Spoon counting machine

A spoon counting machine and frame technology, applied in the direction of conveyor objects, transportation and packaging, packaging, etc., can solve the problems of spoon loss, heavy workload, unreliable quality, etc., to avoid missing or overfilling, easy to operate , to ensure the effect of synchronous transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

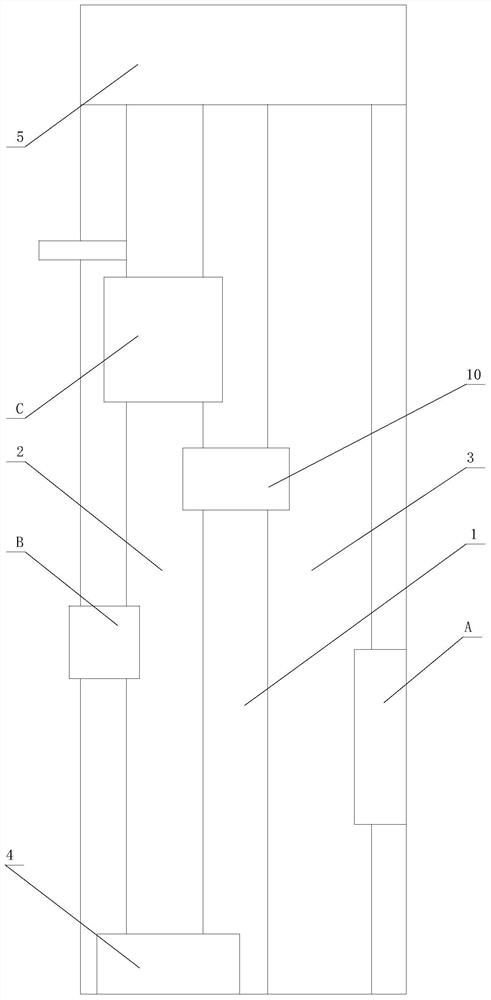

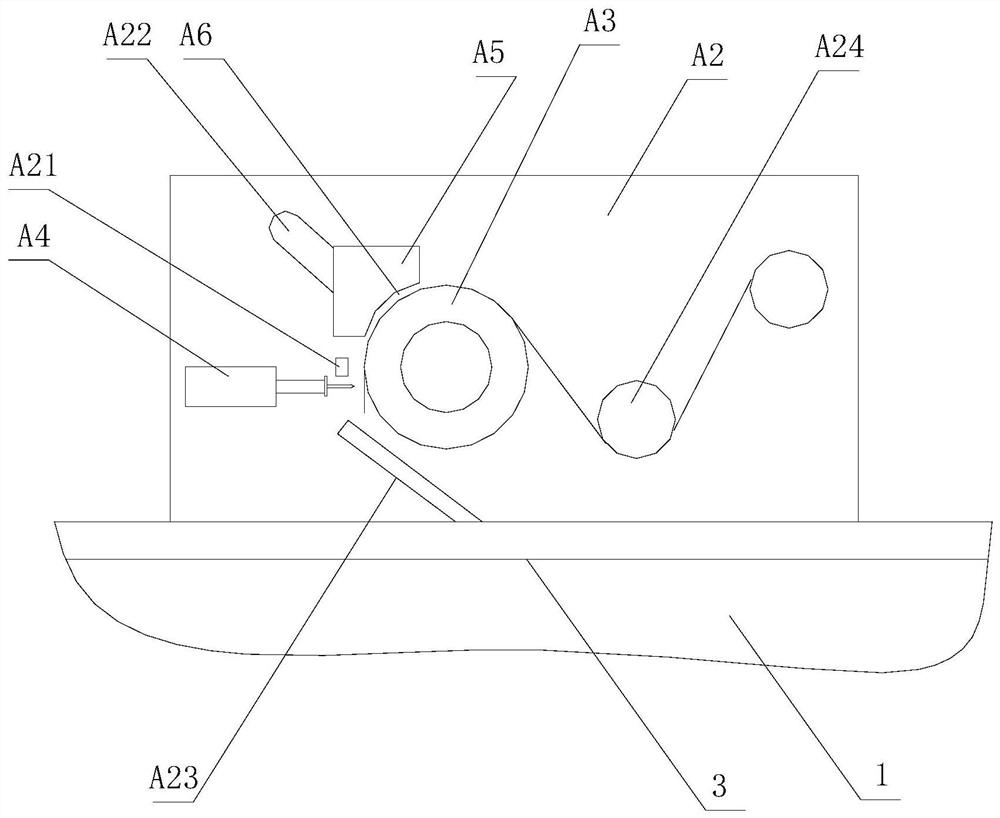

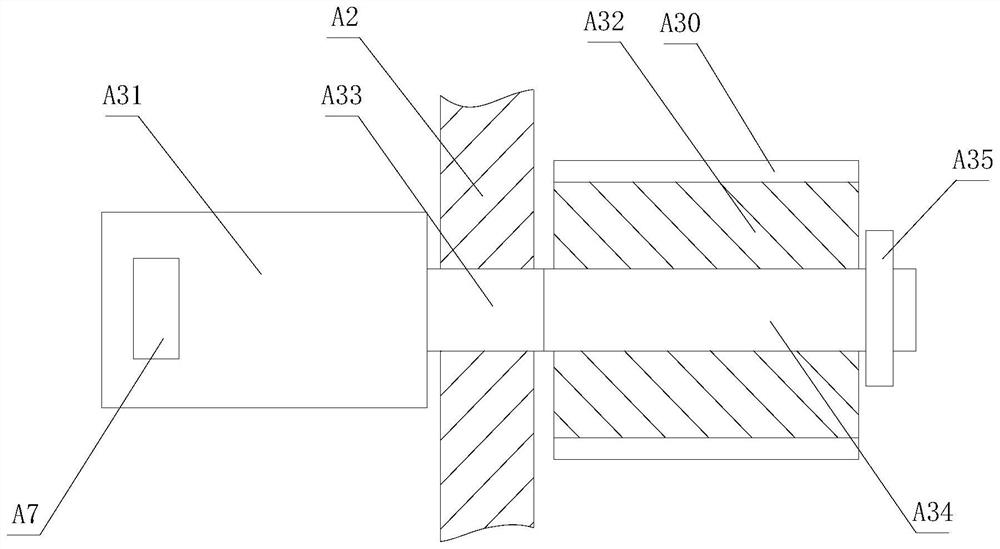

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 Shown, a kind of scoop pointing machine comprises frame 1, and described frame 1 is respectively provided with cup cover conveyer belt 2 and spoon conveyer belt 3, and along conveying direction described frame 1 is provided with to cup cover glue spraying machine successively. The glue spraying device B, the manipulator 10 for putting the spoon into the cup lid, and the visual recognition waste discharge device C for detecting whether there is a spoon in the cup lid, the manipulator in this embodiment is the prior art, and this embodiment does not In detail, a scoop separating device A is provided on the frame 1 above the spoon conveyor belt, and the visual recognition waste discharge device C includes a detection mechanism C2 and a push-out mechanism C7, and the push-out mechanism is arranged at the discharge point of the detection mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com