Synchronizer inner ring conical surface friction material bonding mold and bonding method thereof

A technology of friction material and synchronizer, which is applied in the bonding mold of the inner ring cone friction material of the automobile synchronizer and its bonding field, can solve the problems of high energy consumption, long production cycle and low production efficiency in the production process, and achieve increased Large friction torque, increased friction area, and improved discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

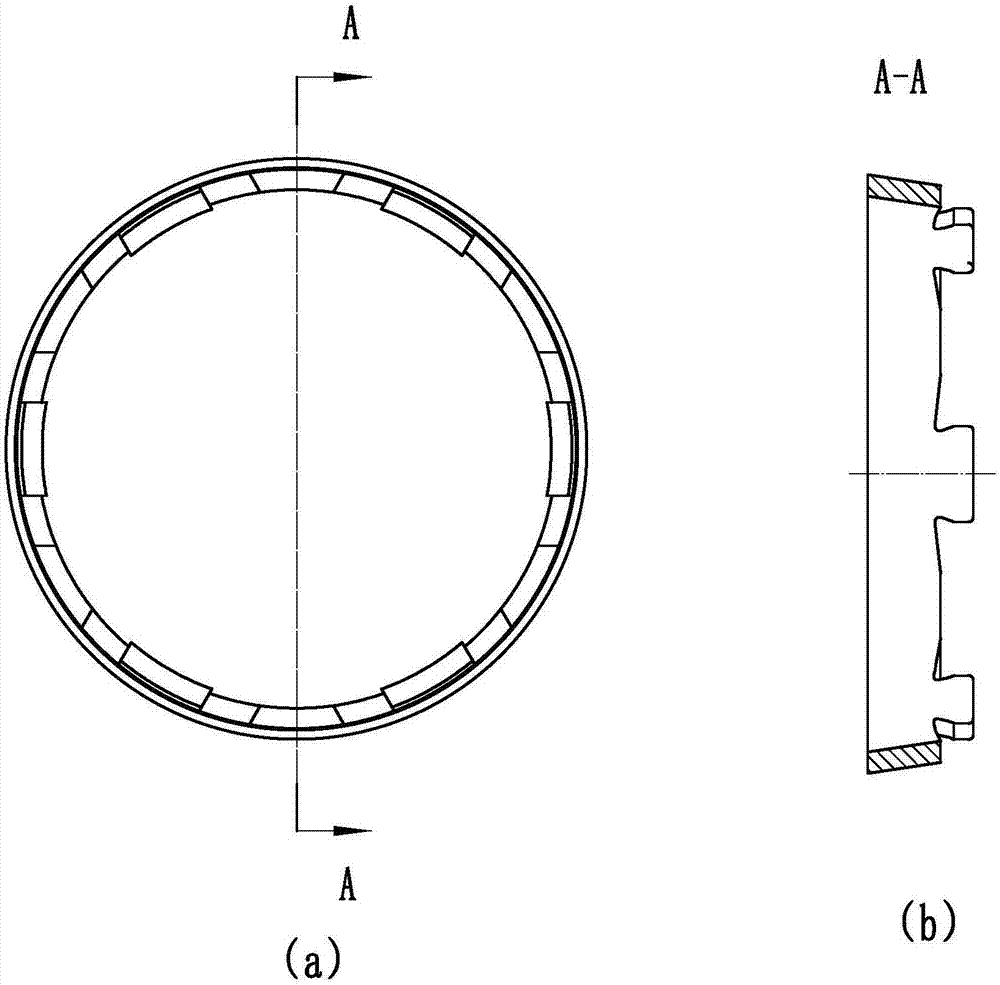

[0063] Embodiment 1 Synchronizer inner ring outer cone surface friction material bonding mold

[0064] Such as Figure 4 to Figure 6 As shown, the mold for bonding the friction material of the inner ring of the synchronizer provided in this embodiment includes a lower mold 1 and an upper mold 2 that cooperate with each other and a heating mechanism.

[0065] The heating mechanism mainly consists of an upper heating plate 31, a lower heating plate 32, a heating rod 33 and a wire 34;

[0066] The lower mold 1 comprises a first lower mold bottom plate 11a, a first ring gauge 15a, a first ejector plate 12a and a first ejector rod 13a, and two cylindrical pins 16a on the position along the circumference pass through the first ring gauge 15a, the first ejector rod 13a The mounting hole of the lower mold bottom plate 11a is fixed in the lower heating plate 32 mounting holes, and the first ring gauge 15a and the first lower mold bottom plate 11a are fixedly connected together by thre...

Embodiment 2

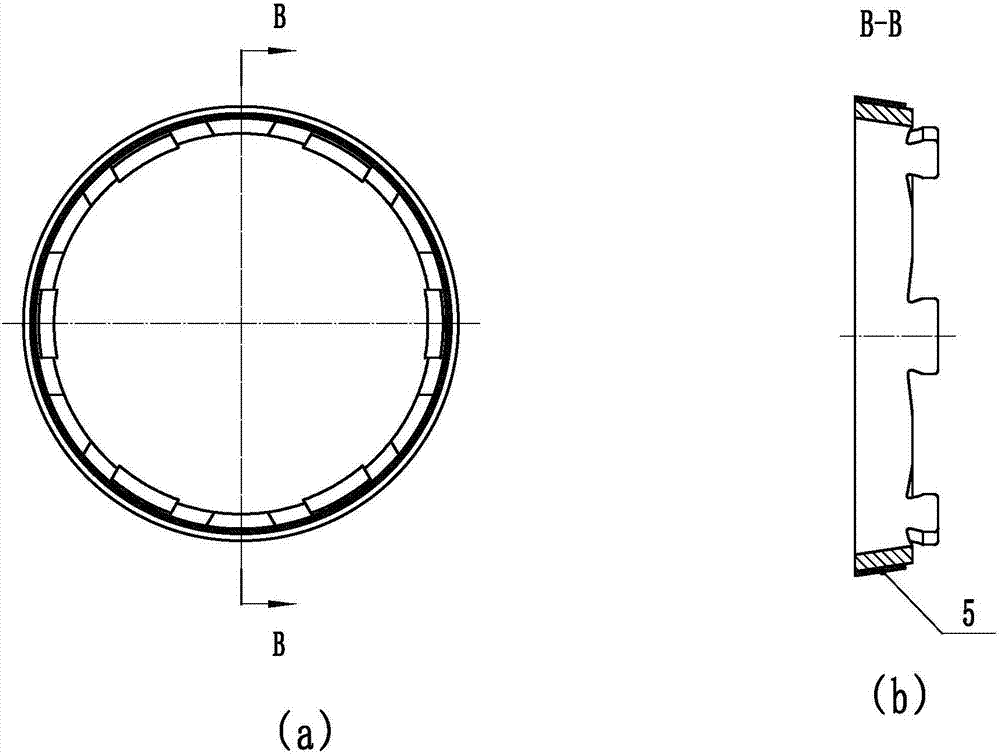

[0080] Example 2 Bonding mold for inner and outer cone friction material of synchronizer inner ring

[0081] Such as Figure 7 to Figure 9 As shown, the mold for bonding the friction material of the inner ring of the synchronizer provided in this embodiment includes a lower mold 1 and an upper mold 2 that cooperate with each other and a heating mechanism.

[0082] The heating mechanism mainly consists of an upper heating plate 31, a lower heating plate 32, a heating rod 33 and a wire 34;

[0083] Lower mold 1 comprises the second lower mold bottom plate 11b, the limit base 12b and the expansion core 13b and the second ejector plate 14b, support block 15b, second ejector rod 16b coaxially connected; the second lower mold bottom plate 11b, limiter The position base 12b and the expansion core 13b are positioned by a cylindrical pin 110b, and are fixedly connected by a plurality of screws 19b, and the screws 19b extend into the lower heating plate 32, and the second lower mold bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com