Glass laminate with inlay obscuration having superior strength and optical quality

A technology for laminated glass and shielding, applied in windshields, glass/slag layered products, coatings, etc., can solve problems such as high thermal gradients and distortion/deformation, and achieve residual stress elimination, less surface mismatch, and residual low stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

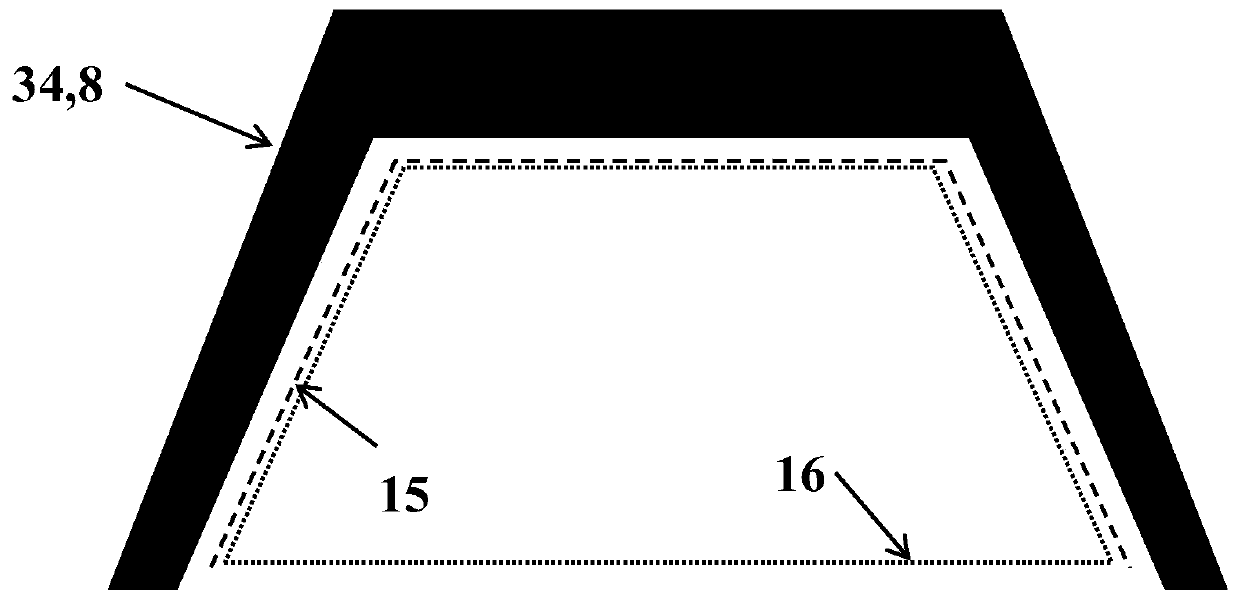

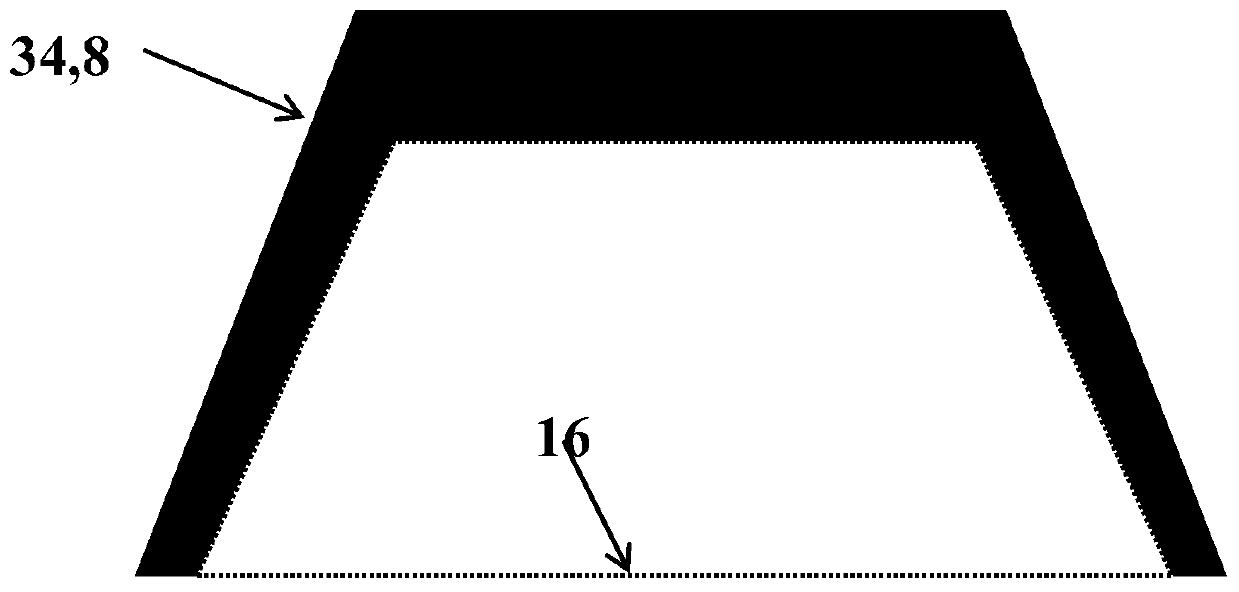

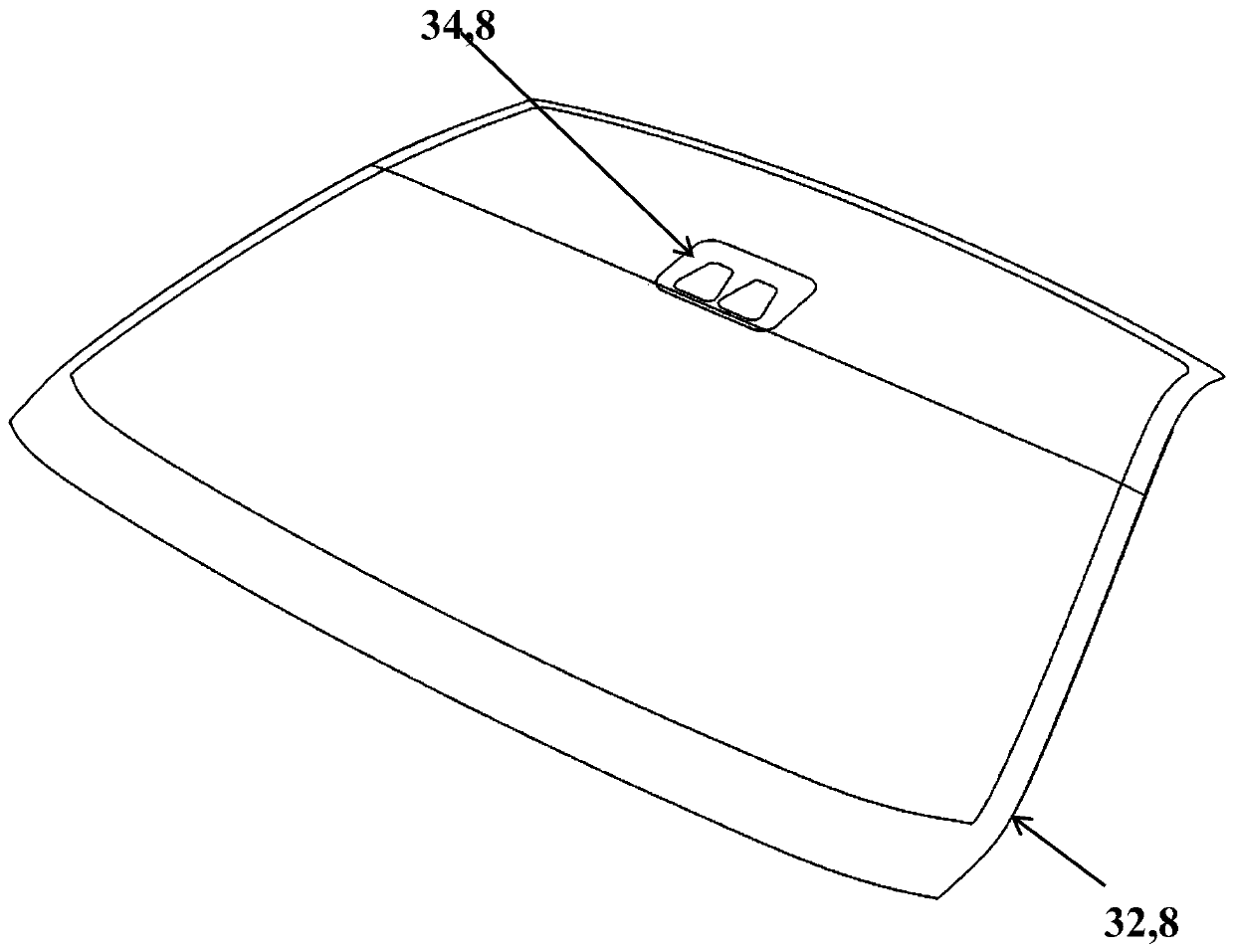

[0124] Figure 8 The windshield comprises a ceramic frit black band 32 and a camera mask 34 produced by an opaque black plastic PVB inlay, which is cut to size and embedded in the plastic into the cutout in the PVB interlayer. The inlay also includes cutouts that allow transparent PVB to be embedded in the field of view of each of the two cameras. In the case of inserting an interlayer for assembly, the inlay is assembled after the glass has been bent and cooled during the lamination process. No adhesion promoter is required.

Embodiment 2

[0126] Figure 8 The windshield shown consists of two wedge-shaped / formed plastic sandwiches with a layer of infrared heat reflective mylar sandwiched between them. A ceramic frit black band 32 is produced by conventional means, and an opaque black plastic PVB inlay is cut to size and embedded in the cutout of the PVB interlayer. The inlay also includes a cutout that allows transparent PVB to be embedded in the field of view of each of the two cameras. In the case of inserting an interlayer for assembly, the inlay is assembled after the glass has been bent and cooled during the lamination process. No adhesion promoter is required.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com