Cloth bonding device

A bonding device and cloth technology, applied in lamination device, lamination auxiliary operation, lamination, etc., can solve problems such as low efficiency, weak cloth bonding, gaps, etc., to ensure the bonding quality and ensure the adhesion Combine processing quality and avoid loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

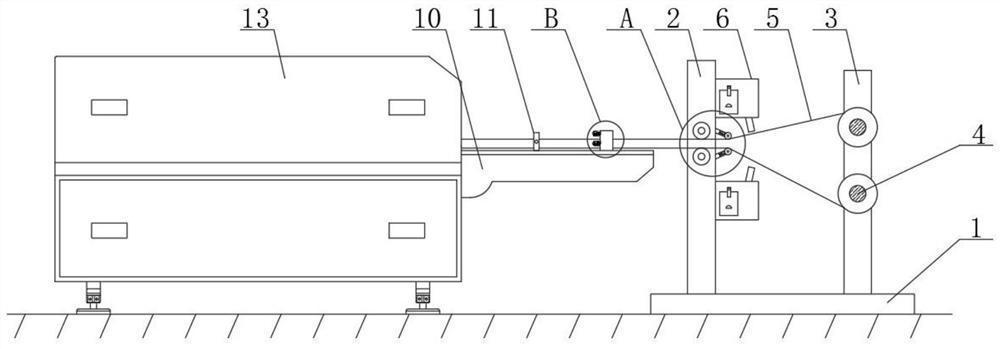

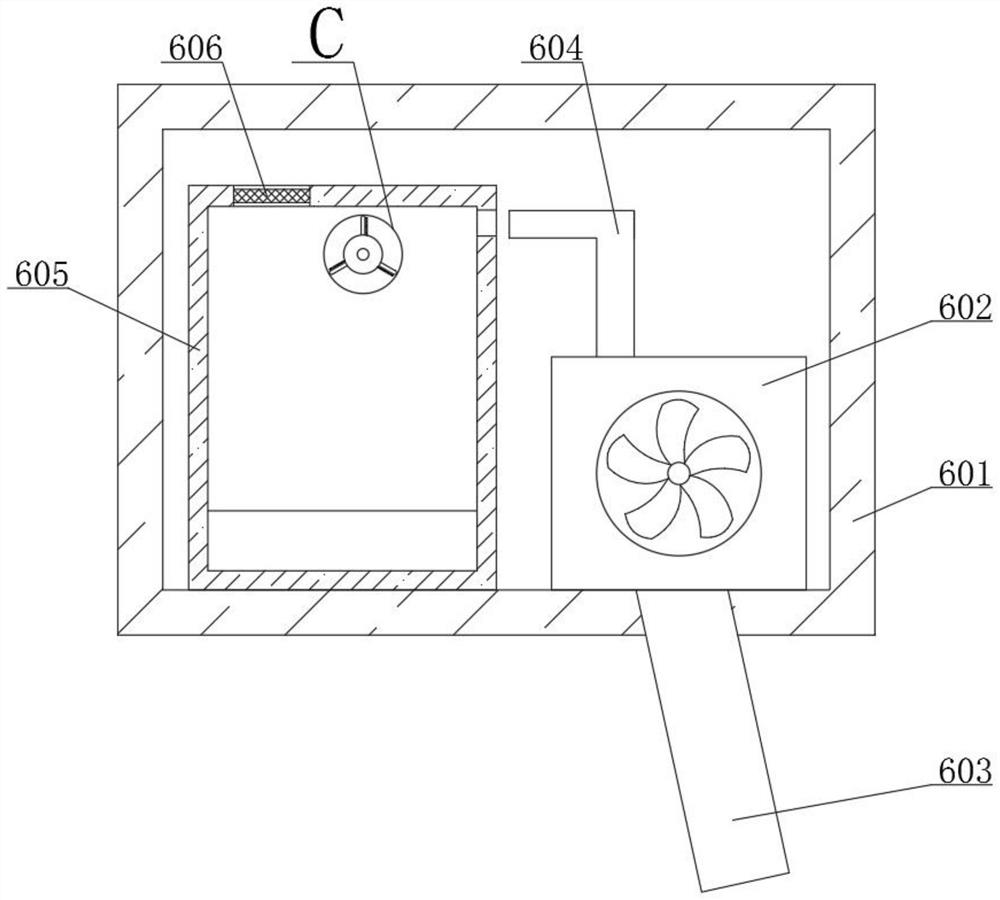

[0028] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , the present invention provides a technical solution:

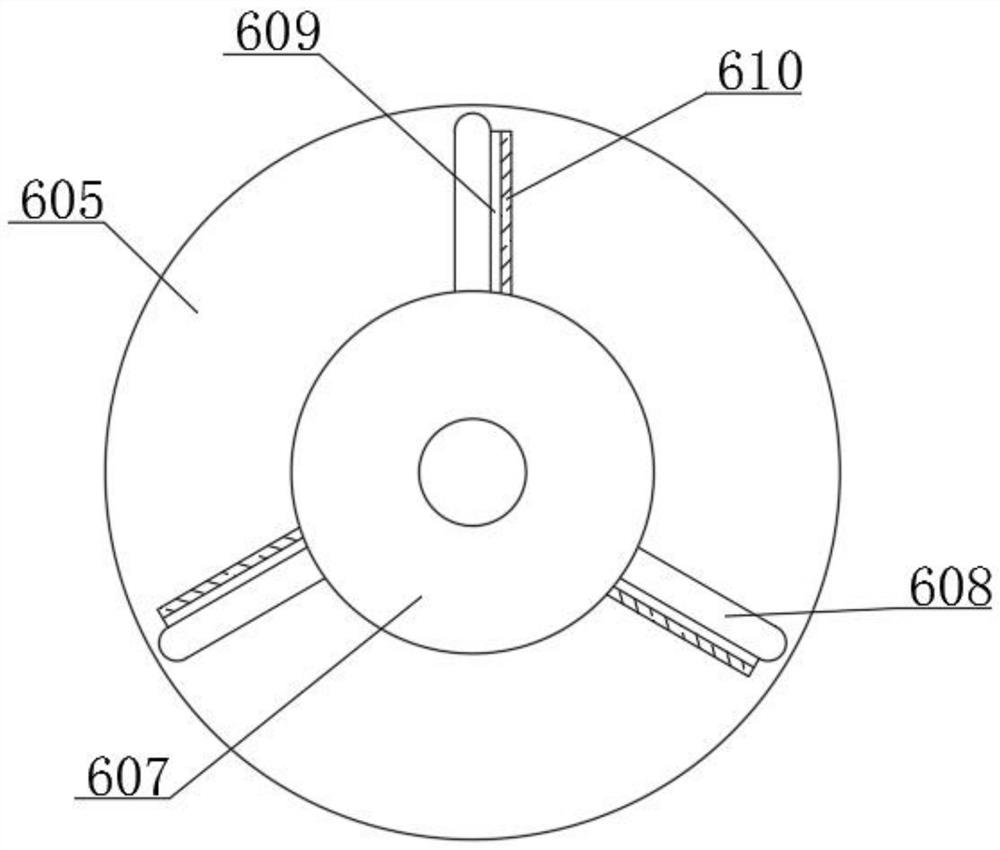

[0029]A fabric bonding device, comprising a base 1 and a left fixing frame 2, the left side fixing frame 2 distributed front and rear is fixedly connected to the left side of the upper end surface of the base 1, and the right side fixed frame distributed front and rear is fixedly connected to the right side of the upper end surface of the base 1. The side fixing frame 3 and the inner side of the right side fixing frame 3 are rotatably connected with a cloth-discharging tray 4 distributed up and down, and a cloth layer 5 is arranged on the outside of the cloth-releasing tray 4, and a dust suction device 6 is connected to the right side of the left side fixing frame 2. The dust collection device 6 includes a dust collection box 601 and a fan 602. The left side of the dust collection box 601 is fixedly connected t...

Embodiment 2

[0032] In embodiment 2, the same part as embodiment 1 is not described in detail, and the difference is that when a large amount of threads are stuck on the surface of its sub-Velcro 610, at this time, the sub-Velcro 610 can be torn off, and then the sub-Velcro can be fixed. The surface of 610 is cleaned, and then bonded together with the mother Velcro 609, which is convenient for continued use next time and avoids waste of resources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com