Bar rolling Haff surface oxidation black belt width measuring method based on image processing

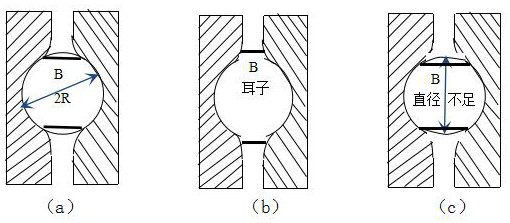

A technology of image processing and measurement methods, which is applied in the field of bar rolling, can solve problems such as hindering research and inability to quantify specifically, and achieve the effect of reducing ear defects and reducing the probability of size overruns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

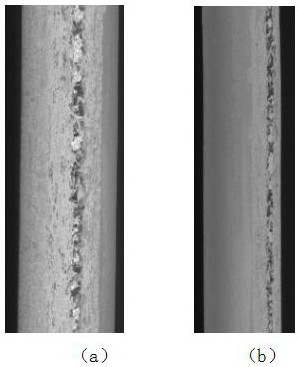

[0045] Step 1. Use a high-speed camera to obtain a photo of the bar after rolling. In the photo, the background is black and the gray scale is less than 30. The bar is off-white with a gray scale of 120~150. less than 70;

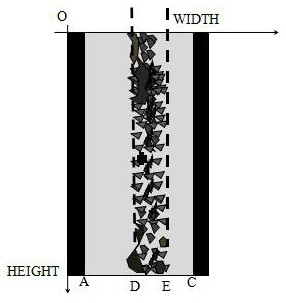

[0046] Step 2. Read the photo data, get the height HEIGHT and width WIDTH of the photo, and calculate the RGB value and gray value of each point:

[0047] Using C# programming, using the API function of C# language, automatically read the camera photos, and automatically obtain the RGB of each point, and use the form shown in formula (1) to calculate the gray value of each point;

[0048]Gray=0.299 * R + 0.587 * G + 0.114 * B (1)

[0049] At the same time, the API function of C# language is used to automatically obtain the width and height of the photo, which are recorded as WIDTH and HEIGHT re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com