Glass laminate with printed obscuration having superior strength and optical quality

A technology for laminated glass, shielding, applied in glass/slag layered products, coatings, layered products, etc., which can solve problems such as high thermal gradients and distortion/deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

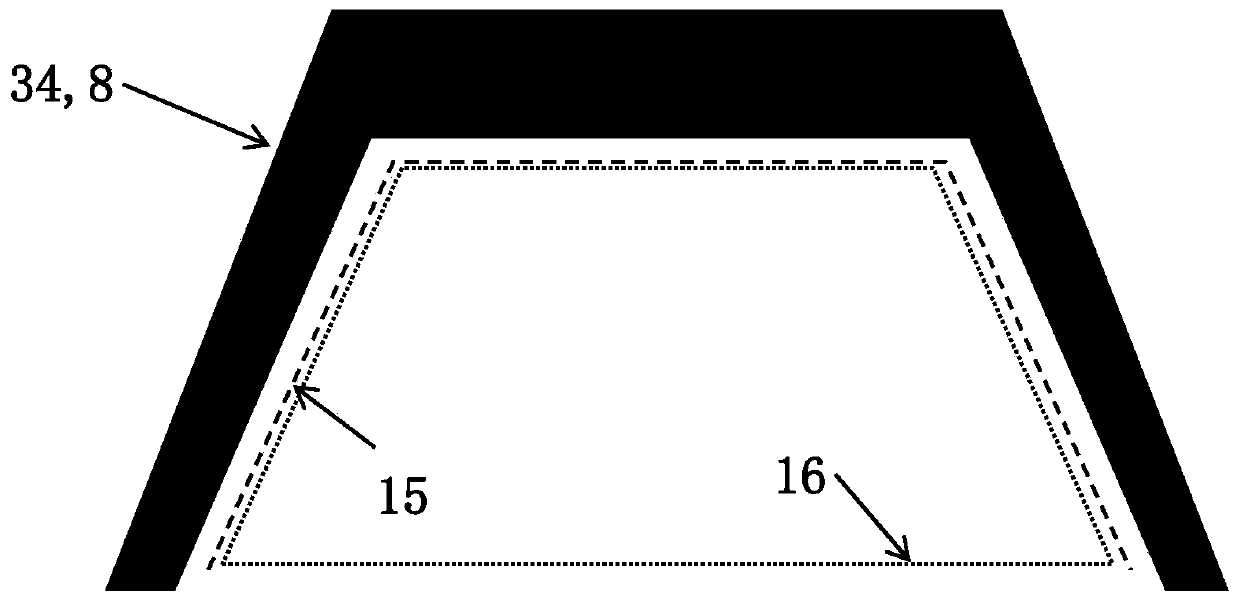

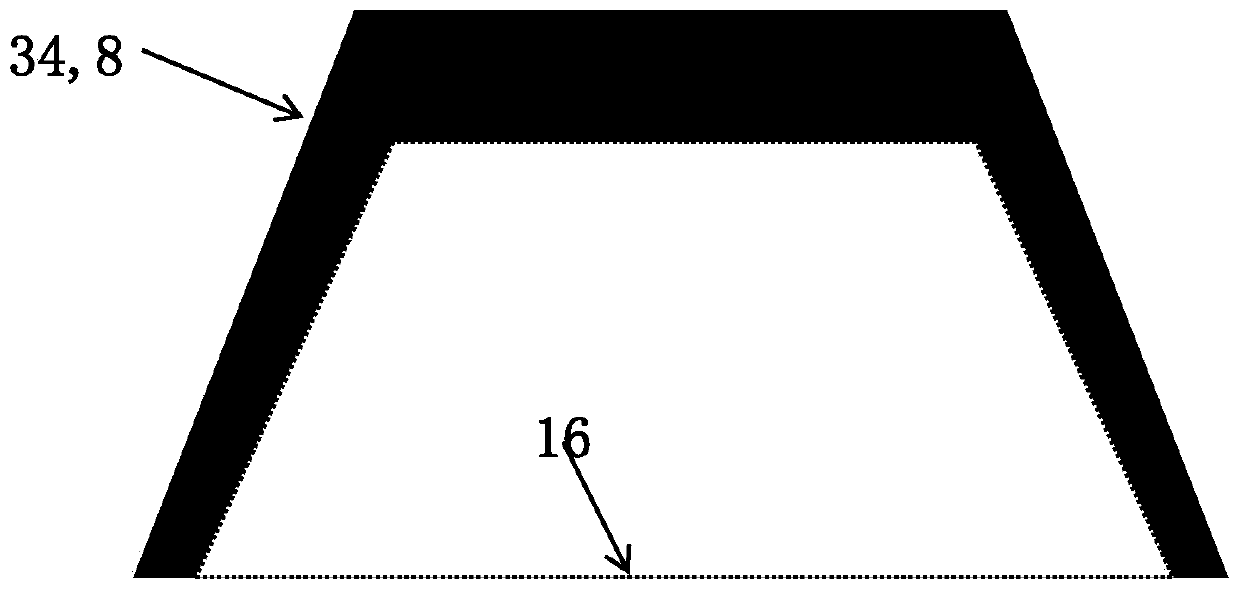

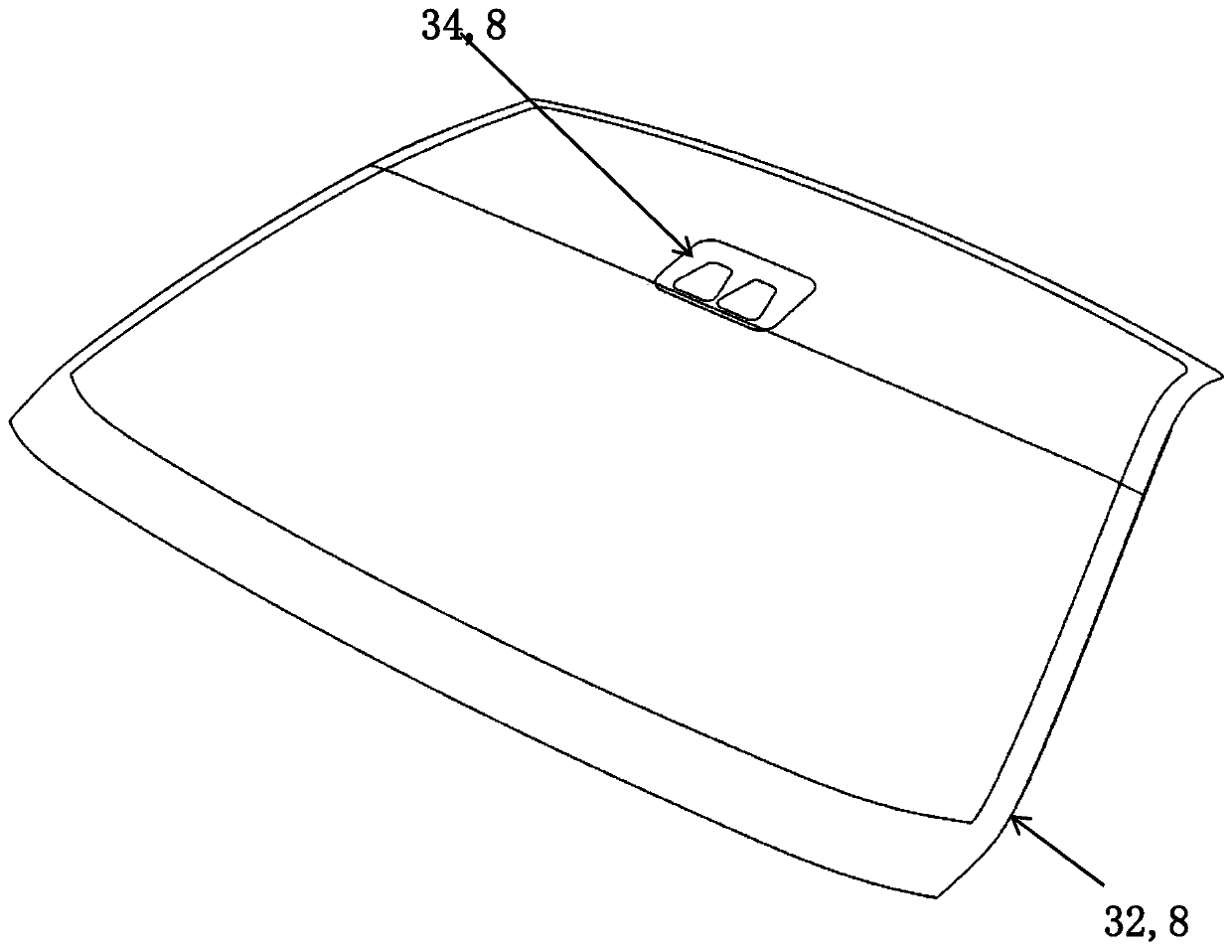

[0123] Figure 8 The windshield contains a ceramic sintered black strip 32 and a camera mask 34 that is printed with an organic black ink after the glass is heated and bent, and printed on the second side of the glass by a mask and spray system. surface 102 .

Embodiment 2

[0125] Figure 8 The windshield contains a ceramic frit black band 32 and a camera mask 34, which is printed with an organic black ink after the glass is heated and bent, and printed on the first layer of the glass by a mask and spray system. on the second surface 102 and the fourth surface 104 of the glass.

Embodiment 3

[0127] Figure 8 The windshield shown comprises a ceramic frit black strip 32 and a camera mask 34, on a second surface 102 of the glass and a fourth surface 104 of the glass, after heating and bending the glass printed by a mask and spray system, Printed with an organic black ink and additionally includes a wedged / formed plastic interlayer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com