Invisible edge solid substrate compensation layer for automotive glazing

A technology of compensation layer and inner glass layer, applied in glass/slag layered products, windshield, vehicle cleaning, etc., can solve the mismatch of refractive index, thickness and color, cannot change the refractive index, reduce the aesthetics, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

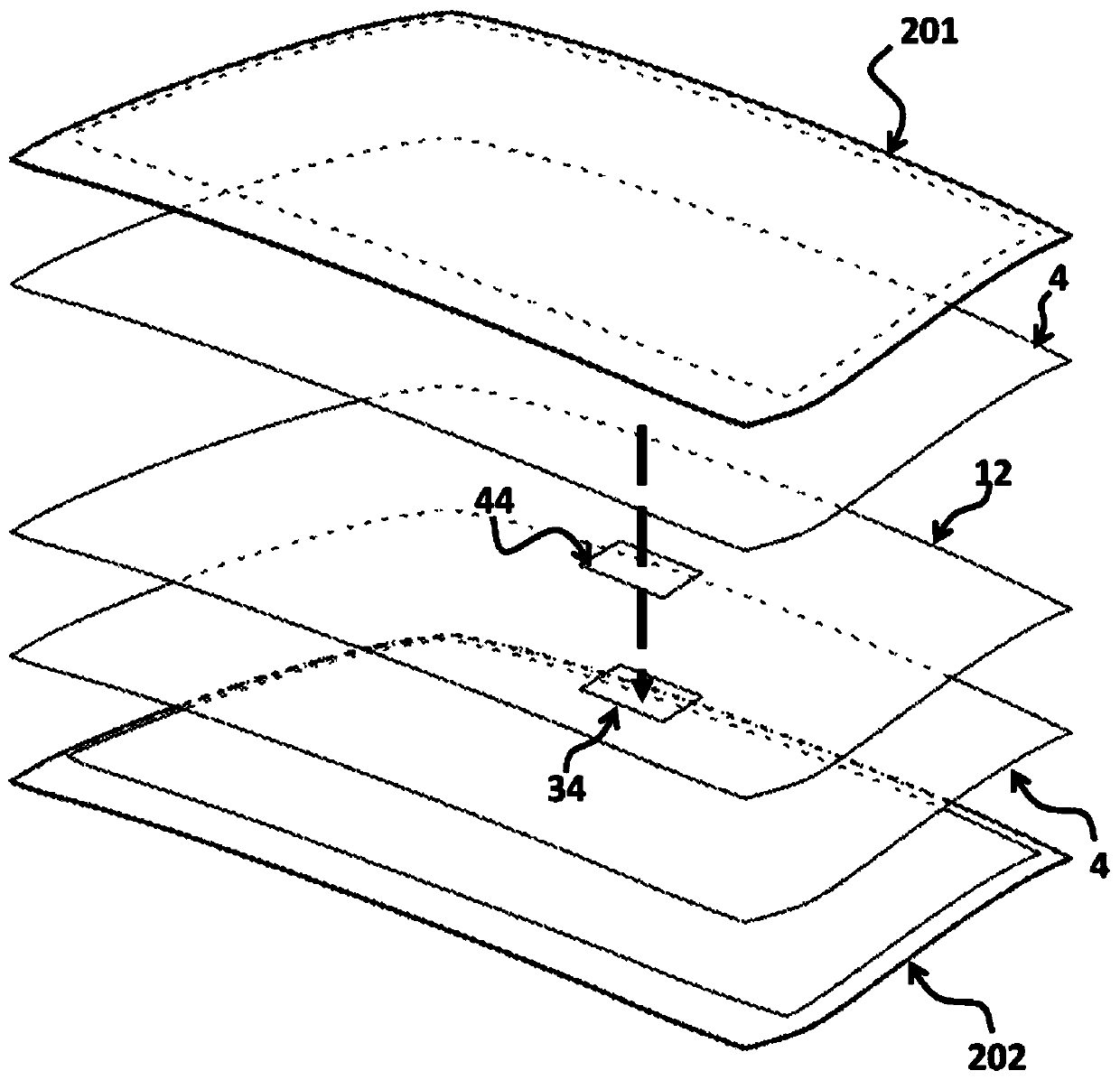

[0031] In general, a laminate is an article consisting of a plurality of sheets of thin material (thin by so-called relative to its length and width), wherein each sheet has two oppositely arranged major faces, usually each The sheets are of relatively uniform thickness, and at least one major face of each sheet is fixedly bonded to another sheet.

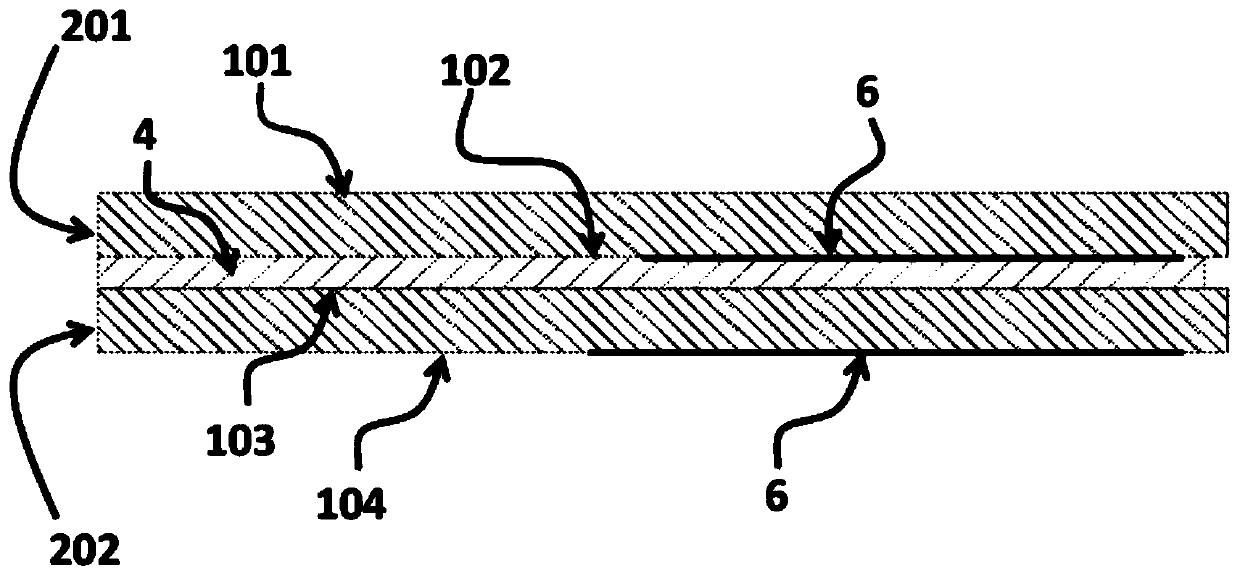

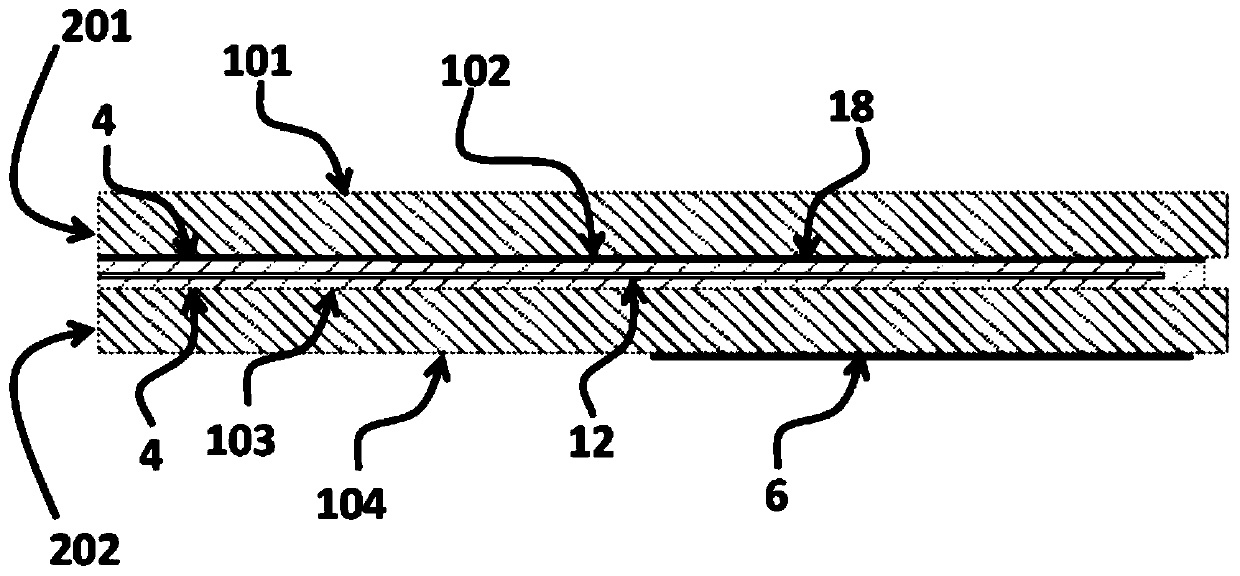

[0032] exist Figure 1A and Figure 1B A cross-sectional view of a typical automotive laminate is shown in . In the embodiment shown, the laminate comprises two layers of glass fixedly bonded together by an interlayer 4 of plastic. The two-layer glass includes an outer or outer glass layer (also called outer glass layer 201 ) and an inner or inner glass layer (also called inner glass layer 202 ). The glass surface on the exterior of the vehicle is referred to as surface one 101 or surface number one. The opposite side of the outer glass layer 201 is surface two 102 or surface number two. The glass surface of the vehicle interio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com