Wall-climbing paint spraying robot with elastic anti-explosion wheels

A robot and wheel technology, applied in the direction of wheels, motor vehicles, vehicle parts, etc., can solve the problems of large volume and weight, economic loss of the application party, and hazards of the application party, and achieve the reduction of the overall shape and volume weight, the overall shape and Simplify the volume and weight, eliminate the effect of burning or flash explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples:

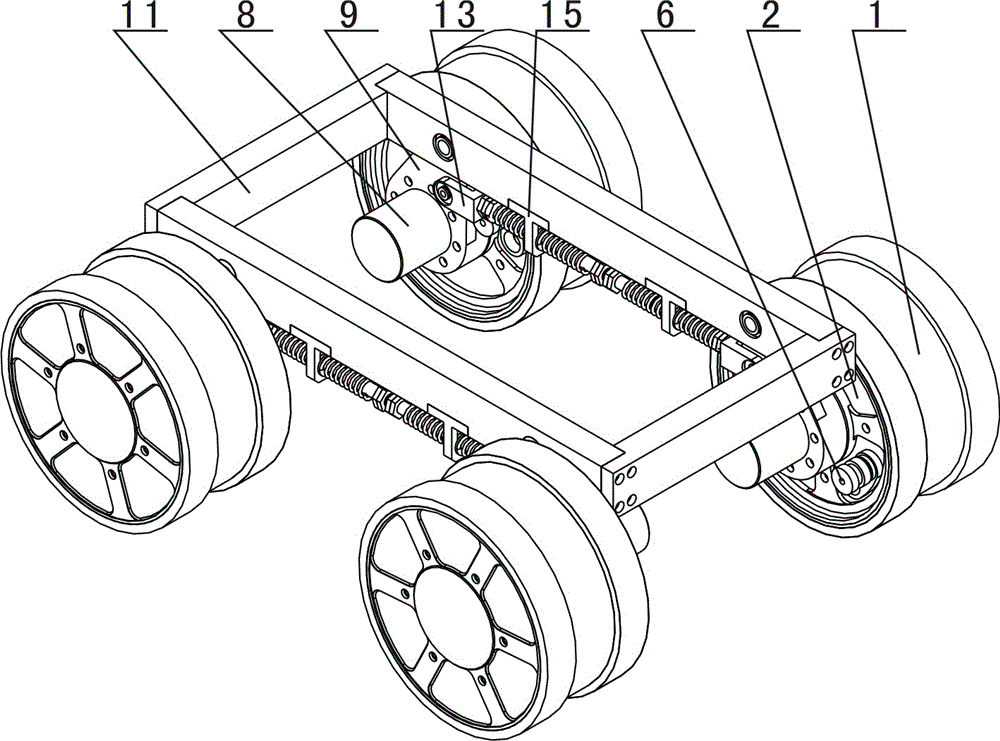

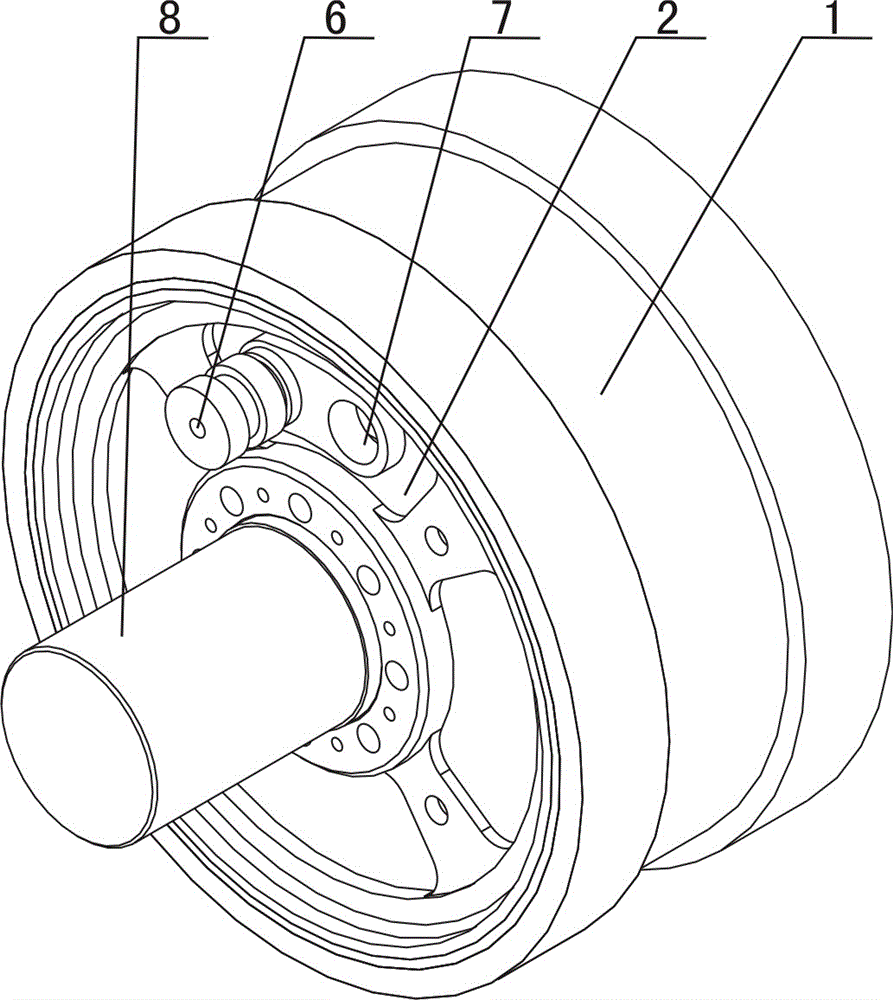

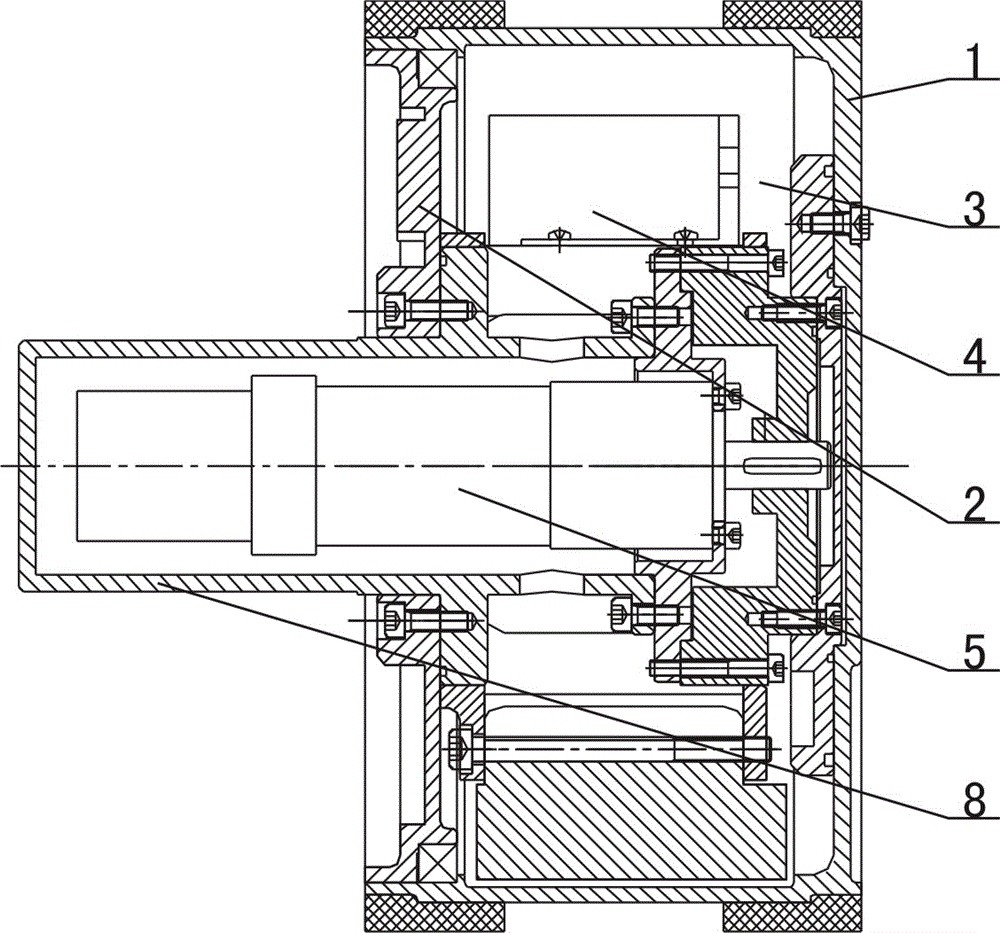

[0030] combined with Figure 1~4 The wall-climbing painting robot with elastic explosion-proof wheels includes explosion-proof wheels and an elastic connection structure; the explosion-proof wheel includes a wheel shell 1, a wheel end cover 2, a wheel drive system, an explosion-proof plug 6 and an inert gas pipe interface 7; The wheel shell 1 and the wheel end cap 2 are in contact with each other to form a cavity 3, and a wheel drive system for driving the explosion-proof wheel is fixedly arranged in the cavity 3, that is, the explosion-proof wheel is installed in the wheel inner cavity 3 The wheel drive system in the drive system drives the rotation; according to the needs, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com