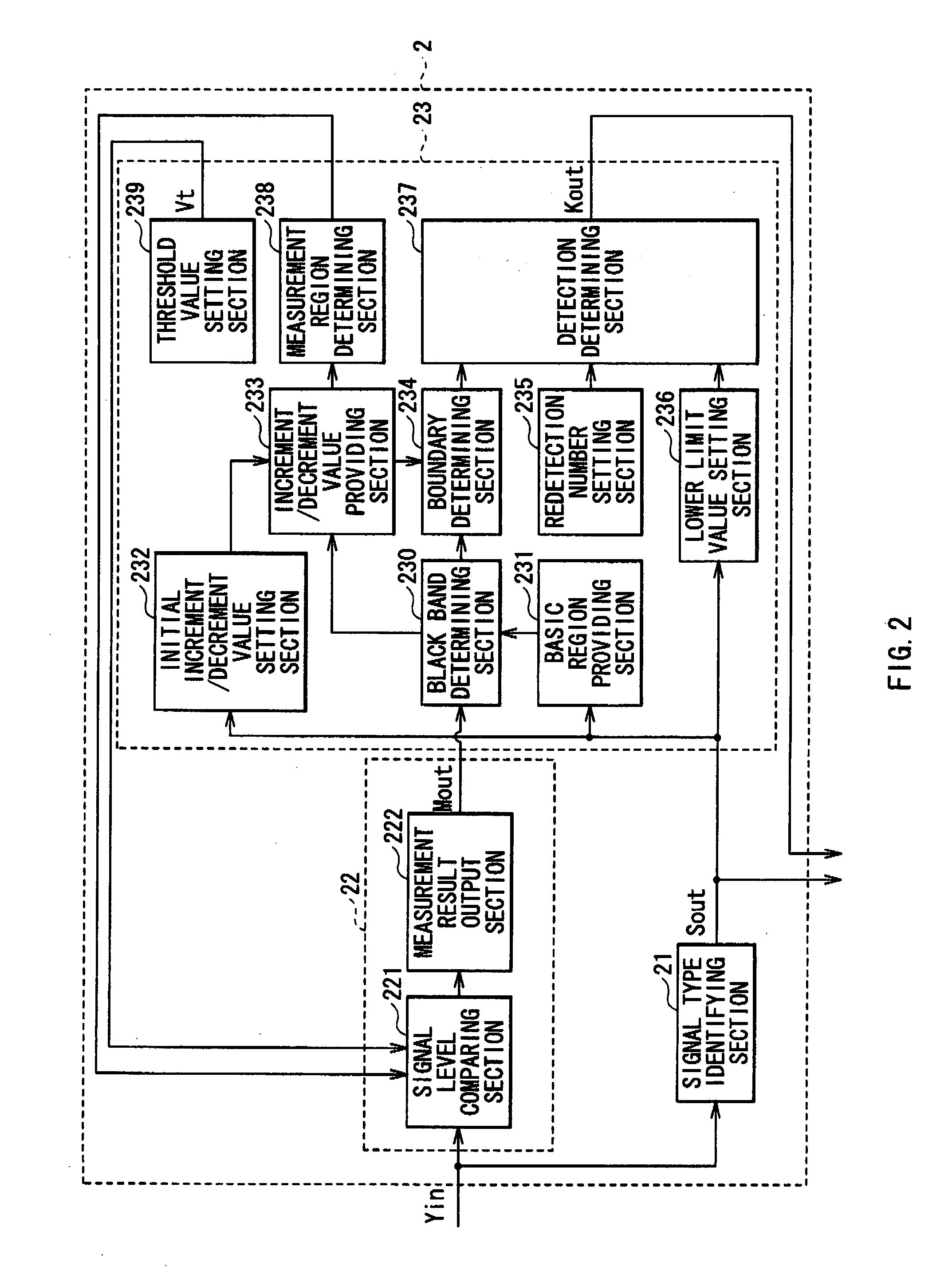

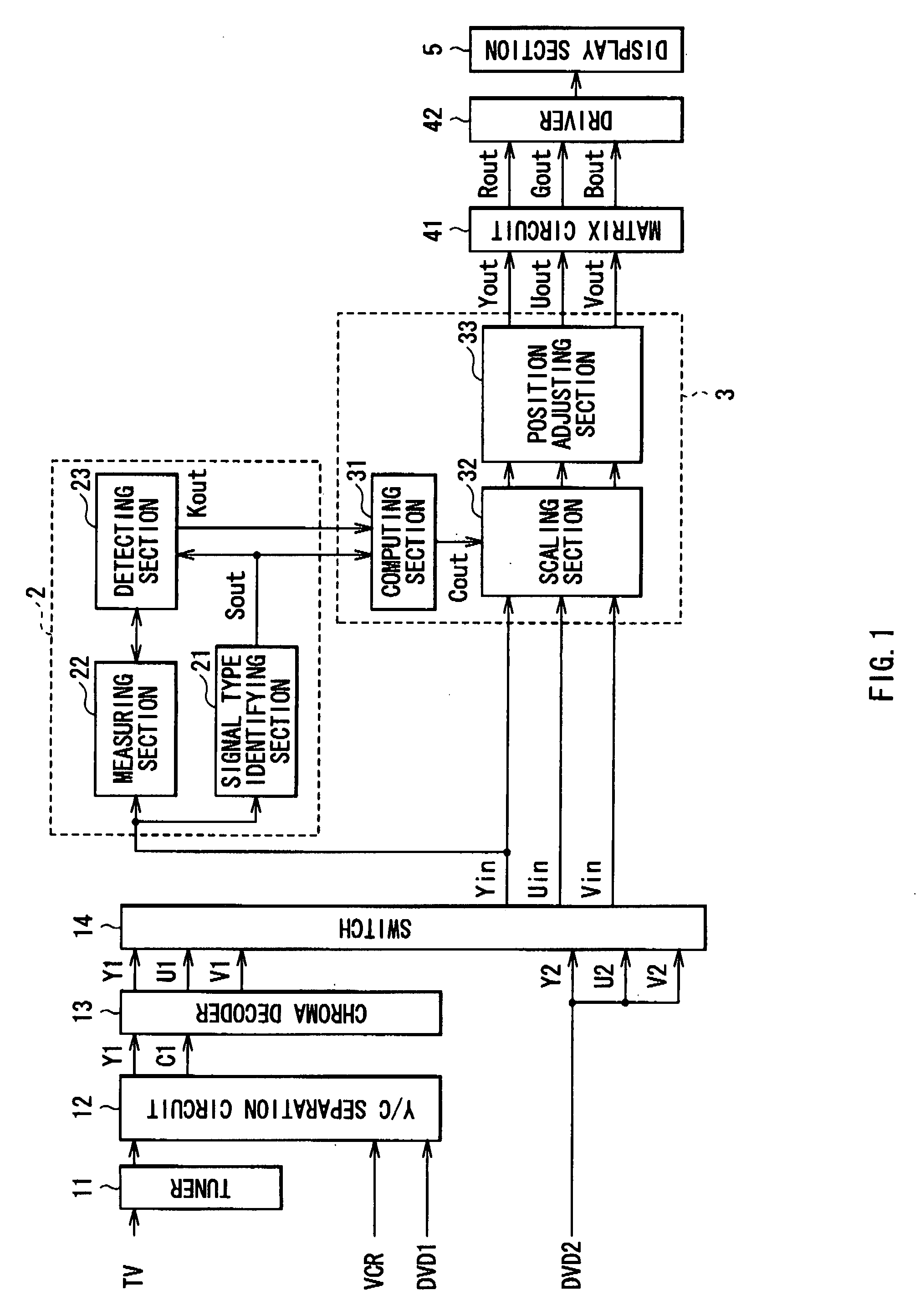

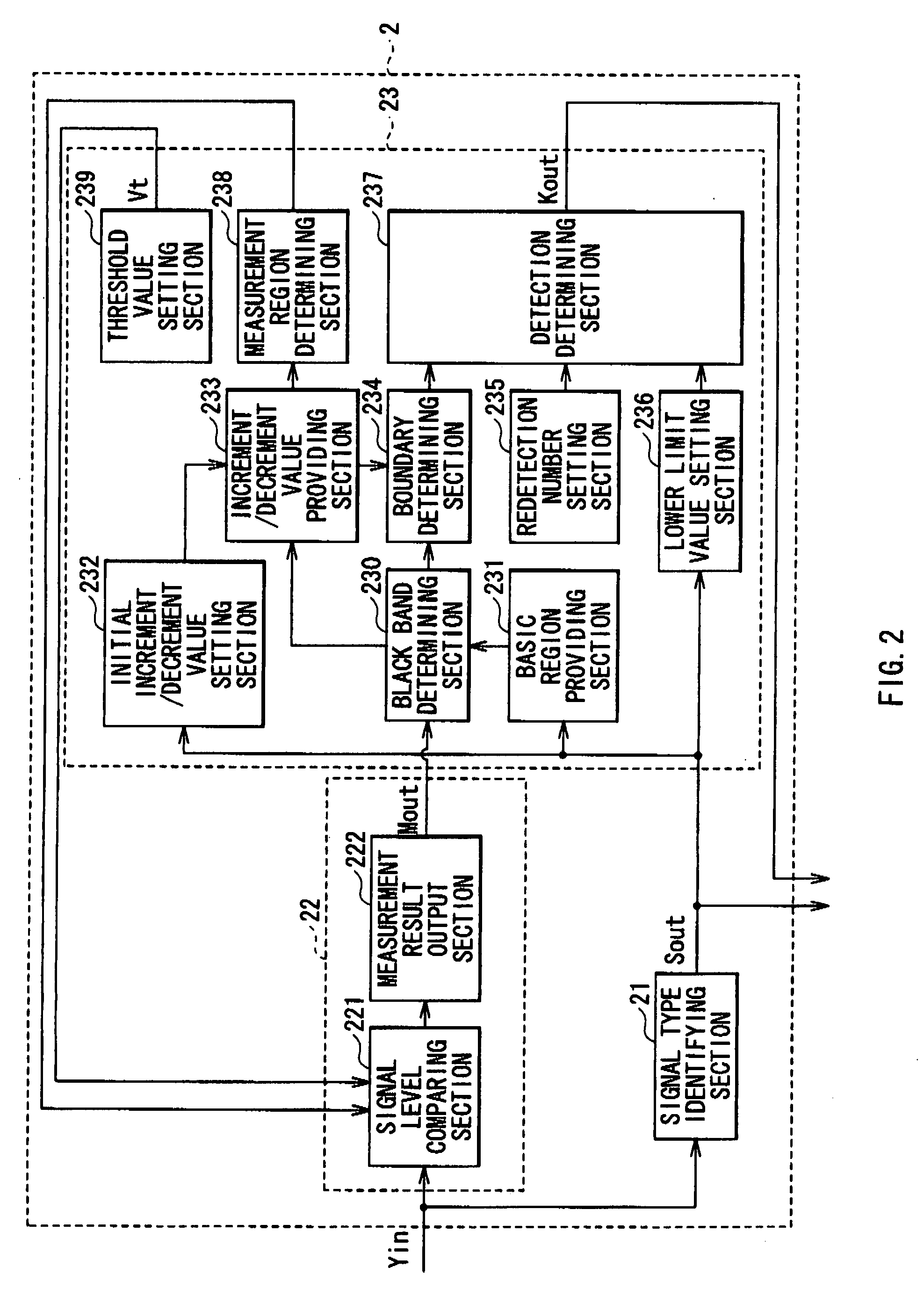

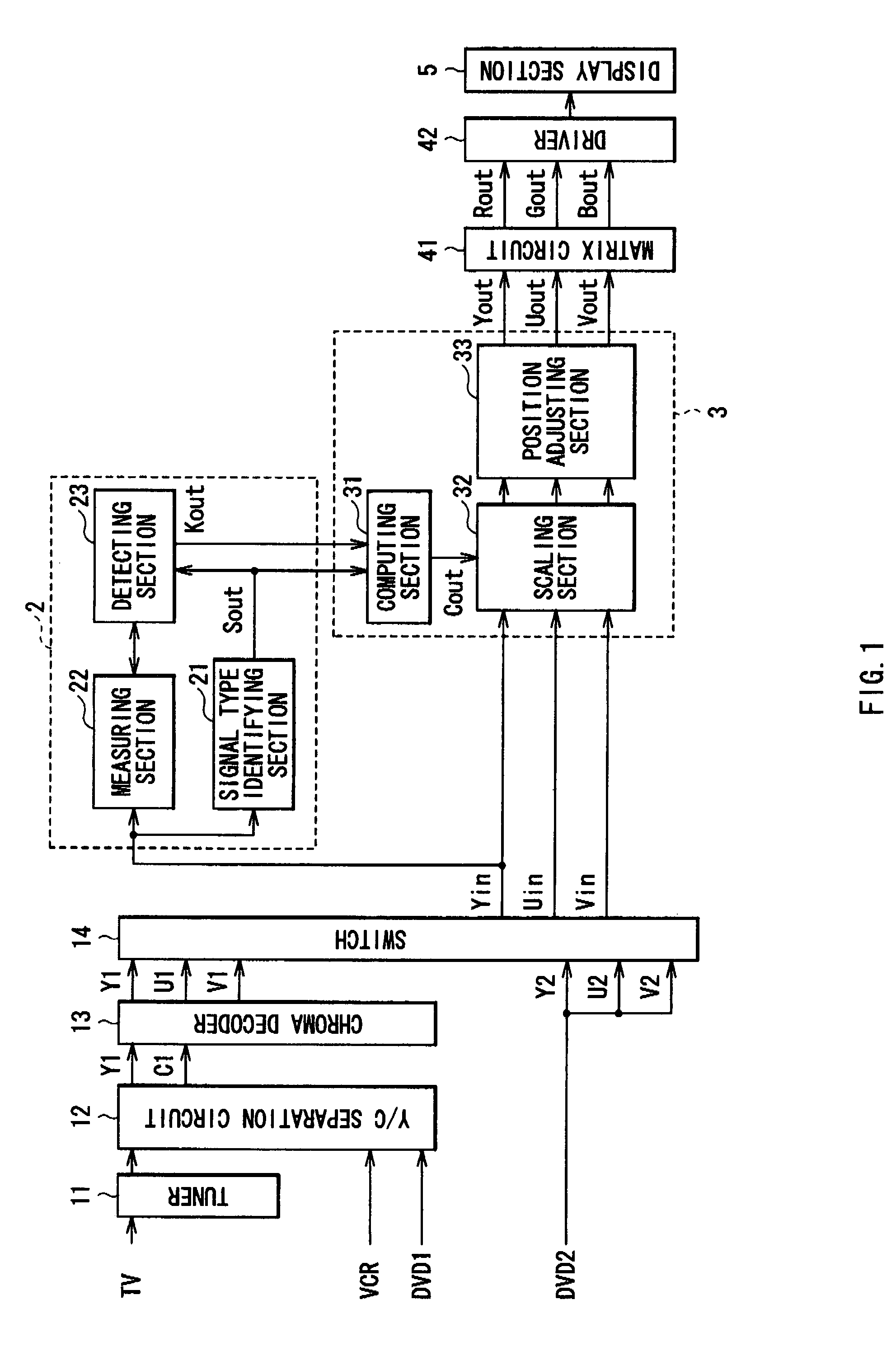

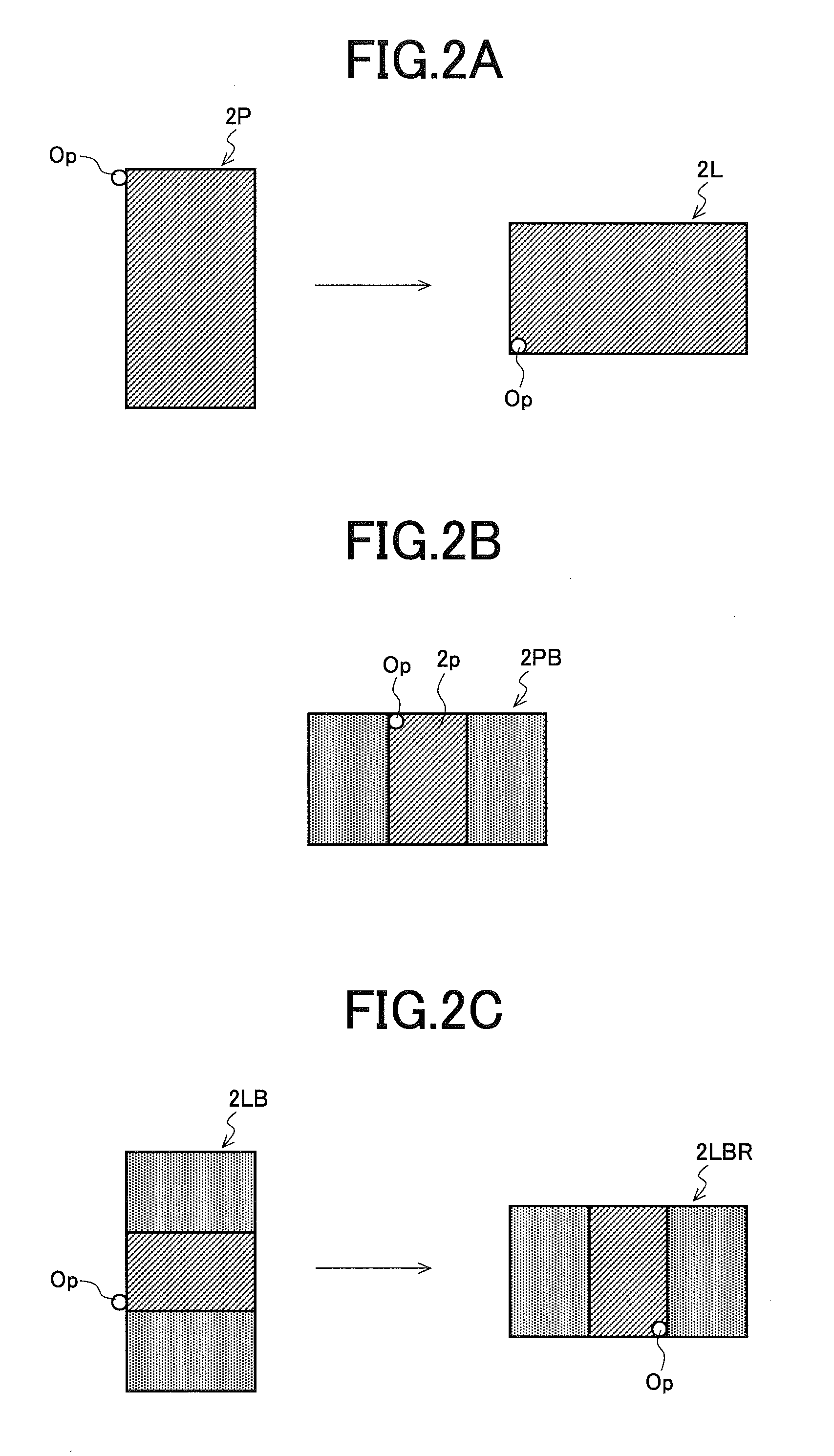

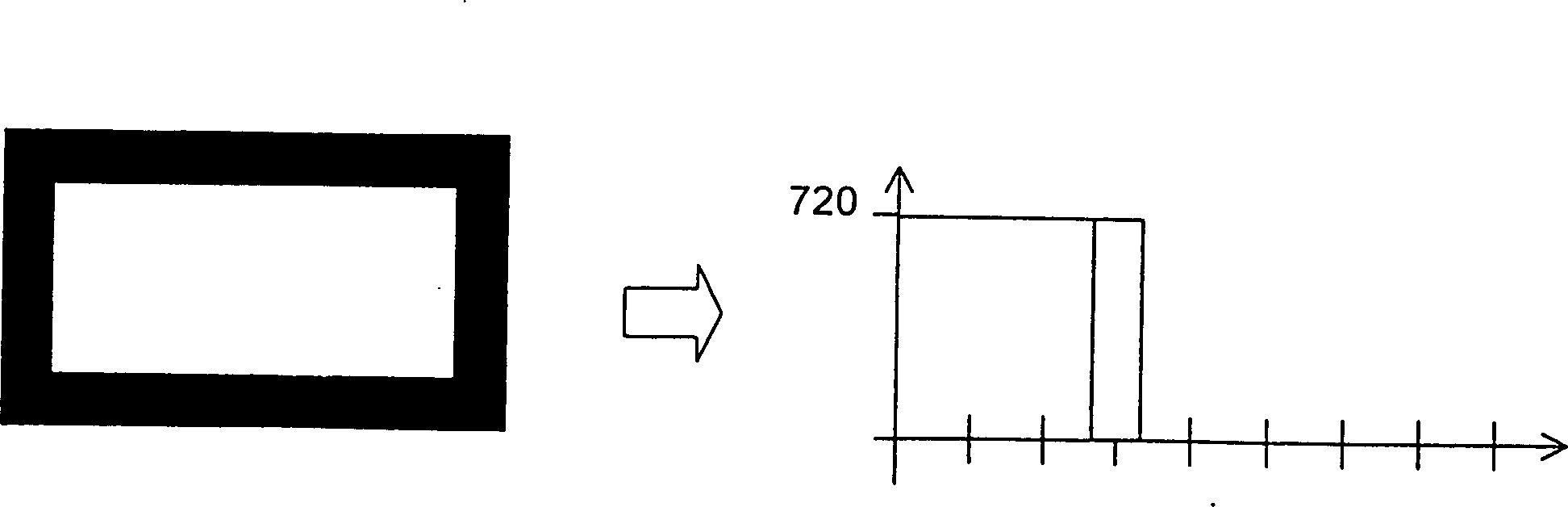

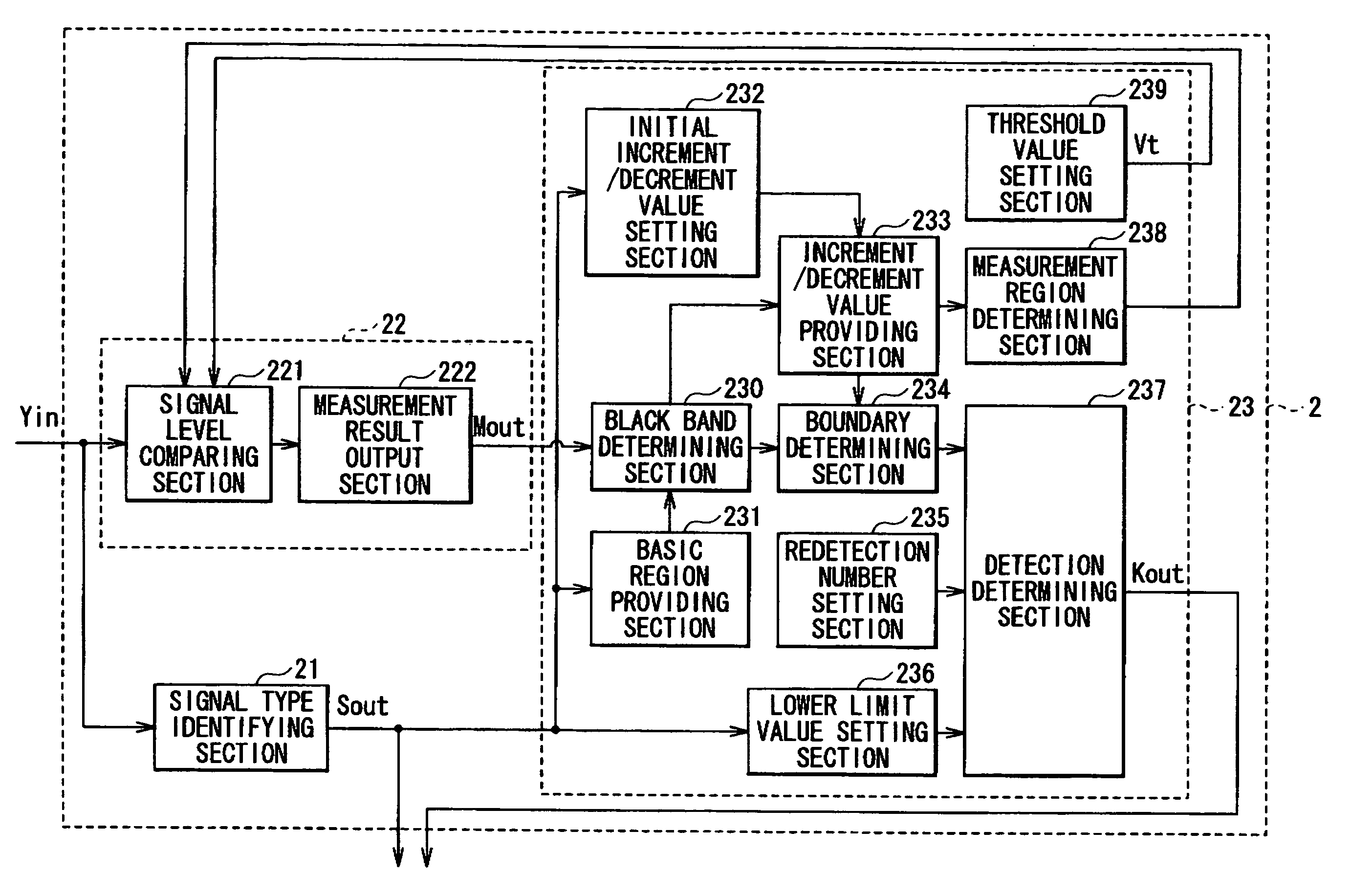

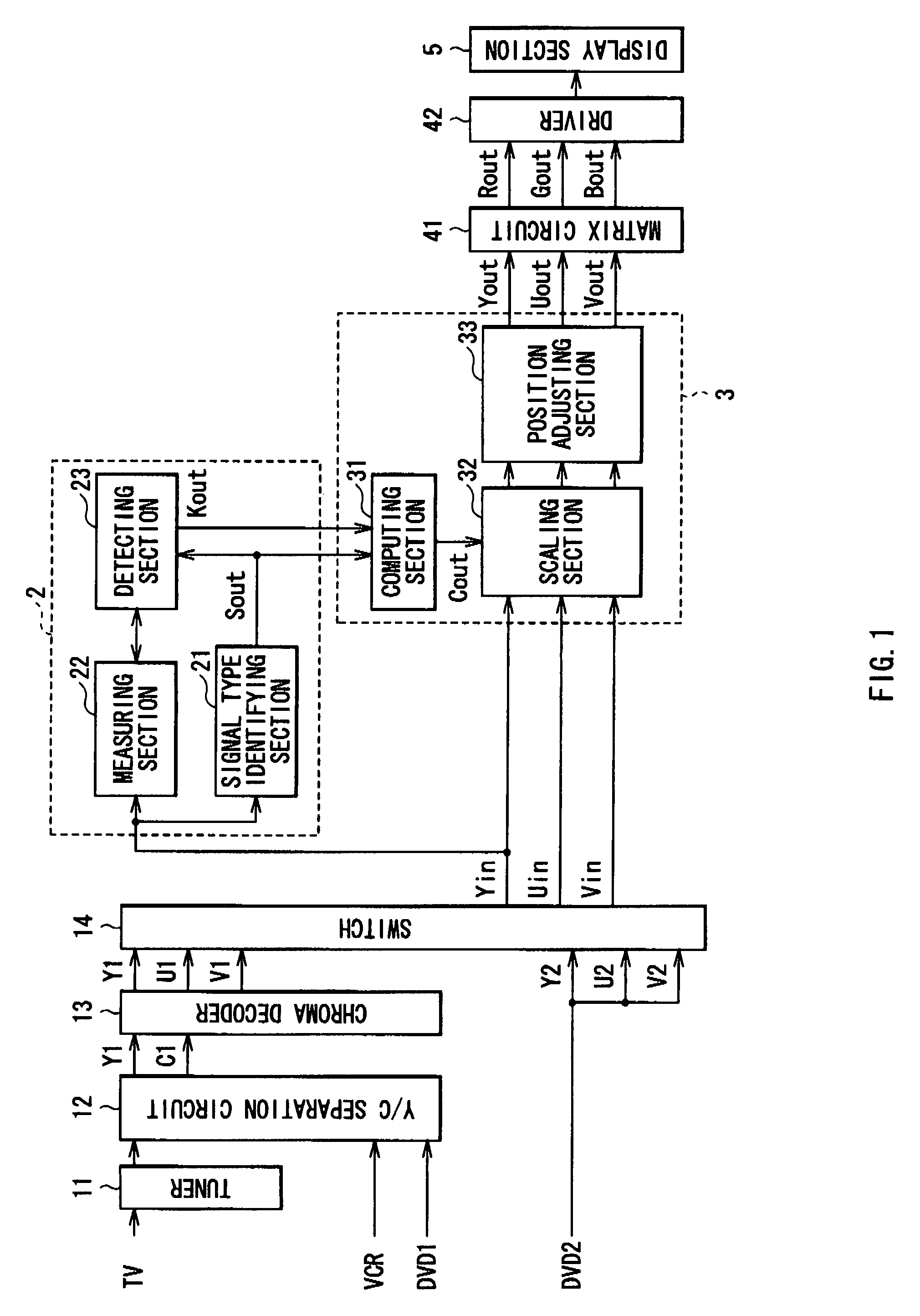

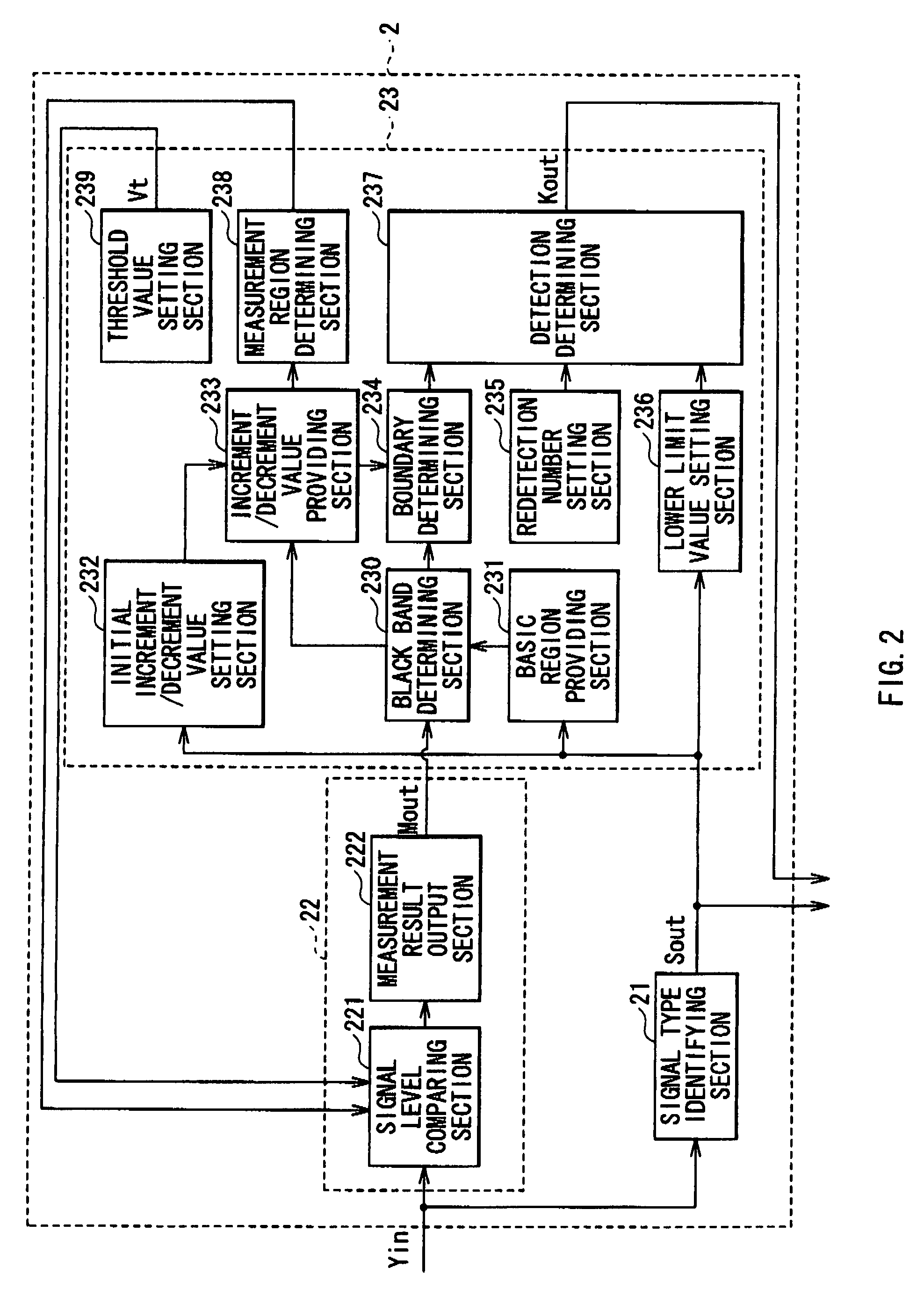

Image signal processing apparatus, image display and image display method

ActiveUS20080007655A1Improve imaging resolutionShort timeTelevision system detailsColor signal processing circuitsMeasurement deviceComputer science

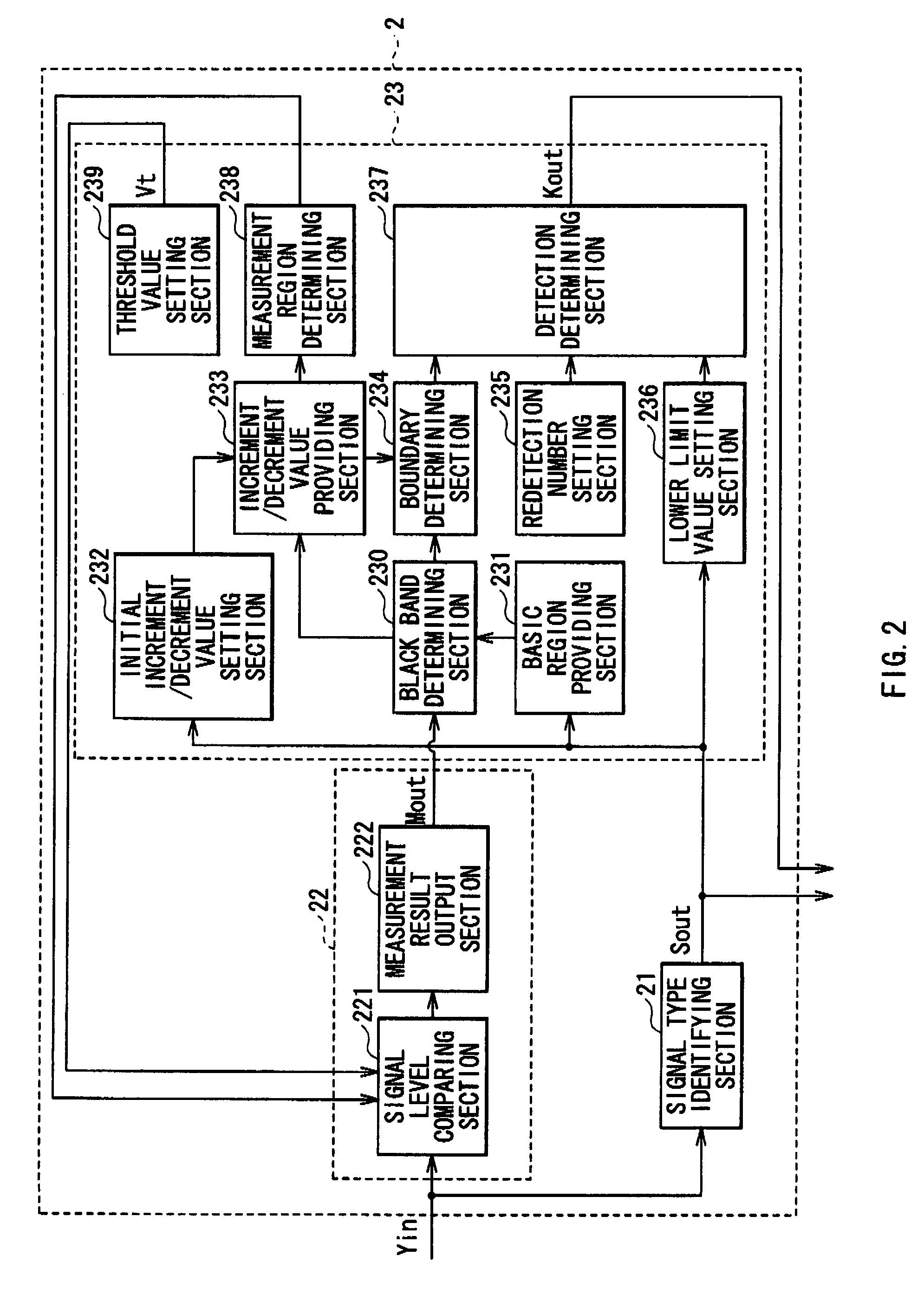

An image signal processing apparatus capable of detecting a black band region included in an input image signal in a shorter time is provided. The image signal processing apparatus may include a measuring means for measuring in a unit frame period whether each pixel in a designated measurement region of an input image signal has a signal level less than a threshold value; and a black band detecting means for detecting a black band region included in the input image signal on the basis of a measurement result from the measuring means.

Owner:SATURN LICENSING LLC

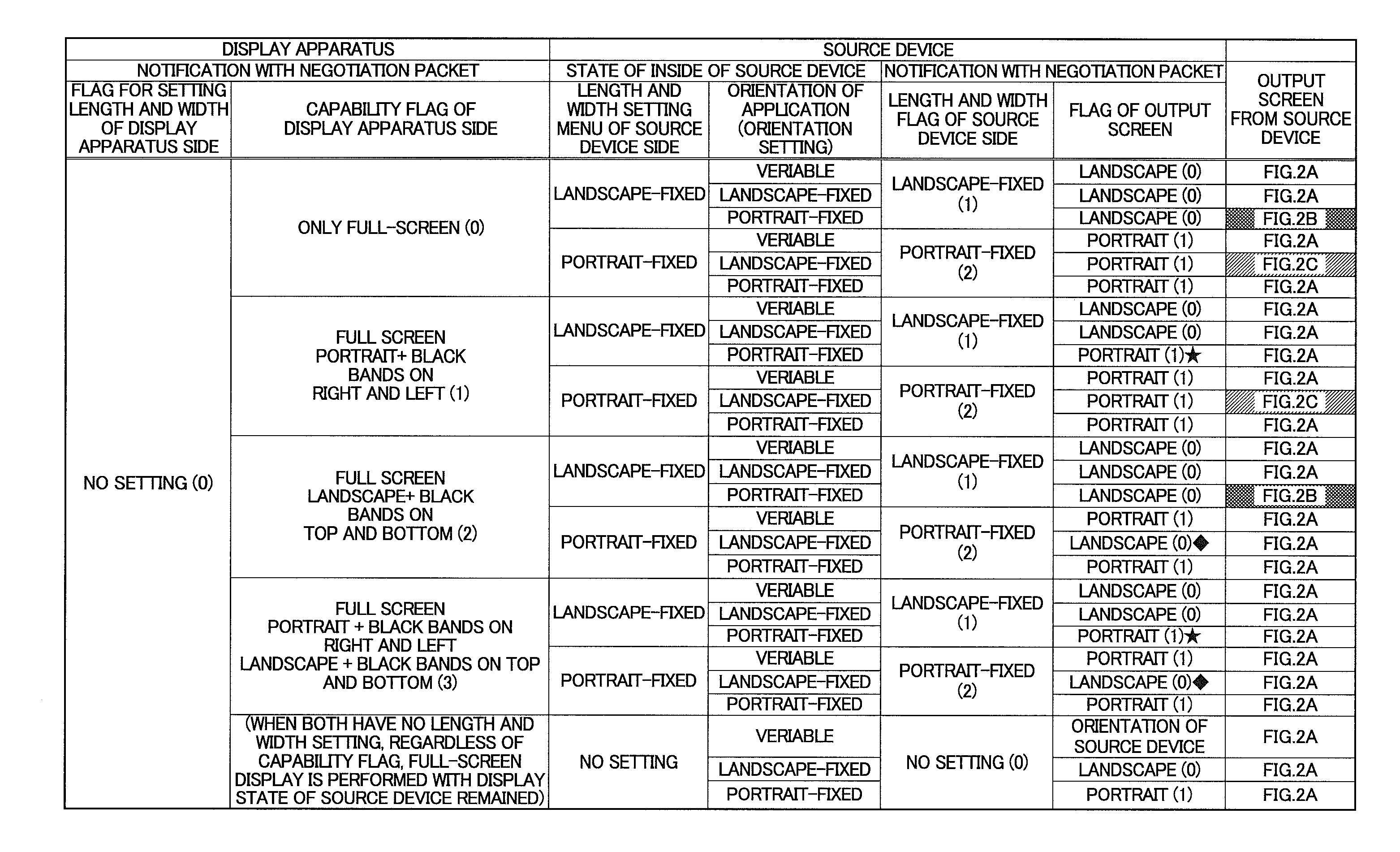

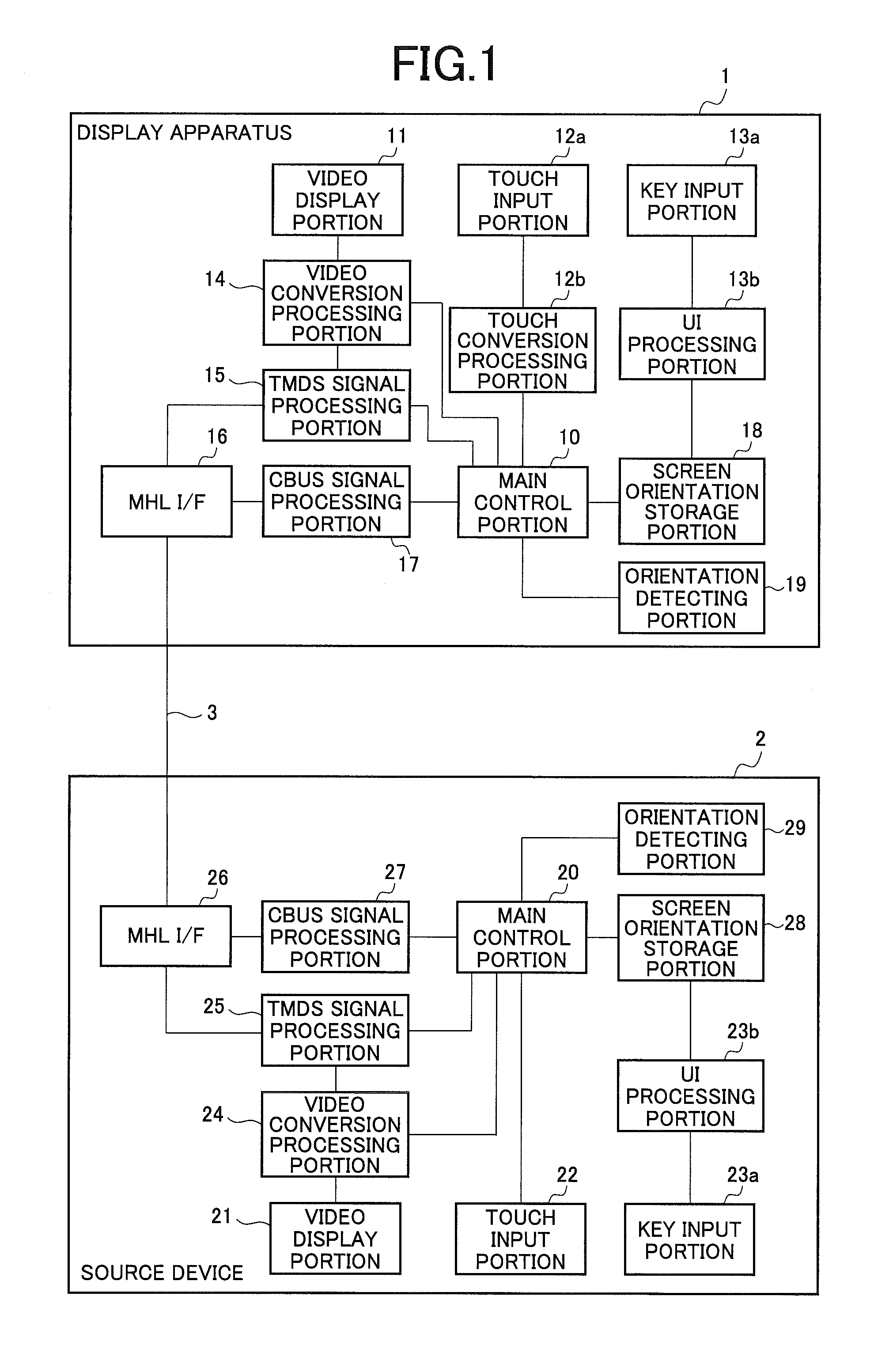

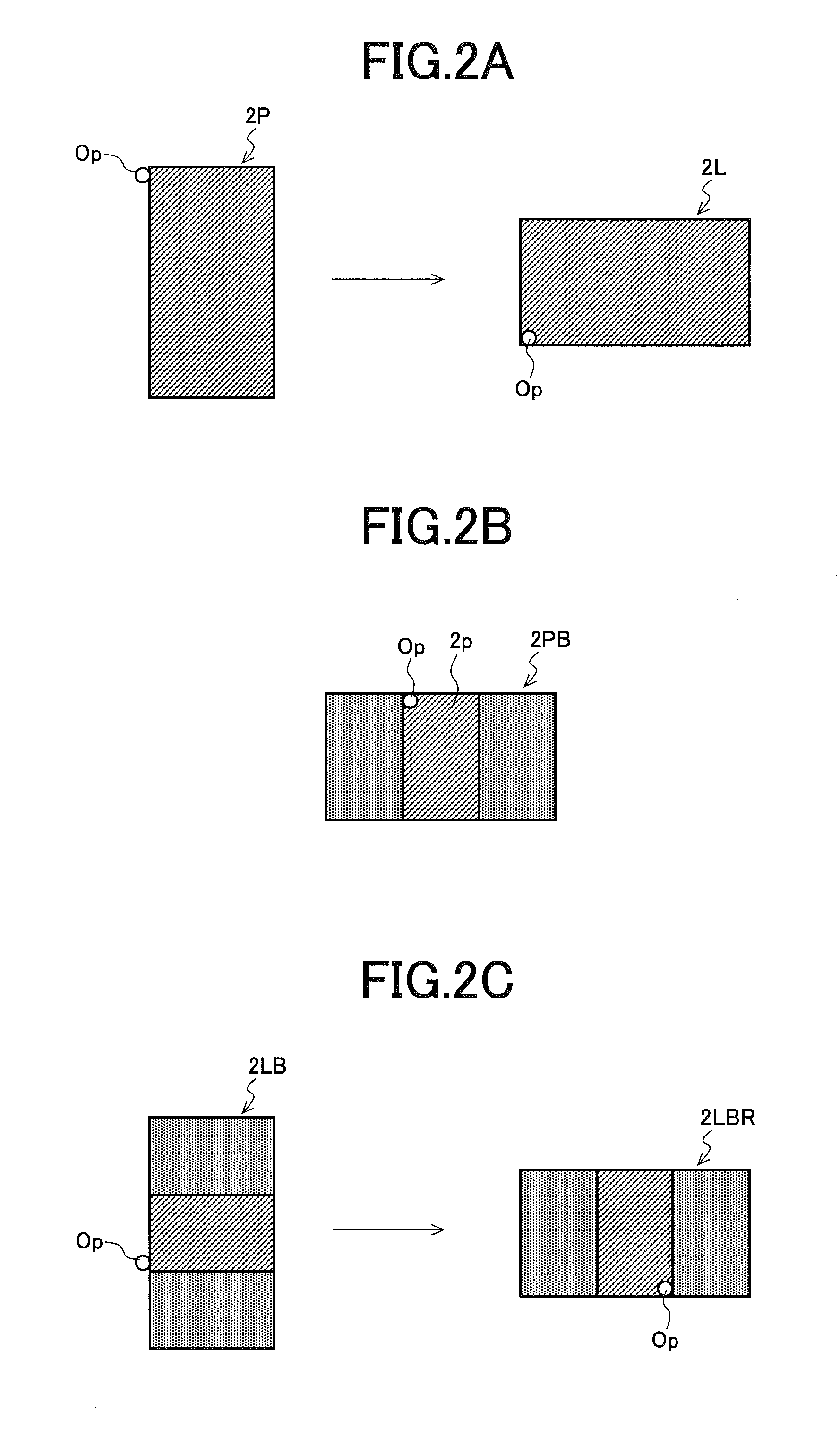

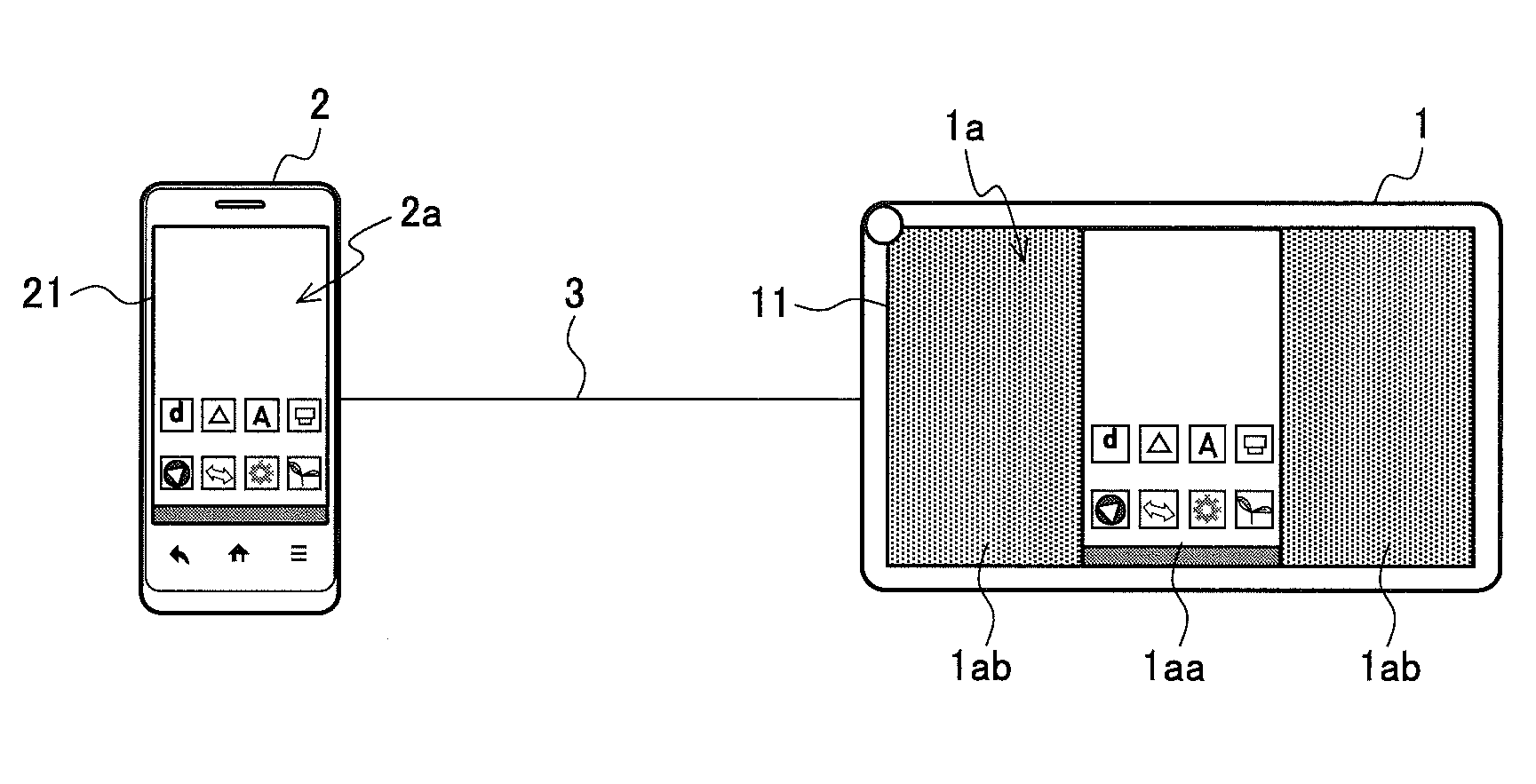

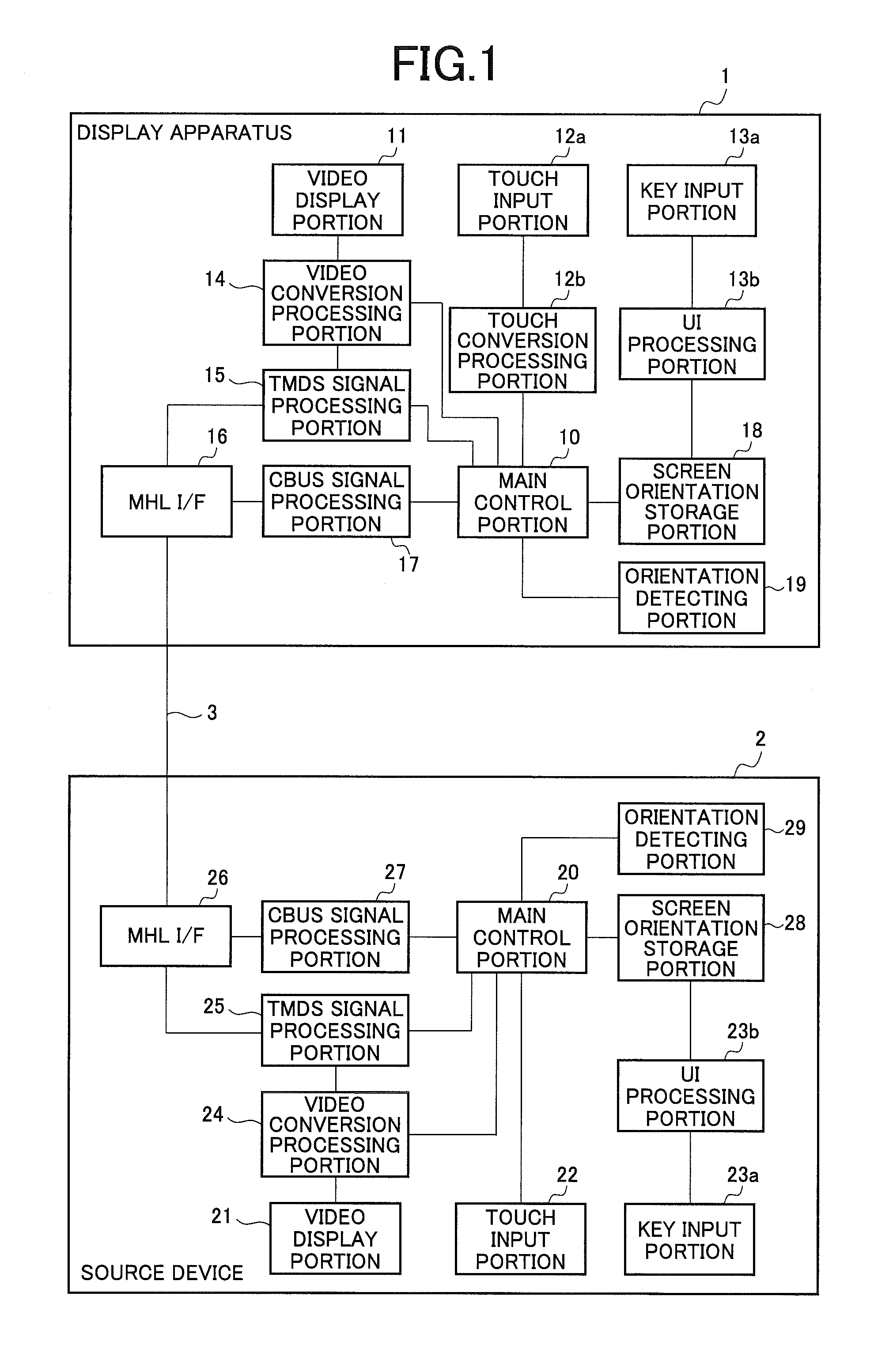

Display apparatus, source device and display system

ActiveUS20150091945A1Geometric image transformationCathode-ray tube indicatorsImaging processingComputer graphics (images)

A display apparatus includes an orientation detecting portion for detecting an orientation of an upper part or a lower part of a display screen of a display portion, a receiving portion for receiving an image signal transmitted from a source device and state information (information showing an orientation of an upper part or a lower part of the transmission image indicated by the image signal and presence / absence of black band parts), and image processing portion that applies, to the transmission image, any one or more processings among rotation processing for rotation such that the orientation of the upper part or the lower part of the display screen coincides with the orientation of the upper part or the lower part of the transmission image, scaling processing, and black-band processing for adding or removing black band parts, according to a detection result of the orientation detecting portion and the state information.

Owner:SHARP KK

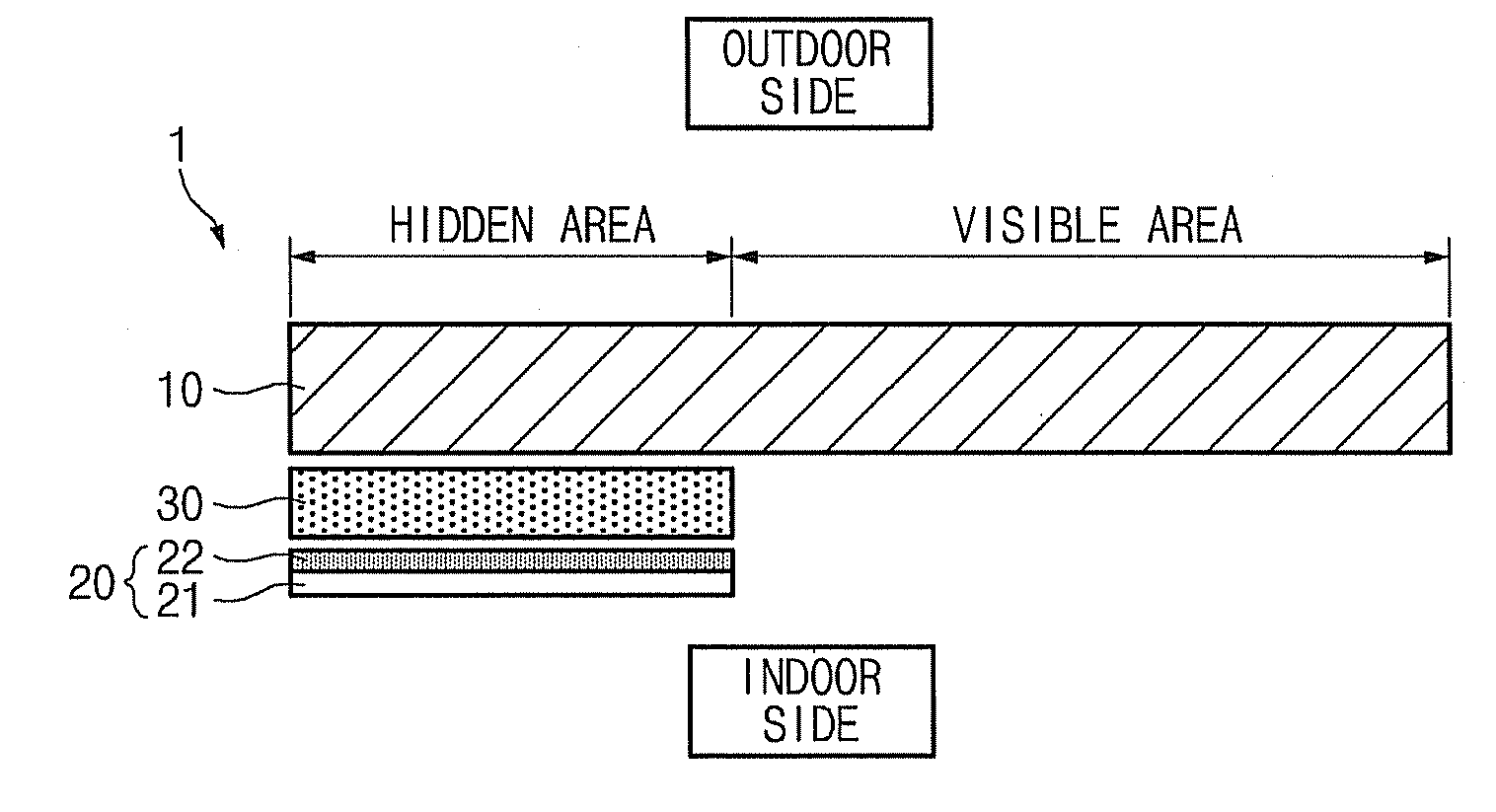

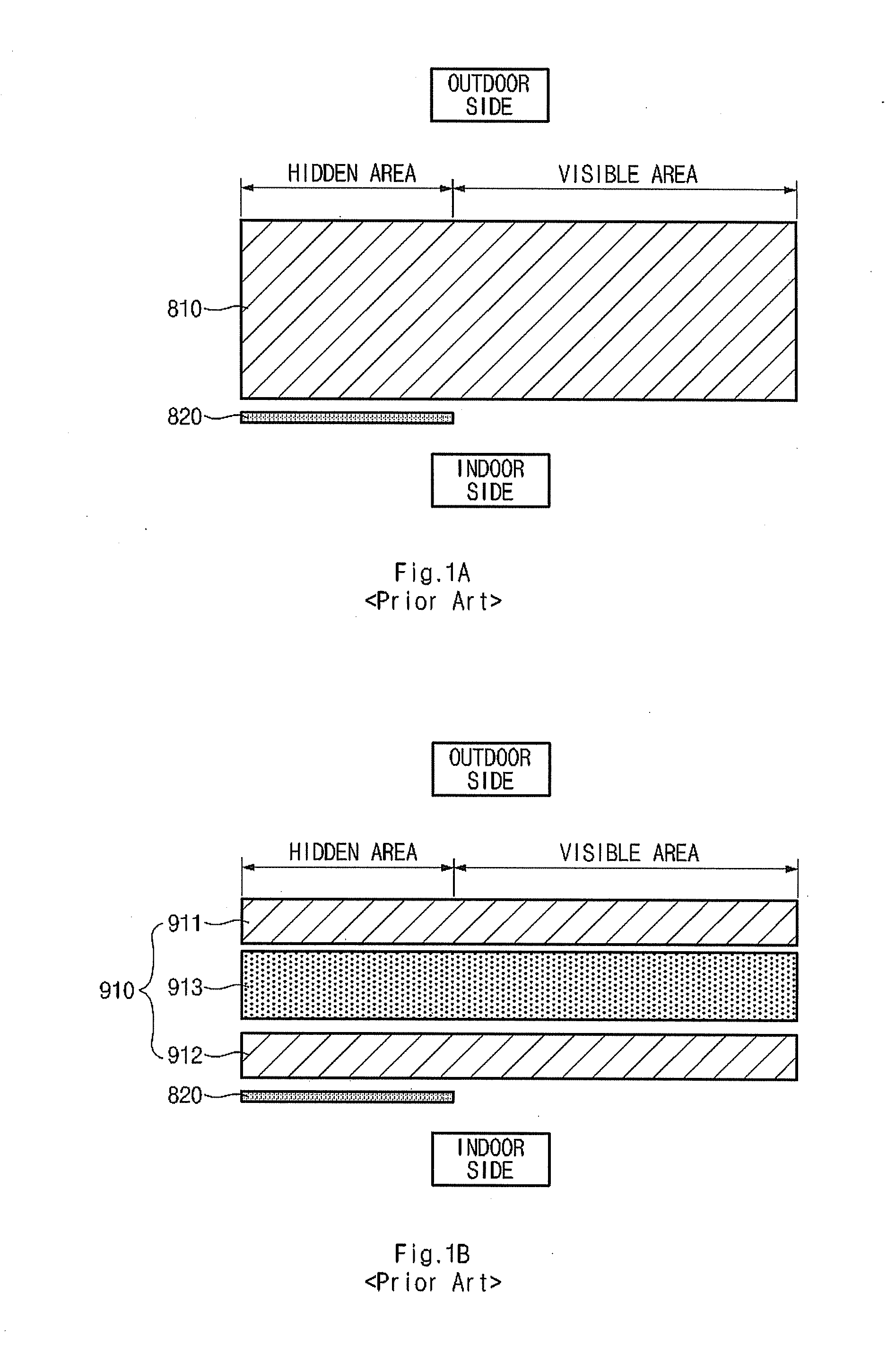

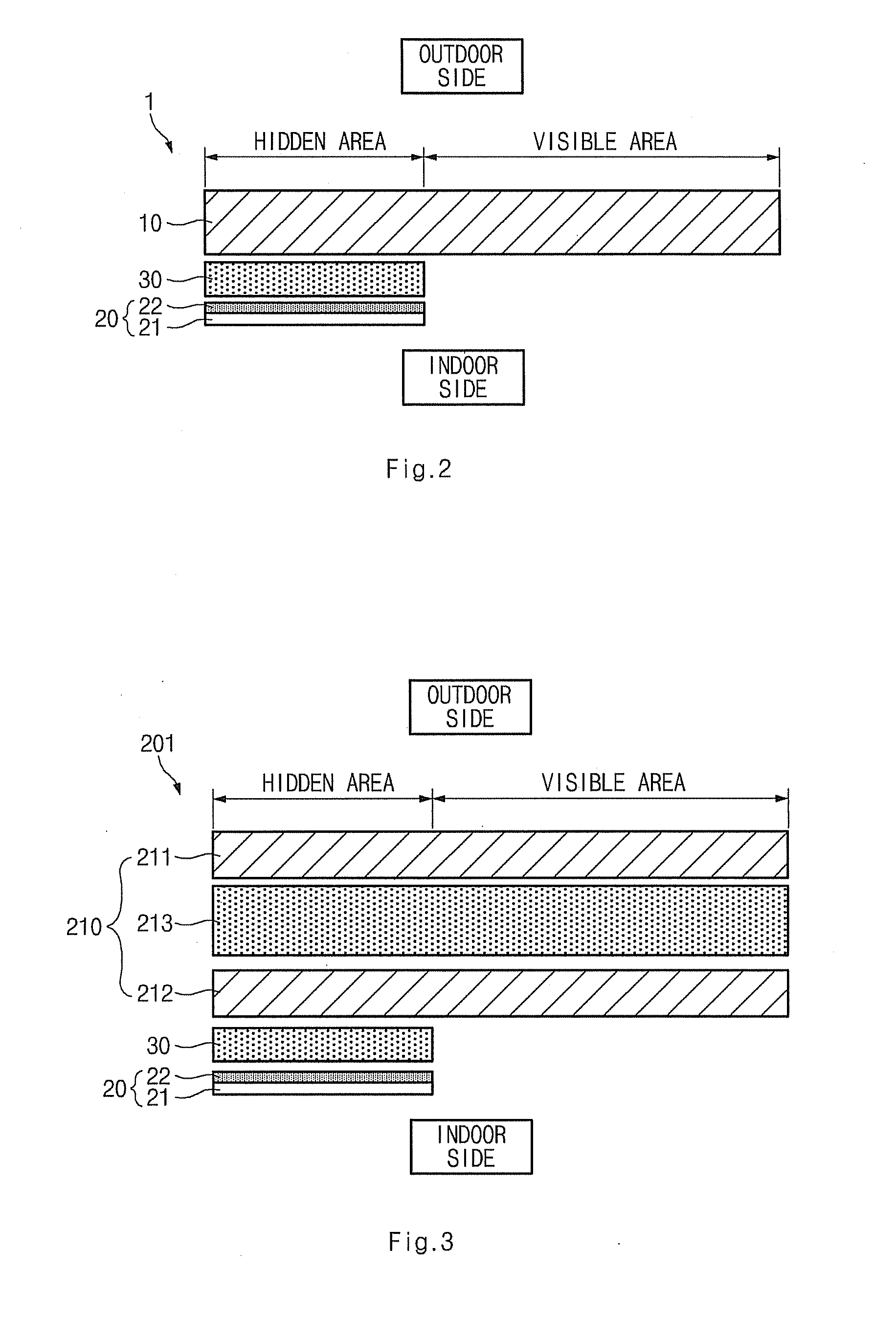

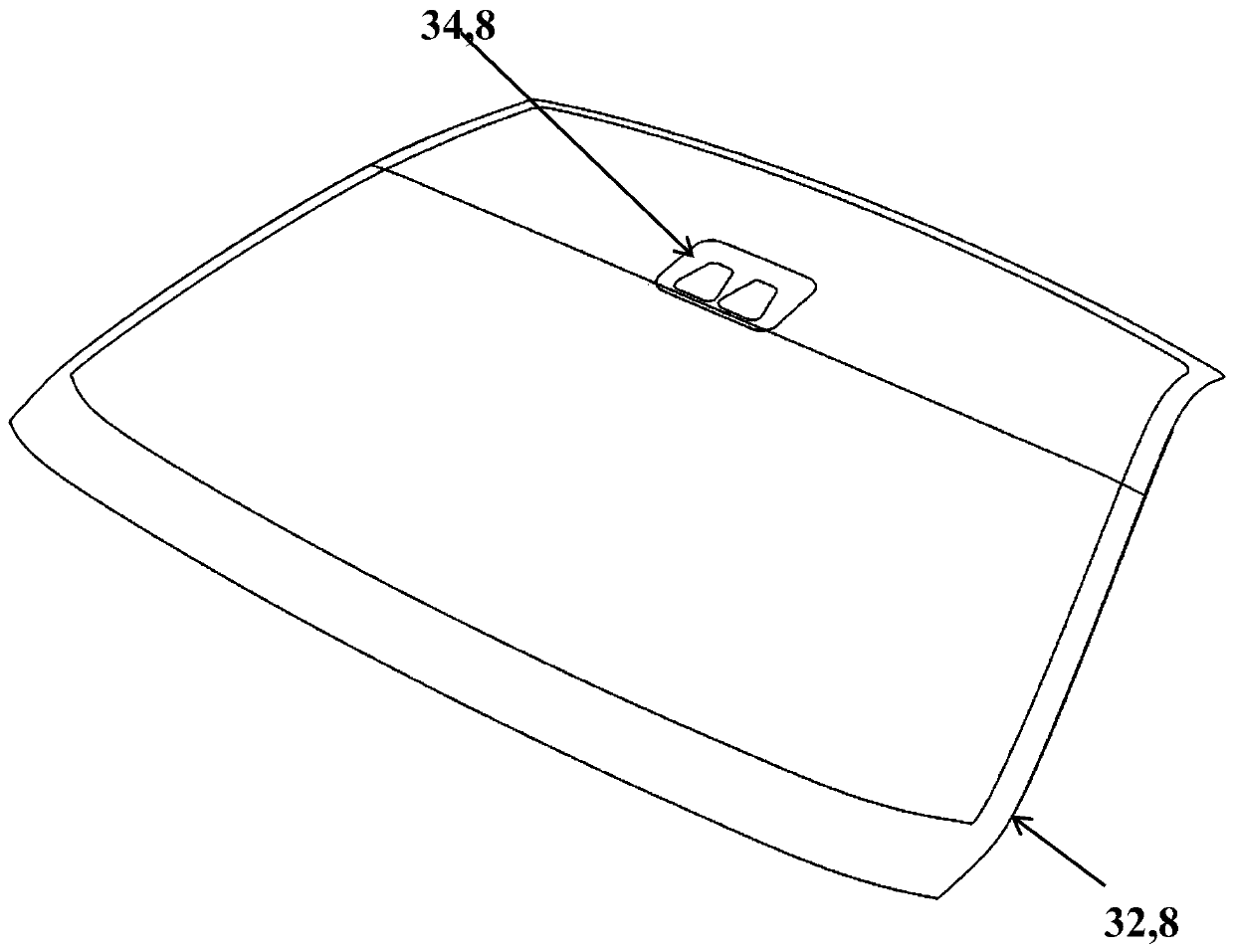

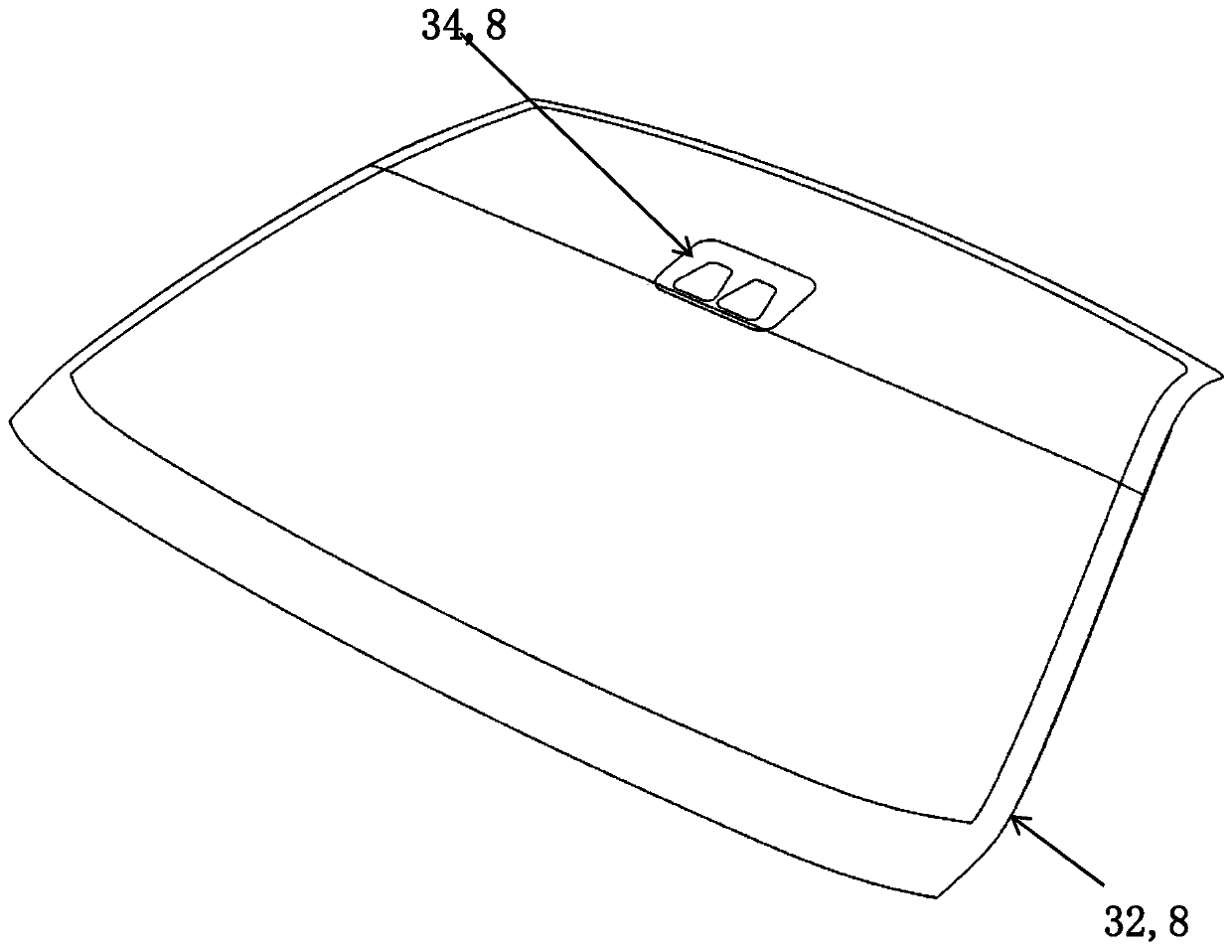

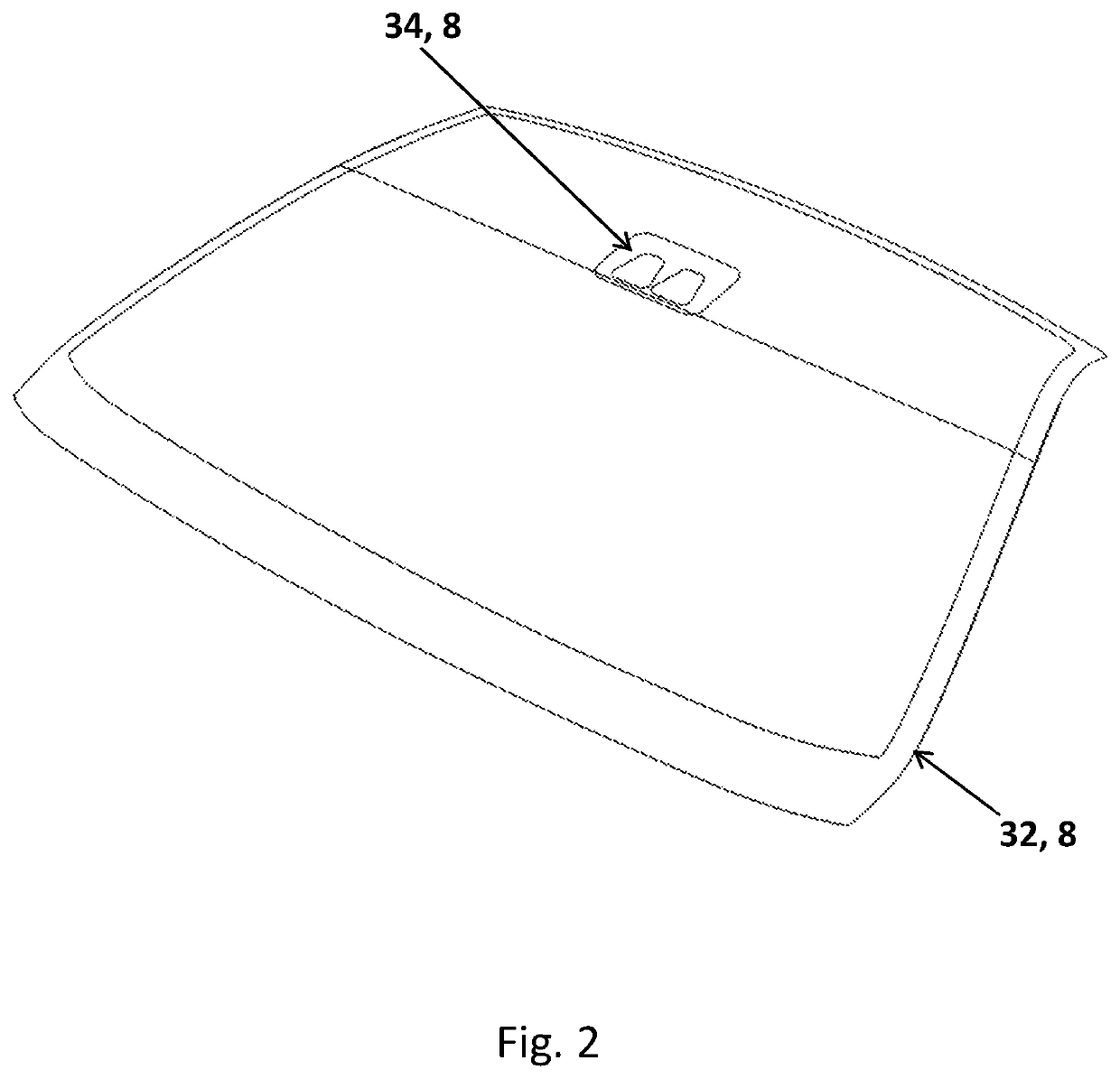

Glass window for a vehicle having a solar cell portion therewith

A glass window for a vehicle that is divided into a hidden area and a visible area is provided, which includes a glass portion, a solar cell portion provided inside the glass portion and composed of a substrate made of a flexible material and a plurality of solar cells disposed on an upper surface of the substrate in the hidden area, and a solar cell adhesive film disposed between the glass portion and the solar cell portion. Since solar cells are provided in a black band / hidden portion of the glass window instead of mounting the solar cells within a separate thick piece of glass of the roof of the vehicle, the amount of weight traditionally added to a vehicle can be minimized.

Owner:HYUNDAI MOTOR CO LTD

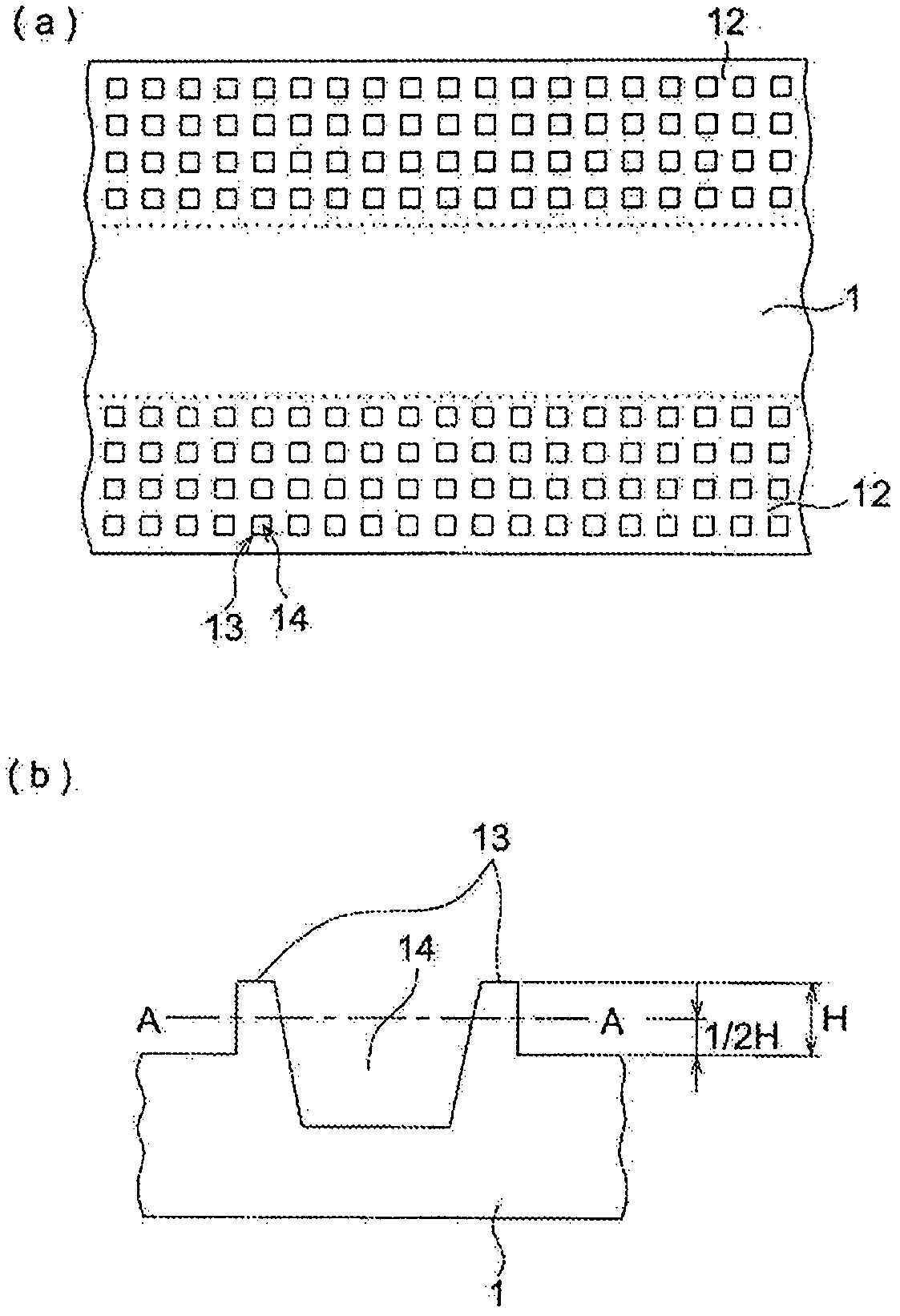

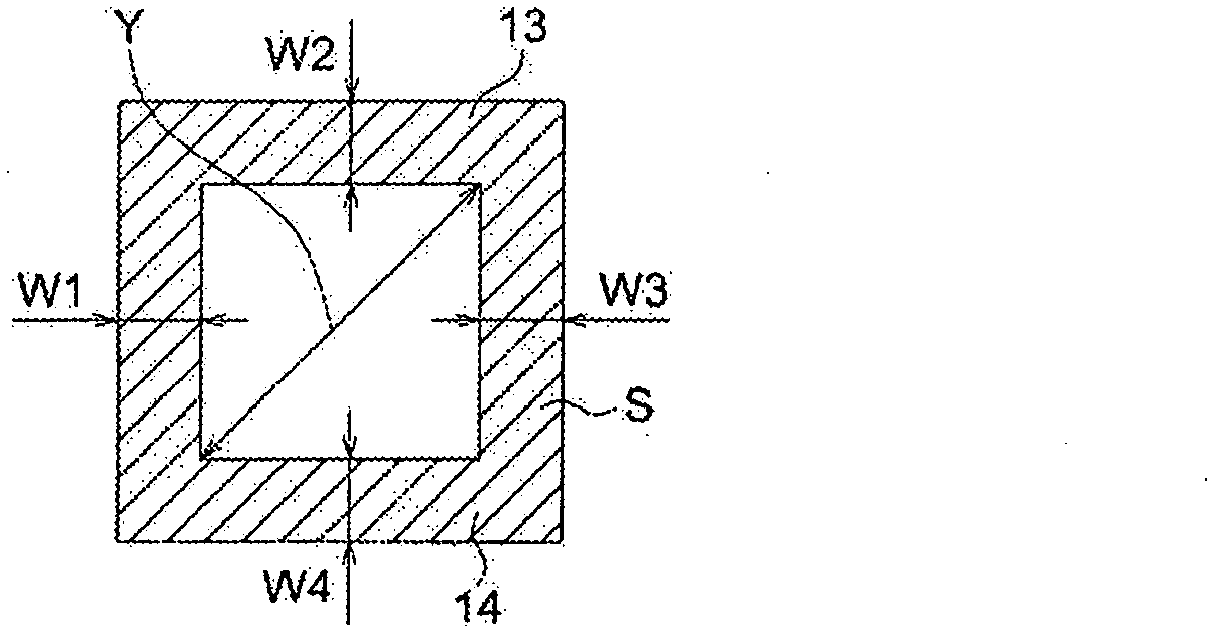

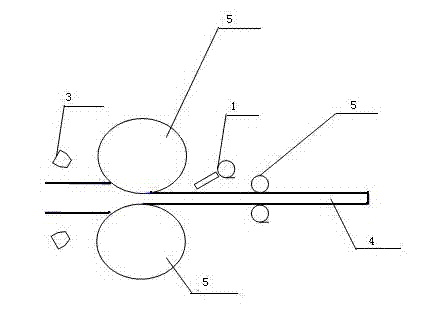

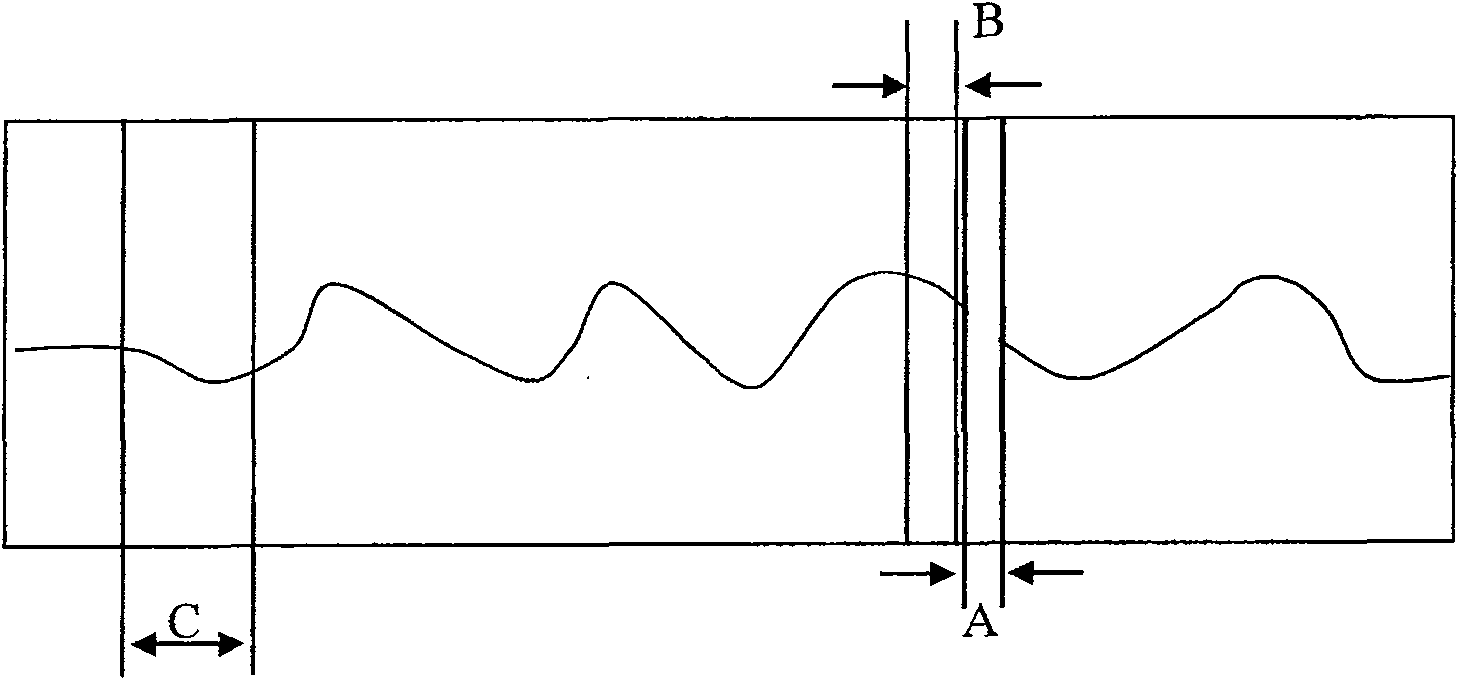

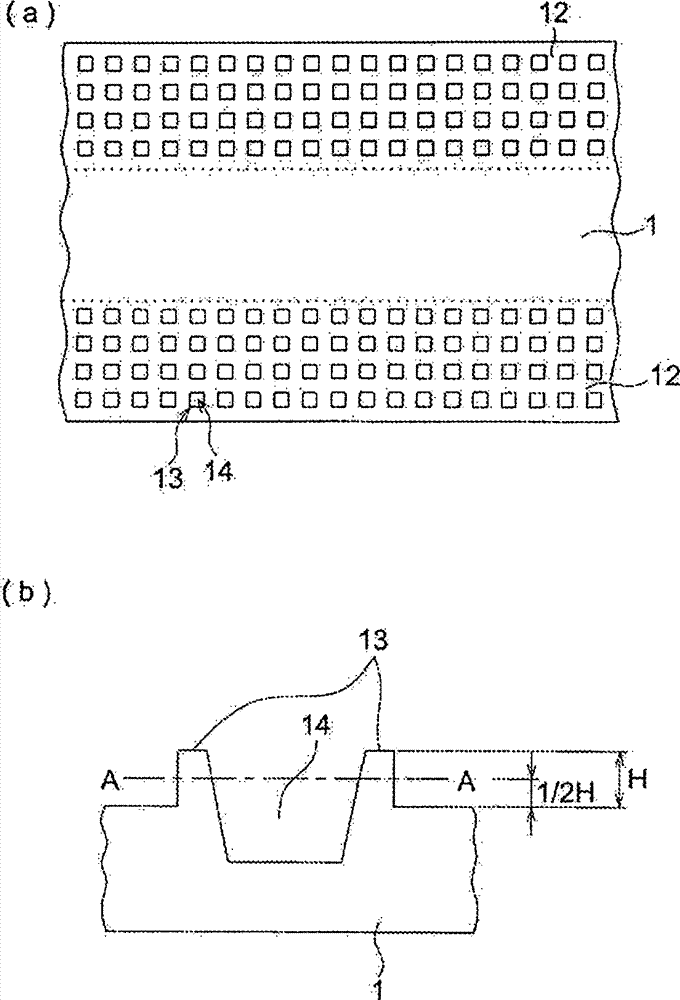

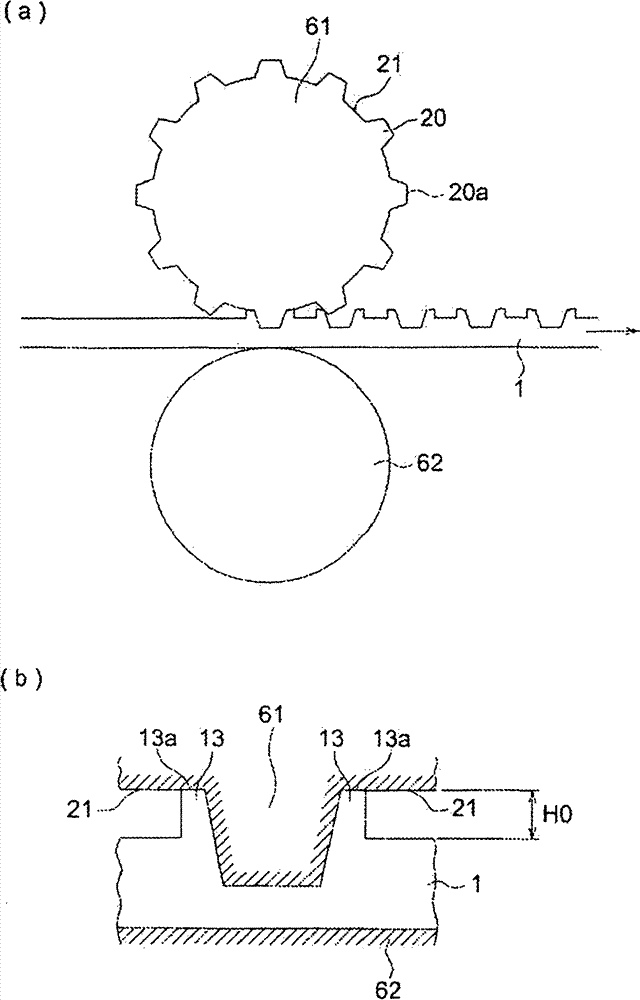

Method of manufacturing optical film, optical film, deflection plate, and liquid crystal display device

ActiveCN102483481ANon-blockingWrinkle freeOptical articlesPolarising elementsWrinkle skinForeign matter

Disclosed is a method of manufacturing an optical film wherein a failure due to foreign matters, a black band while the film is rolled, and blocking never occur in the surface of the film, eliminating wrinkles and flaws. The method of manufacturing the optical film comprises a process of clamping a member comprising a plurality of projections onto both side edge sections of the long film in the width direction, thereby knurling the side edge sections by irregularity, and a process of taking up the film. In the process of knurling, the height of projecting portions formed by a film member clamped away by the projections when the projections are clamped onto the surface of the film is restricted by a flat portion configuring the base of the projections, so that the height of the projecting portions is determined height.

Owner:KONICA MINOLTA OPTO

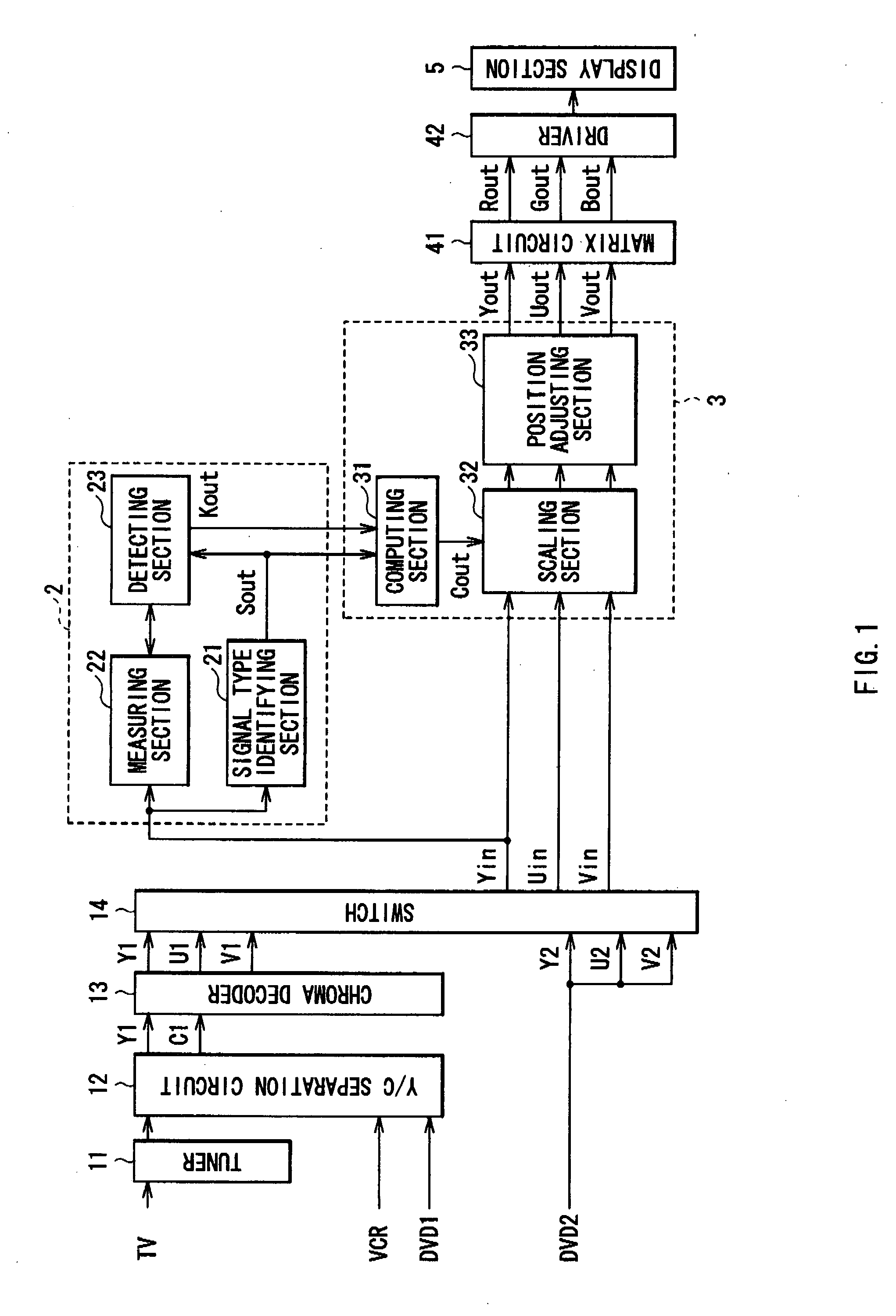

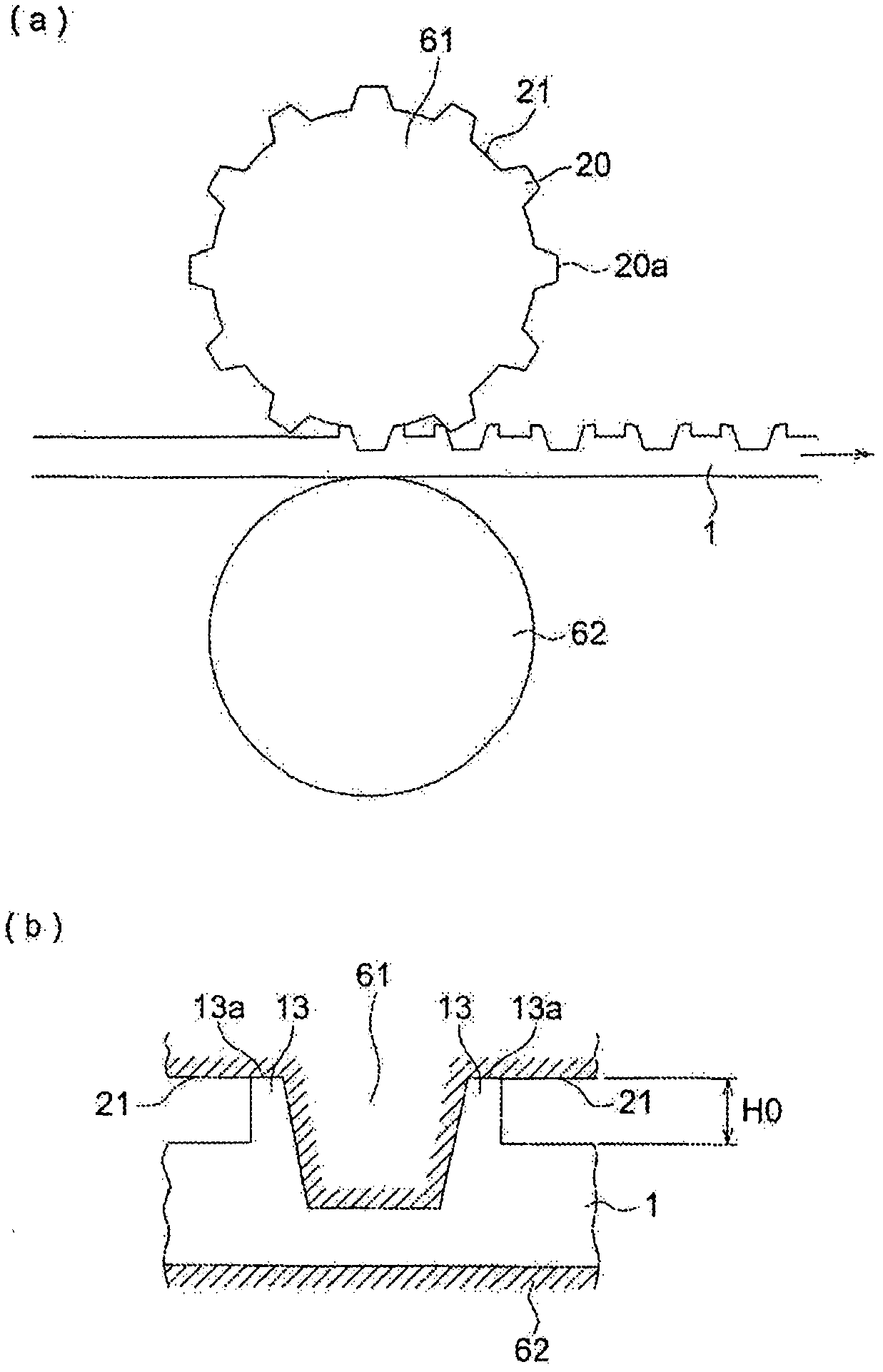

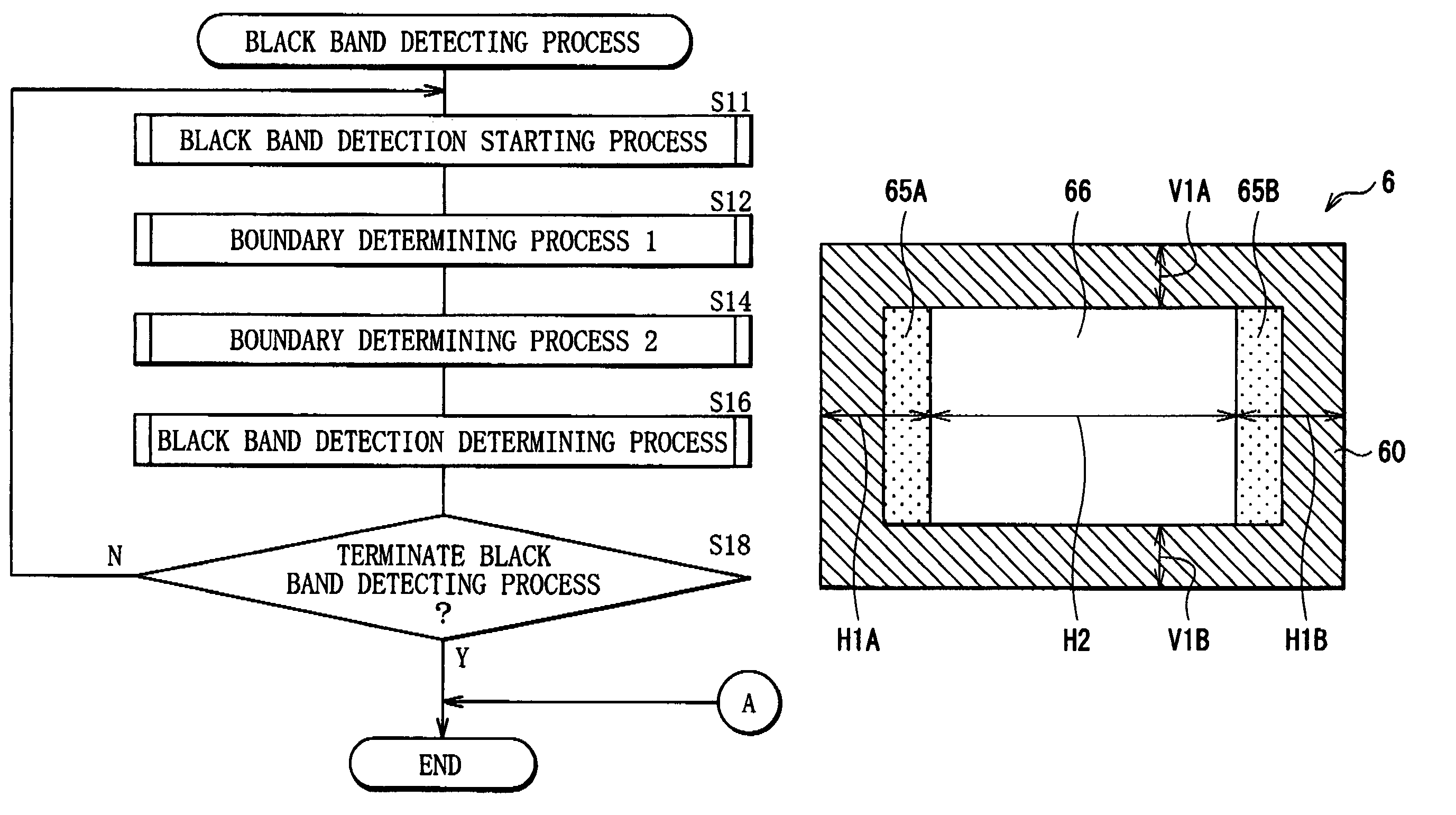

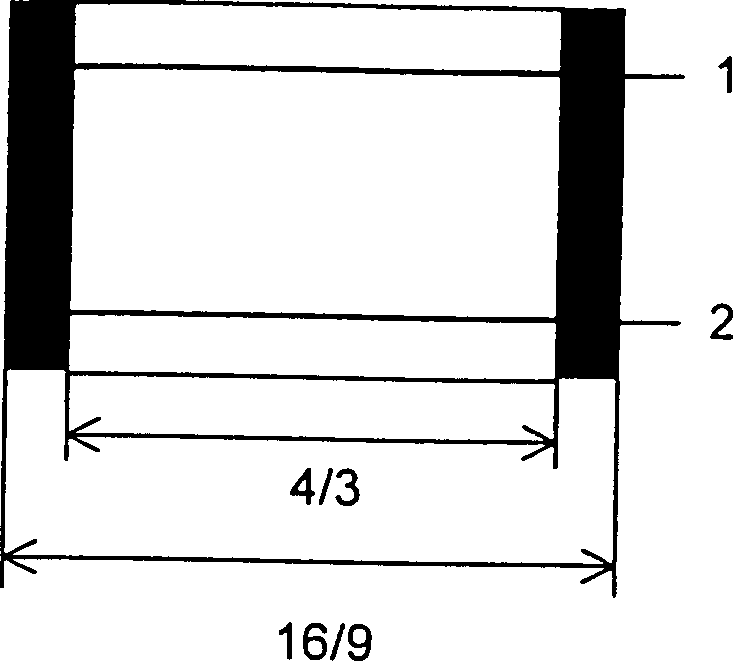

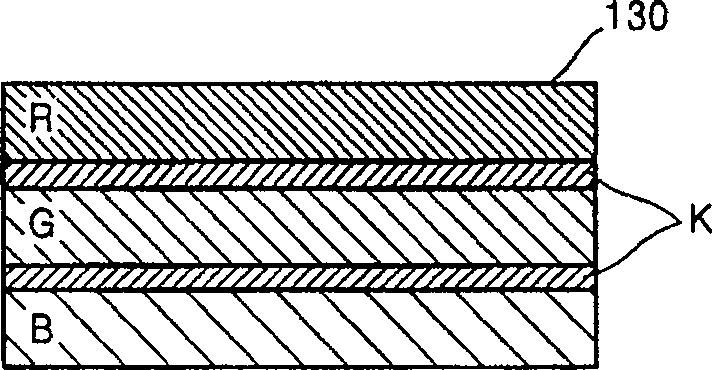

Image signal processing apparatus, image display, and image display method

InactiveUS20070296866A1Improve imaging resolutionShort timeTelevision system detailsColor signal processing circuitsPattern recognitionDisplay device

An image signal processing apparatus, an image display, and an image display method that enable detecting a black band region included in an input image signal in a shorter time and realizes a more viewable image are provided. The image signal processing apparatus includes a black band detecting means for detecting in a unit frame period a black band region included in an input image signal, a calculating means for calculating a scaling ratio of the input image signal while maintaining an aspect ratio thereof based on a detection result from the black band detecting means, and a scaling means for scaling the input image signal up or down based on the ratio obtained by the calculating means.

Owner:SONY CORP

Image signal processing apparatus, image display and image display method

ActiveUS8098328B2Improve imaging resolutionShort timeTelevision system detailsColor signal processing circuitsComputer scienceImage signal

An image signal processing apparatus capable of detecting a black band region included in an input image signal in a shorter time is provided. The image signal processing apparatus may include a measuring means for measuring in a unit frame period whether each pixel in a designated measurement region of an input image signal has a signal level less than a threshold value; and a black band detecting means for detecting a black band region included in the input image signal on the basis of a measurement result from the measuring means.

Owner:SATURN LICENSING LLC

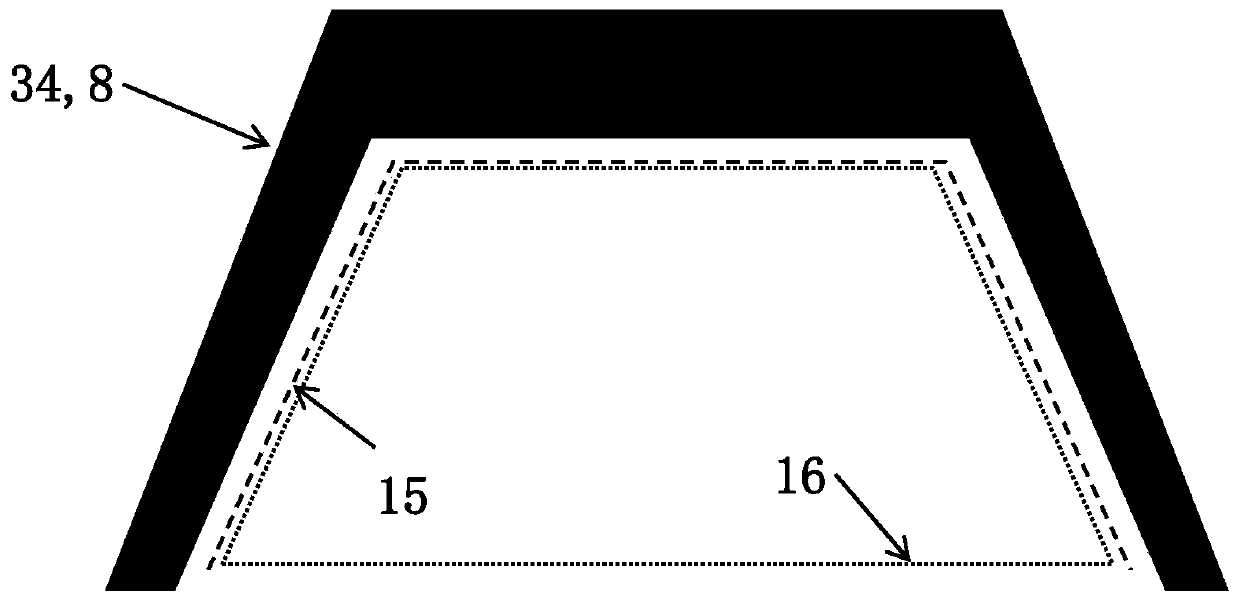

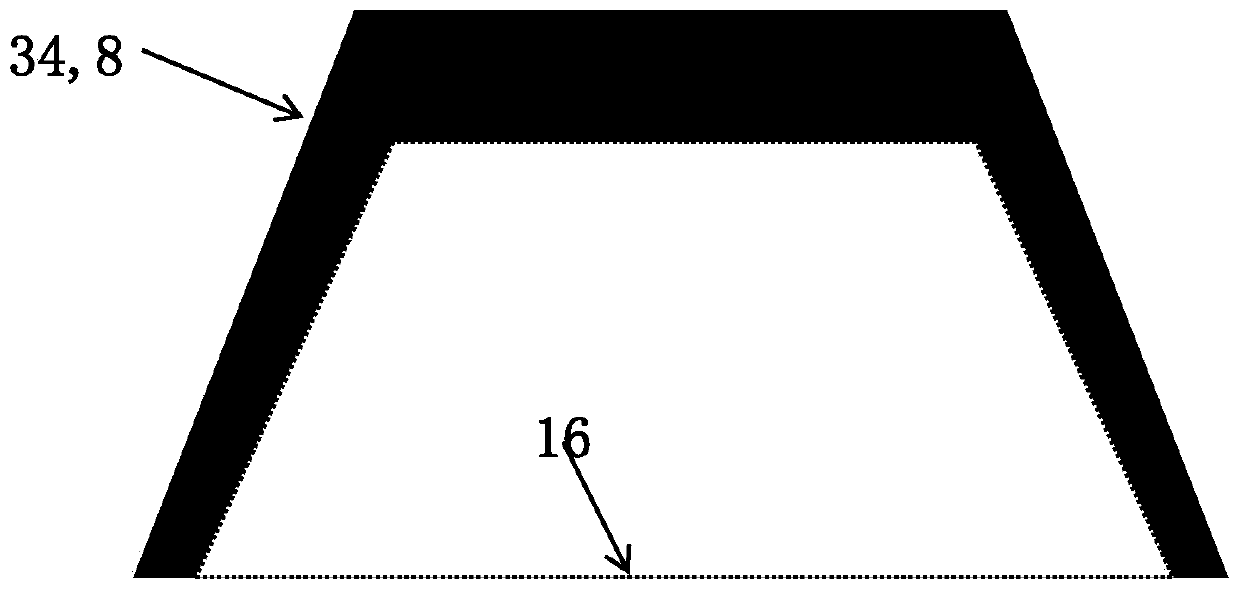

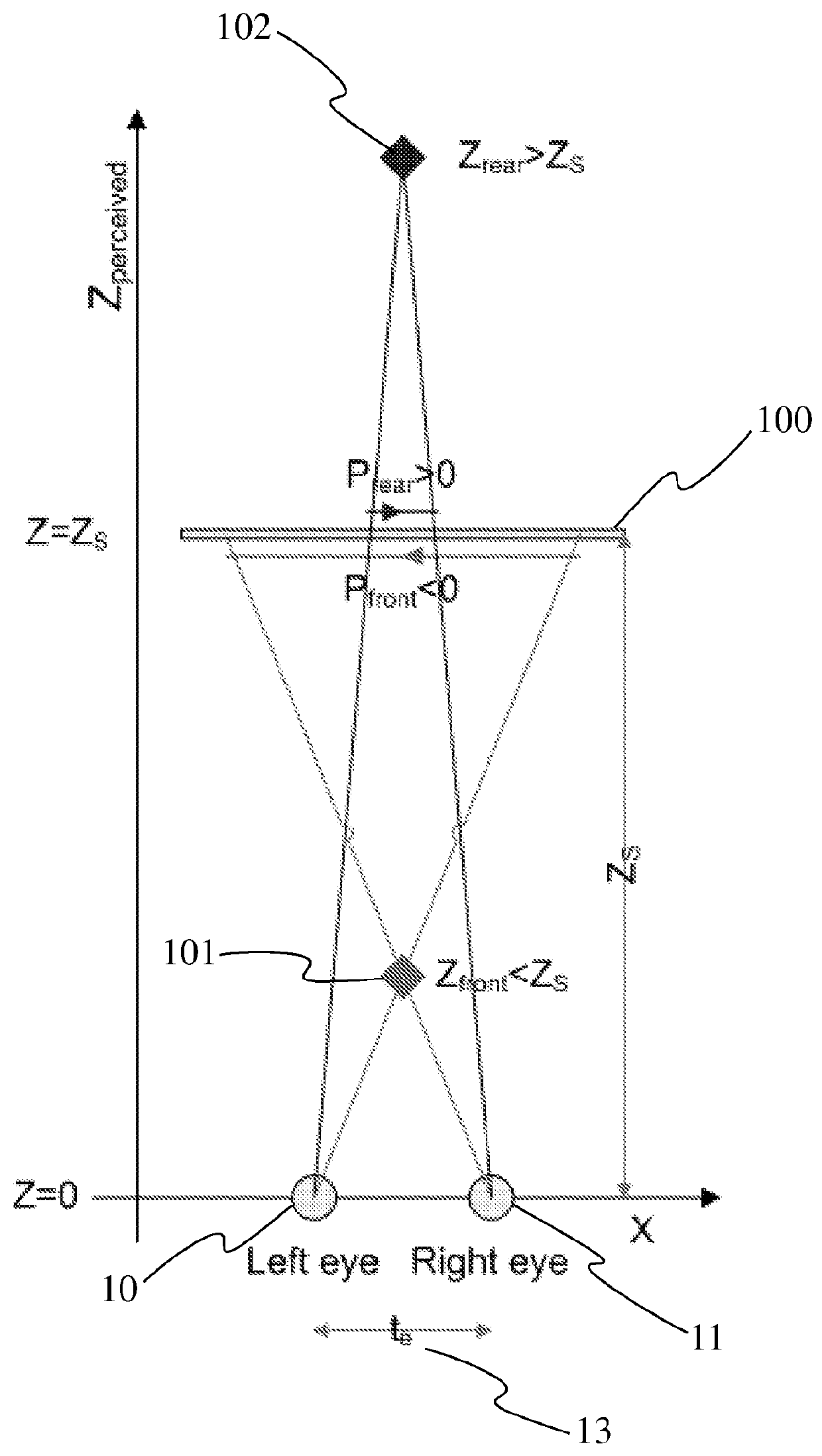

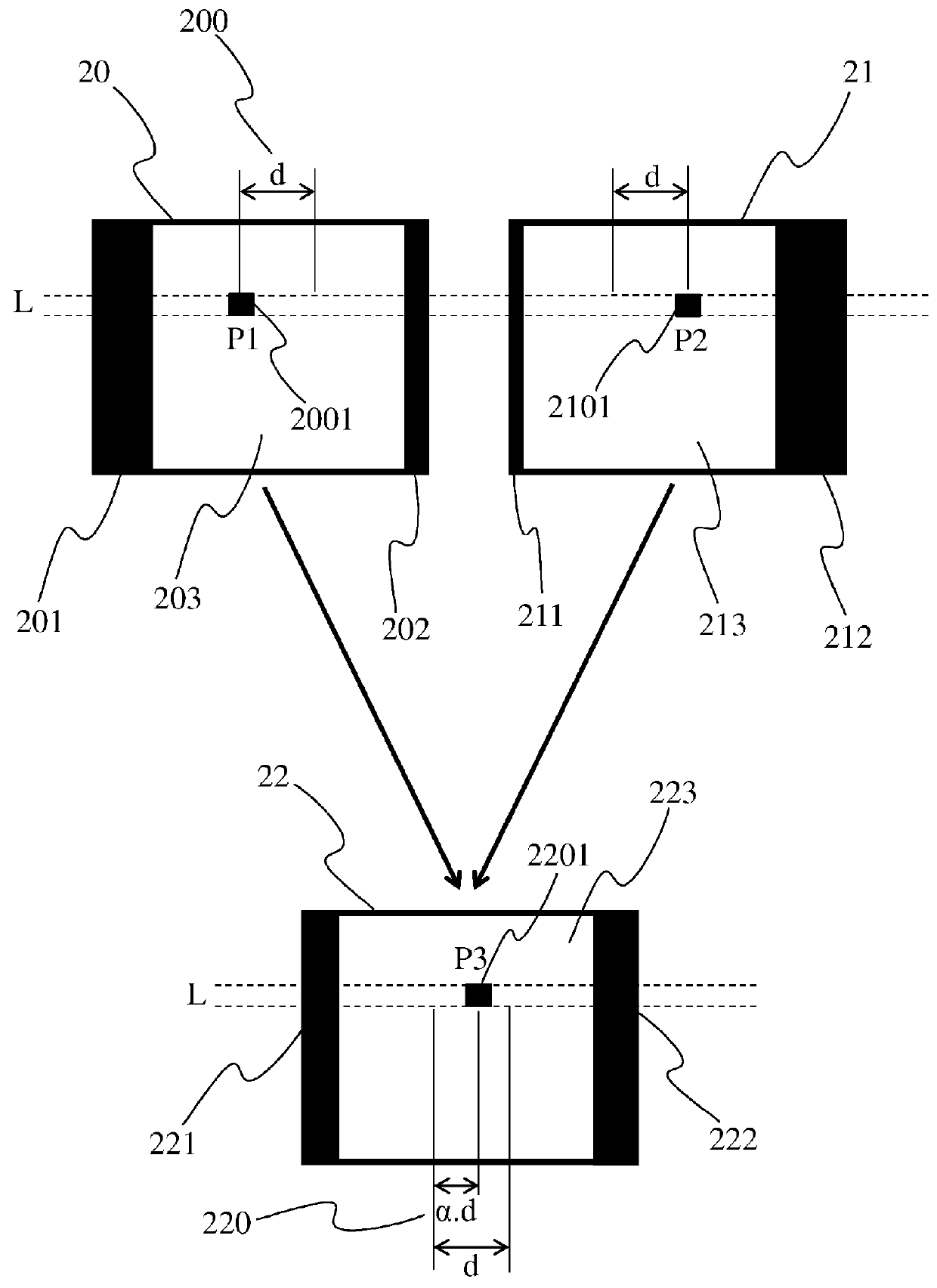

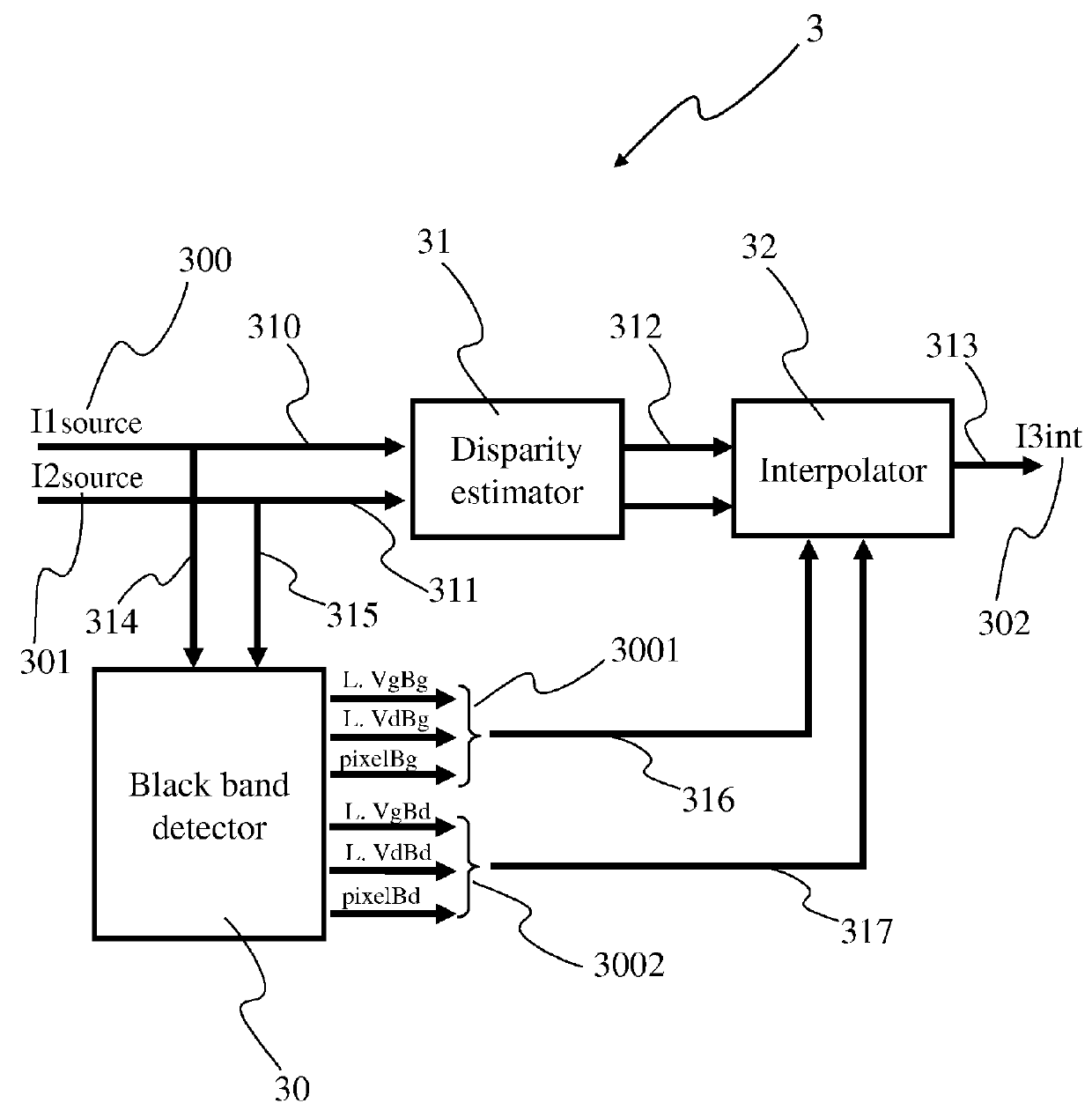

Method for Processing a Stereoscopic Image Comprising a Black Band and Corresponding Device

ActiveUS20120206569A1Reduce displayGeometric image transformationSteroscopic systemsImaging processingDisplay device

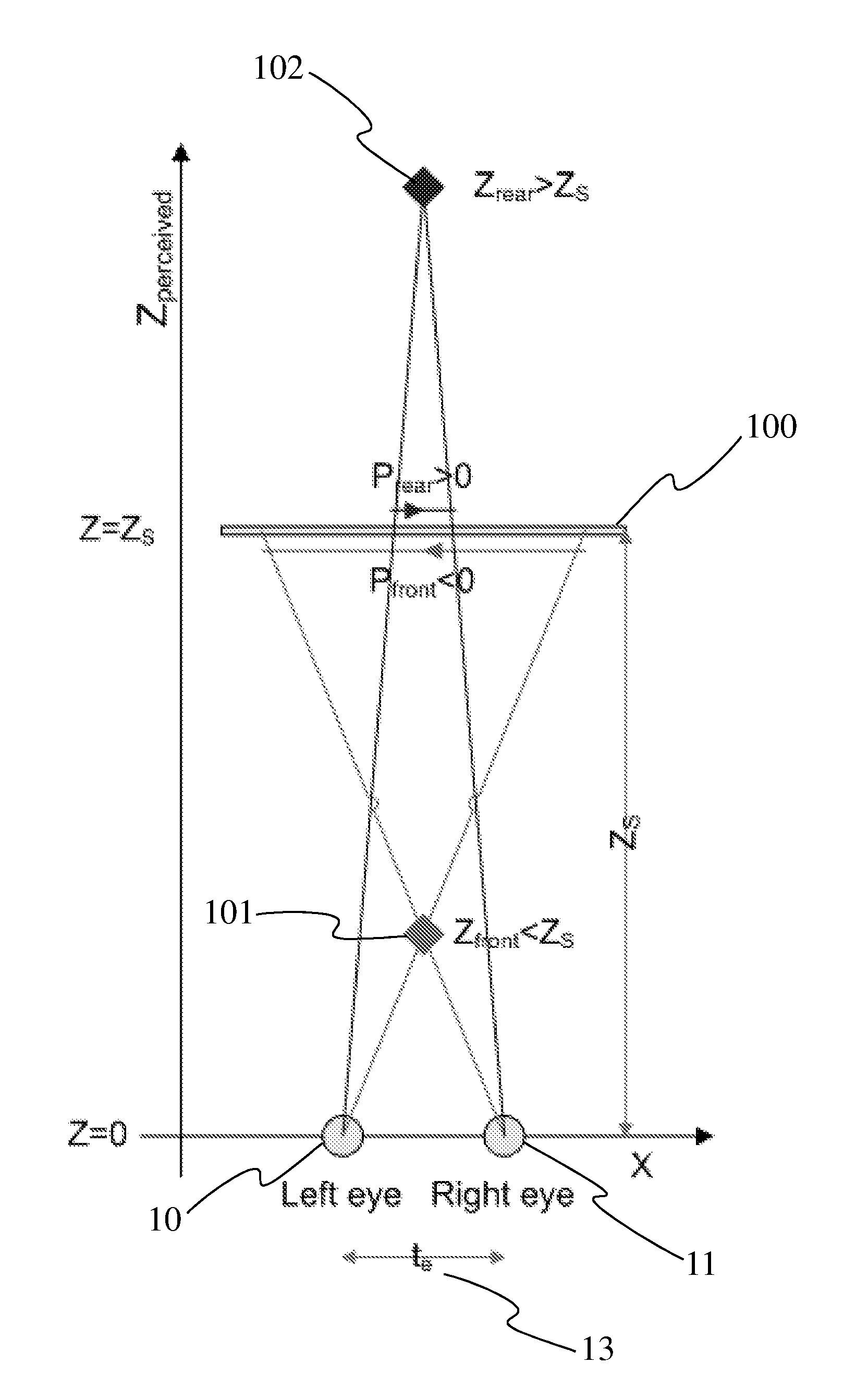

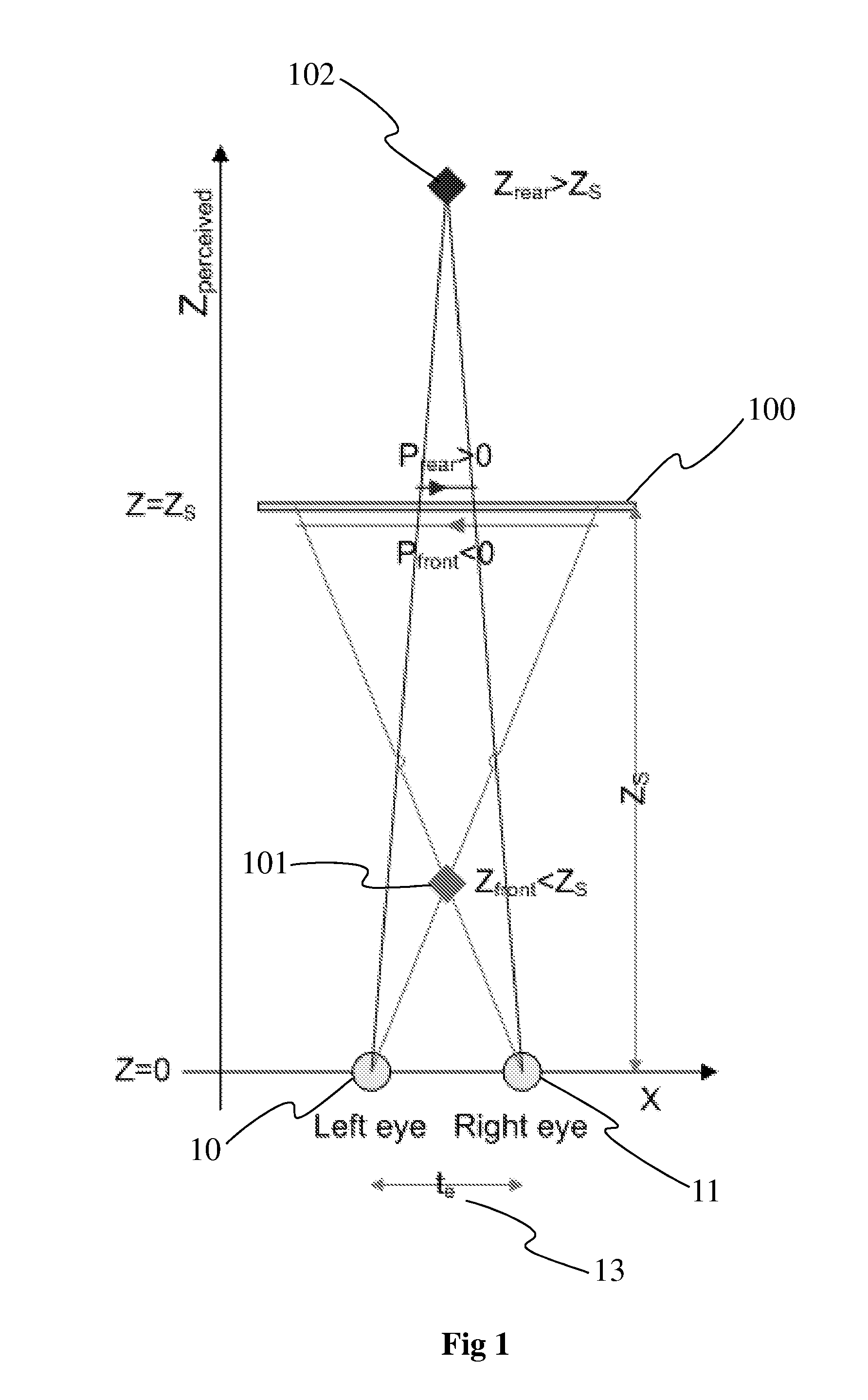

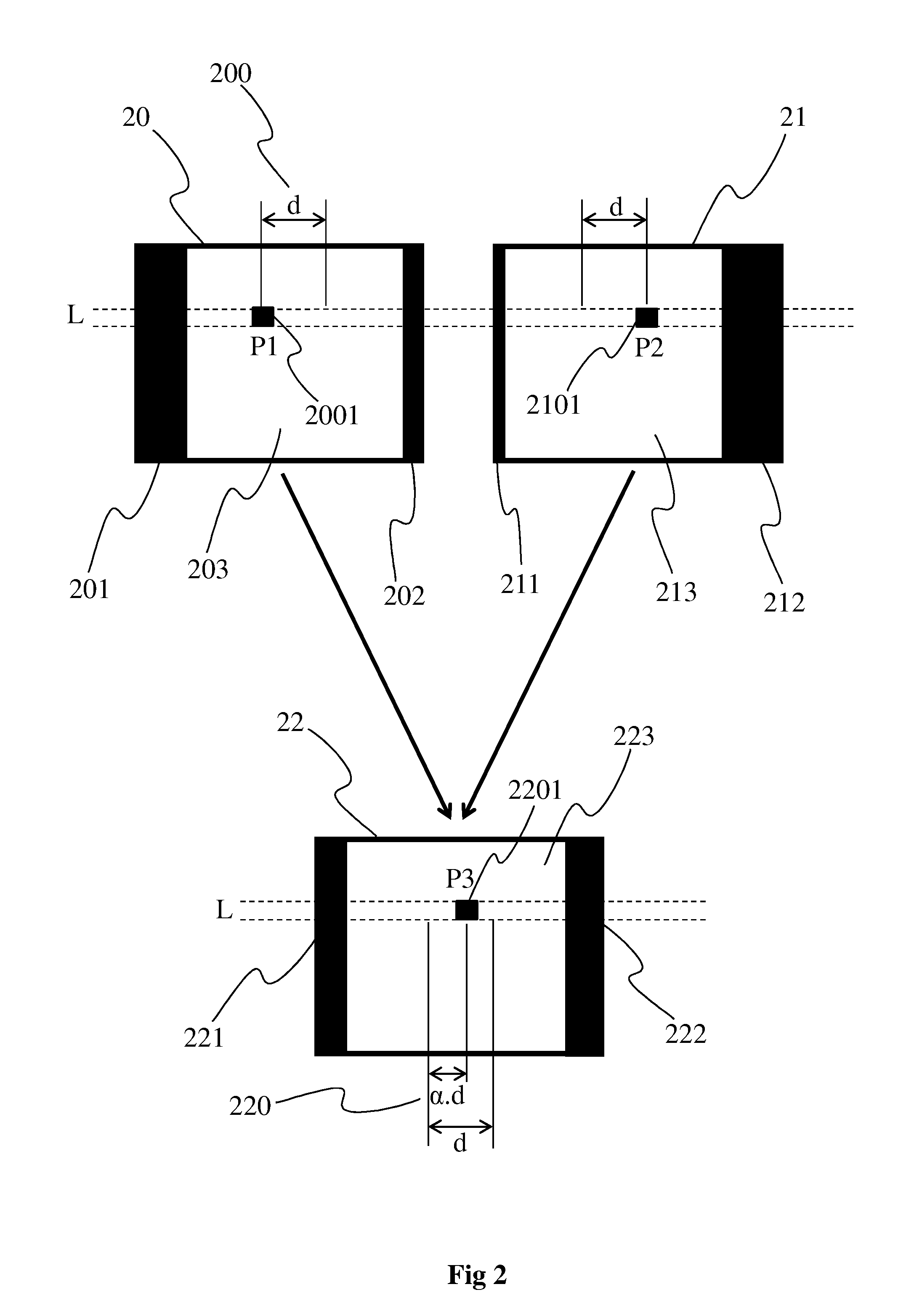

The invention relates to a method for processing a stereoscopic image, said stereoscopic image comprising a first image and a second image comprising at least one first black band. In order to reduce the display errors linked to black bands, the method comprises steps for:estimation of at least one first parameter representative of said at least one first black band,generation of a third image from said stereoscopic image by disparity compensated interpolation, said third image comprising at least one second black band, at least one second parameter representative of said at least one black band being a function of at least one first parameter.The invention also relates to a corresponding stereoscopic image processing module and a display device comprising the processing module.

Owner:INTERDIGITAL MADISON PATENT HLDG

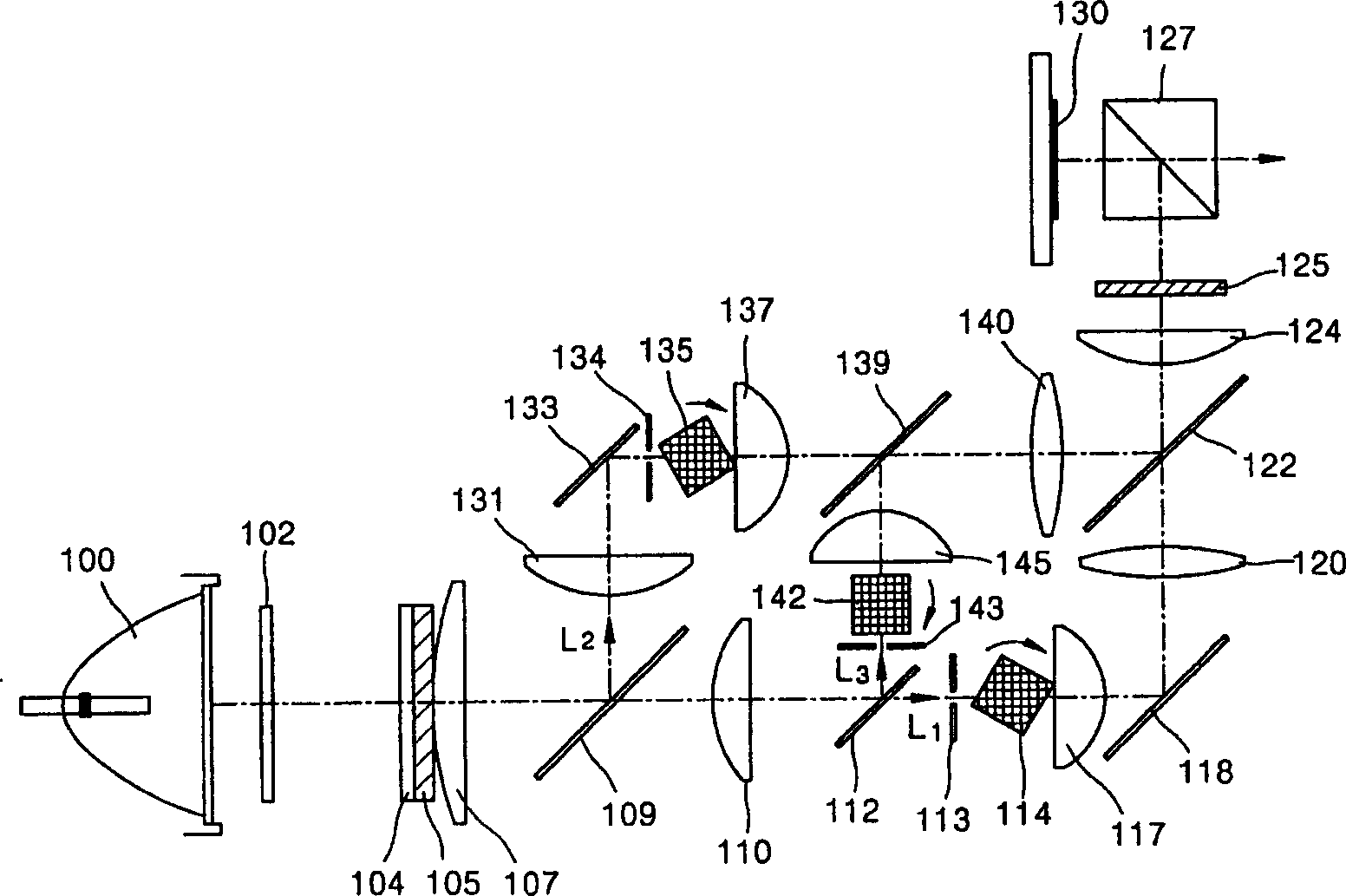

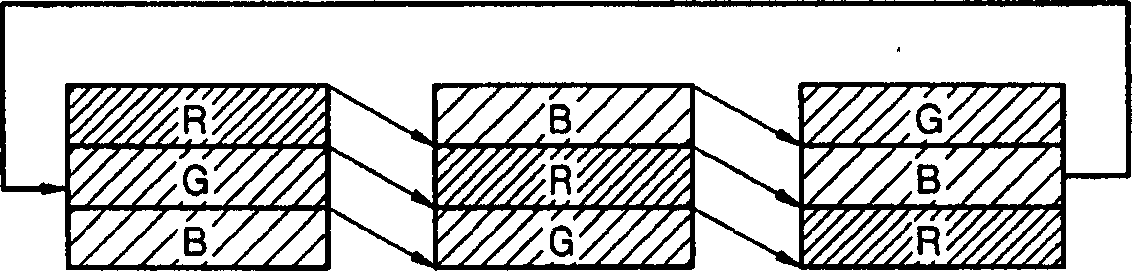

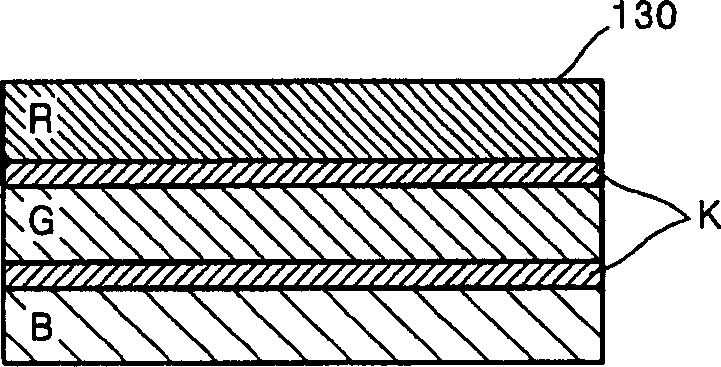

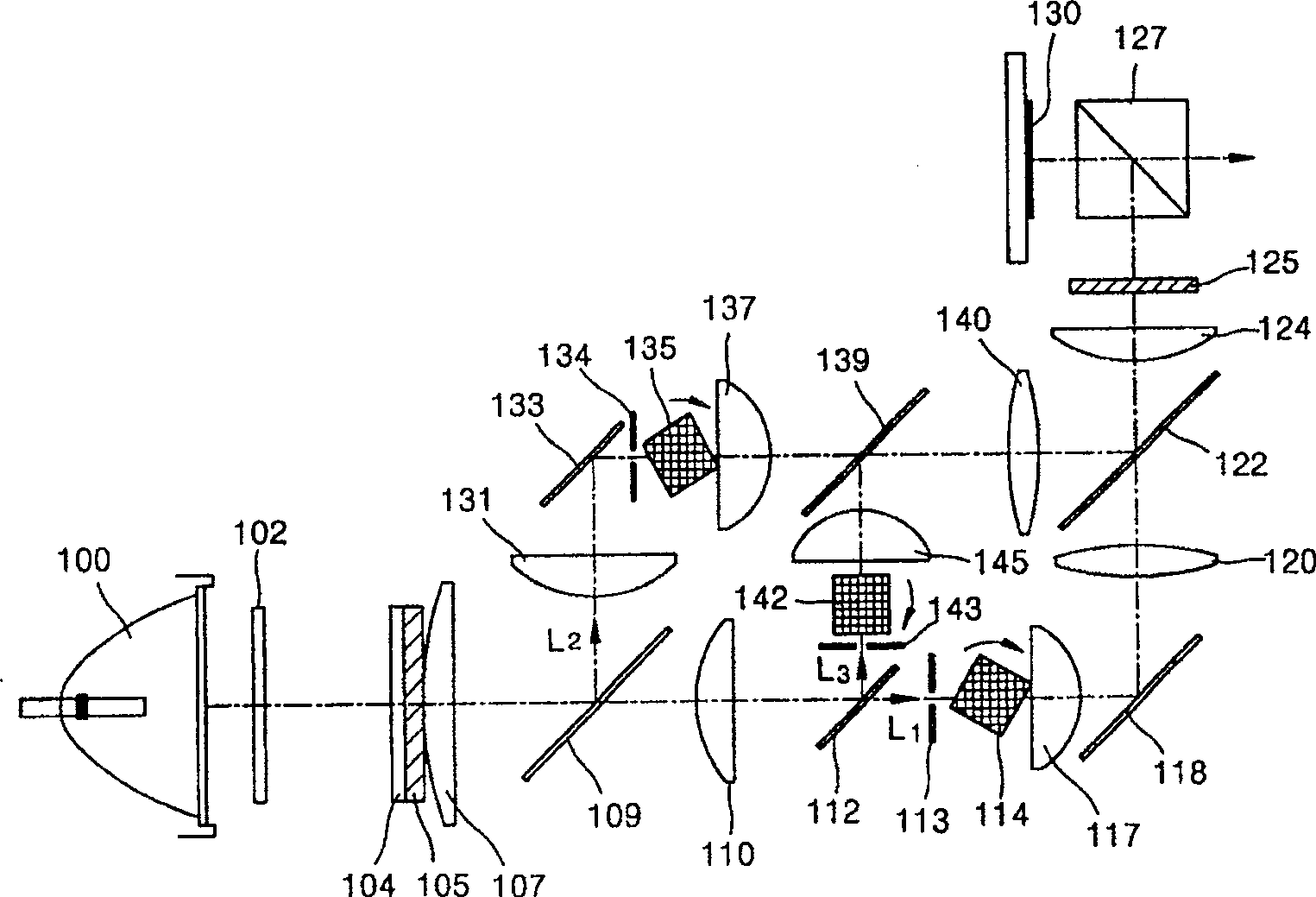

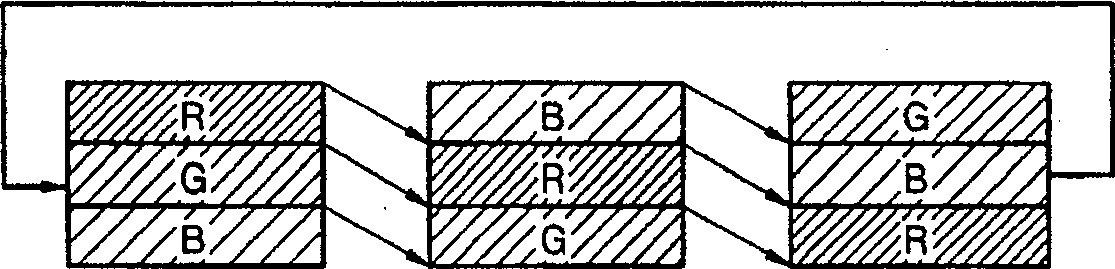

Projection system and method for forming color image

A projection system and method are provided. The projection system includes a light source, at least one filter having a slit, a scrolling unit, a color separator, and a light valve. The slit in the at least one filter controls a divergence angle of light emitted from the light source. The scrolling unit scrolls an incident beam. The color separator has a plurality of dichroic filters which separate an incident beam emitted from the light source according to color. The light valve receives a plurality of color beams from the color separator and transmitted by the scrolling unit on corresponding color areas and forms a plurality of color bars by scrolling the color beams. A black bar is formed between adjacent color bars by controlling a distance between adjacent dichroic filters or by controlling the width of the slit in the at least one filter.

Owner:SAMSUNG ELECTRONICS CO LTD

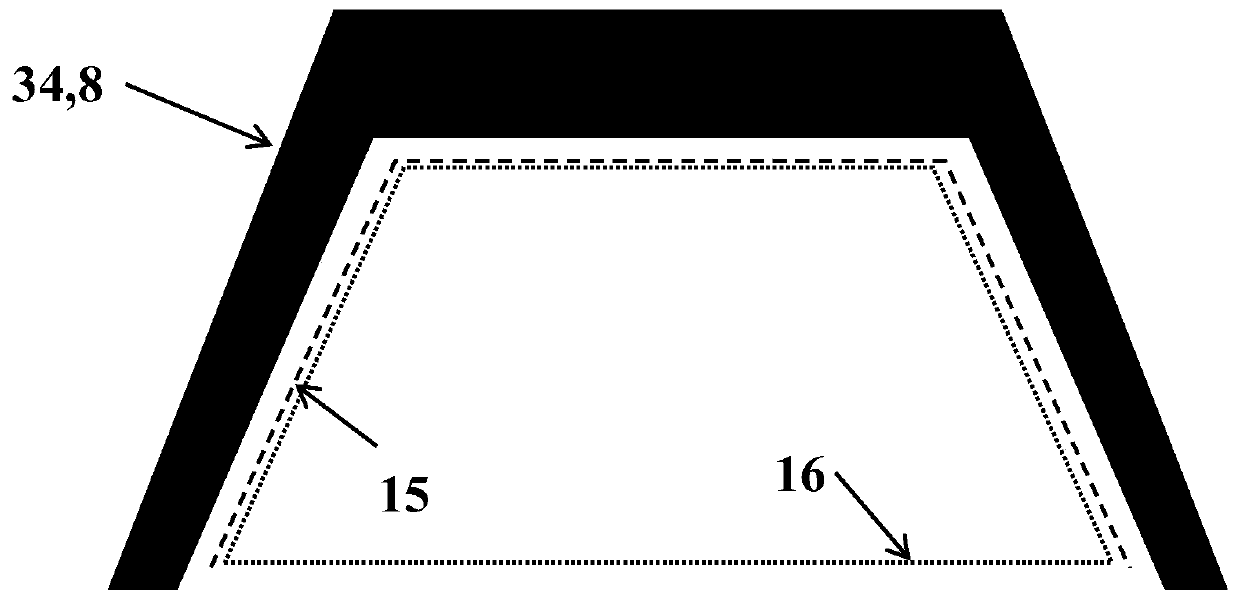

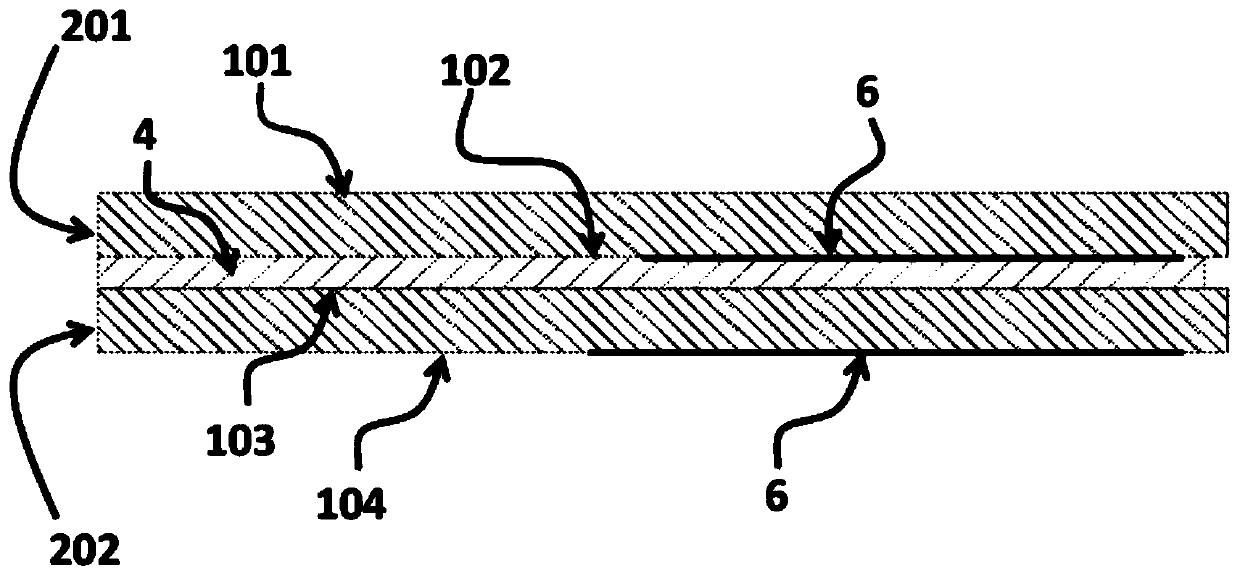

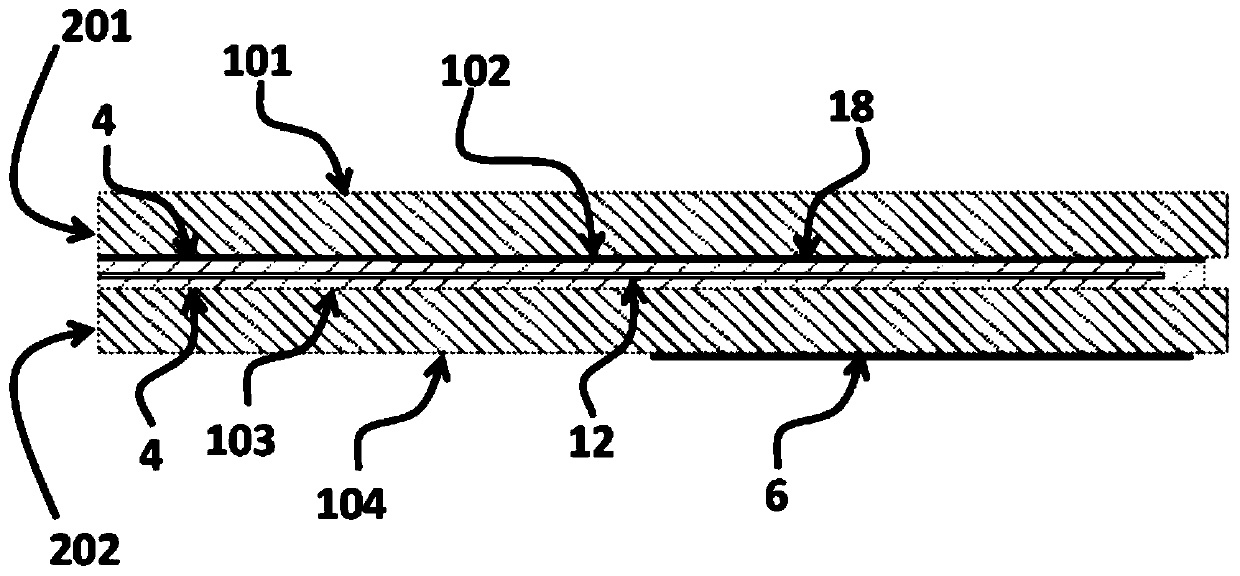

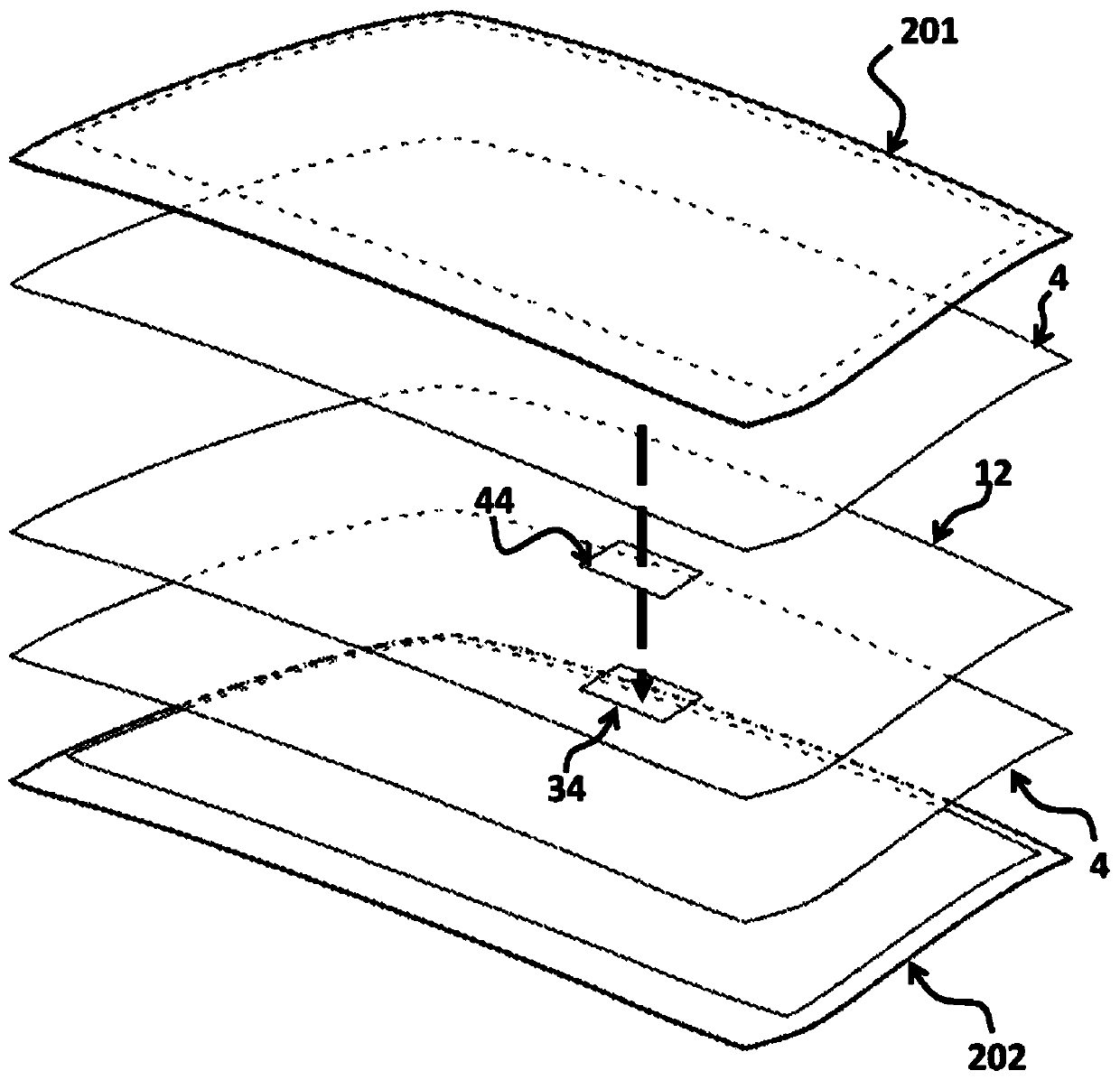

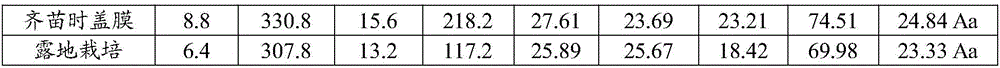

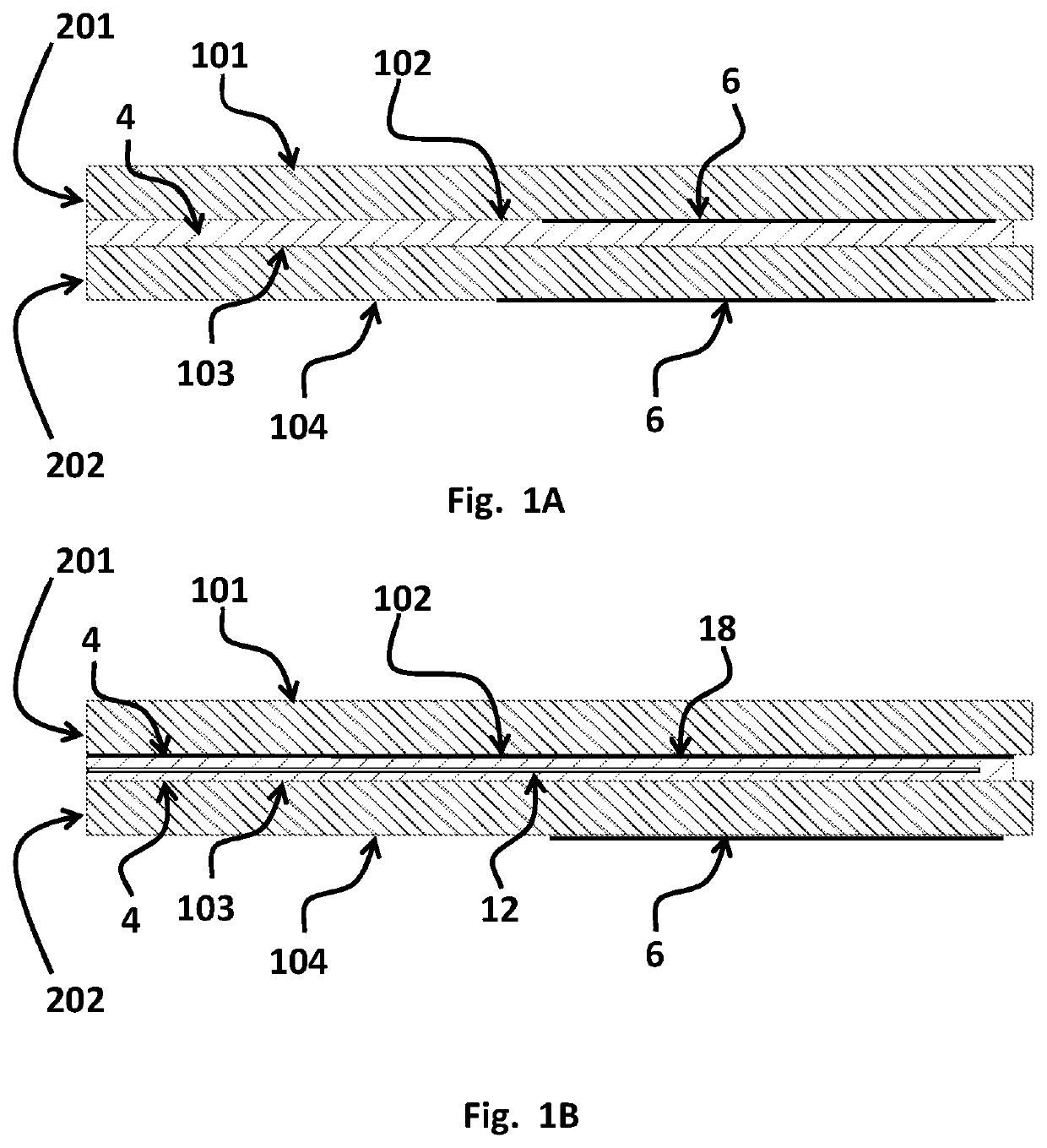

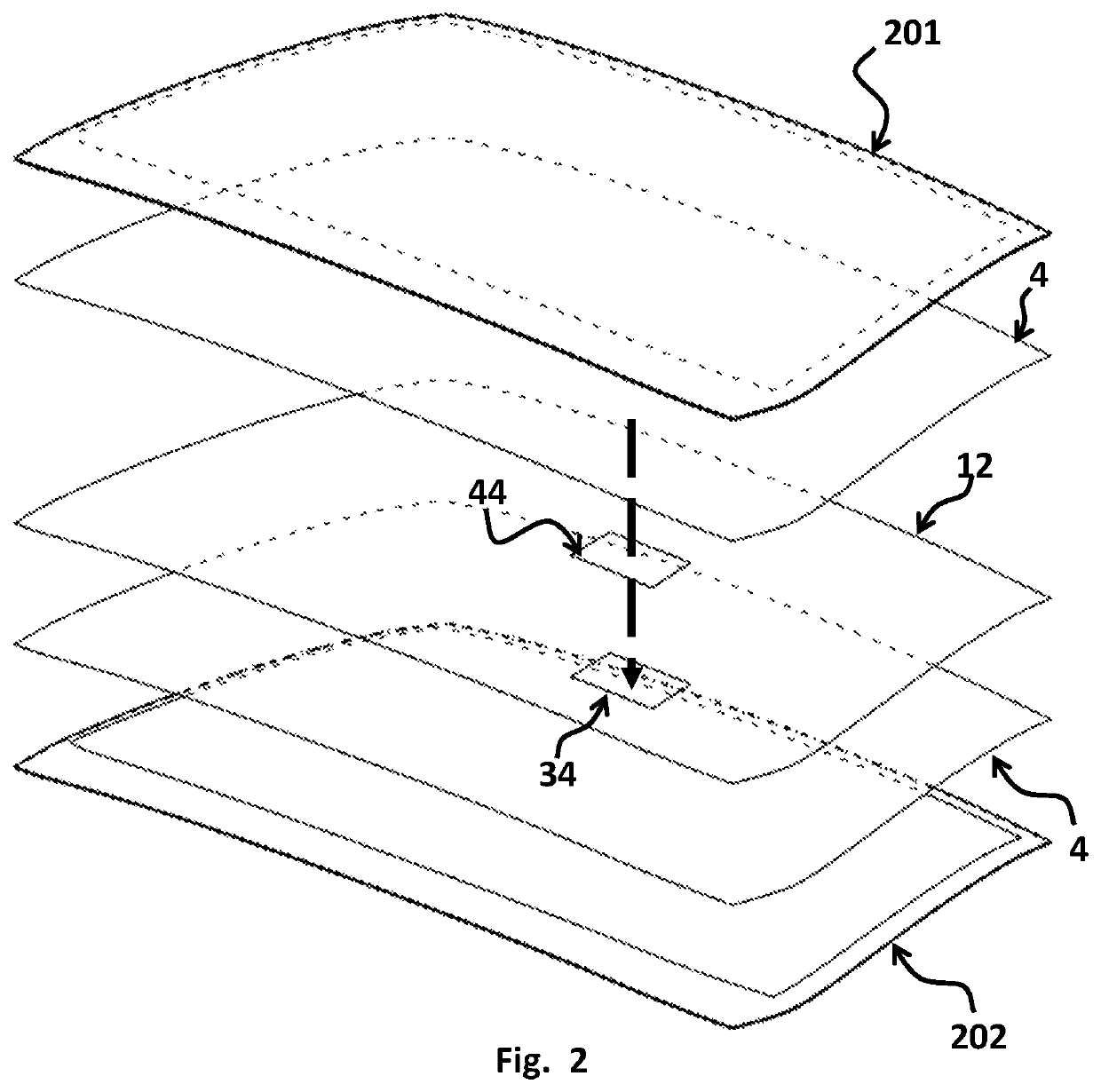

Glass laminate with inlay obscuration having superior strength and optical quality

The use of camera-based safety systems is growing at a rapid rate in modern automobiles. At the same time, windshields, where many of the cameras are mounted, are becoming larger and more complex in shape. As the industry moves towards vehicles with full autonomous capability, the number of cameras required and the resolution of the cameras are both increasing. However, the optical quality of thewindshield is less than optimal. One of the problems is caused by the typical black enamel frit that is printed on the glass, prior to heating and bending, to hide or obscure the camera hardware. Theabrupt thermal gradients during bending, caused by the heat absorbing black frit, result in a high level of distortion in the camera field of view. The object of this invention is to provide a laminated automotive glazing having an obscuration area produced by creating an obscuration after heating and bending the glass by removing a portion of the plastic interlayer glass in or near the camera field of view (camera obscuration) or / and in the edges of the windshield (black band) and replacing it with an inlay made of a substantially opaque plastic or other suitable material in or near the camera field of view (camera obscuration) or / and in the edges of the windshield (black band) rather than printing and firing an enamel frit on the glass. This results in a laminate having superior opticalquality, higher strength and a lower probability of breakage as compared to a laminate with a black enamel frit obscuration.

Owner:AGP AMERICA

Display apparatus, source device and display system

A display apparatus includes an orientation detecting portion, a receiving portion and an image processing portion. The orientation detecting portion detects an orientation of an upper part or a lower part of a display screen of a display portion. The receiving portion receives an image signal transmitted from a source device and state information (information showing an orientation of an upper part or a lower part of the transmission image indicated by the image signal and presence / absence of black band parts). The image processing portion applies, to the transmission image, rotation processing such that the orientation of the upper part or the lower part of the display screen coincides with the orientation of the upper part or the lower part of the transmission image, scaling processing, and / or black-band processing for adding or removing black band parts, according to a detection result of the orientation detecting portion and the state information.

Owner:SHARP KK

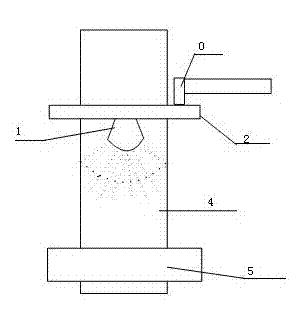

Purging device for cleaning line-free mill

InactiveCN102218451ANot subject to collision damageReduce replacement costsWork treatment devicesMetal rolling arrangementsEmulsionProcess engineering

The invention relates to a purging device for a mill, in particular to a purging device for a cleaning procedure-free mill. In order to overcome defects that the residual amount of emulsion on a surface is high and a black band is easily formed on the surface of a strip in the cleaning procedure-free mill, the invention provides a surging device for a cleaning line-free mill, which comprises a purging pipe. One end of the purging pipe is provided with a compressed air inlet, and the other end of the purging pipe is provided with an outlet communicated with a purging nozzle. Compared with the prior art, the purging device has the advantage that: the purging nozzle has a duckbill shape to ensure no black band on the surface of a rolled piece in a cleaning procedure-free cold rolling process so as to meet the requirement on the surface of a cold-rolled sheet.

Owner:NANJING MEISHAN METALLURGY DEV +1

Invisible edge solid substrate compensation layer for automotive glazing

InactiveCN111417514AHigh glass transition temperatureImprove aestheticsWindowsWindscreensHead-up displayHemt circuits

Vehicle glazing, which once served just to provide for vision and protect from the elements, has been taking on new functions as the complexity and functionality of modern automobiles has evolved. Performance films and interlayers are often used to add to and enhance the functionality of laminates. These functions include solar control, sound dampening, head up display and variable light transmittance. Recent advances have made it possible to produce electronic circuits on thin transparent substrates that are essentially invisible under normal lighting conditions. While these circuits can be inserted into the laminate and successfully laminated, the edges of the circuit insert are prone to objectionable aesthetics due to mismatch between the substrate and the interlayer index of refraction, thickness and color. The present invention compensates the edge of the solid insert by providing a sheet of a compatible compensation material that the substrate of the insert and which extends to at least the black band or the edge of glass of the laminate making the insert edge essentially invisible.

Owner:AGP AMERICA

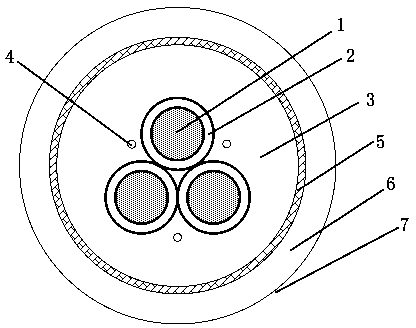

Tension type sea floating type wind power generation cable

InactiveCN103646688AIncrease in sizeReduce weightClimate change adaptationInsulated cablesYarnHigh intensity

The invention discloses a tension type sea floating type wind power generation cable. The cable comprises a cable core formed by twisting multiple power cores. The cable core is externally provided with a foaming lining layer; the middle of the foaming lining layer is provided with a monitoring core; the foaming lining layer is wrapped by a water blocking band; a high-strength aramid fiber yarn is braided outside the water blacking band; and the high-strength aramid fiber yarn is wrapped by an oversheath in an extruding manner. The cable provided by the invention has a floating function, the tensile strength is quite high, the service life is prolonged, and since the monitoring core is arranged inside the cable, the cable has quite high safety performance.

Owner:JIANGSU ZHONGMEI CABLE

Amphilophus citrinellus puffed compound feed capable of fading black and whitening in fattening period

InactiveCN104397380AShorten the production cycleEasy to useAnimal feeding stuffAnimal scienceWhitening Agents

An Amphilophus citrinellus puffed compound feed capable of fading black and whitening in the fattening period comprises the following raw materials in parts by weight: imported fish meal 20-30, shrimp powder 5-10, soybean meal 15-25, miscellaneous meal 15-25, algae powder 1-3, lecithin 1, fish oil 5, flour 10-30, a black fading and whitening agent 0.5, and VC phospholipid 0.2. The feed is convenient to use, without any toxic action. According to the physiological characters of Amphilophus citrinellus, the raw materials such as imported fish meal, the high-quality soybean meal and the shrimp powder are used to provide the essential nutrients for quick fattening of juvenile Amphilophus citrinellus, and the black fading and whitening agent is added to help the Amphilophus citrinellus to quickly fade black band, the production period of Amphilophus citrinellus is shortened, and the economic benefit is improved.

Owner:TIANJIN CHENHUI FEED

Glass laminate with printed obscuration having superior strength and optical quality

The use of camera-based safety systems is growing at a rapid rate in modern automobiles. At the same time, windshields, where many of the cameras are mounted, are becoming larger and more complex in shape. As the industry moves towards vehicles with full autonomous capability, the number of cameras required and the resolution of the cameras are both increasing. However, the optical quality of thewindshield is less than optimal. One of the problems is caused by the typical black enamel frit that is printed on the glass, prior to heating and bending, to hide or obscure the camera hardware. Theabrupt thermal gradients during bending, caused by the heat absorbing black frit, result a high level of distortion in the camera field of view. The object of this invention is to provide a laminatedautomotive glazing having an obscuration area produced by creating an obscuration, after heating and bending of the glass, by printing the obscuration on one or more of the surfaces of the bent glassin or near the camera field of view (camera obscuration) or / and in the edges of the windshield (black band) rather than printing and firing an enamel frit on the glass. This results in a laminate having superior optical quality, higher strength and a lower probability of breakage as compared to a laminate with a black enamel frit obscuration.

Owner:AGP AMERICA

Method for processing a stereoscopic image comprising a black band and corresponding device

ActiveUS9251564B2Reduce displayGeometric image transformationSteroscopic systemsParallaxImaging processing

A method for processing a stereoscopic image that includes a first image and a second image that has at least one first black band. To reduce the display errors linked to black bands, the method estimating at least one first parameter representative of the at least one first black band generating a third image from the stereoscopic image by disparity compensated interpolation. The third image includes at least one second black band, with at least one second parameter representative of the at least one black band being a function of at least one first parameter. The invention also relates to a corresponding stereoscopic image processing module and a display device including the processing module.

Owner:INTERDIGITAL MADISON PATENT HLDG

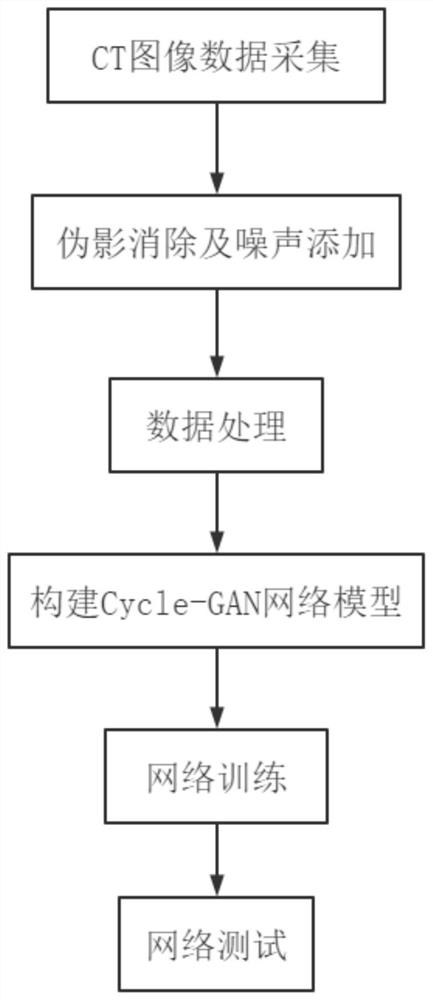

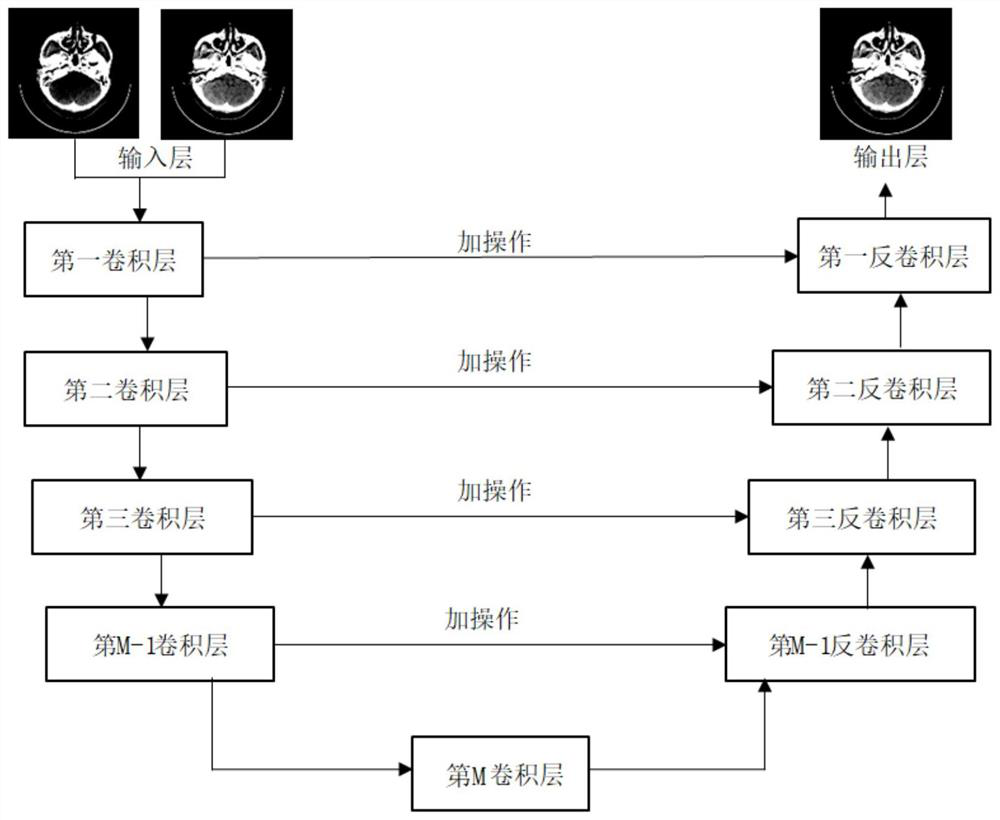

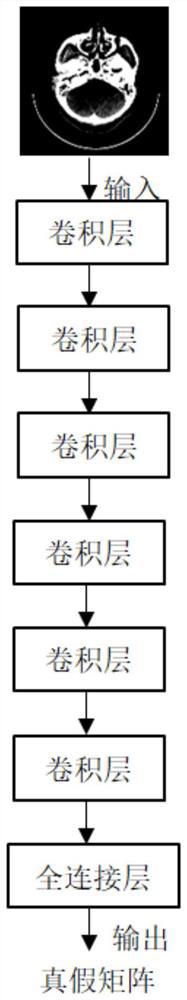

CT image black band artifact elimination method and system based on deep learning

PendingCN112446840AEliminate black band artifactsEliminate artifactsImage enhancementImage analysisRadiologyNetwork model

The invention relates to a CT image black band artifact elimination method based on deep learning. The method comprises the steps that a CT image with black band artifacts and a CT image without blackband artifacts which is not matched with the CT image with black band artifacts are collected; artifact elimination is carried out on the CT image with the black band artifacts; noise is added to theCT image without black band artifacts; normalization processing is respectively performed on the four CT images; a Cycle-GAN network model is constructed according to the model; network training is performed on the network model by utilizing the processed CT image with the black band artifacts, the CT image without the black band artifacts, the CT image with the CT value offset and the CT image with the noise until network parameters of the network model reach target conditions, so as to obtain a trained network model; and artifact elimination is performed on the CT image to be processed, andthe CT images before and after artifact elimination are input into the network model to obtain a CT image. According to the method, under the condition that the overall CT value of the CT image is basically unchanged, the black band artifacts in the CT image are effectively relieved.

Owner:FMI MEDICAL SYST CO LTD

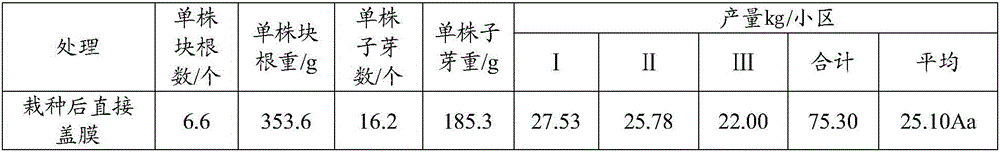

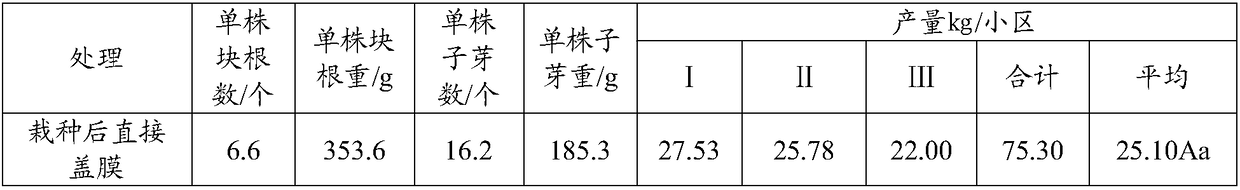

Method of cultivating Radix scrophulariae by covering color matching film

ActiveCN105766351AReduce labor costsMembrane inoculation is easyPlant cultivationCultivating equipmentsEconomic benefitsComputer science

The invention relates to a method of cultivating Radix scrophulariae by covering a color matching film and belongs to the technical field of traditional Chinese medicine cultivation.The method includes following steps: after seedlings of Radix scrophulariae are complete, weeding, fertilizing, and covering the color matching film, wherein the color matching film comprises a white transparent band in the middle and black bands which are connected and positioned on two lateral sides of the white transparent band, and a ratio of width of the color matching film to that of a ridge is 1-1.2:1; breaking the color matching film to expose the seedlings of Radix scrophulariae, and using soil to cover film holes.Technology of the color matching film is utilized, so that the method is low in labor cost and high in planting and economic benefit.

Owner:CHONGQING ACAD OF CHINESE MATERIA MEDICA

Glass laminate with printed obscuration having superior strength and optical quality

PendingUS20200290318A1High yieldReduce residual stressVehicle componentsGlass/slag layered productsImage resolutionFrit

The use of camera-based safety systems is growing at a rapid rate in modern automobiles. At the same time, windshields, where many of the cameras are mounted, are becoming larger and more complex in shape. As the industry moves towards vehicles with full autonomous capability, the number of cameras required and the resolution of the cameras are both increasing. However, the optical quality of the windshield is less than optimal. One of the problems is caused by the typical black enamel frit that is printed on the glass, prior to heating and bending, to hide or obscure the camera hardware. The abrupt thermal gradients during bending, caused by the heat absorbing black frit, result a high level of distortion in the camera field of view. The object of this invention is to provide a laminated automotive glazing having an obscuration area produced by creating an obscuration, after heating and bending of the glass, by printing the obscuration on one or more of the surfaces of the bent glass in or near the camera field of view (camera obscuration) or / and in the edges of the windshield (black band) rather than printing and firing an enamel frit on the glass. This results in a laminate having superior optical quality, higher strength and a lower probability of breakage as compared to a laminate with a black enamel frit obscuration.

Owner:AGP AMERICA

Low-response-time liquid-crystal screen

InactiveCN106154656AFast conversionIncrease the driving voltageNon-linear opticsLight guideOptical membrane

The invention discloses a low-response-time liquid-crystal screen. The low-response-time liquid-crystal screen comprises two substrates, wherein a plurality of liquid crystal pixel points are arranged between the two substrates; the inner side faces of the two substrates are provided with pixel electrodes; the pixel electrodes correspond one by one according to the liquid crystal pixel points; each liquid crystal electrode is in parallel connection with a buffer resistor. Light sources on two sides of a light guide plate are provided, so that black bands can be avoided during shining, and the shining quality of a backlight module is enhanced; an optical membrane is provided, so that light rays reflected by the light guide plate can be unified in order that working personnel can conveniently view from a front side.

Owner:HEFEI HUIKE JINYANG TECH

Method for detecting horizontal black tape in video image

InactiveCN1178474CTelevision system detailsTelevision system scanning detailsPattern recognitionComputer graphics (images)

A process for detecting black bands in a video image within a luminance range corresponding to low luminance values comprises the steps of: calculating, for each line situated in a location in which a black band can be expected to be found if present in said video image, a value relating to a maximum number of occurrences of points having the same luminance value; averaging said value over said lines in said location; calculating a threshold dependent on said average; and, comparing said value relating to said maximum number of occurrences obtained for a new line with said threshold. Applications relate, for example, to the detection of the ''letterbox'' format.

Owner:THOMSON MULTIMEDIA SA

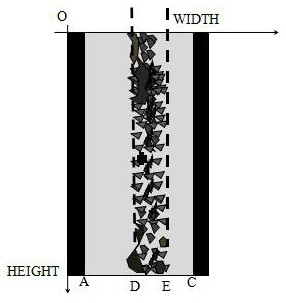

Obtaining method of interception factor of trough parabolic concentrator based on image processing

InactiveCN106846405BImprove work efficiencyReduce labor costsImage enhancementImage analysisImaging processingData recording

The invention discloses a method for obtaining the interception factor of a trough parabolic concentrator based on image processing, and relates to the technical field of solar energy application. Technical key points of the present invention: image acquisition step: erect an image acquisition device at a certain distance from the trough parabolic concentrator; control the image acquisition device to capture the front view of the trough parabolic concentrator; position data recording step: measure the image acquisition device and The relative position of the parabolic concentrator; the calculation steps for the theoretical position of the black band of the collector tube; the coordinate conversion step: converting the theoretical position of the black band on the longitudinal section of the parabola into the pixel coordinates of the corresponding reflector on the parabolic surface; the black band image processing steps; The steps for expressing the interception factor of a reflector are as follows: Calculate the light escape area of the black band area of the reflector based on the theoretical black band image sequence and the actual black band image sequence of a certain reflector; draw the escape area on the theoretical black band position on the reflector.

Owner:SICHUAN UNIV

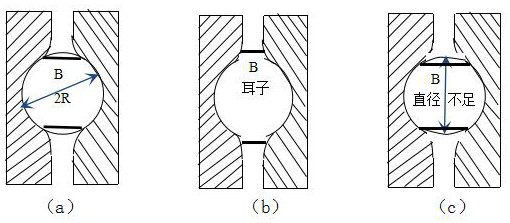

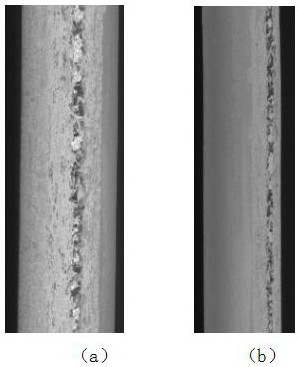

Bar rolling Haff surface oxidation black belt width measuring method based on image processing

PendingCN114119712ARealize measurementReduce defectsImage analysisUsing optical meansImaging processingSurface oxidation

The invention discloses an image processing-based method for measuring the width of a Hough surface oxidation black belt in bar rolling, which is characterized in that on the basis of image processing, a traversal search method is adopted, and boundary coordinates of a bar and boundary coordinates of an oxide scale black belt in a picture are read by setting a specific gray threshold, so that the width of the Hough surface oxidation black belt in bar rolling is measured. And the width of the oxide scale black belt is obtained through the proportion of the coordinates and the real object radius of the bar, and then measurement of the width of the oxide scale black belt in bar rolling is achieved. By means of the mode, data quantification of the oxide scale black bands can be achieved, and data support can be provided for technological parameter formulation, rule searching, related big data processing, machine learning and the like for large-scale classes.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD +1

Projection system and method for forming color image

A projection system and method for forming color images are provided. In this method, the rise time and fall time of the imaging signal are changed required to obtain multiple color bands formed on the light valve. First, install at least one filter with slits. Next, the incident light is rolled by converting the rotation of the rolling unit into a linear motion of the incident light passing through the lens element of the rolling unit. The light beam emitted from the light source is then separated according to color using a color separator containing a plurality of color-selective mirrors, each of which transmits the incident beam as a beam of one wavelength and reflects a beam of another wavelength. Then, multiple color beams separated by the color separator and rolled by the rolling unit are incident on the corresponding color areas on the light valve, thereby generating multiple color strips. Then a black band is formed between adjacent color bands by controlling the distance between adjacent color selection mirrors or controlling the width of the slit.

Owner:SAMSUNG ELECTRONICS CO LTD

Image signal processing apparatus, image display, and image display method

InactiveUS8111328B2Improve imaging resolutionShort timeTelevision system detailsTelevision system scanning detailsPattern recognitionDisplay device

An image signal processing apparatus, an image display, and an image display method that enable detecting a black band region included in an input image signal in a shorter time and realizes a more viewable image are provided. The image signal processing apparatus includes a black band detecting means for detecting in a unit frame period a black band region included in an input image signal, a calculating means for calculating a scaling ratio of the input image signal while maintaining an aspect ratio thereof based on a detection result from the black band detecting means, and a scaling means for scaling the input image signal up or down based on the ratio obtained by the calculating means.

Owner:SONY CORP

A kind of method for covering cultivation of Scrophulariaceae with color-matching film

ActiveCN105766351BReduce labor costsMembrane inoculation is easyPlant cultivationCultivating equipmentsEconomic benefitsBiology

The invention relates to a method of cultivating Radix scrophulariae by covering a color matching film and belongs to the technical field of traditional Chinese medicine cultivation.The method includes following steps: after seedlings of Radix scrophulariae are complete, weeding, fertilizing, and covering the color matching film, wherein the color matching film comprises a white transparent band in the middle and black bands which are connected and positioned on two lateral sides of the white transparent band, and a ratio of width of the color matching film to that of a ridge is 1-1.2:1; breaking the color matching film to expose the seedlings of Radix scrophulariae, and using soil to cover film holes.Technology of the color matching film is utilized, so that the method is low in labor cost and high in planting and economic benefit.

Owner:CHONGQING ACAD OF CHINESE MATERIA MEDICA

Wave shape extracting method for medical instrument video information extractor

ActiveCN100548026CReduce distractionsSmall distortionTelevision system detailsColor television detailsWave shapeRandom noise

Owner:ENJOYOR COMPANY LIMITED

Method of manufacturing optical film

ActiveCN102483481BNon-blockingWrinkle freeOptical articlesPolarising elementsWrinkle skinForeign matter

Disclosed is a method of manufacturing an optical film wherein a failure due to foreign matters, a black band while the film is rolled, and blocking never occur in the surface of the film, eliminating wrinkles and flaws. The method of manufacturing the optical film comprises: a process of clamping a member comprising a plurality of projections onto both side edge sections of the long film in the width direction, thereby knurling the side edge sections by irregularity; and a process of taking up the film. In the process of knurling, the height of projecting portions formed by a film member clamped away by the projections when the projections are clamped onto the surface of the film is restricted by a flat portion configuring the base of the projections, so that the height of the projecting portions is determined height.

Owner:KONICA MINOLTA OPTO

Invisible edge solid substrate compensation layer for automotive glazing

Vehicle glazing, which once served just to provide for vision and protect from the elements, has been taking on new functions as the complexity and functionality of modern automobiles has evolved. Performance films and interlayers are often used to add to and enhance the functionality of laminates. These functions include solar control, sound dampening, head up display and variable light transmittance. Recent advances have made it possible to produce electronic circuits on thin transparent substrates that are essentially invisible under normal lighting conditions. While these circuits can be inserted into the laminate and successfully laminated, the edges of the circuit insert are prone to objectionable aesthetics due to mismatch between the substrate and the interlayer index of refraction, thickness and color. The present invention compensates the edge of the solid insert by providing a sheet of a compatible compensation material that the substrate of the insert and which extends to at least the black band or the edge of glass of the laminate making the insert edge essentially invisible.

Owner:AGP AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com