Purging device for cleaning line-free mill

A non-cleaning, rolling mill technology, used in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of inability to purify the emulsion liquid film, the formation of black strips on the surface of the strip, and the high amount of emulsion residues, to reduce Equipment replacement cost, the effect of reducing the emulsion on the board surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

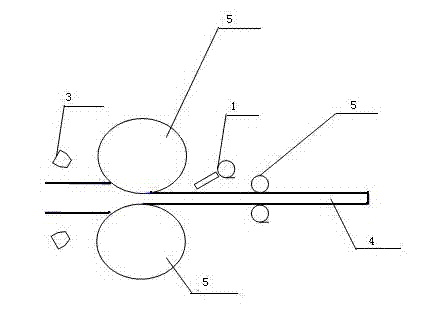

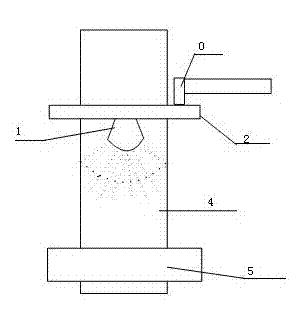

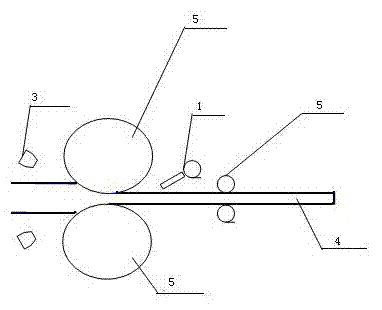

[0012] Such as figure 1 with figure 2 As shown, experienced fitters use measuring tools such as angle plates, feeler gauges, and spirit levels, and use steel rulers to simulate the direction of laminar flow for angle adjustment to ensure that the installation angle of the purge nozzle 1 on the purge beam 2 is accurate. Compressed air of 0.5Mpa is pressed in from the compressed air inlet 0, and enters the purge nozzle 1 through the purge pipe, and the emulsion sprayed from the emulsion nozzle 3 forms a laminar flow at the purge nozzle 1, and its state is as follows figure 2 As shown by the dotted line, the emulsion does not drip onto the surface of the rolled piece 4 when the rolled piece 4 passes the roll 5, thereby avoiding the problem of black bands caused by the annealing caused by the residual emulsion. Sampling the board surface after purging and sending it to Meigang Science and Technology Center to test the residue on the board surface, the test result is 1.76mg / m 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com