A bonding mold and bonding method for tapered surface friction material of synchronizer intermediate ring

A technology of friction materials and intermediate rings, which is applied in the direction of connecting components, manufacturing tools, presses, etc., and can solve problems such as difficult control of the joint position of friction materials and intermediate rings, unstable bonding quality of products, and high labor intensity of workers. , to achieve the effect of being conducive to lightweight design, reducing installation and debugging time, and avoiding the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 Synchronizer intermediate ring outer cone surface friction material bonding mold

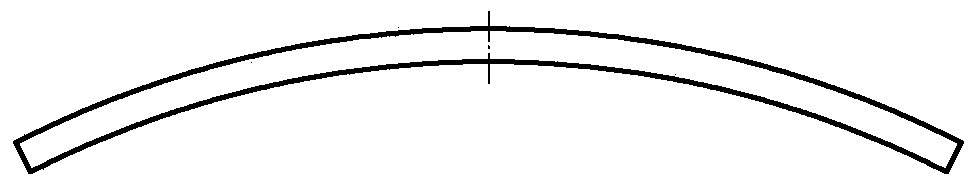

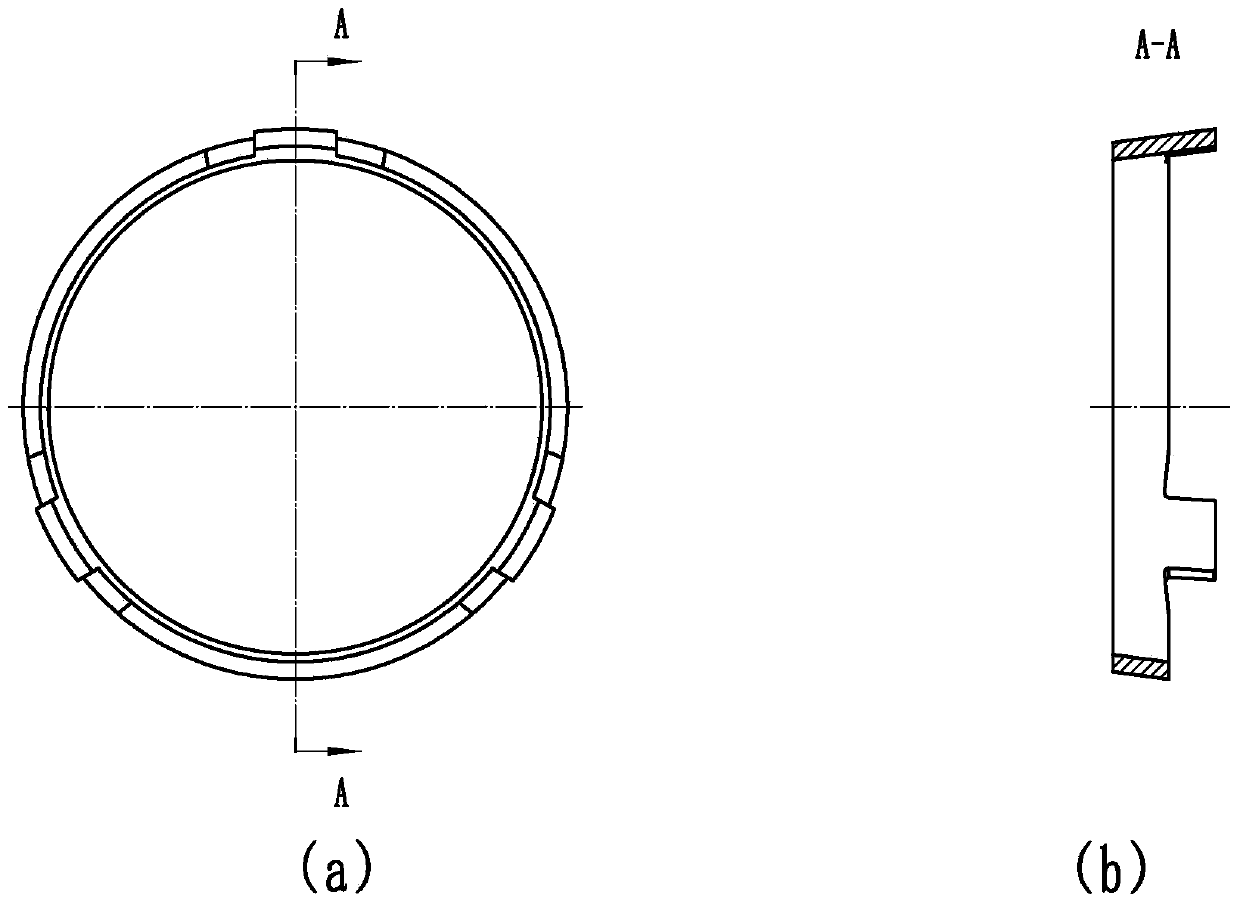

[0053] The intermediate ring structure targeted by this embodiment is as figure 2 shown, where figure 2 (a) main view, figure 2 (b) is a cross-sectional view along line A-A. The intermediate ring of the synchronizer has 3 convex keys, and the intermediate ring of the synchronizer in embodiment 2 has 6 convex keys.

[0054] Such as Figure 4 to Figure 5 As shown, the outer cone friction material bonding mold of the synchronizer intermediate ring provided in this embodiment includes an upper mold 1 , a lower mold 2 and a heating mechanism 3 that cooperate with each other.

[0055] The upper mold 1 includes a first upper mold bottom plate 101a, a first pressure plate 102a that is clearance-fitted with the first upper mold bottom plate 101a, and three groups for adjusting the parallelism of the lower mold 2 and the upper mold 1 along the circumferential direction of the fi...

Embodiment 2

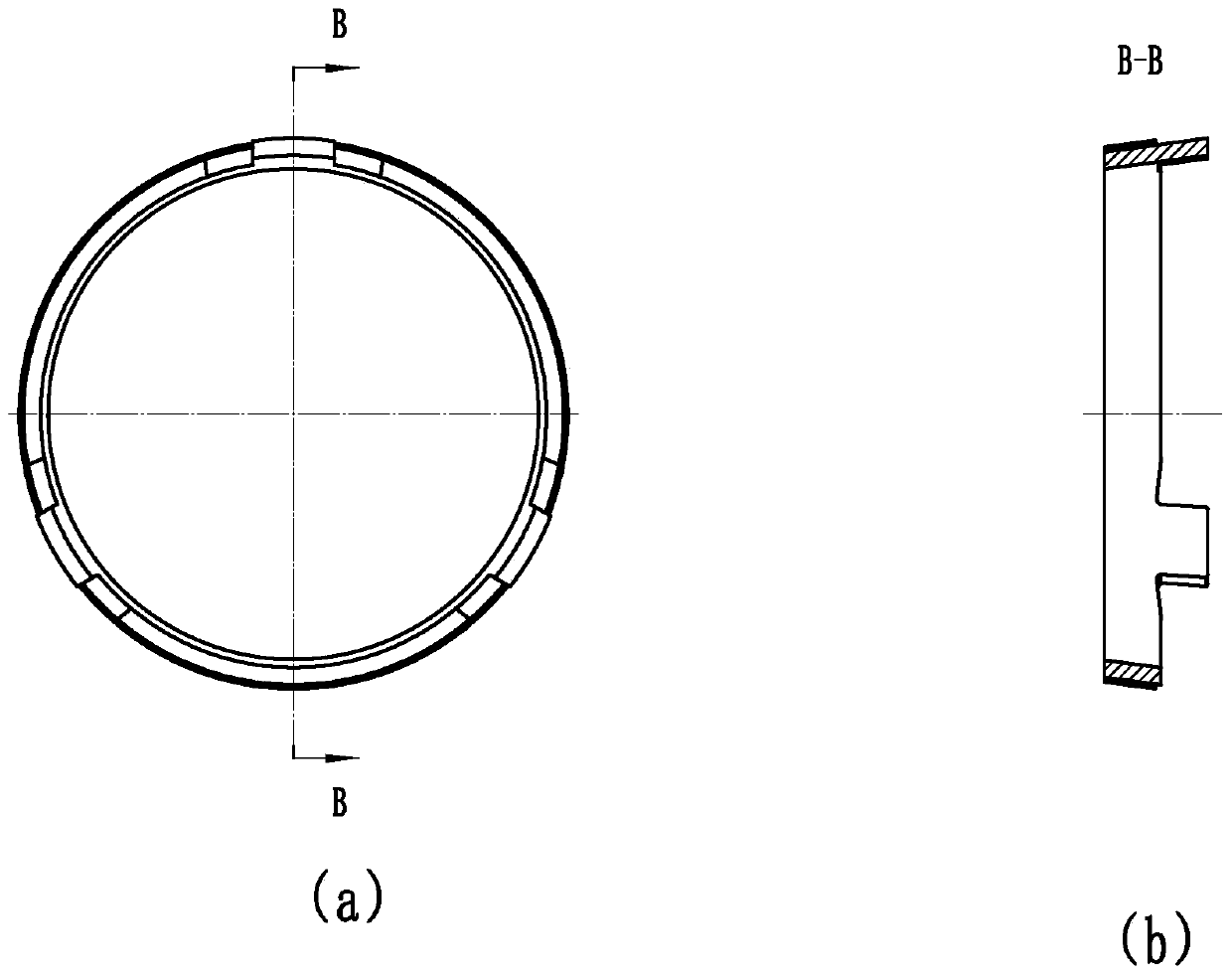

[0070] Example 2 Bonding mold for inner / outer cone surface friction material of synchronizer intermediate ring

[0071] Such as Figure 6 to Figure 8 As shown, the inner / outer cone friction material bonding mold of the synchronizer intermediate ring provided in this embodiment includes an upper mold 1 , a lower mold 2 and a heating mechanism 3 that cooperate with each other.

[0072] The upper mold 1 includes a second upper mold bottom plate 101b, a second pressure plate 102b that fits in a gap with the second upper mold bottom plate 101b, an expanding core 105b that matches the inner cone of the middle ring bonded with friction material, along the circumferential direction of the second pressure plate 102b. Three sets of floating assemblies for adjusting the parallelism between the lower mold 2 and the upper mold 1 and three sets of unloading assemblies arranged along the circumferential direction of the second pressing plate 102b; the docking positions of the second pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com