Preparation method of phenolic resin for auto-industry filter paper

A technology of the automobile industry and phenolic resin, which is applied in the field of preparation of phenolic resin, and can solve the problems of poor flame retardancy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

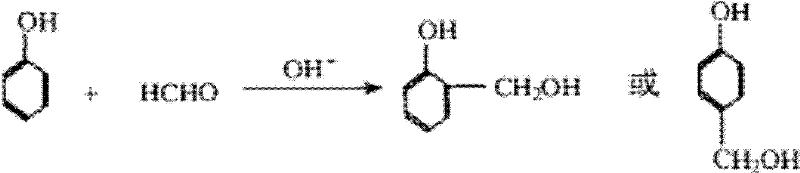

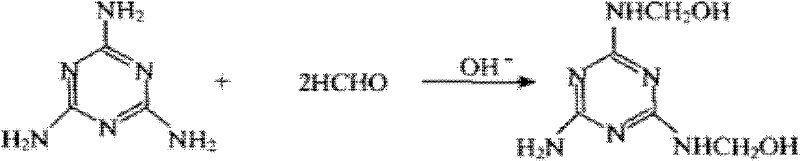

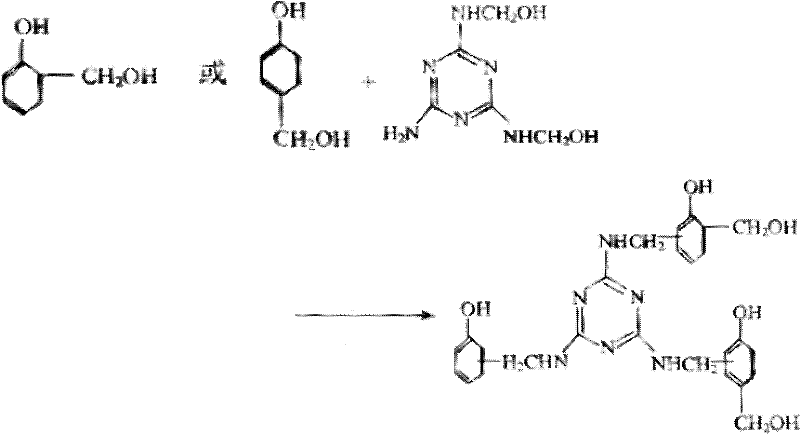

Method used

Image

Examples

Embodiment 1

[0027] Phenol 940g (10mol), the concentration is 37% formaldehyde 1621.6g (2.0mol), add sodium hydroxide 14.1g, slowly heat up to 75 ℃, constant temperature reaction for 2 hours, add melamine 188g, constant temperature for 45 minutes, vacuum distillation to moisture content 7.5 %, add 400g of methanol, 400g of tetrahydrofuran, and 94g of triphenyl phosphate, stir and dissolve, evenly cool down to 40°C and discharge.

Embodiment 2

[0029] Phenol 940g (10mol), the concentration is 37% formaldehyde 1621.6g (2.0mol), add sodium hydroxide 14.1g, slowly heat up to 75-80 ℃, constant temperature reaction for 2 hours, add dicyandiamine 188g, constant temperature for 45 minutes, vacuum Distill to a water content of 7.5%, add 400g of methanol, 400g of tetrahydrofuran, and 188g of triphenyl phosphate, stir and dissolve evenly, cool down to 40°C and discharge.

Embodiment 3

[0031] Phenol 940g (10mol), concentration 37% formaldehyde 1621.6g (2.0mol), add sodium hydroxide 14.1g, slowly heat up to 78 ℃, constant temperature reaction for 2 hours, add melamine 376g, constant temperature for 45 minutes, vacuum distillation to moisture content 7.5 %, add 400g of methanol, 400g of tetrahydrofuran, and 94g of triphenyl phosphate, stir and dissolve, evenly cool down to 40°C and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com