UV-resistant graphene quantum dot composite p-aramid fiber preparation method

A technology of graphene quantum dots and para-aramid fibers, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, single-component synthetic polymer rayon, etc., can solve the problems of poor UV resistance and improve UV resistance , Excellent UV resistance, and the effect of improving dispersion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

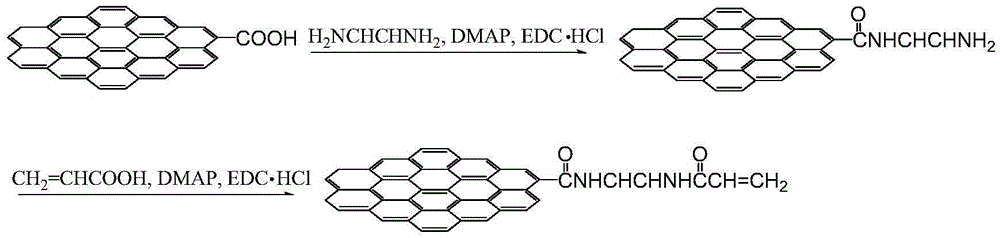

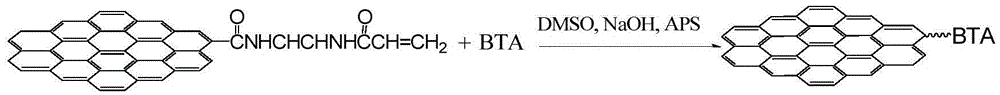

[0039] A kind of preparation method of anti-ultraviolet graphene quantum dot composite para-aramid fiber, comprises the following steps:

[0040] 1) Vinyl functionalization of graphene quantum dots

[0041] Dissolve 100mg of graphene oxide quantum dots in 100ml of ethylenediamine, add 50mg of 4-dimethylaminopyridine and 50mg of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt acid salt, ultrasonically dispersed for 30min, reacted at 90°C for 24h, cooled to room temperature, filtered and washed with water, and dried at 60°C for 12h. The reaction product was added to a mixed solution of 50 mg of 4-dimethylaminopyridine, 50 mg of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 20 ml of dewatered acrylic acid Ultrasonic dispersion in medium for 30min, then reacted at 50°C for 12h, filtered and washed with water, and dried at 60°C for 12h to obtain vinyl-functionalized graphene quantum dots.

[0042] The graphene quantum dots have a thickness of 0.34-1 nm and a ...

Embodiment 2

[0051] A kind of preparation method of anti-ultraviolet graphene quantum dot composite para-aramid fiber, comprises the following steps:

[0052] 1) Vinyl functionalization of graphene quantum dots

[0053] Dissolve 200mg of graphene oxide quantum dots in 100ml of ethylenediamine, add 50mg of 4-dimethylaminopyridine and 50mg of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt acid salt, ultrasonically dispersed for 30min, reacted at 90°C for 24h, cooled to room temperature, filtered and washed with water, and dried at 60°C for 12h. The reaction product was added to a mixed solution of 50 mg of 4-dimethylaminopyridine, 50 mg of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 20 ml of dewatered acrylic acid Ultrasonic dispersion in medium for 30min, then reacted at 50°C for 12h, filtered and washed with water, and dried at 60°C for 12h to obtain vinyl-functionalized graphene quantum dots.

[0054] The graphene quantum dots have a thickness of 0.34-1 nm and a ...

Embodiment 3

[0063] A kind of preparation method of anti-ultraviolet graphene quantum dot composite para-aramid fiber, comprises the following steps:

[0064] 1) Vinyl functionalization of graphene quantum dots

[0065] Dissolve 500mg of graphene oxide quantum dots in 100ml of ethylenediamine, add 50mg of 4-dimethylaminopyridine and 50mg of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt acid salt, ultrasonically dispersed for 30min, reacted at 90°C for 24h, cooled to room temperature, filtered and washed with water, and dried at 60°C for 12h. The reaction product was added to a mixed solution of 50 mg of 4-dimethylaminopyridine, 50 mg of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 20 ml of dewatered acrylic acid Ultrasonic dispersion in medium for 30min, then reacted at 50°C for 12h, filtered and washed with water, and dried at 60°C for 12h to obtain vinyl-functionalized graphene quantum dots.

[0066] The graphene quantum dots have a thickness of 0.34-1 nm and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet diameter | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com