Patents

Literature

44results about How to "High bonding precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

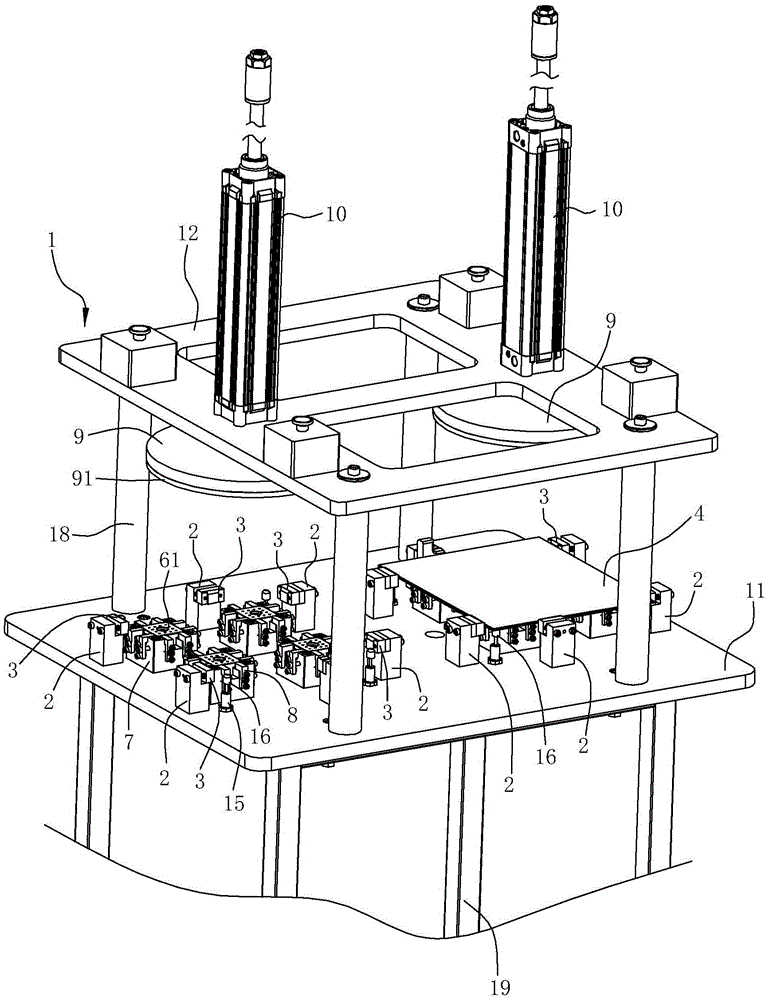

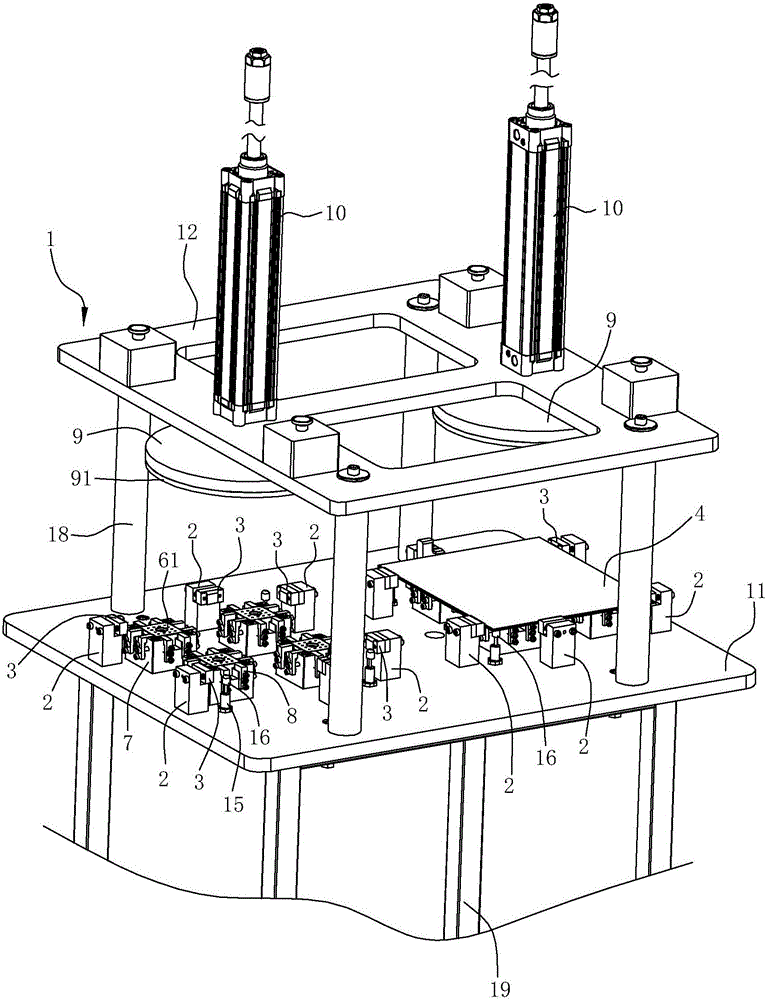

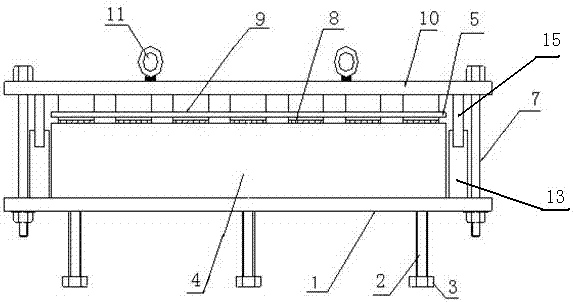

Bonding tool capable of simultaneously bonding various parts onto glass panel

ActiveCN105422567AImprove bonding efficiencyHigh bonding precisionMaterial gluingElectrical junctionEngineering

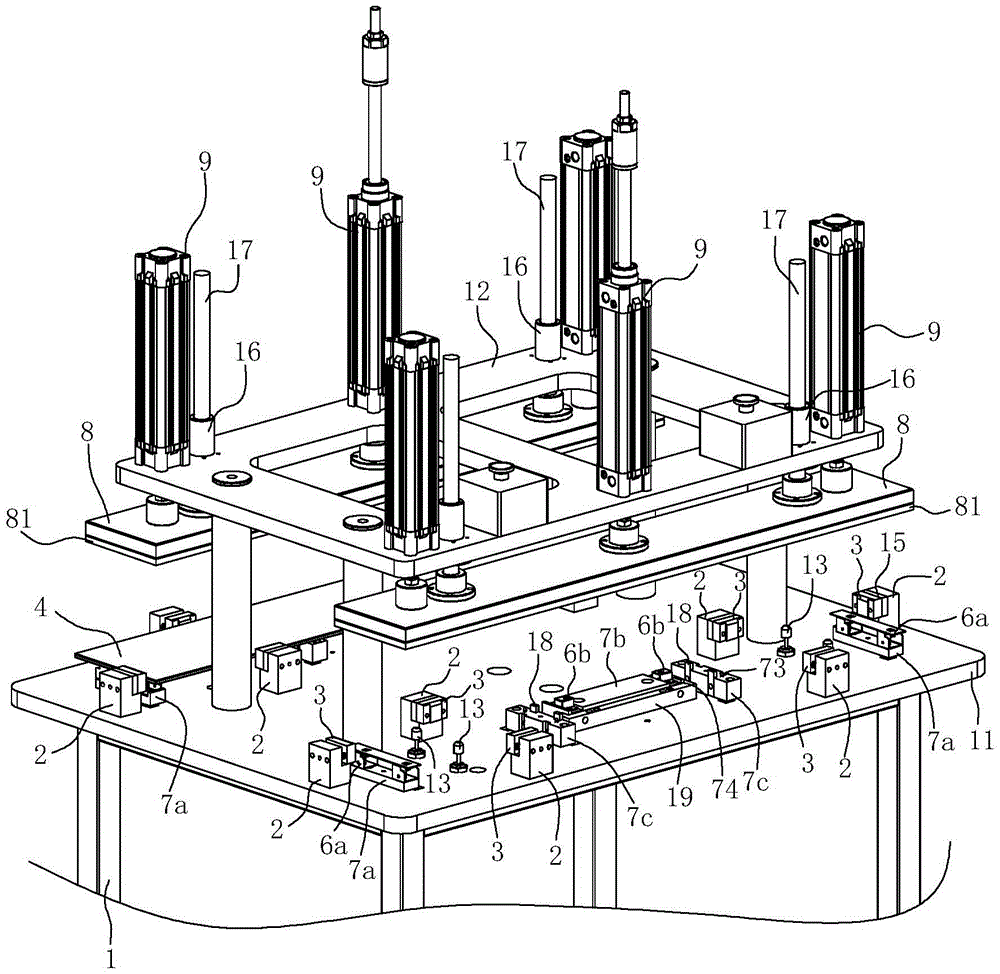

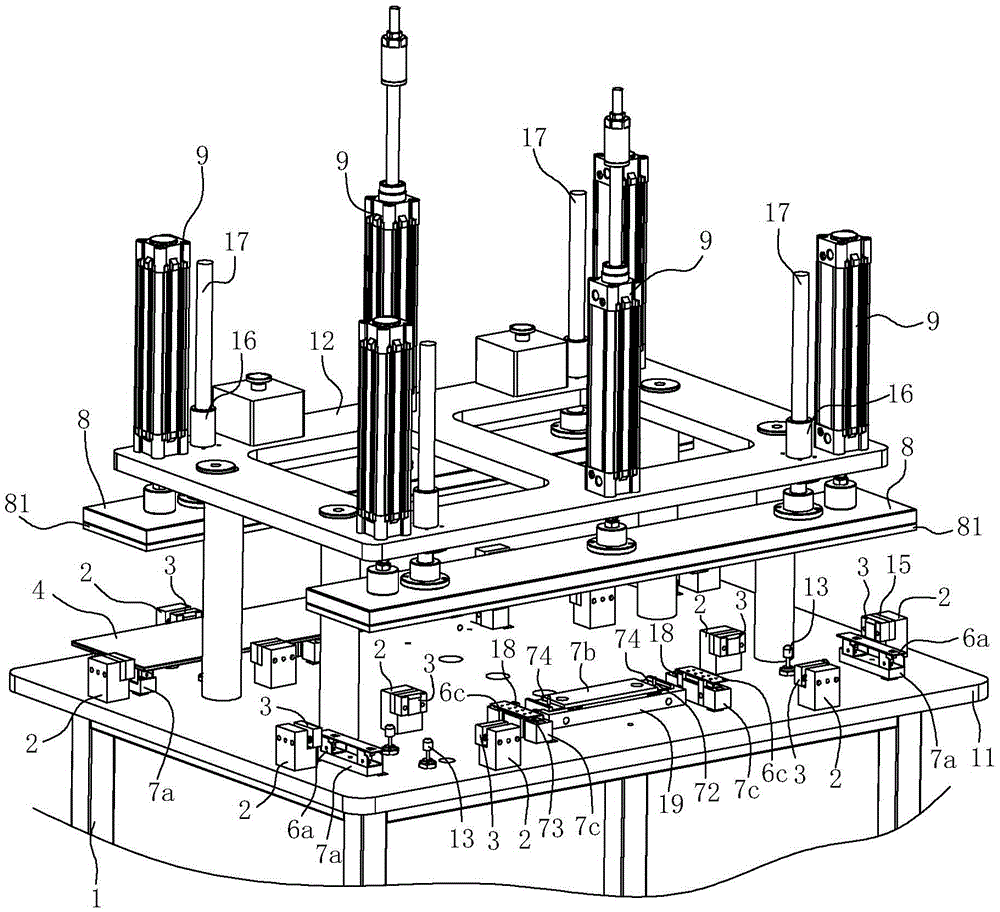

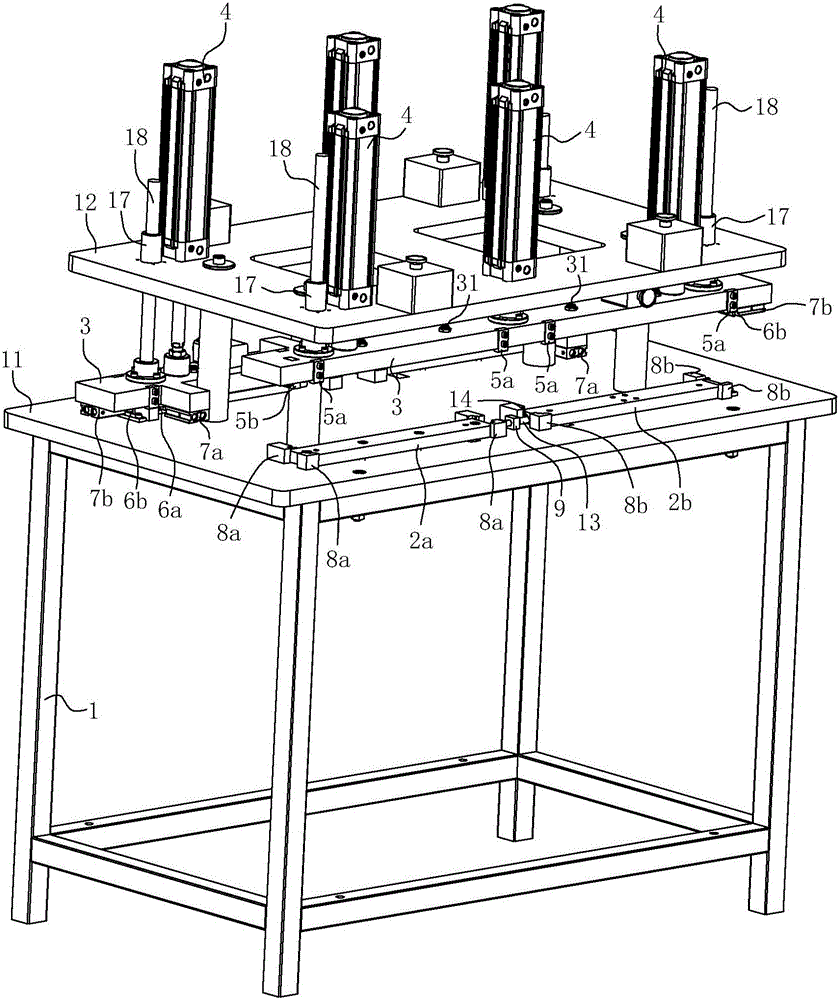

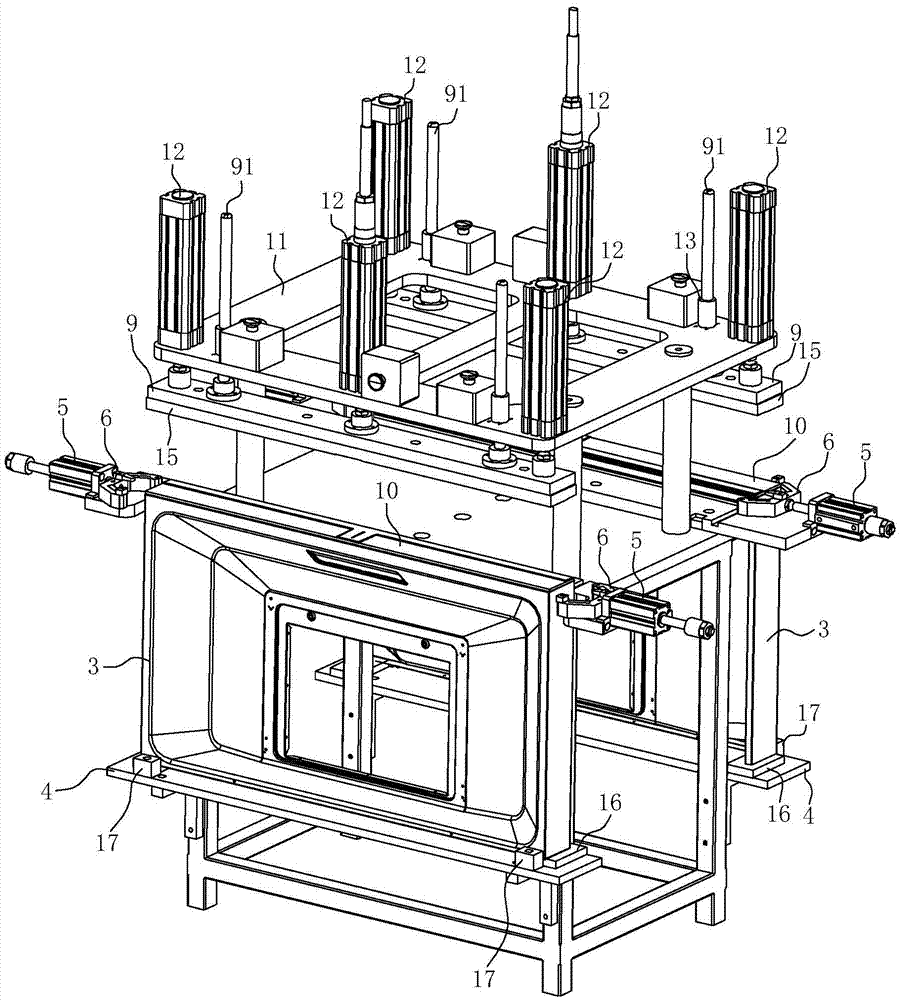

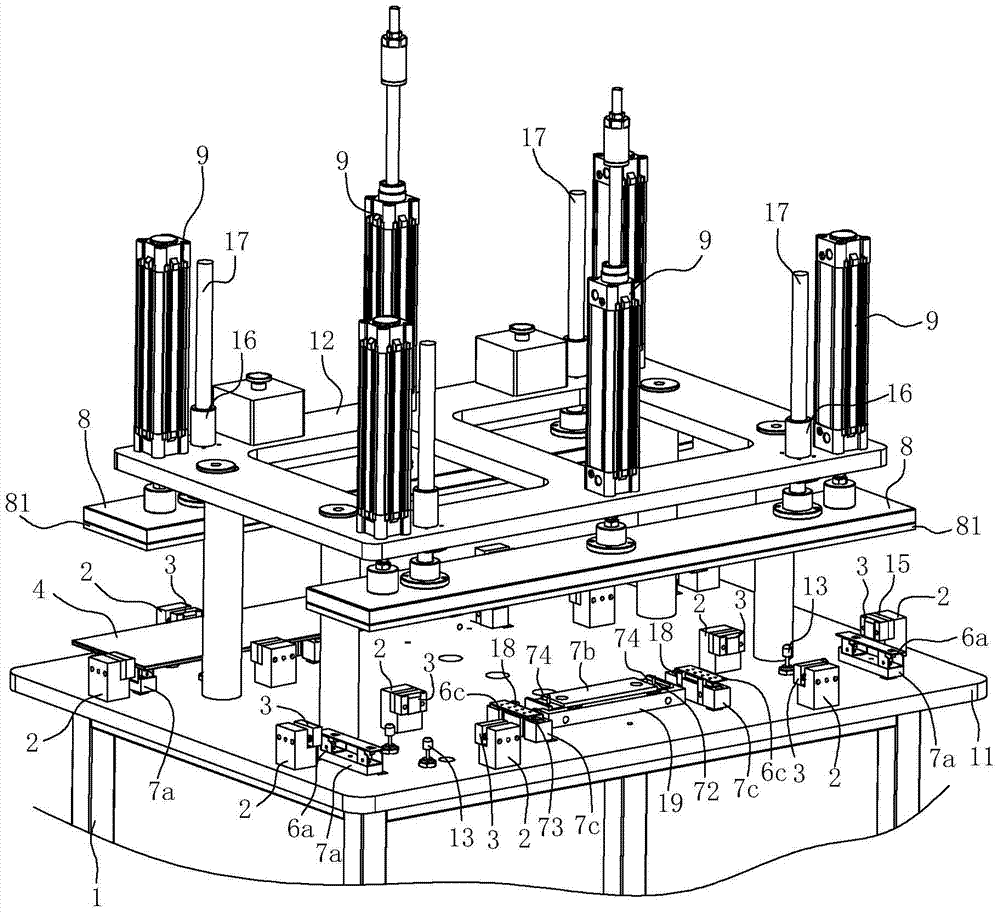

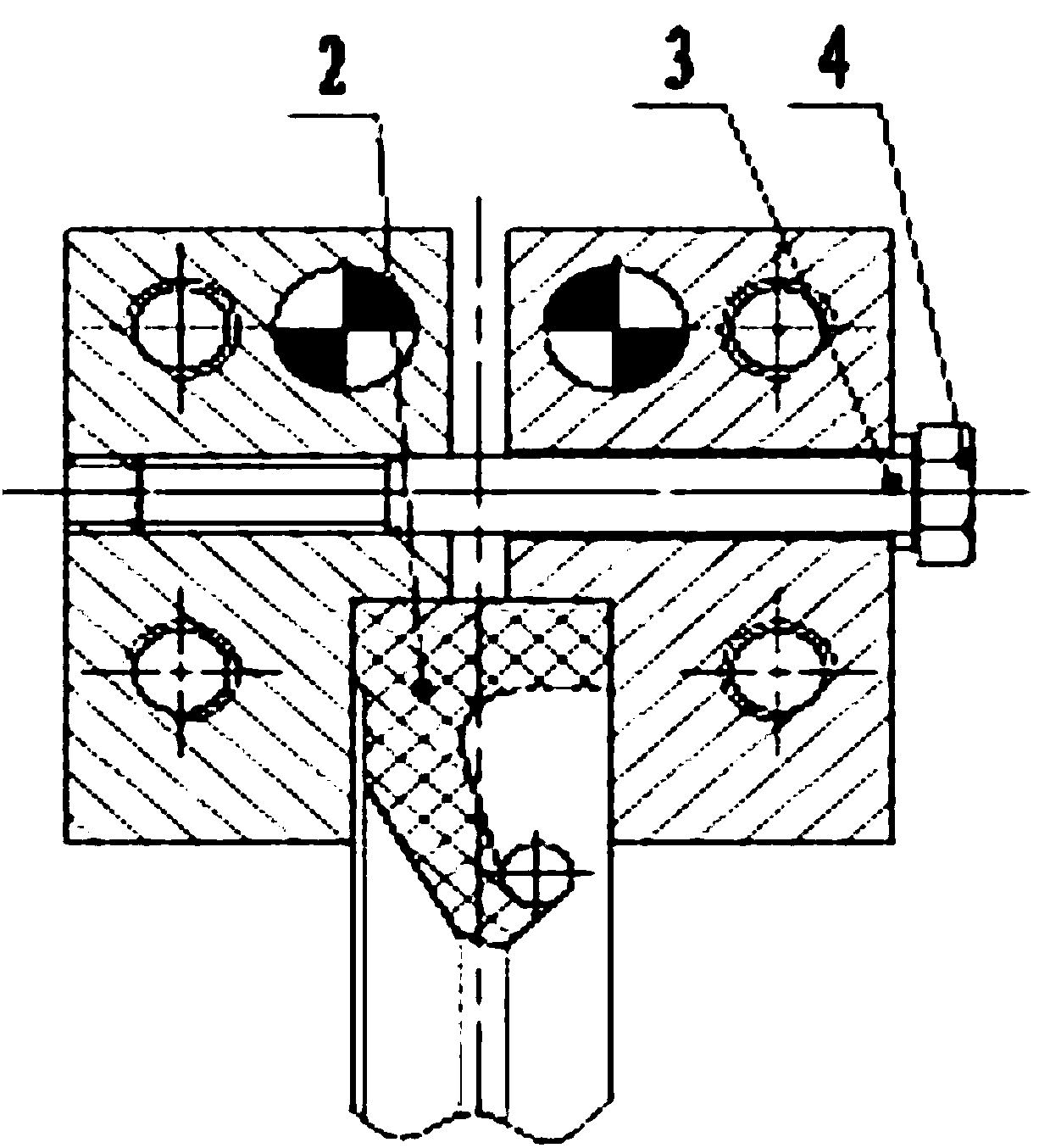

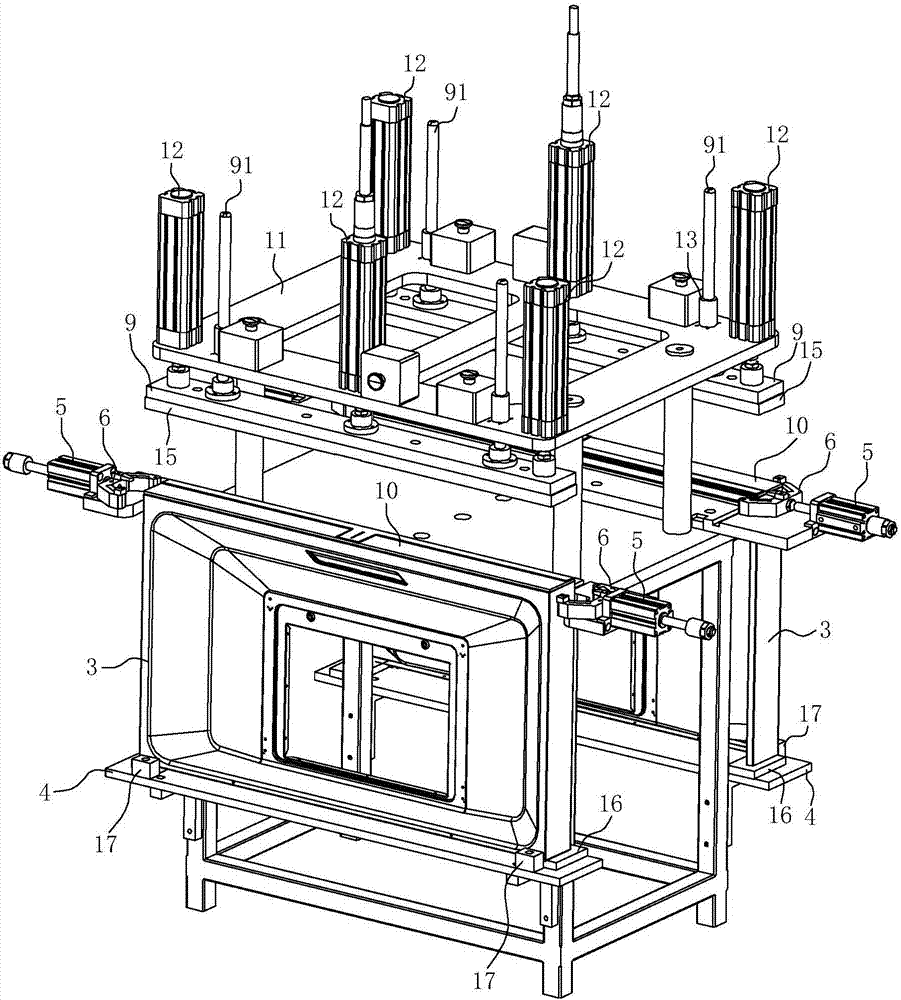

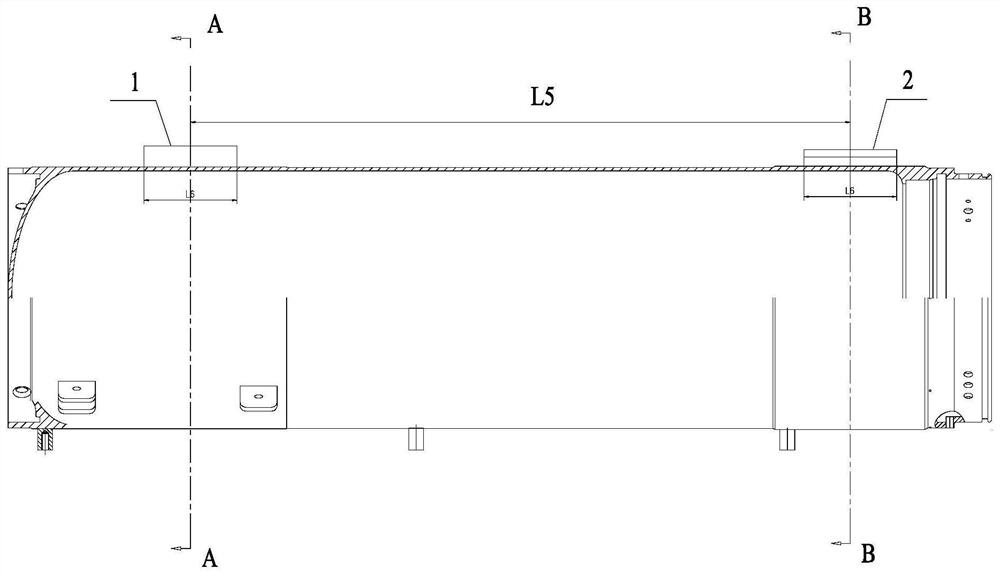

The invention relates to a bonding tool capable of simultaneously bonding various parts onto a glass panel. The bonding tool comprises a frame body which is provided with a table board and an upper mounting plate, and at least one set of a bonding structure. The bonding tool is characterized in that the bonding structure comprises a peripheral limiting structure for peripherally restraining the glass panel, a first lay-up block which is fixed on the table board for restraining a glass panel bracket, a second lay-up block which is fixed on the table board for restraining a first switch bracket, a third lay-up block which is fixed on the table board for restraining a second switch bracket, and a pressure maintaining block which is arranged above the table board, is driven by a pressure maintaining air cylinder mounted on the upper mounting plate to move up and down vertically, wherein the pressure maintaining block is pressed for pressing the glass panel to the bonding surface of each bracket to carry out pressure maintaining. The tool works once, so that not only can the glass bracket and the switch bracket be bonded onto the glass panel, but also bonding mounting of switch brackets of different models on the glass panel can be adapted, and therefore, the tool has the advantages of high bonding efficiency and high bonding precision, less processes, and convenient operation.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

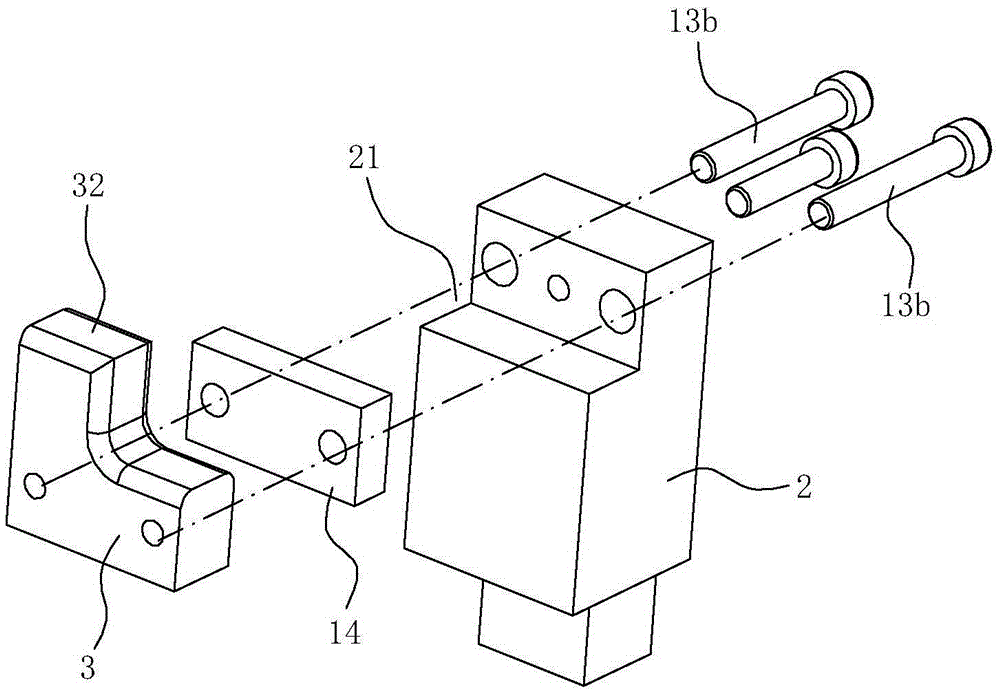

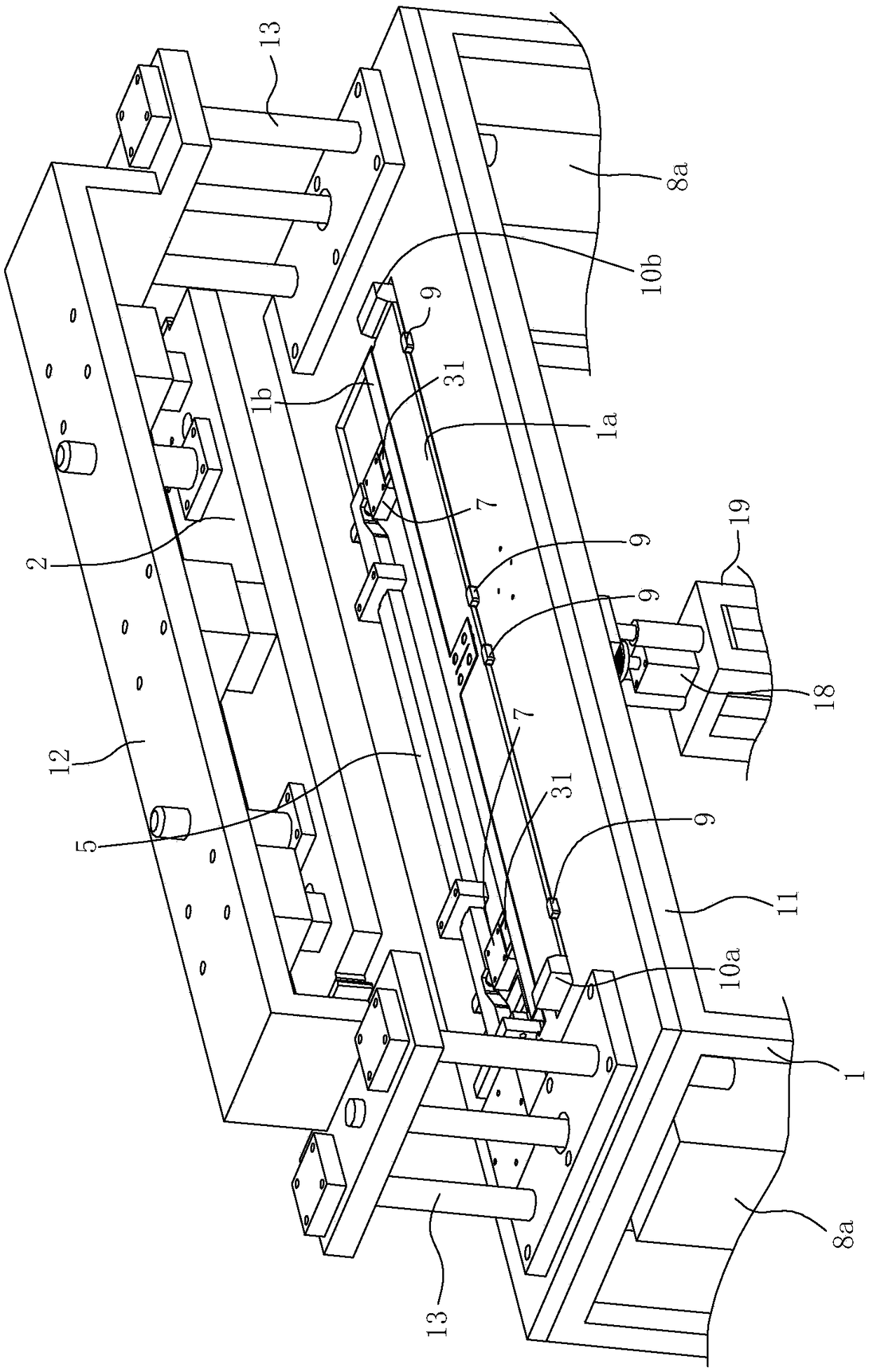

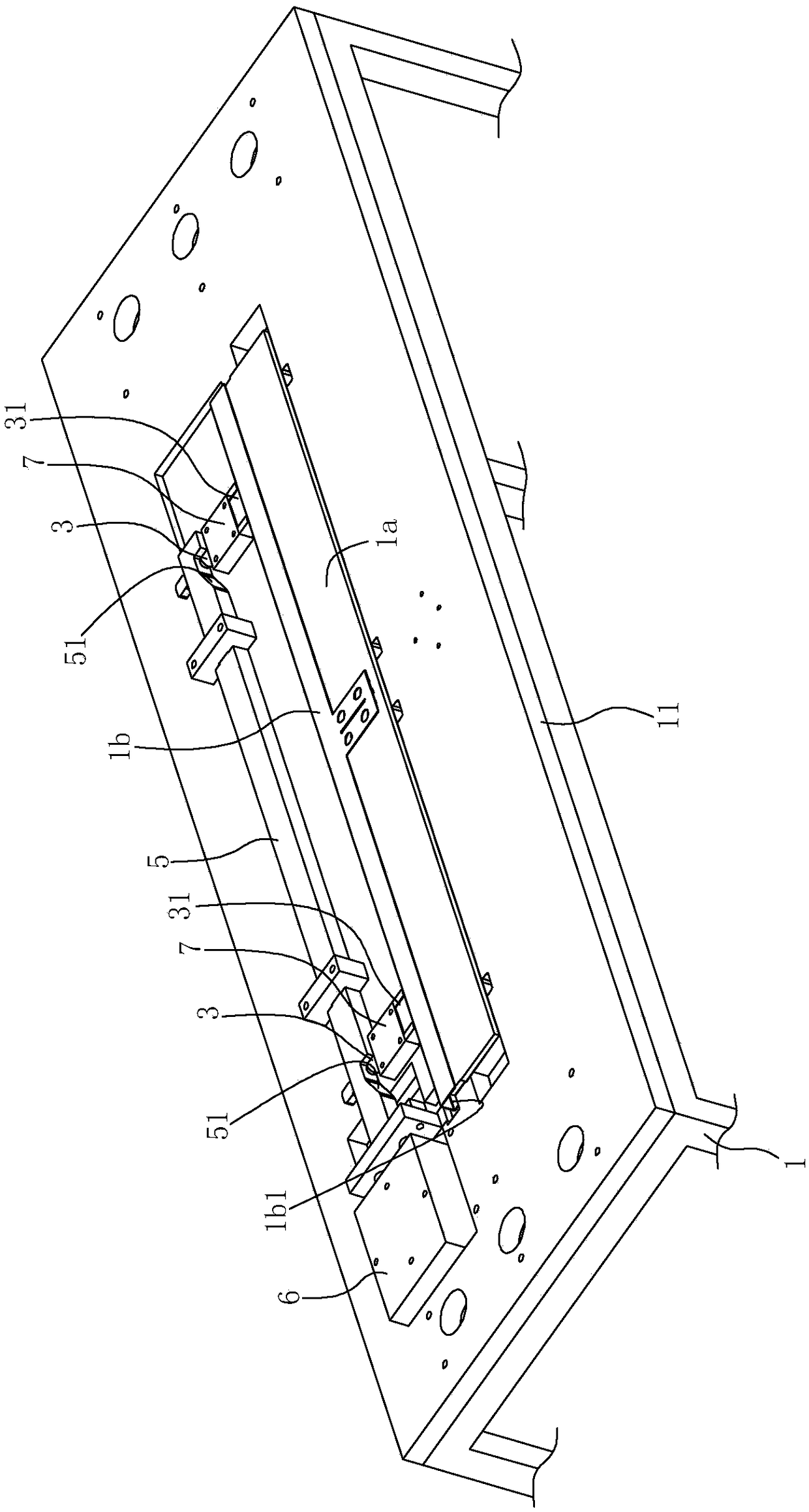

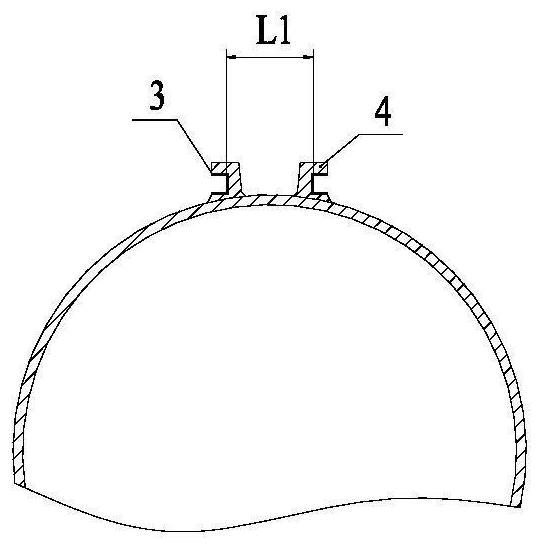

Splicing tool used for splicing decoration panel to glass faceplate

ActiveCN106050853AGood adhesionSolve the problem of bonding misalignmentMaterial gluingSurface plate

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

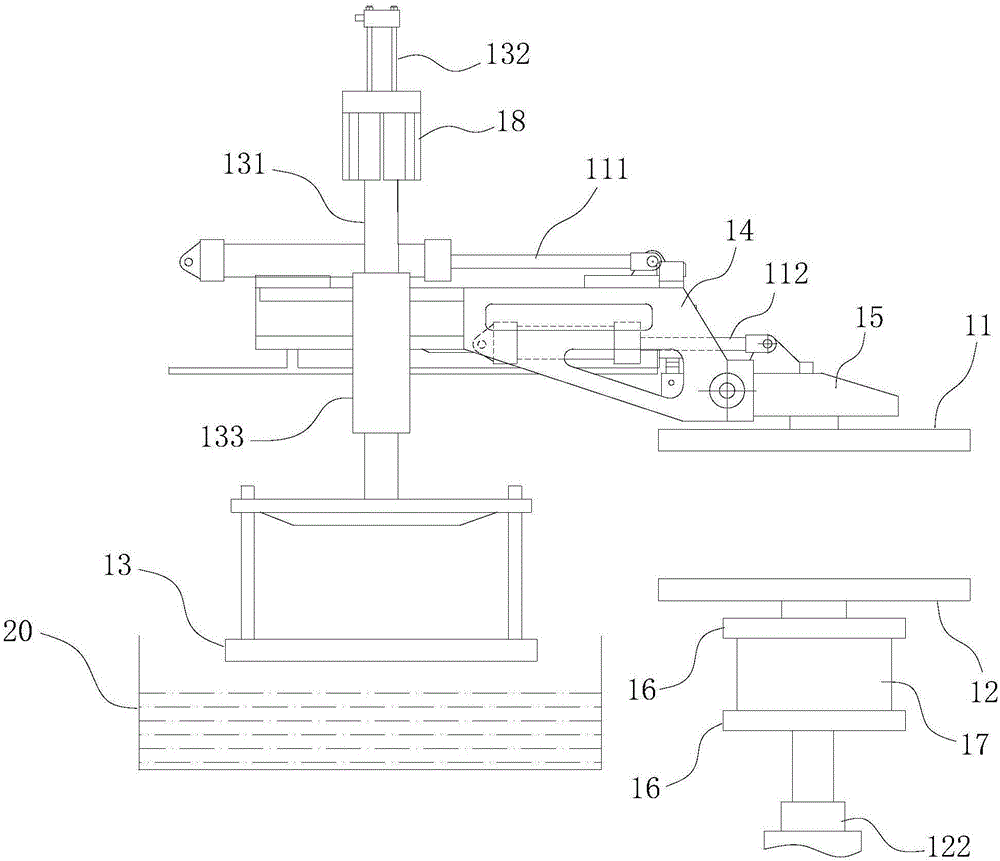

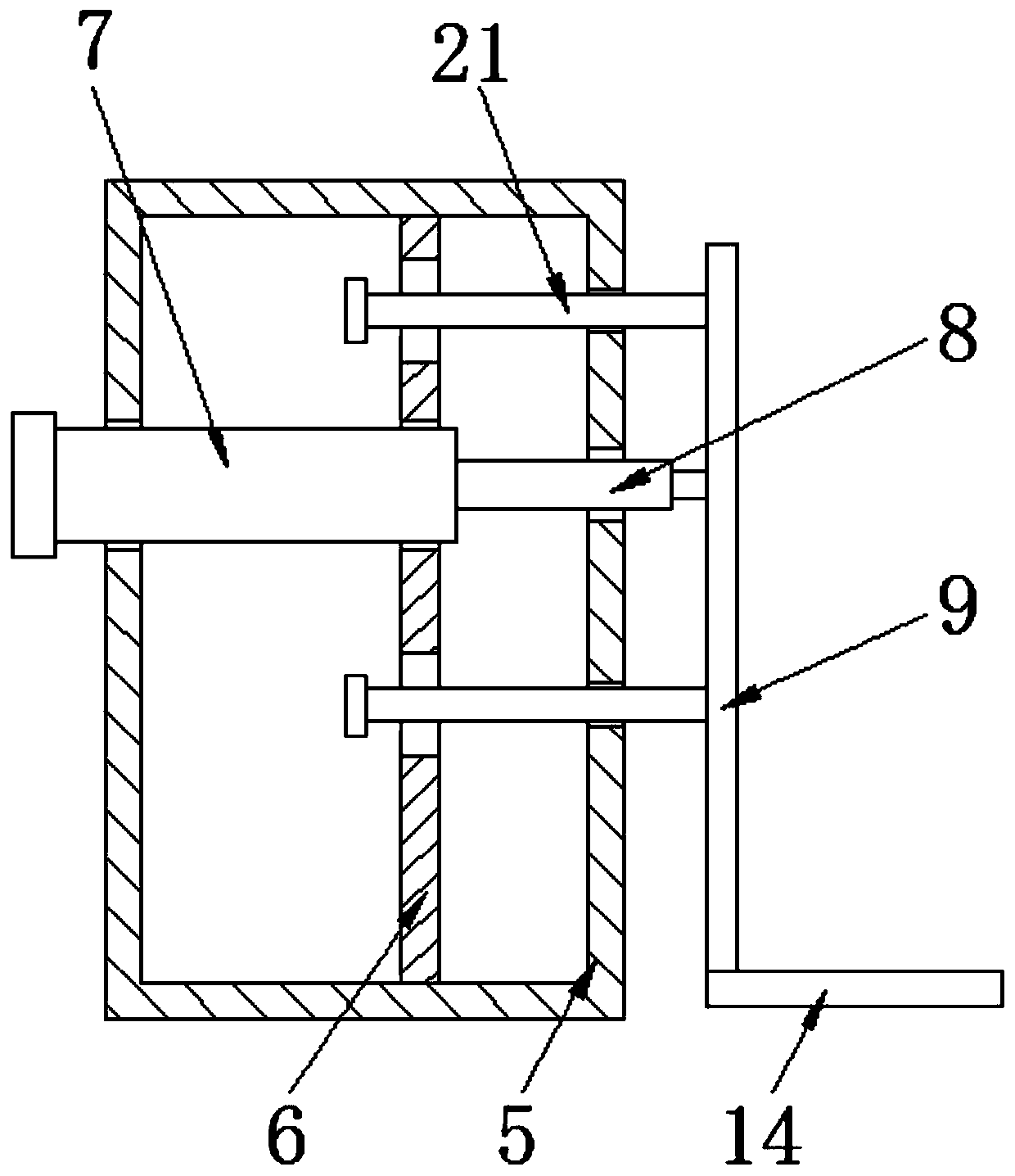

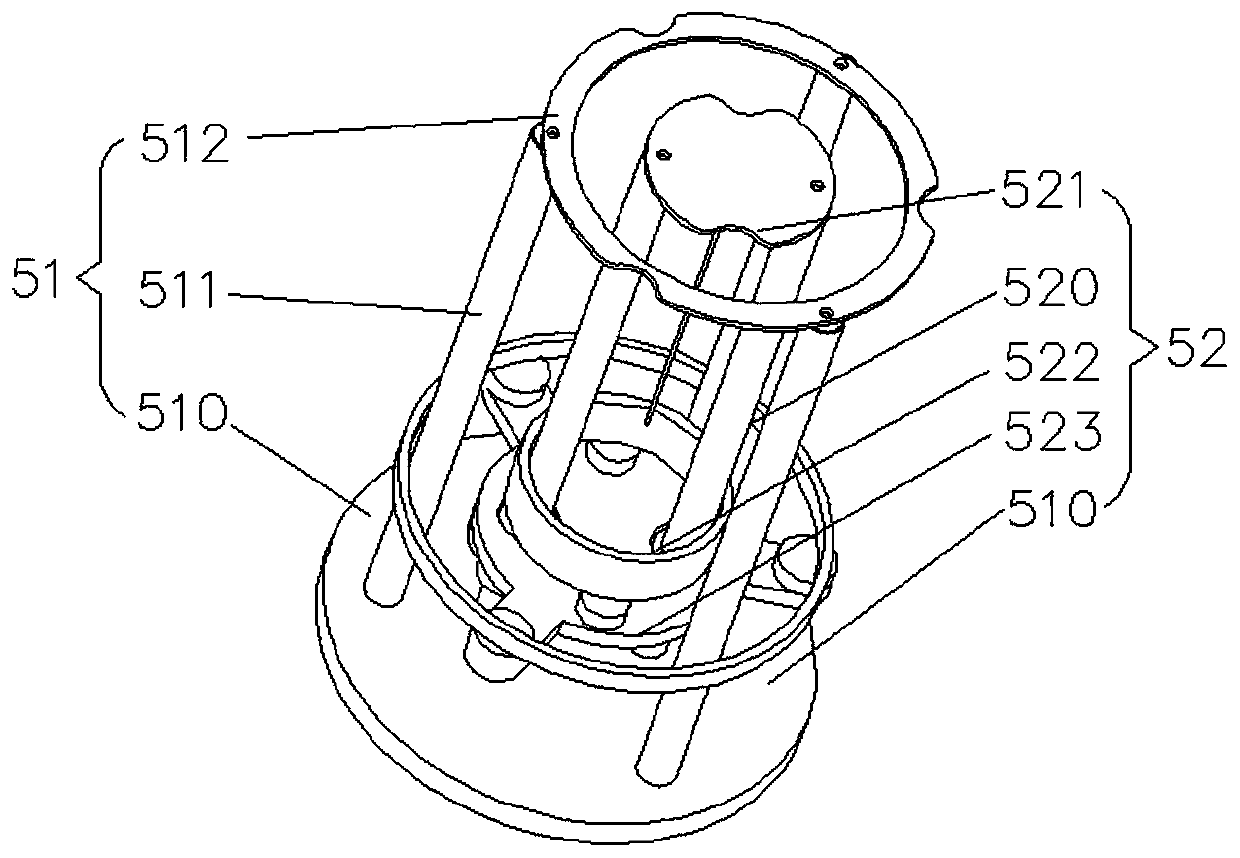

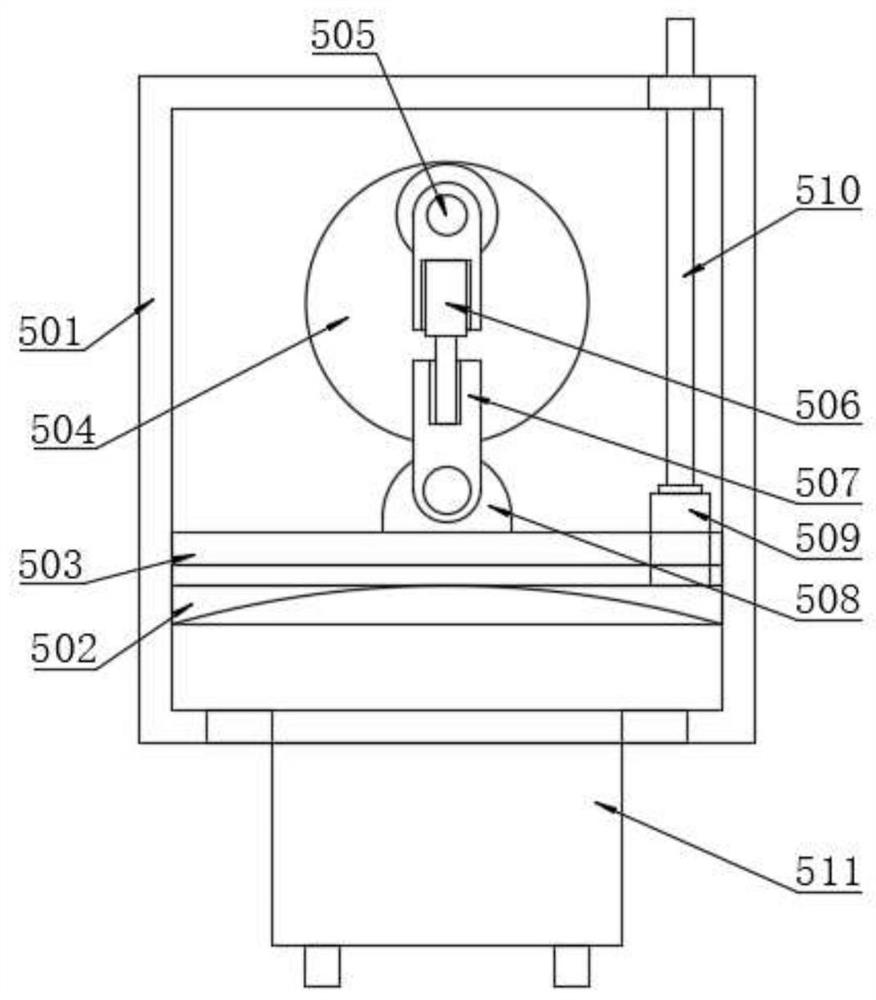

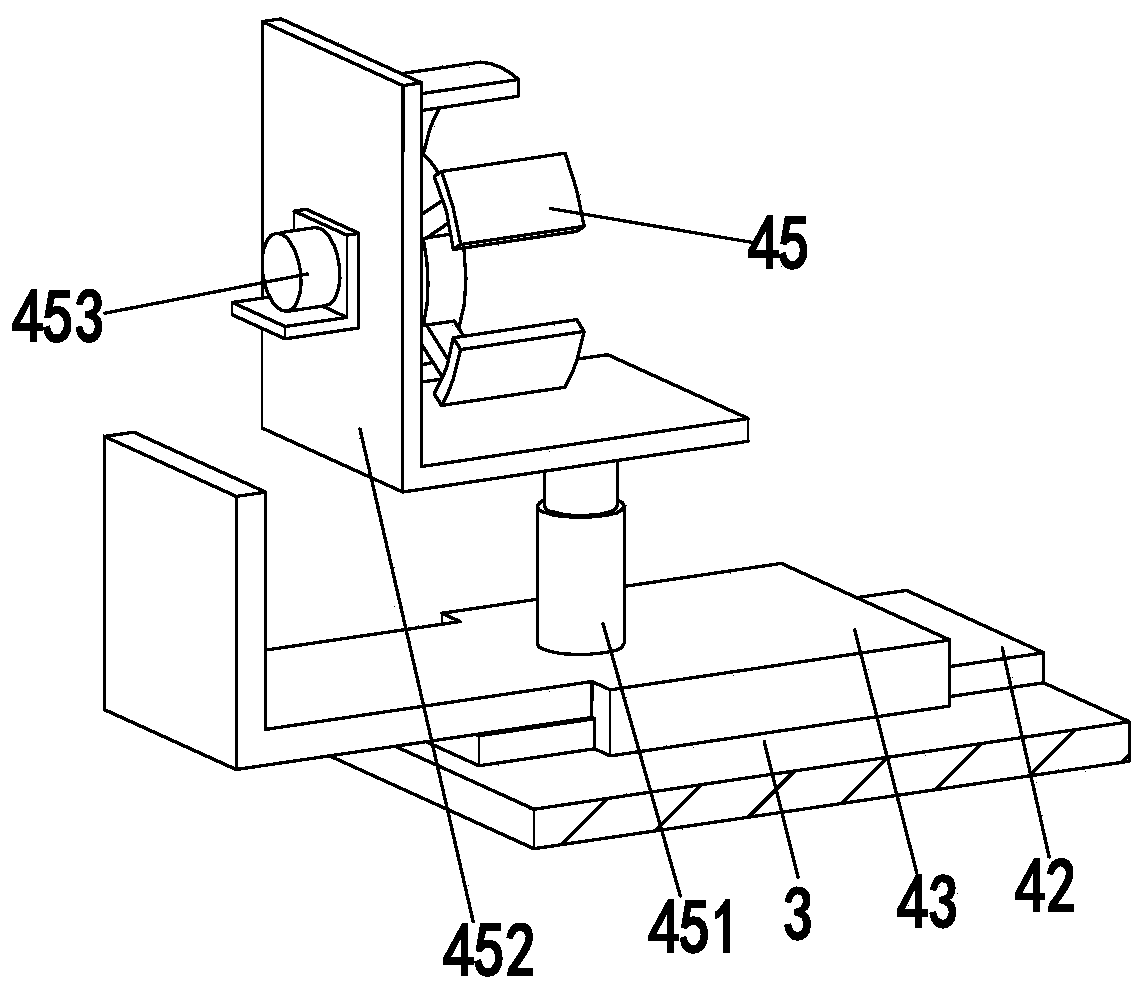

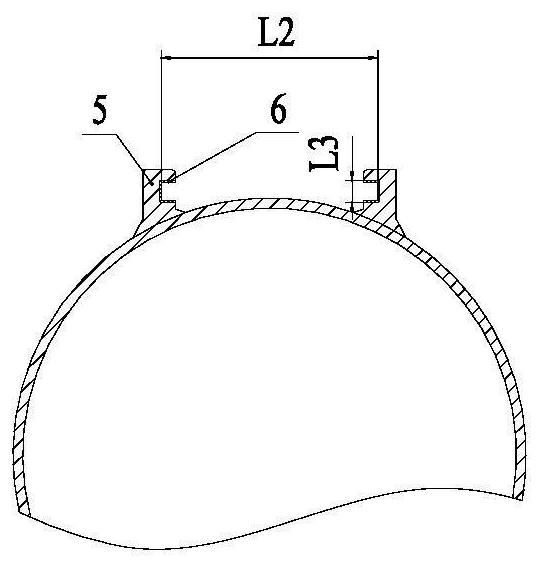

Adhesion clamp for smoke baffle

ActiveCN105818020AEasy to operateGood adhesionMaterial gluingWork holdersMechanical engineeringSmoke

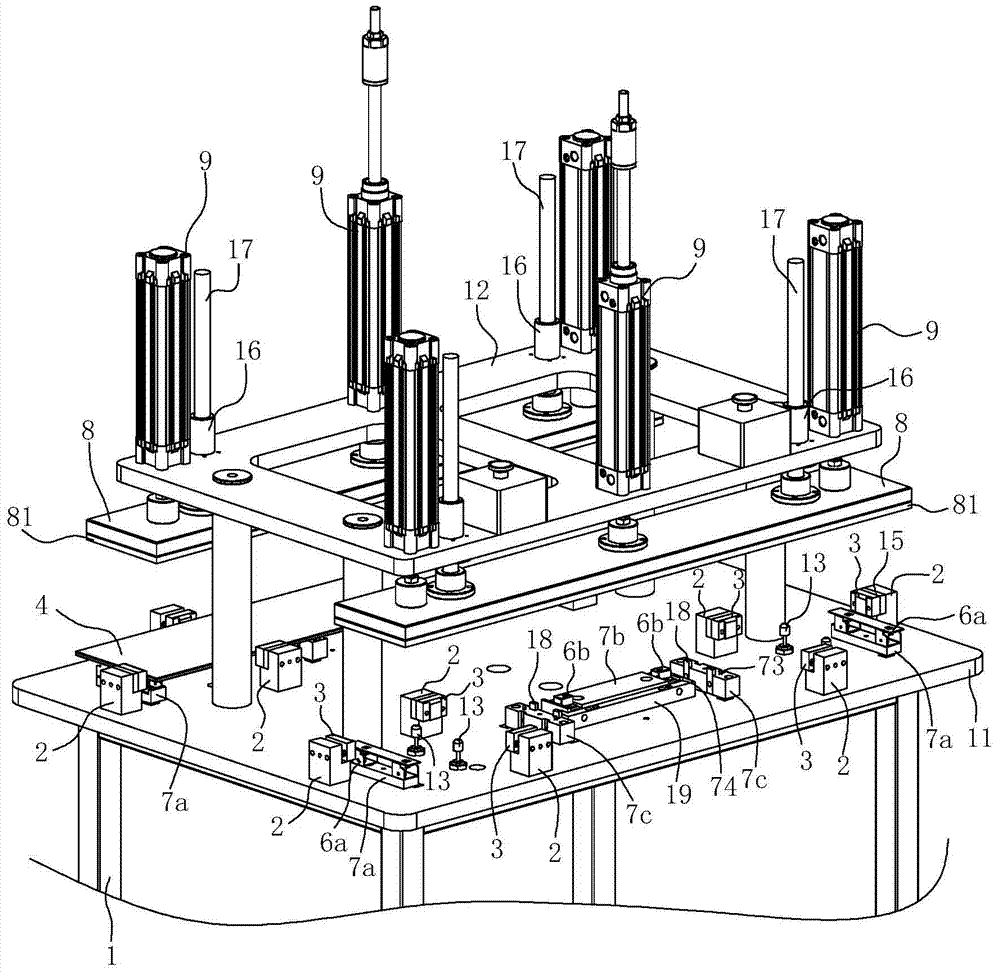

The invention relates to an adhesion clamp for a smoke baffle. The adhesion clamp for the smoke baffle comprises a frame. The frame is provided with a table top, an upper mounting plate and at least one set of adhesion structure. The adhesion clamp for the smoke baffle is characterized in that the adhesion structure comprises a shelf, a circumferential limiting structure, two L-shaped limiting blocks and two pressing mechanisms; the circumferential limiting structure is used for restraining the smoke baffle in the circumferential direction, and comprises a front positioning block, a rear positioning block, a left positioning block and a right positioning block; the front positioning block and the rear positioning block are fixed to the shelf; the left positioning block and the right positioning block are restrained on the shelf and can slide left and right synchronously; the two L-shaped limiting blocks are used for limiting rotary shaft components, and can move vertically under driving of an air cylinder mounted on the upper mounting plate; and the two pressing mechanisms can press the rotary shaft components onto the upper end face of the smoke baffle to maintain the pressure for adhesion. By means of the adhesion clamp, the rotary shaft components can be accurately and firmly mounted onto the smoke baffle, the dimensions of the rotary shaft components at the two ends of the smoke baffle can be accurate, the both sides are balanced in error, and the situation that errors are lumped at one end is avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

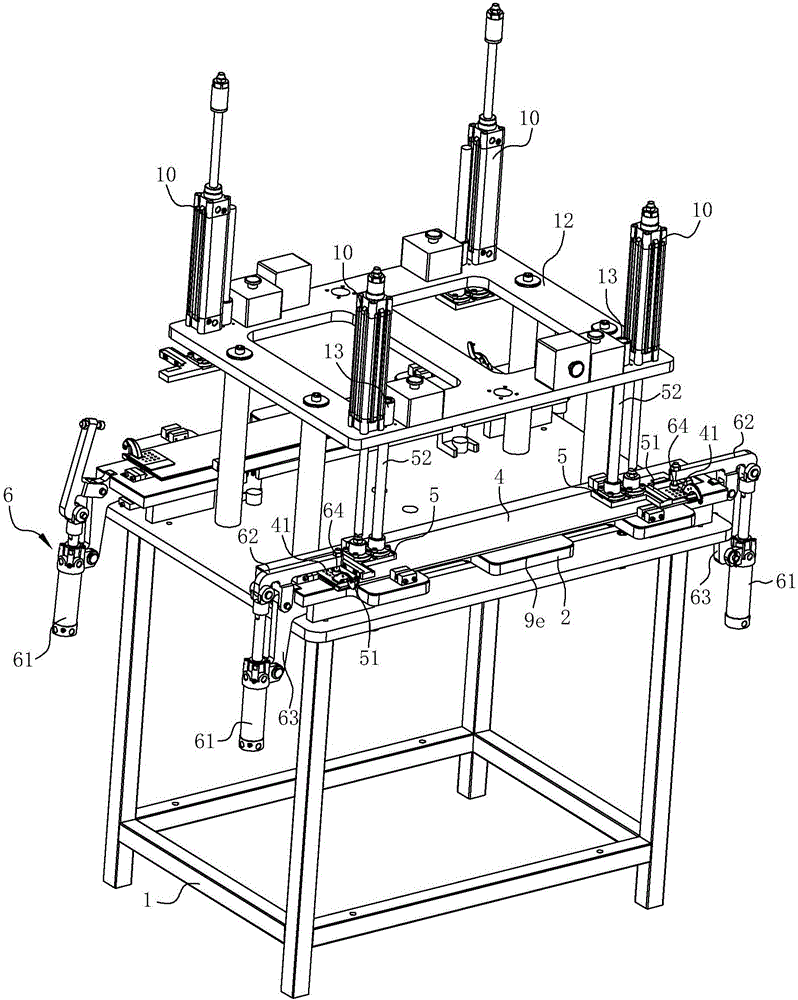

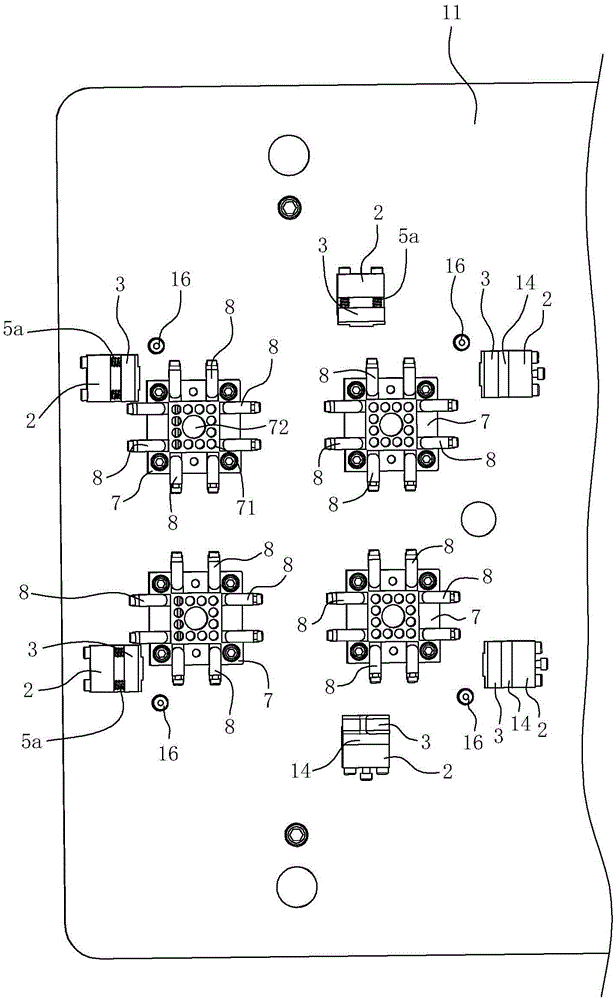

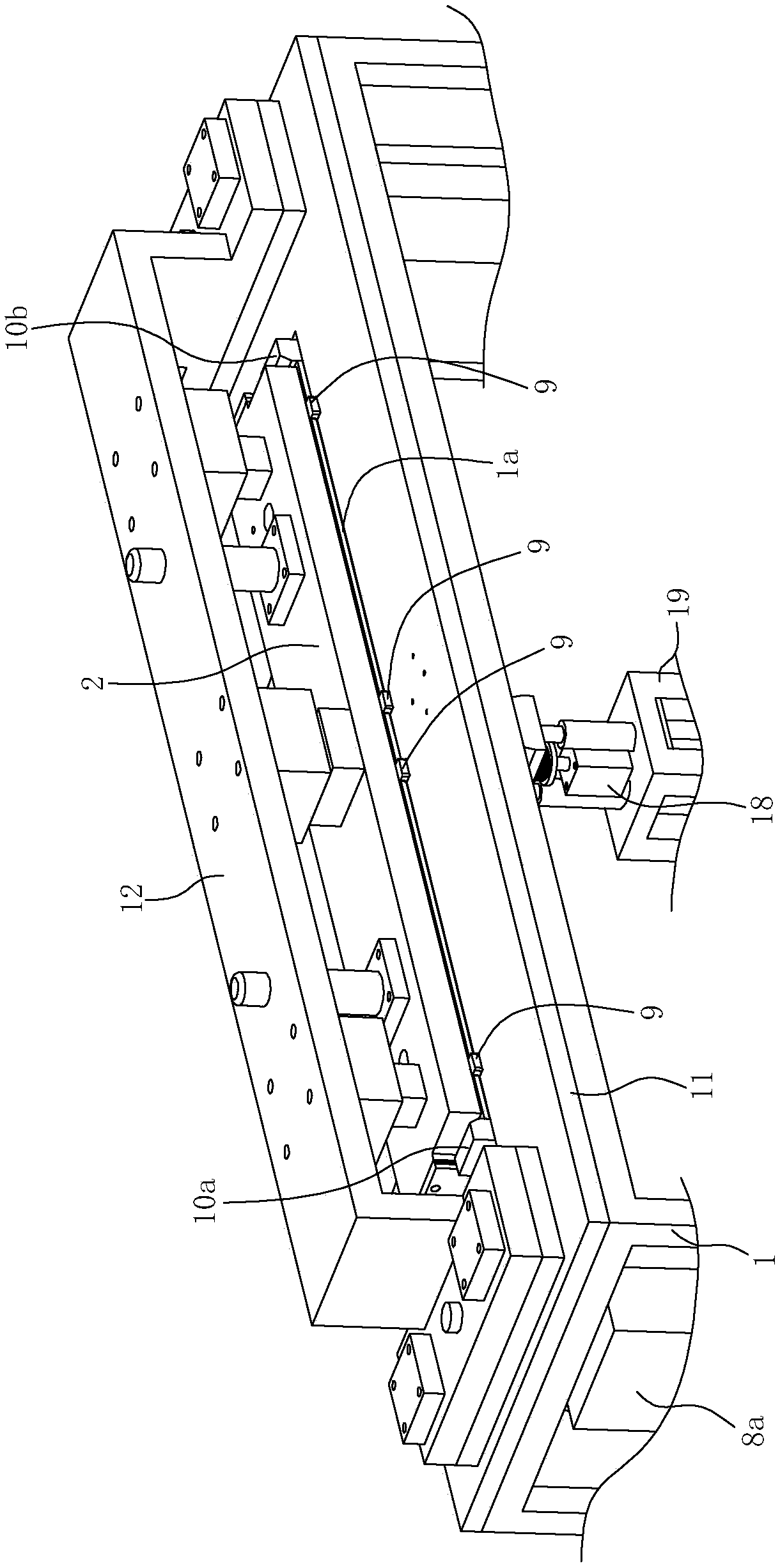

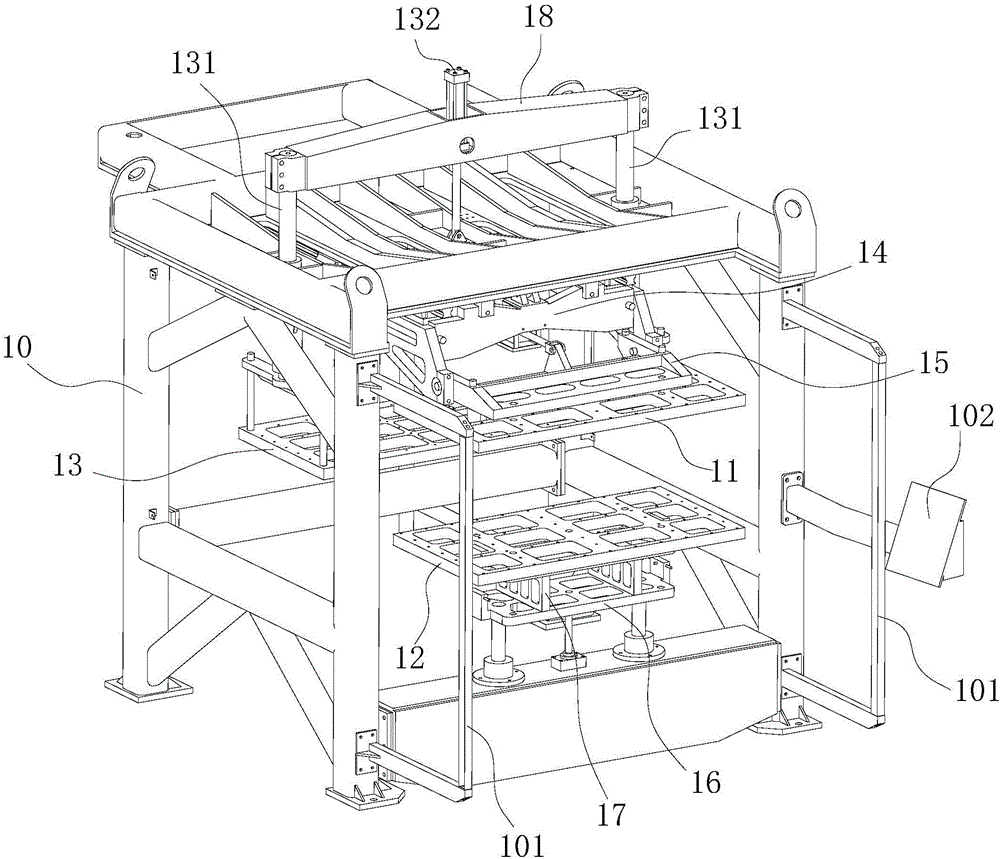

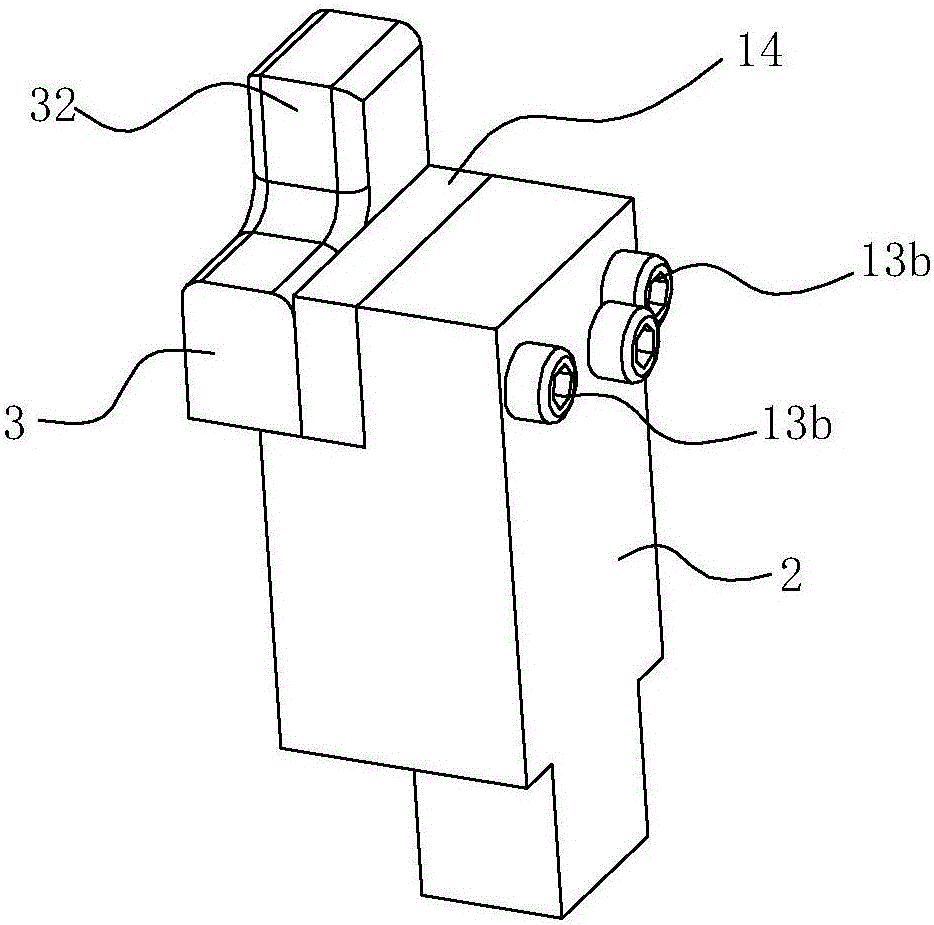

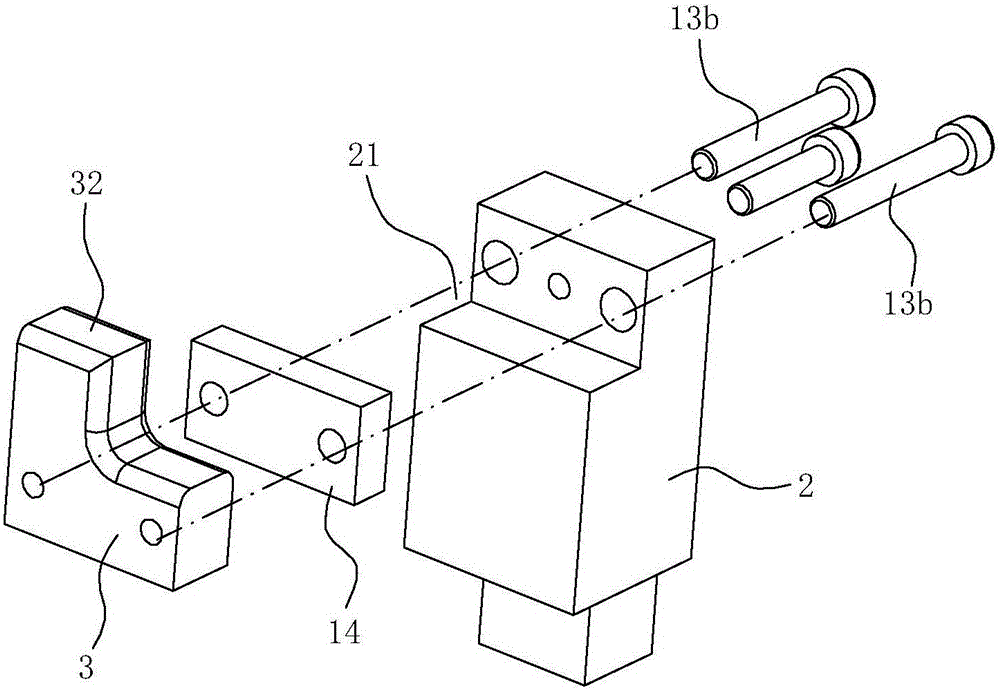

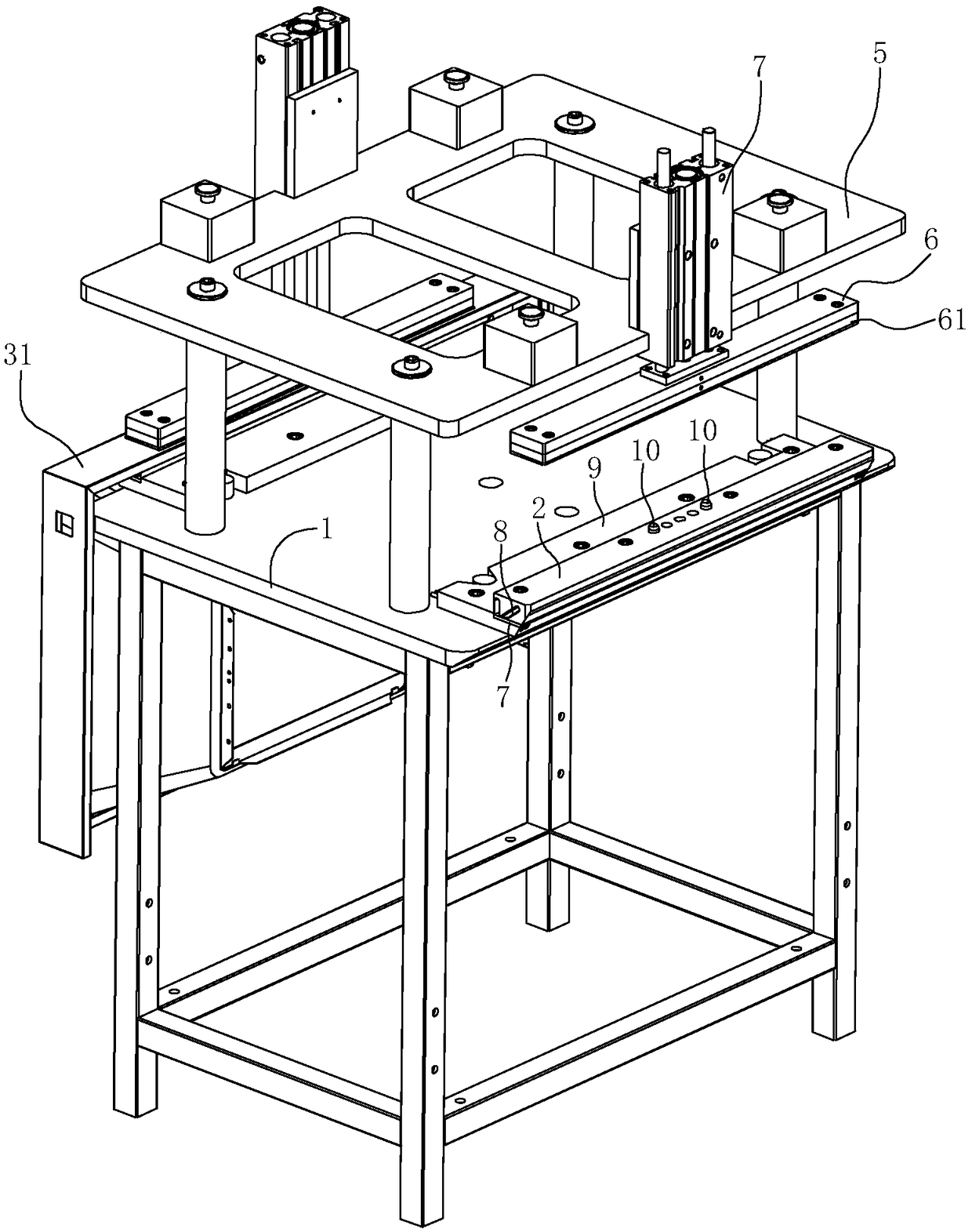

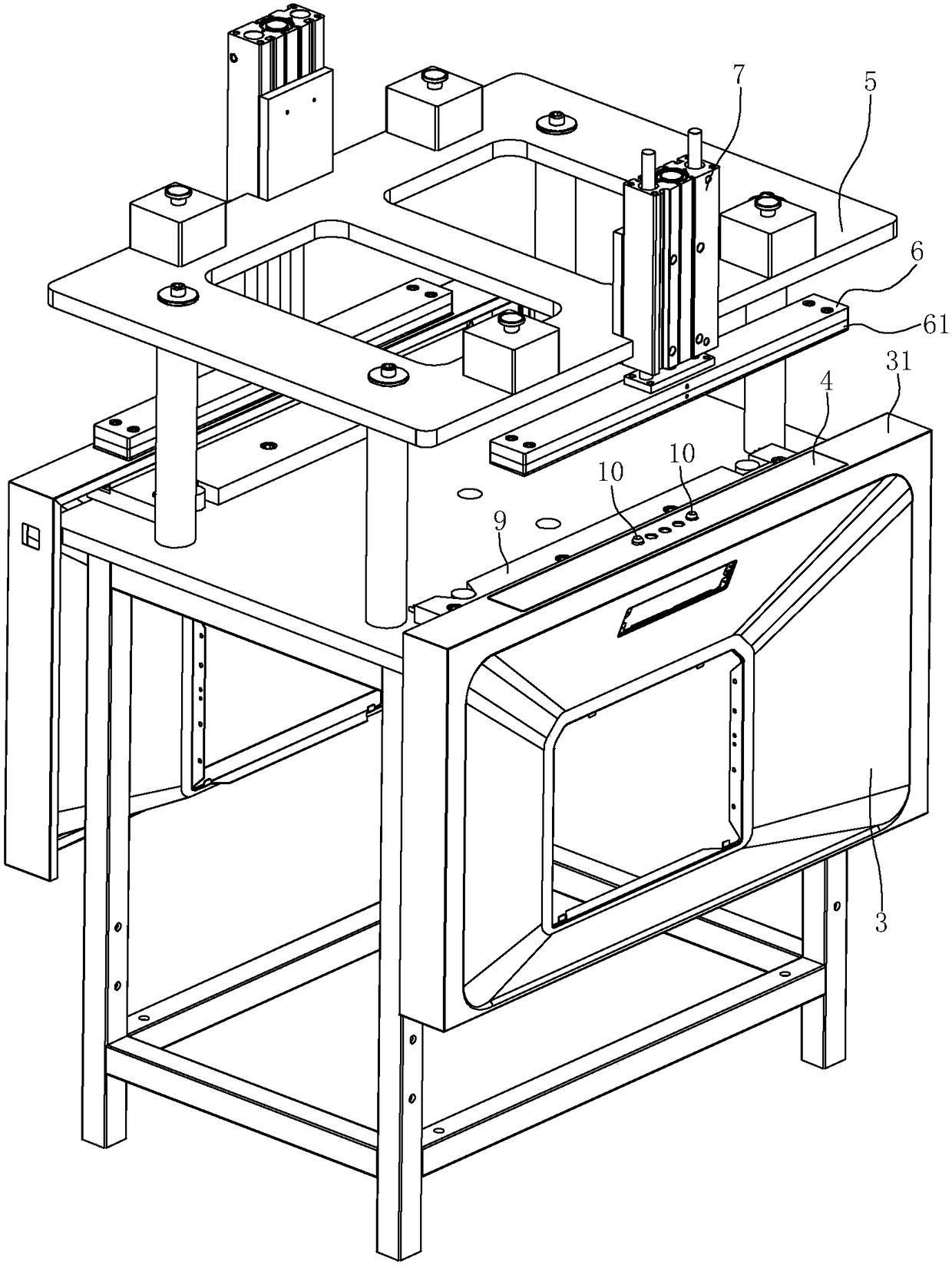

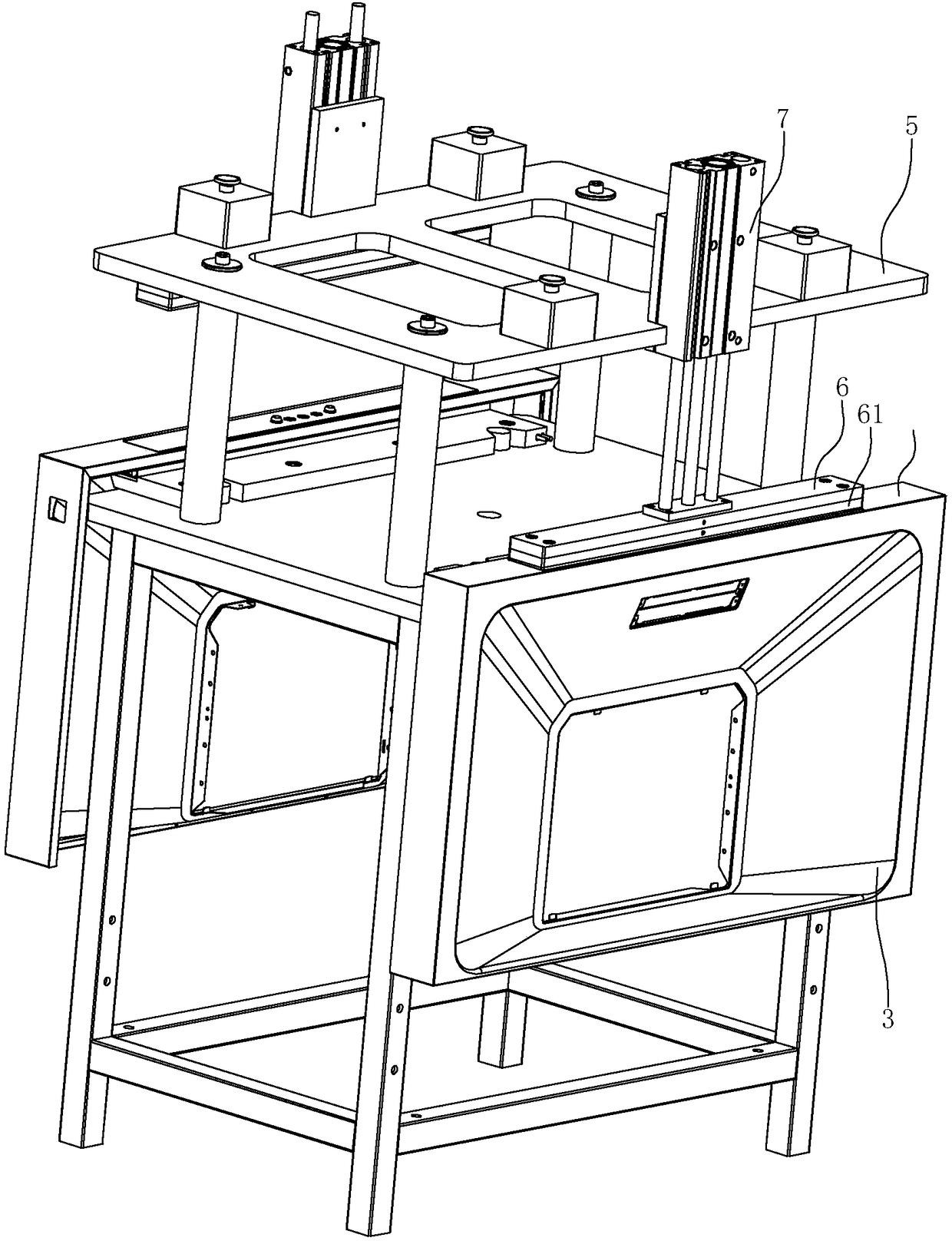

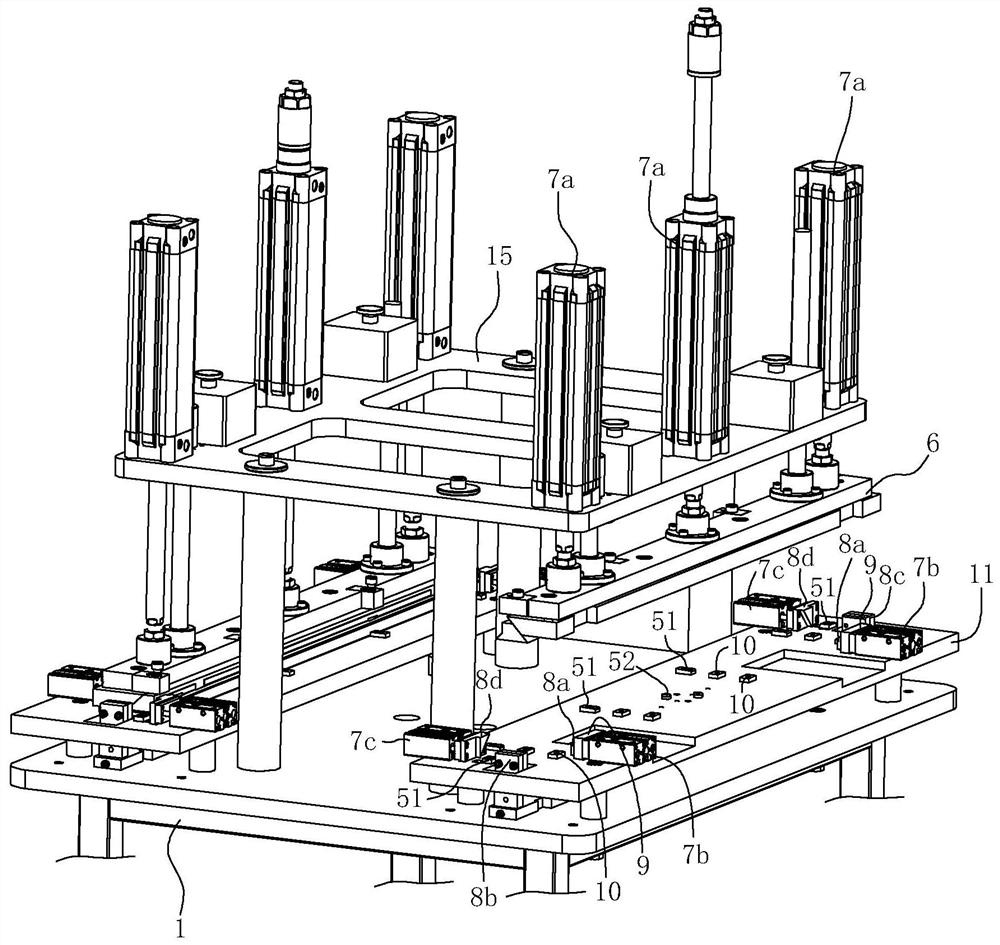

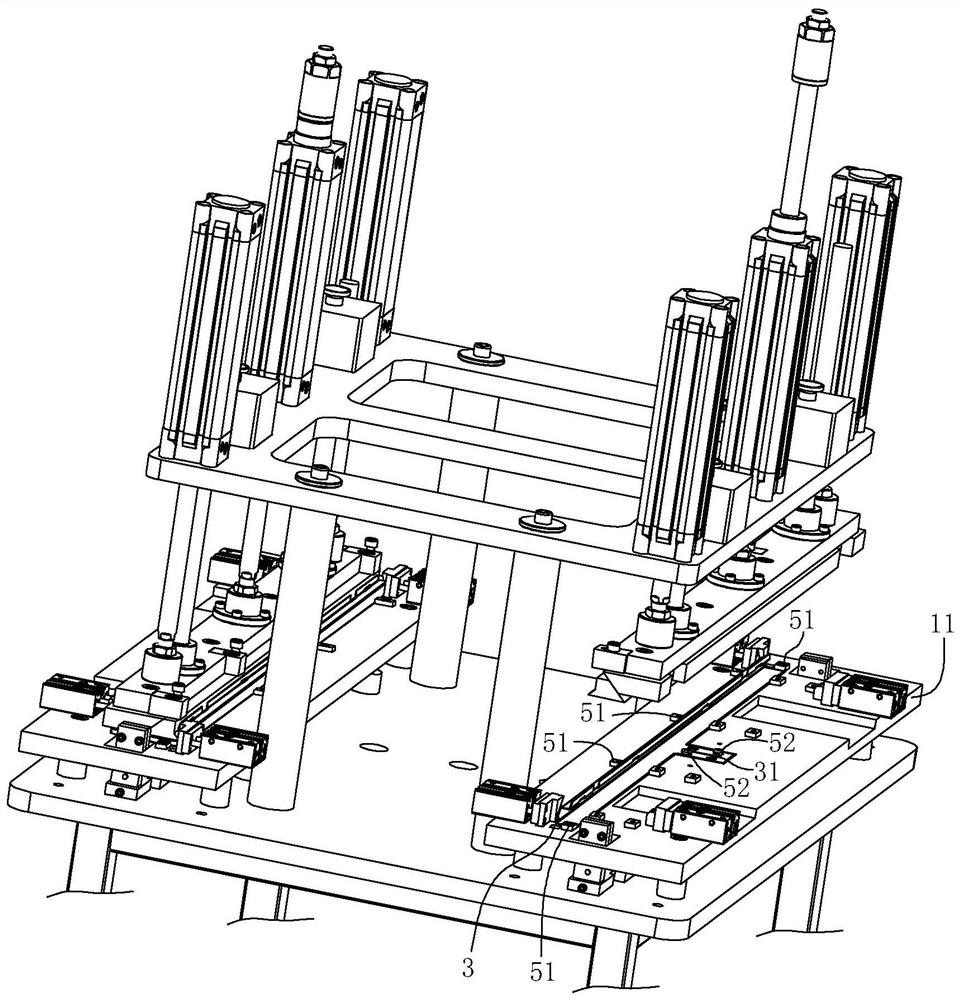

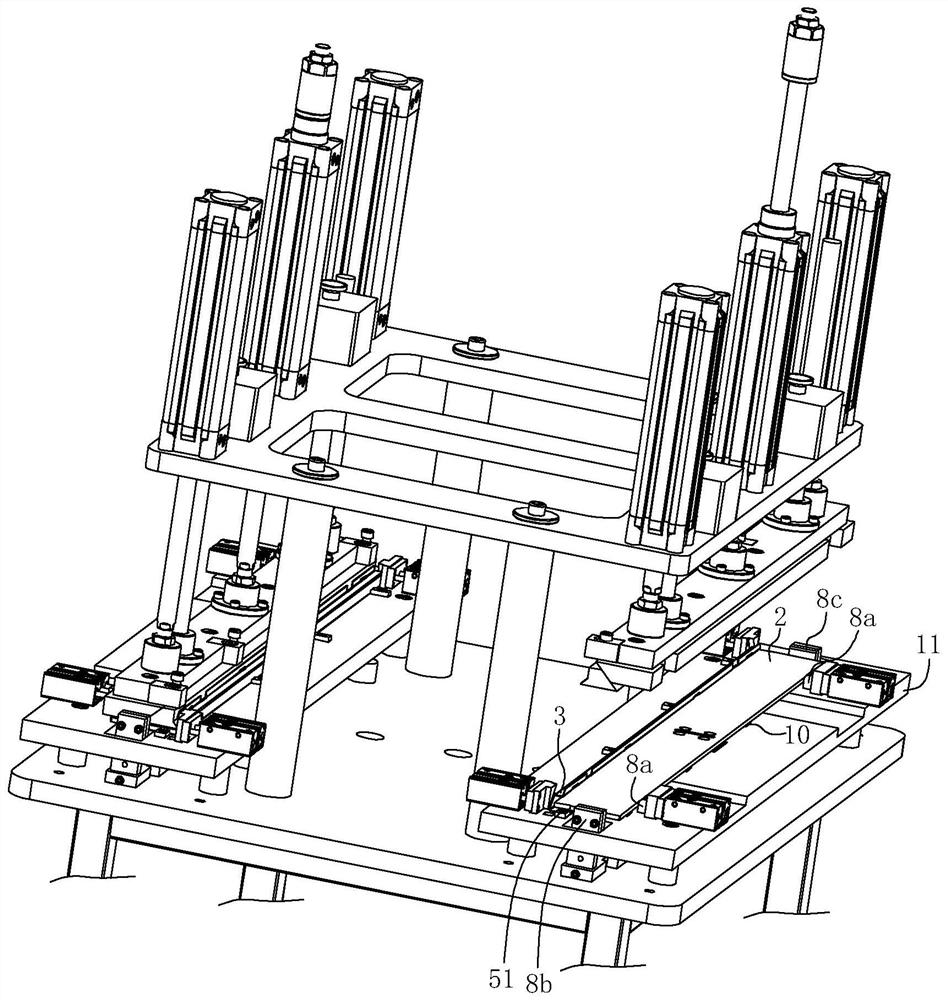

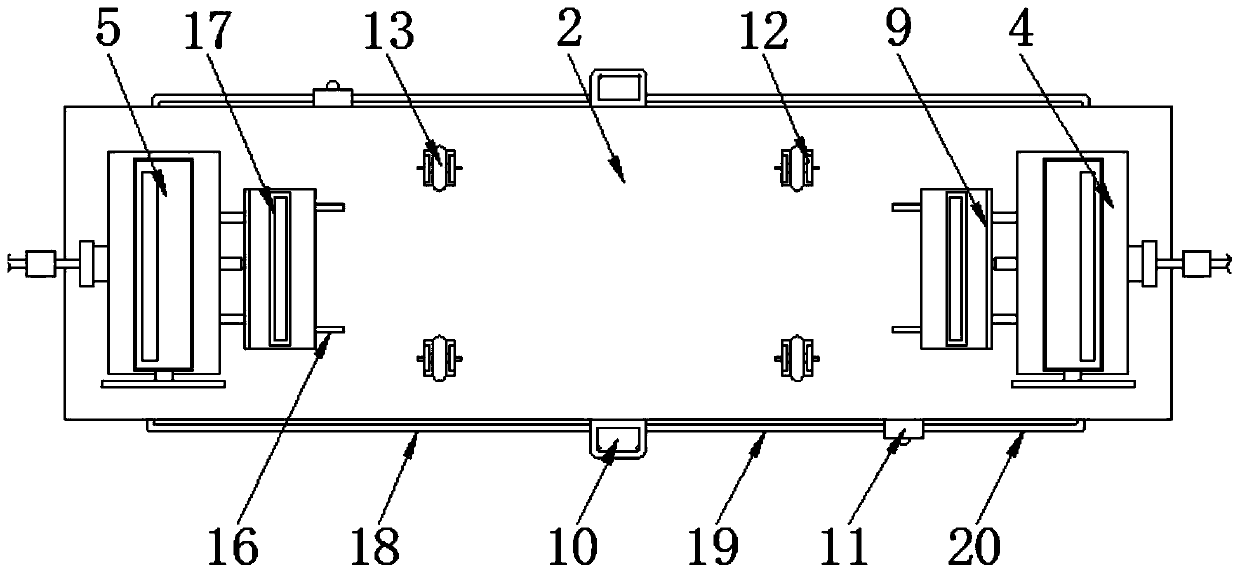

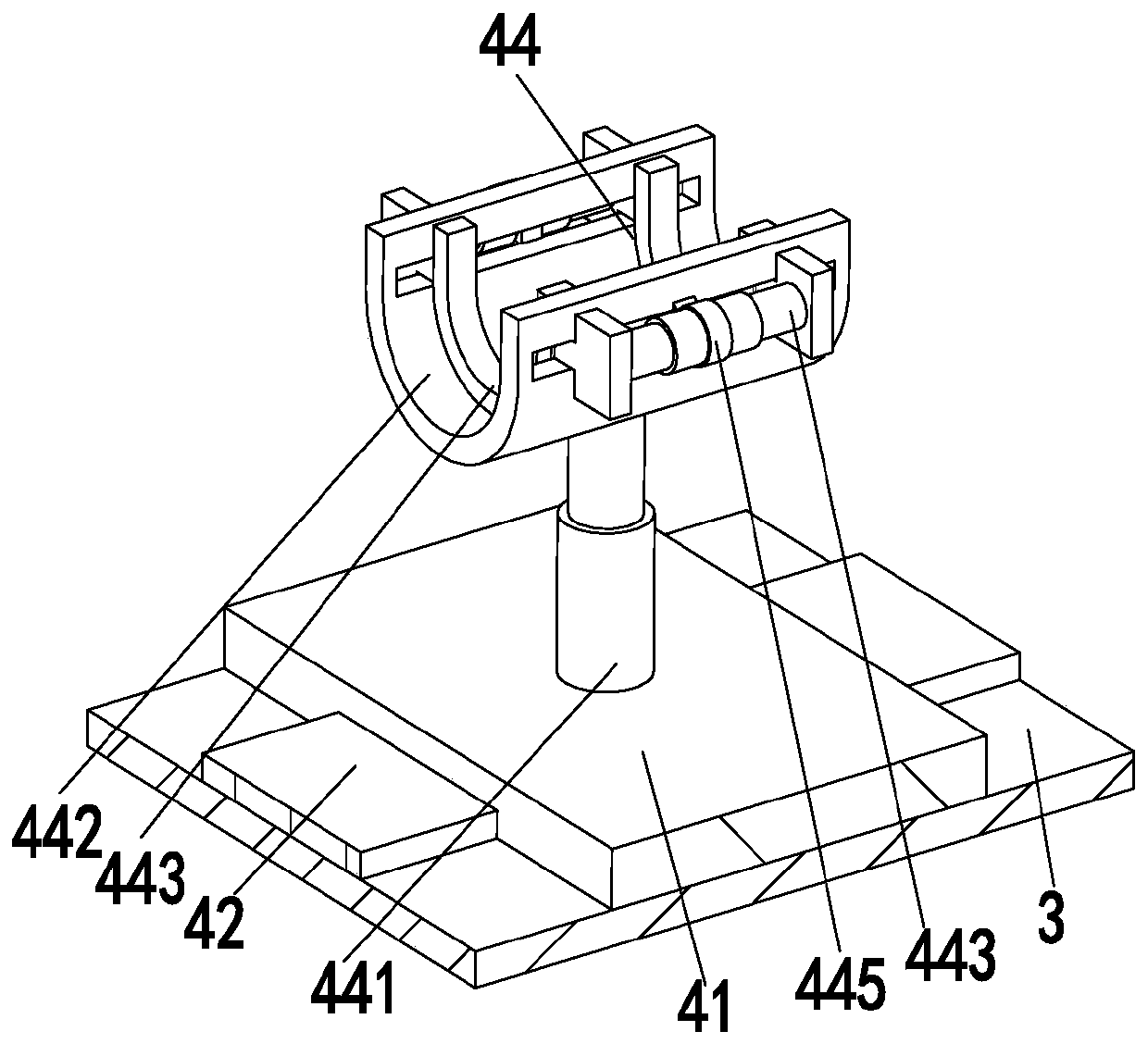

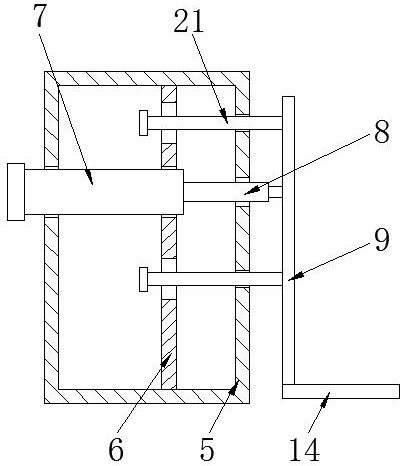

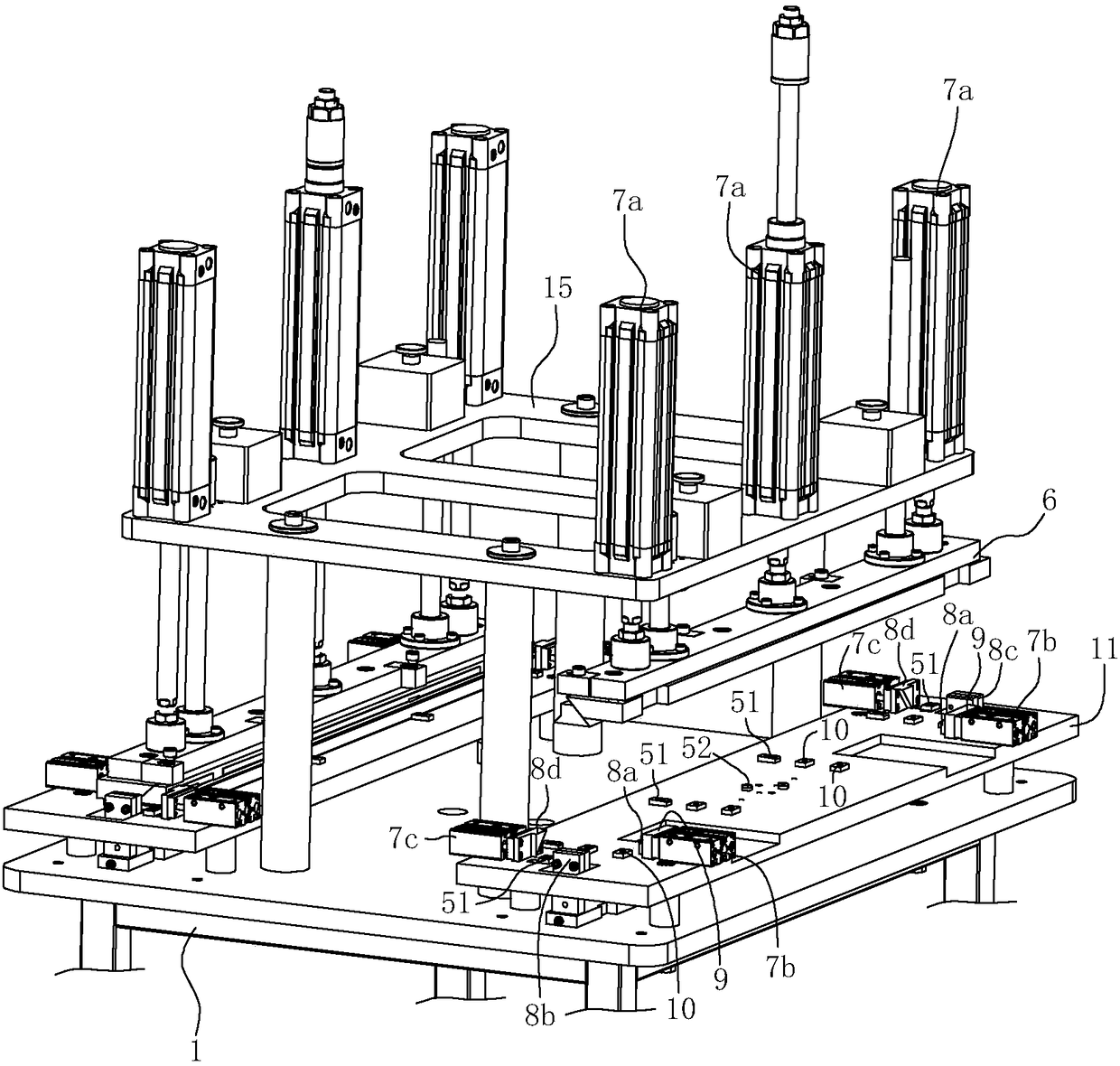

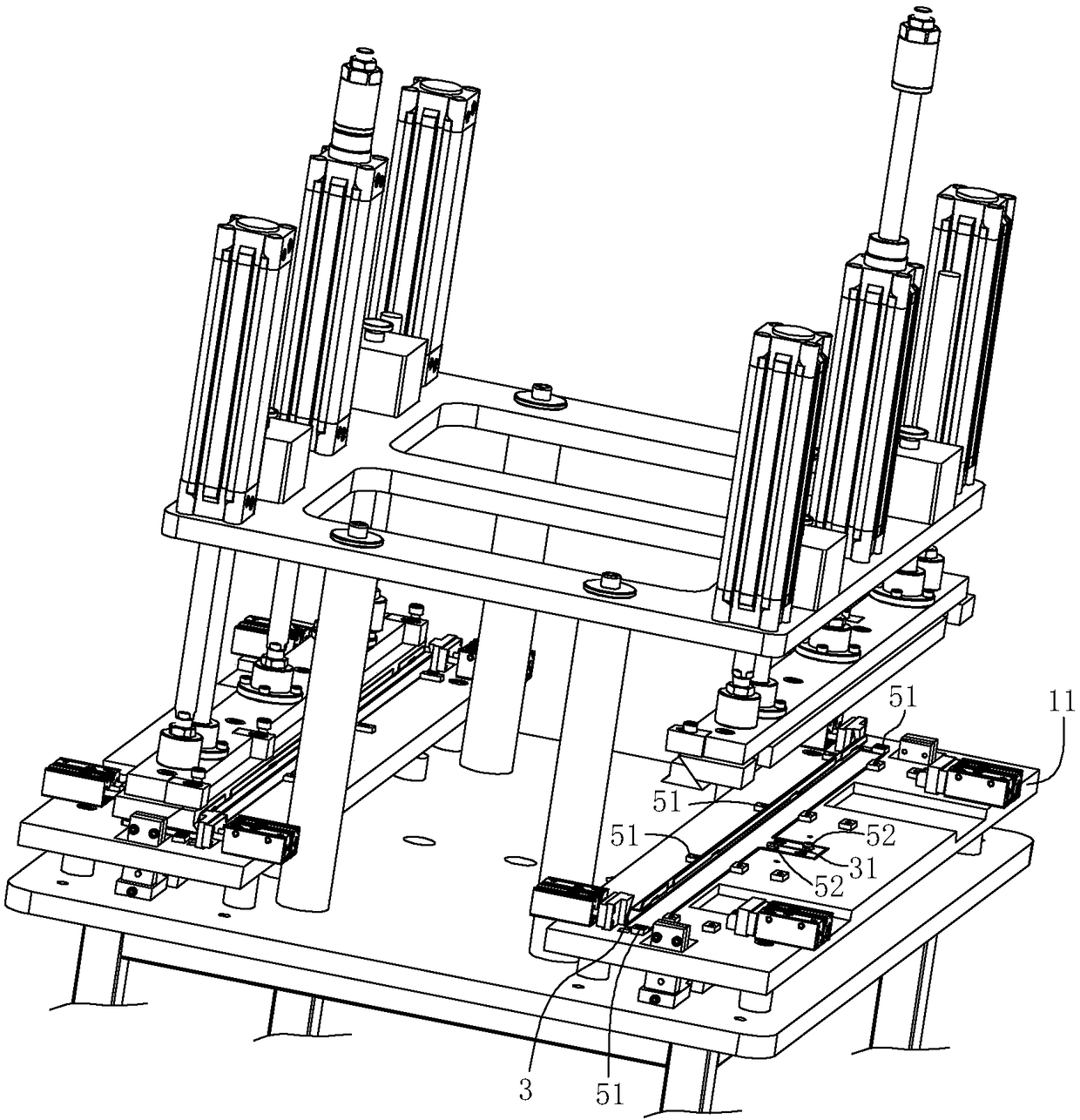

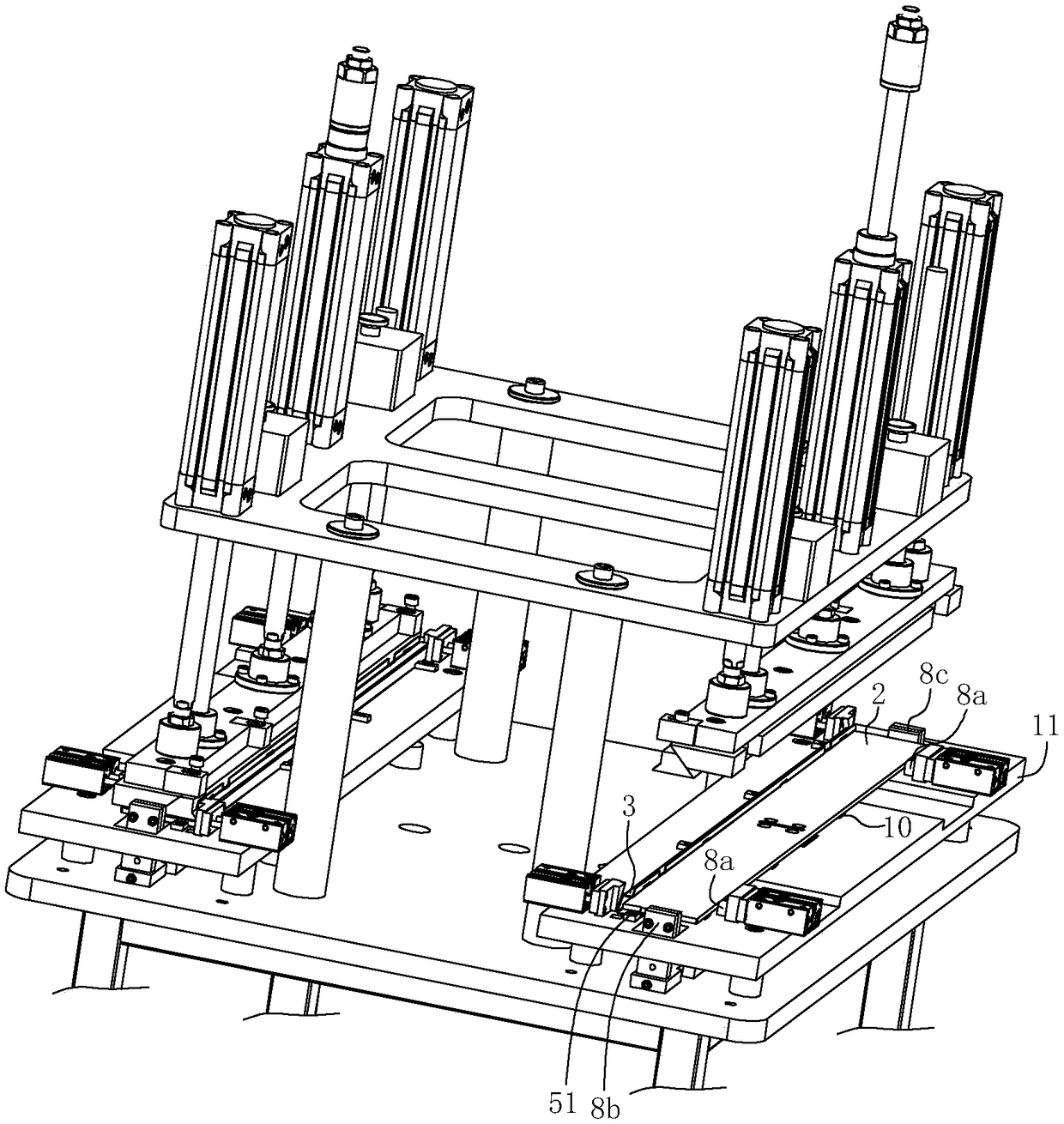

Bonding tool for mounting part on glass assembly and capable of adjusting dimensions in any direction

ActiveCN105538187AHigh bonding precisionHigh bonding efficiency and precisionWork holdersElectrical junctionEngineering

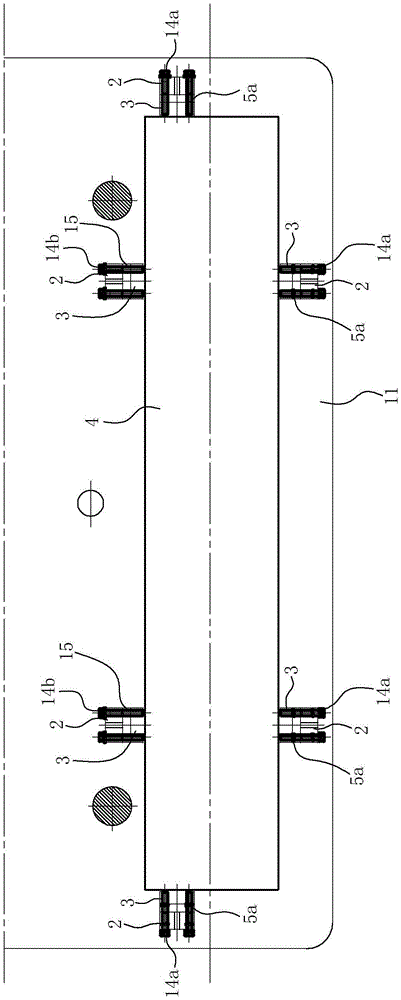

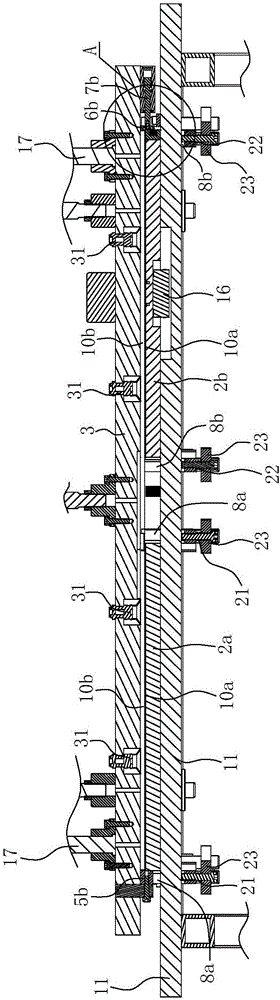

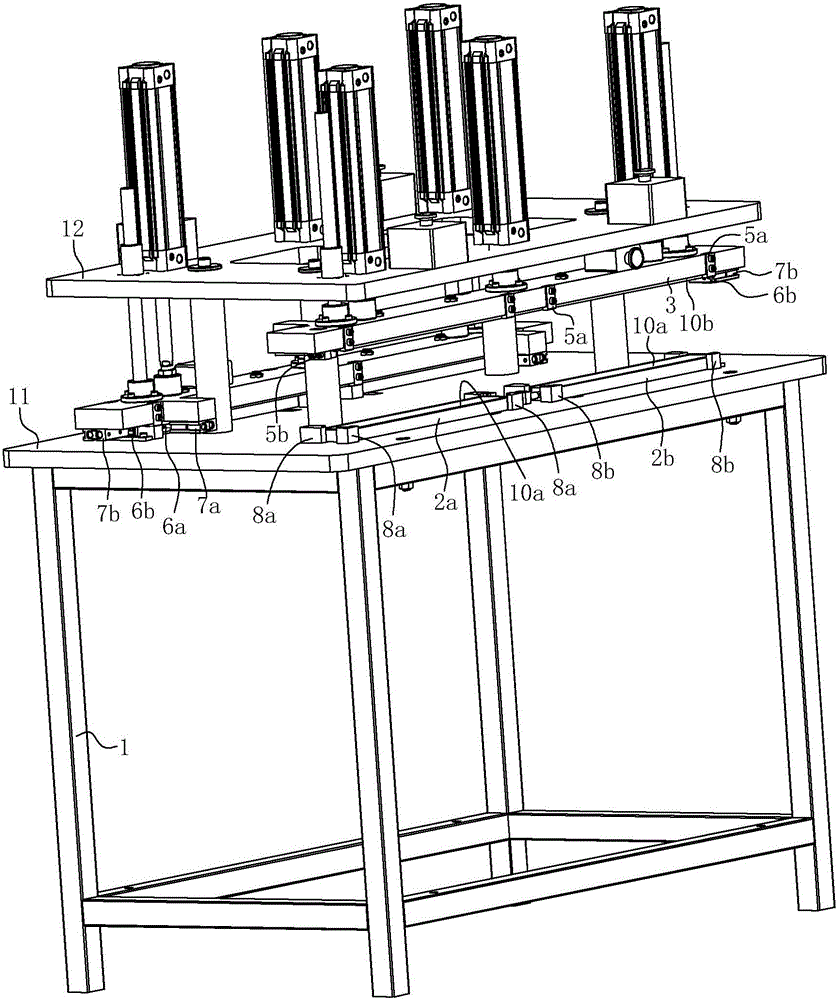

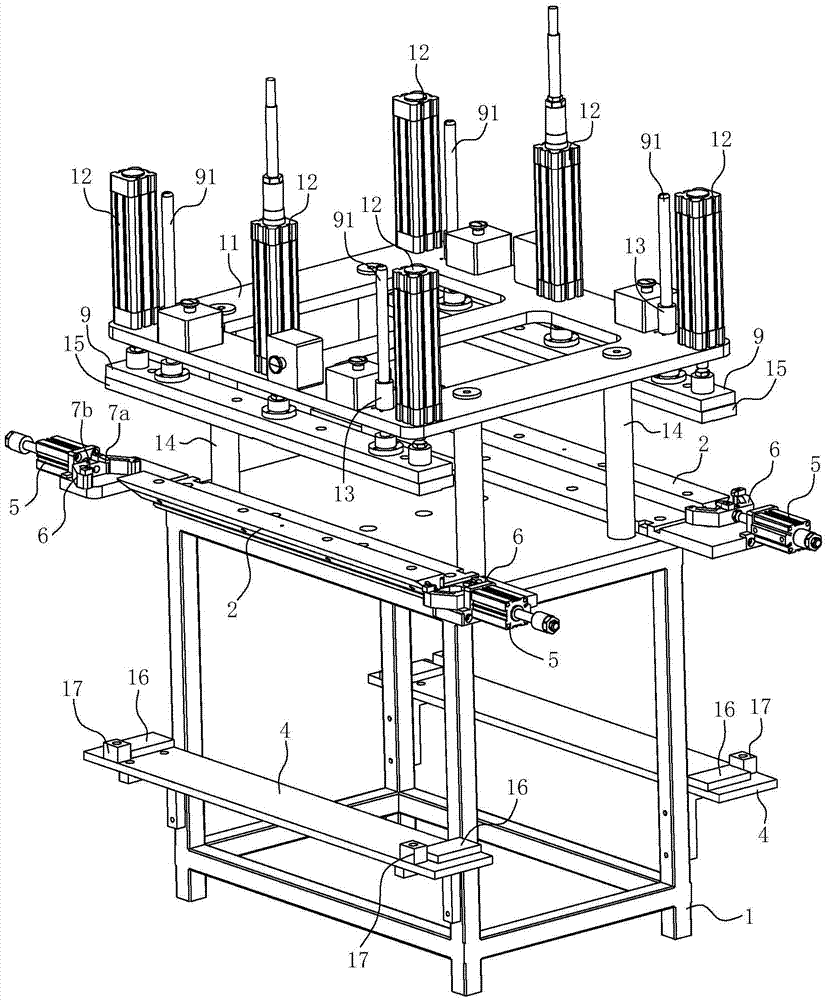

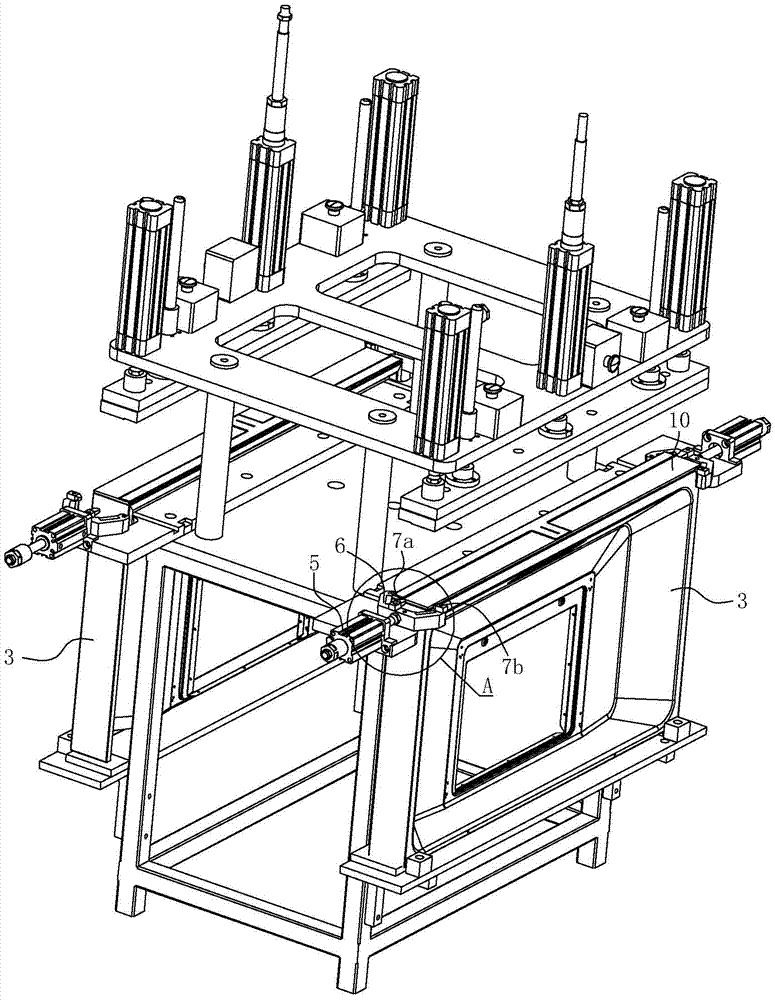

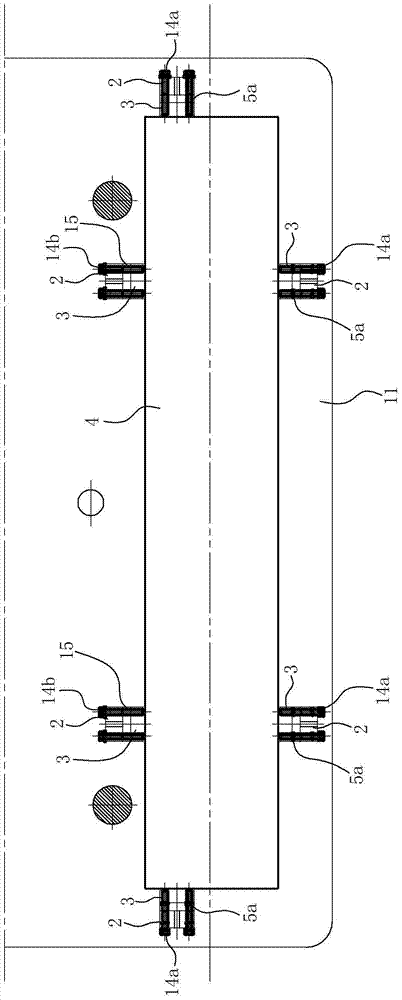

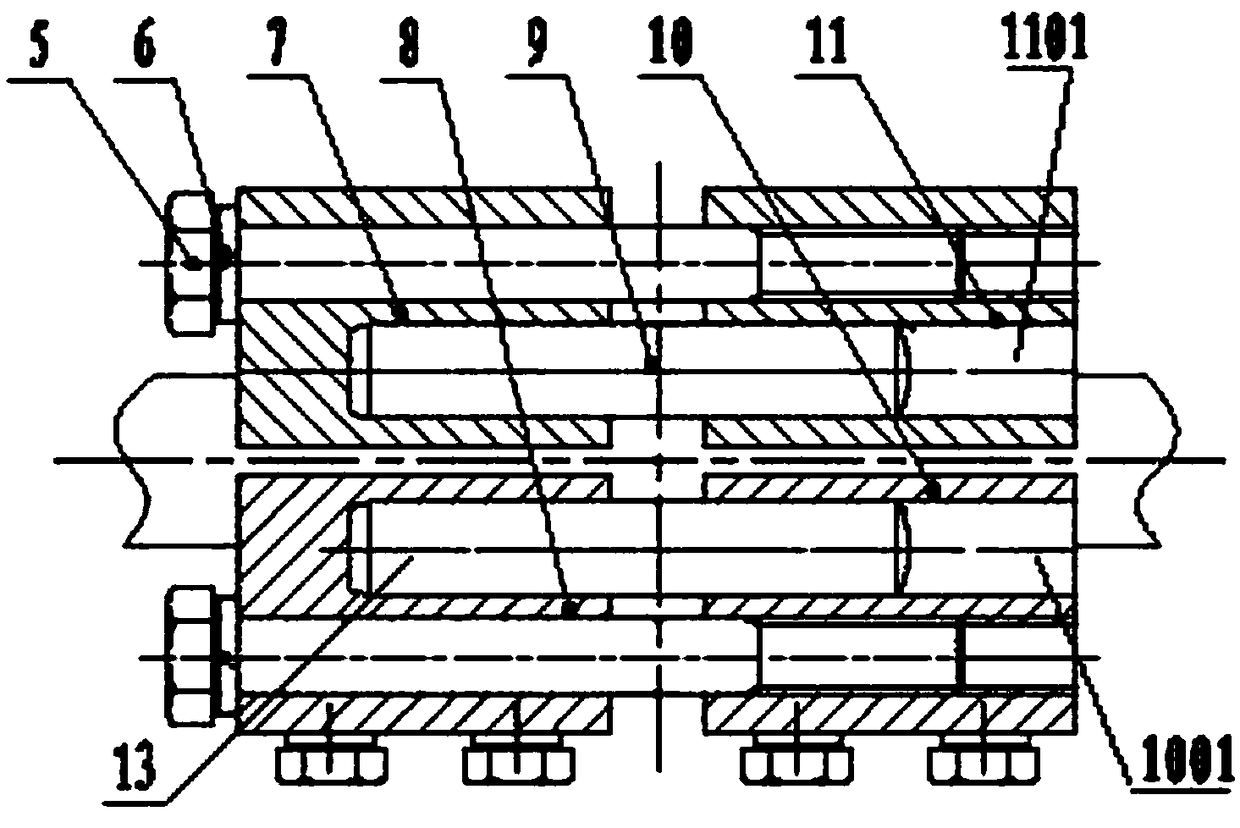

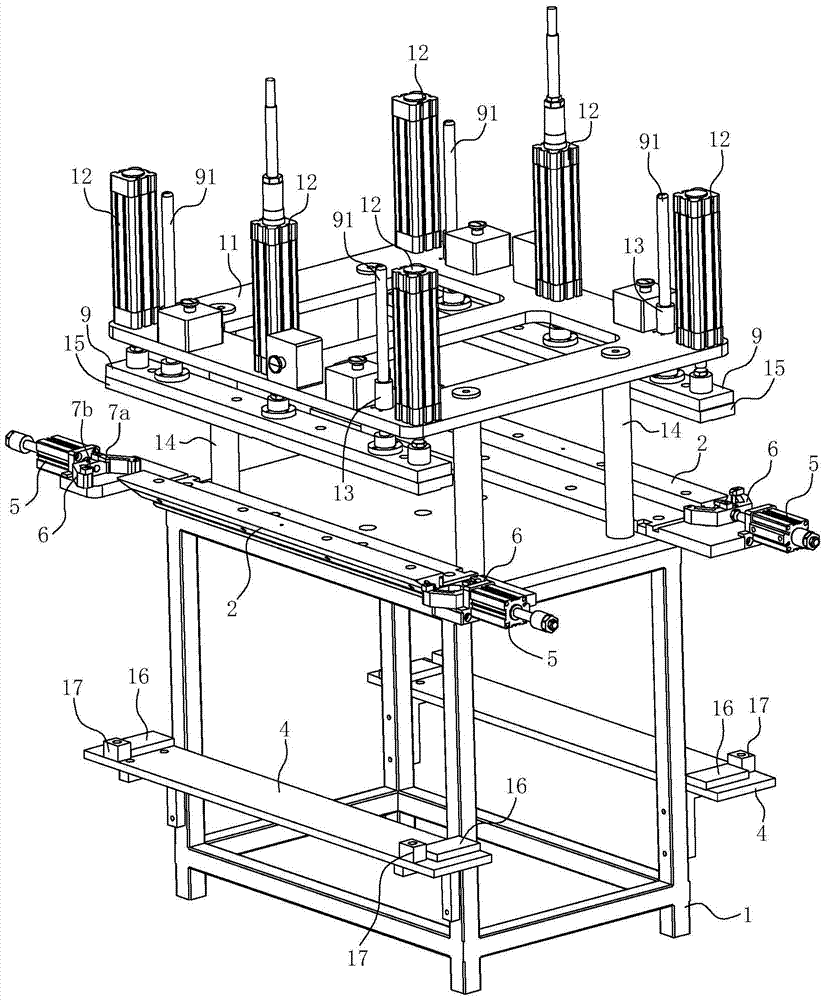

The invention relates to a bonding tool for mounting a part on a glass assembly and capable of adjusting dimensions in any direction. The bonding tool is characterized in that the tool comprises a rack body, glass panel limiting structures, support limiting structures and pressure maintaining blocks; the rack body is provided with a table board and an upper mounting plate; the glass panel limiting structures are used for limiting glass panels; the support limiting structures are used for limiting buckle supports; the pressure maintaining blocks are located above the glass panel limiting structures, and are driven by pressure maintaining cylinders mounted on the upper mounting plate to vertically move up and down; and the down pressing of the pressure maintaining blocks enables the glass panels to be tightly pressed on the bonding faces of the buckle supports to conduct pressure maintaining. In the bonding process, the relative position relation of the buckle supports and the glass panels is kept unchanged through the limiting of the glass panel limiting structures to the glass panels and the restraint of the support limiting structures to the buckle supports, and the bonding precision is high; the pressure maintaining blocks are driven by the action of the pressure maintaining cylinders to press the glass panels to the bonding faces, coated with glue, of the buckle supports and conduct pressure maintaining for a certain time, so that the buckle supports and the glass panels are firmly fixed.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

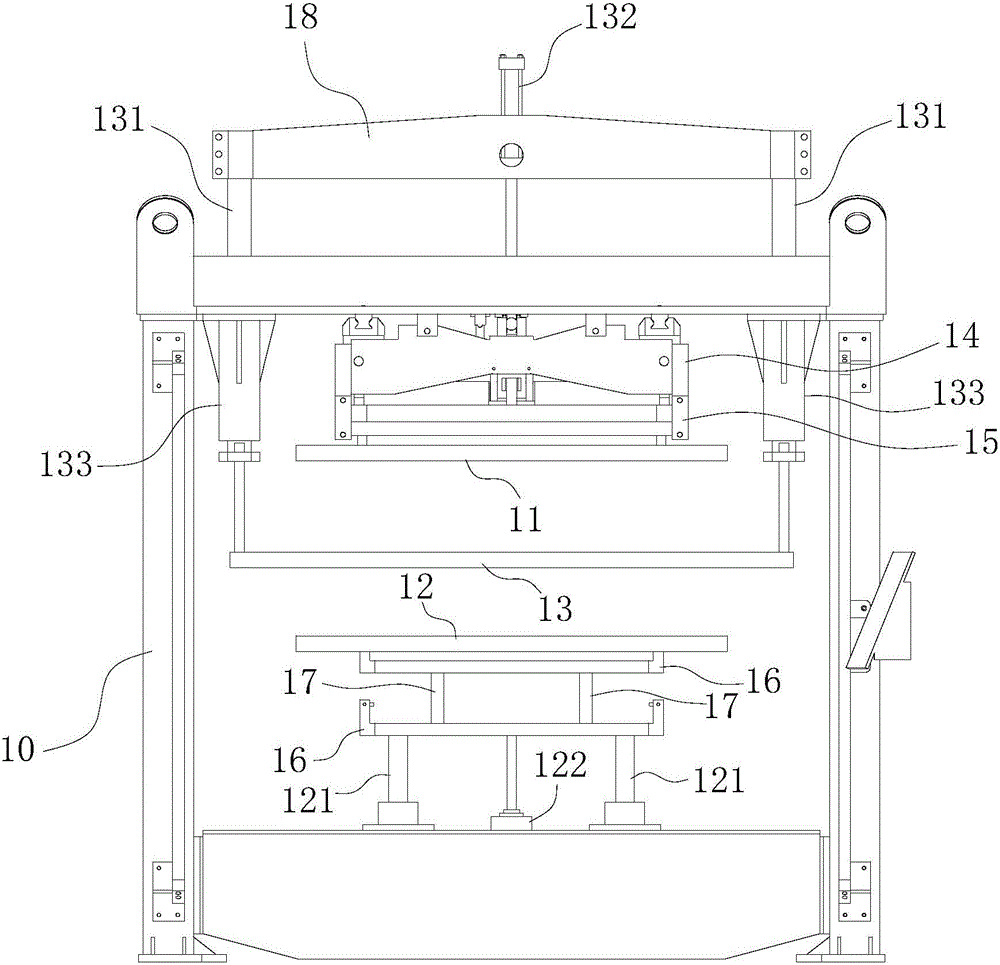

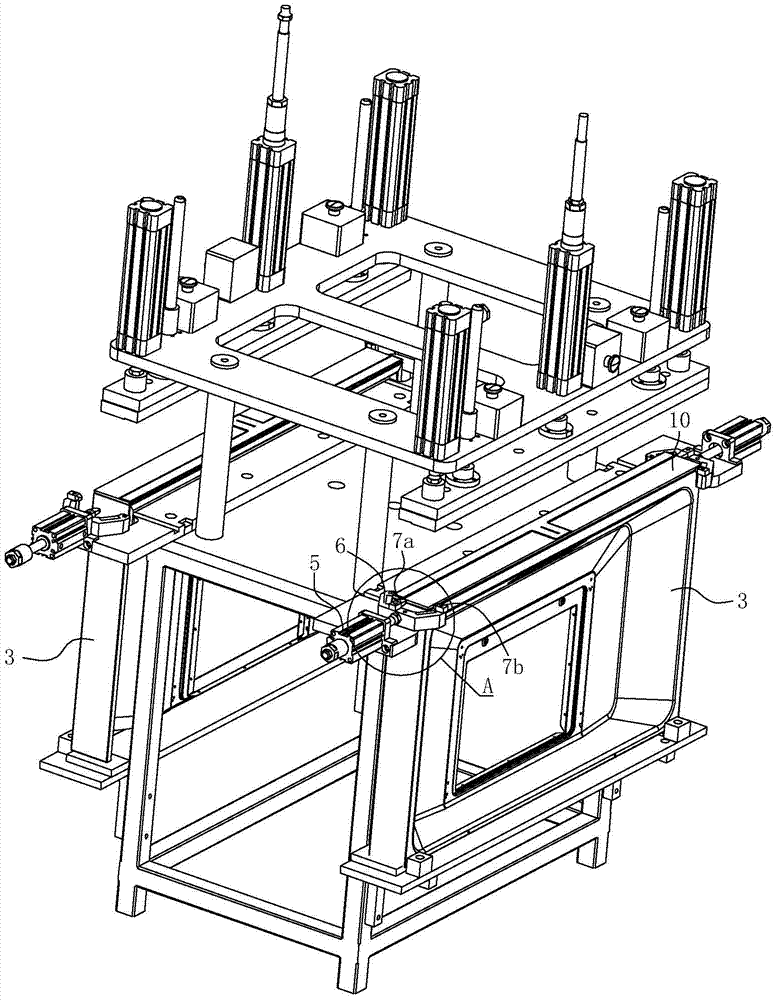

Adhering tool for adhering glass panel to exhaust fume collecting hood

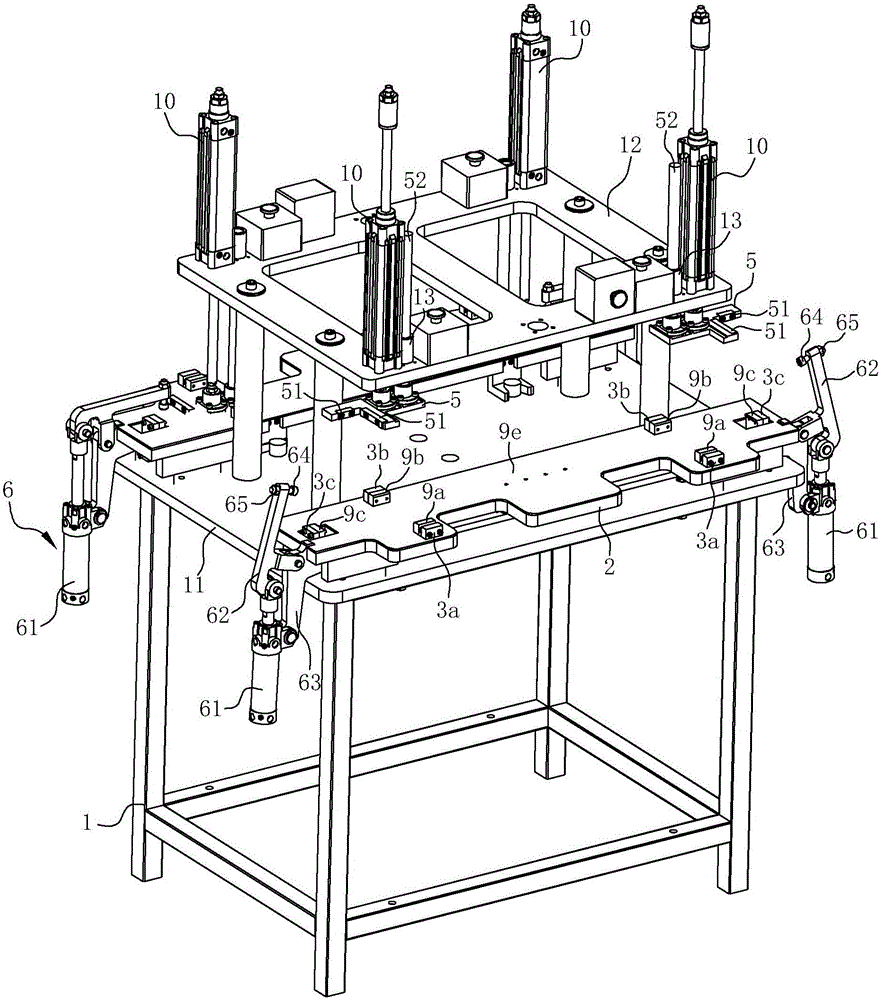

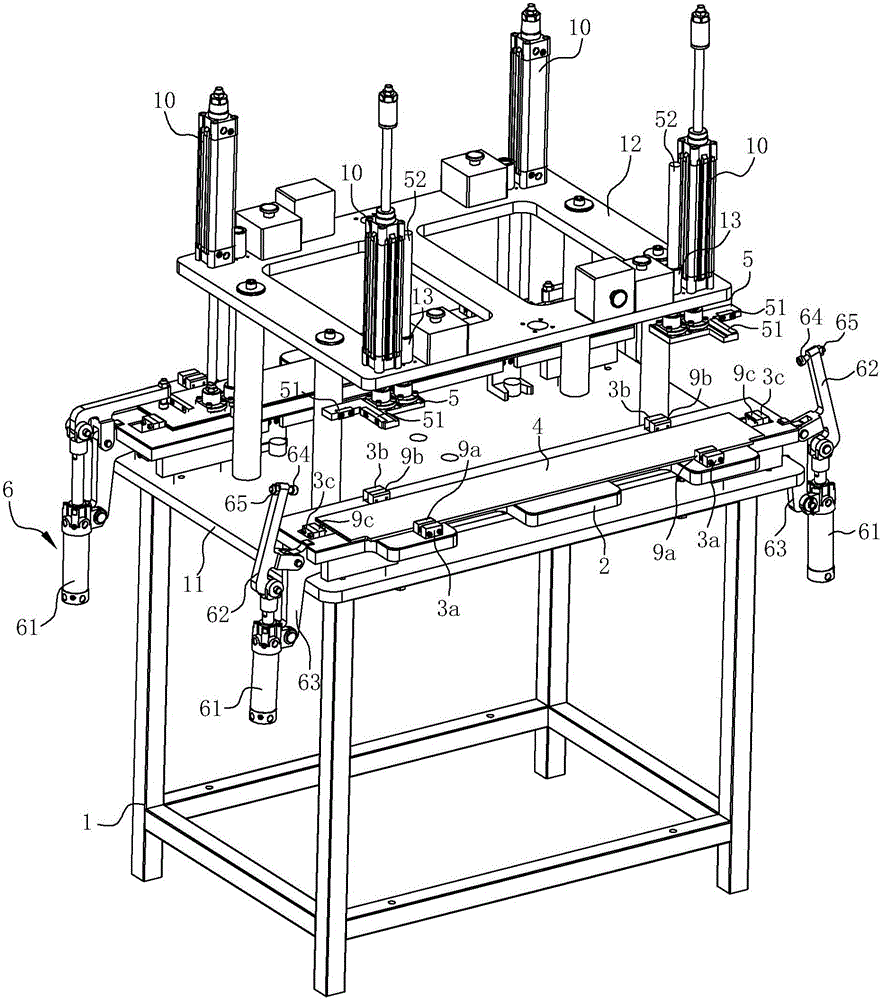

The invention relates to an adhering tool for adhering a glass panel to an exhaust fume collecting hood. The adhering tool comprises a support, and an adhering structure is at least arranged on one side of the support. The adhering tool is characterized in that the adhering structure comprises an upper bearing board, a lower bearing board, two positioning air cylinders, an upper installation board and compression blocks, wherein locating detents are installed on piston rods of the positioning air cylinders and provided with horizontal arms and inclined arms; first positioning blocks are fixed to the horizontal arms; second positioning blocks are fixed to the ends of the inclined arms on at least one side; the upper installation board is fixed above the support; the upper installation board and a top board of the support are spaced vertically; the compression blocks are located over the upper bearing board and driven by a compression air cylinder to vertically and perpendicularly move; the compression blocks press downwards to compress the glass panel to the front end face of the exhaust fume collecting hood for pressure maintaining. The adhering tool has the advantages that structural design is reasonable, the glass panel adheres to the exhaust fume collecting hood accurately and firmly, the binding efficiency and precision are high, a few procedures are needed, and operation is convenient.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Bonding tool for bonding multiple parts to glass panels at the same time

ActiveCN105422567BImprove bonding efficiencyHigh bonding precisionMaterial gluingWork holdersElectrical junctionEngineering

The invention relates to a bonding tool capable of simultaneously bonding various parts onto a glass panel. The bonding tool comprises a frame body which is provided with a table board and an upper mounting plate, and at least one set of a bonding structure. The bonding tool is characterized in that the bonding structure comprises a peripheral limiting structure for peripherally restraining the glass panel, a first lay-up block which is fixed on the table board for restraining a glass panel bracket, a second lay-up block which is fixed on the table board for restraining a first switch bracket, a third lay-up block which is fixed on the table board for restraining a second switch bracket, and a pressure maintaining block which is arranged above the table board, is driven by a pressure maintaining air cylinder mounted on the upper mounting plate to move up and down vertically, wherein the pressure maintaining block is pressed for pressing the glass panel to the bonding surface of each bracket to carry out pressure maintaining. The tool works once, so that not only can the glass bracket and the switch bracket be bonded onto the glass panel, but also bonding mounting of switch brackets of different models on the glass panel can be adapted, and therefore, the tool has the advantages of high bonding efficiency and high bonding precision, less processes, and convenient operation.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

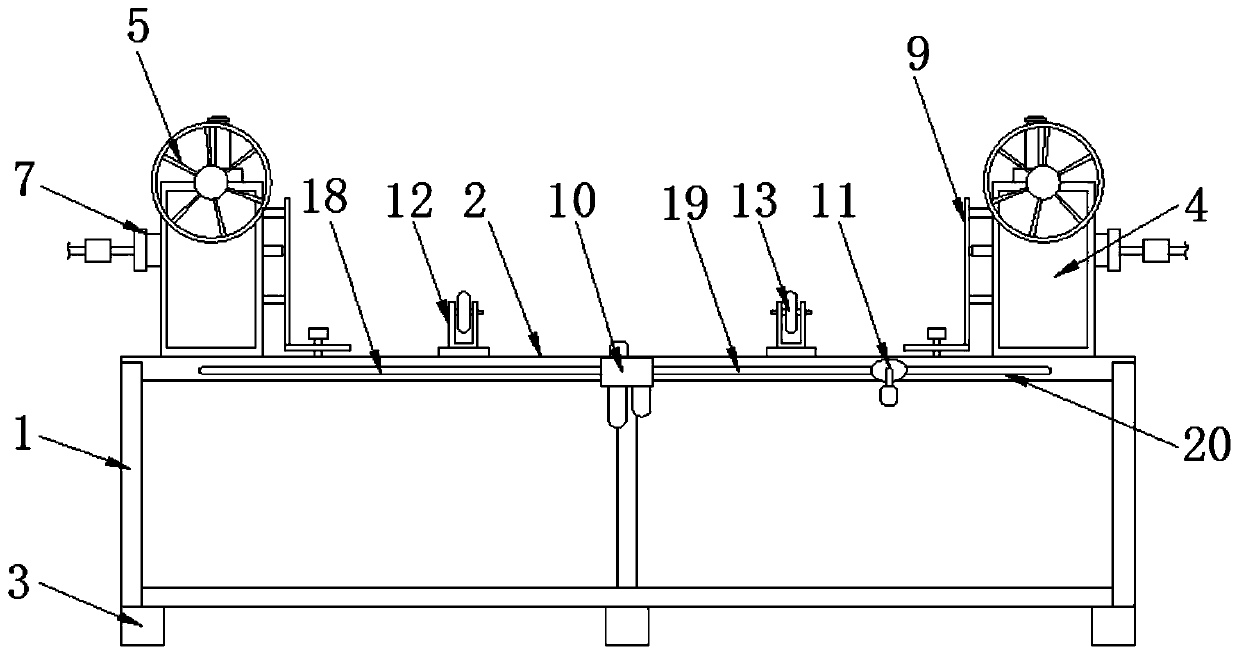

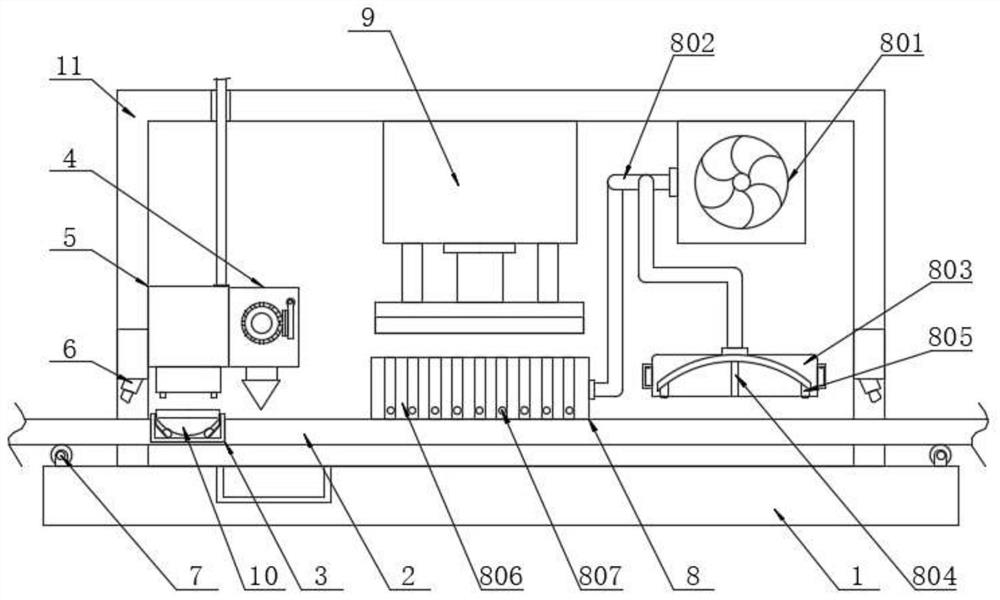

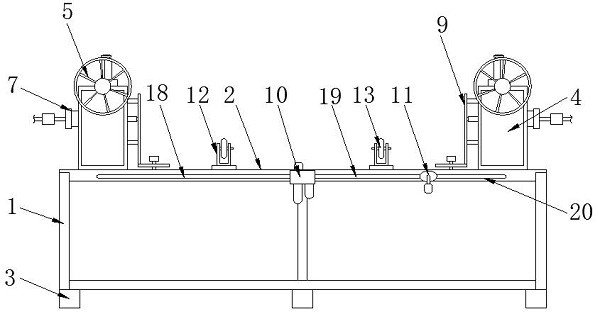

Bonding equipment for bonding trim strips on glass panels

The invention relates to bonding equipment for bonding trim strips on glass panels. The bonding equipment comprises a frame with a worktable surface for placing the glass panels and the trim strips, aconstraint structure arranged on the worktable surface for constraint limiting of the glass panels, an upper pressing plate arranged above the worktable surface, and a vertical driving structure fordriving the upper pressing plate to move up and down perpendicular to the worktable surface. The bonding equipment is characterized by further comprising a pushing structure and a return structure, wherein the pushing structure is arranged on the worktable surface for shifting the trim strips behind the glass panels to the direction of the glass panels to clamp in the back parts of the glass panels; and the return structure is used for enabling the pushing structure to return. The equipment enables the trim strips with U-shaped cross sections to automatically clamp into the glass panels, and realizes pressure-maintained bonding to guarantee automation in the bonding process of the trim strips.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

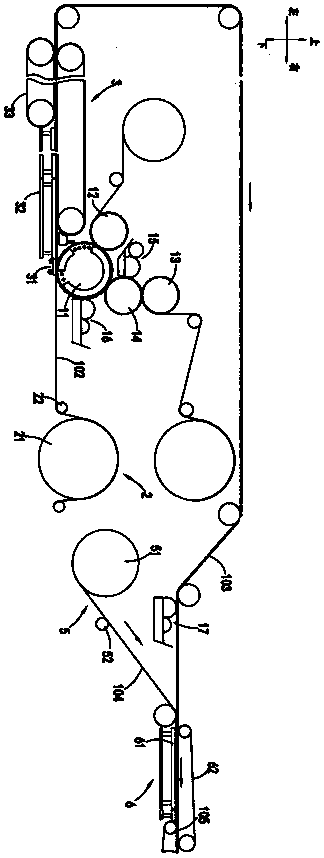

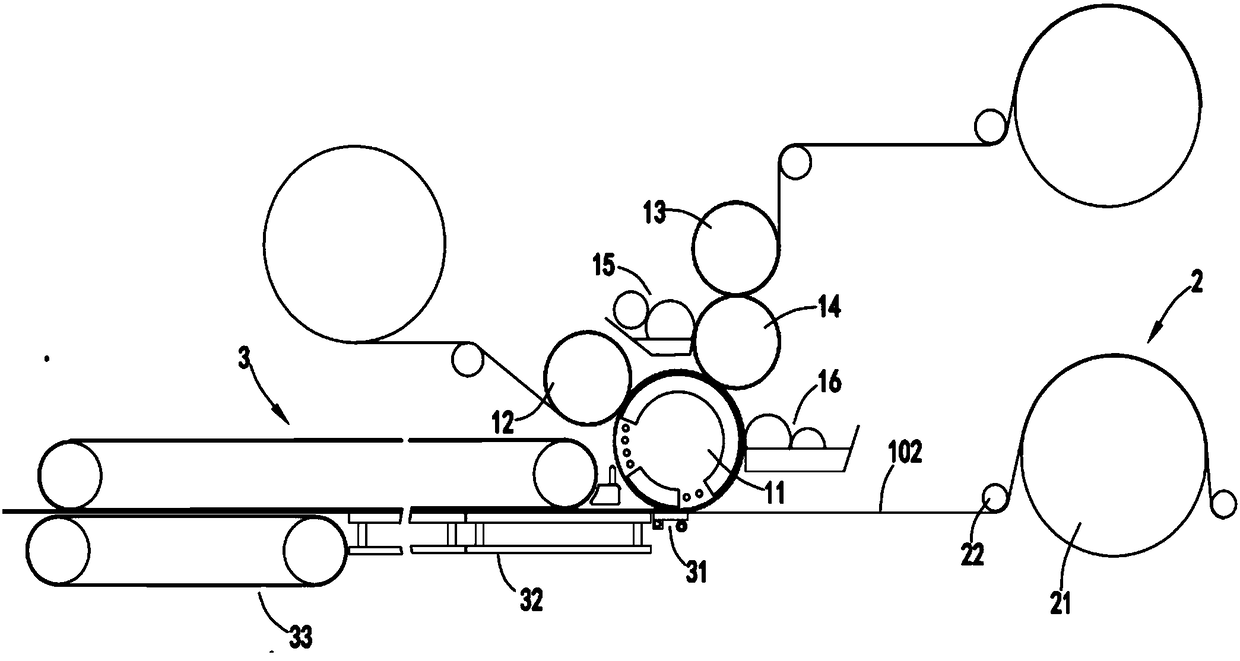

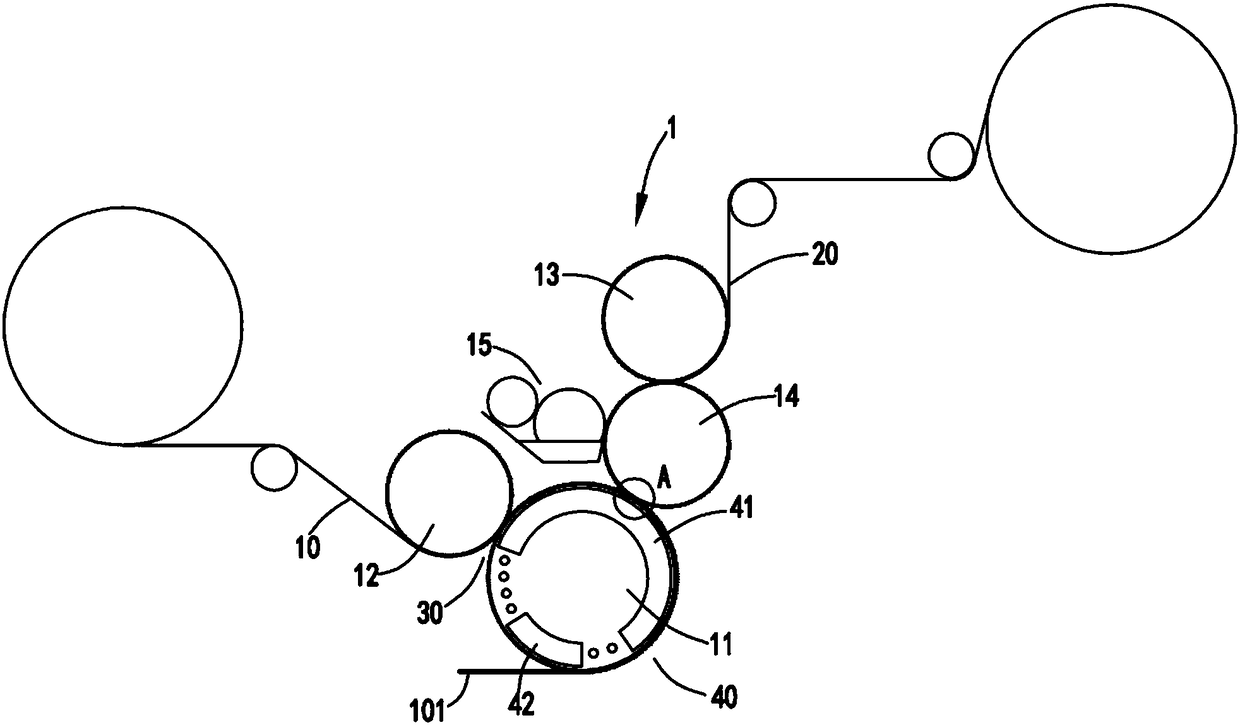

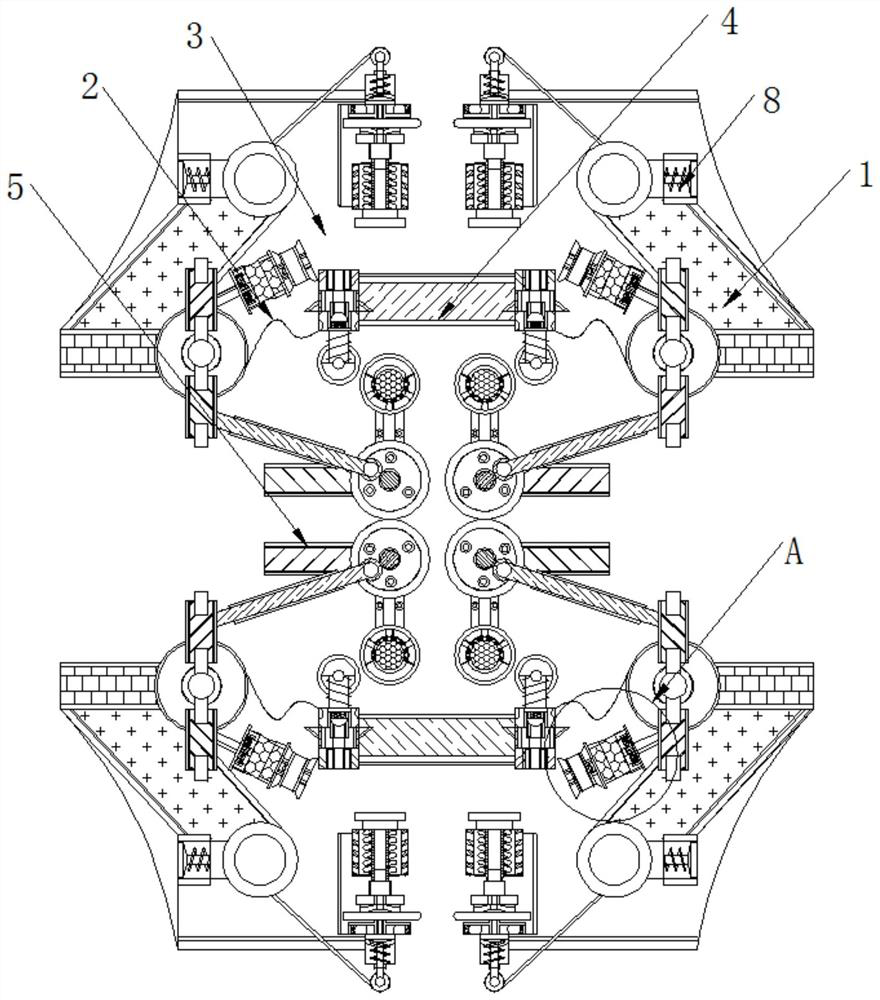

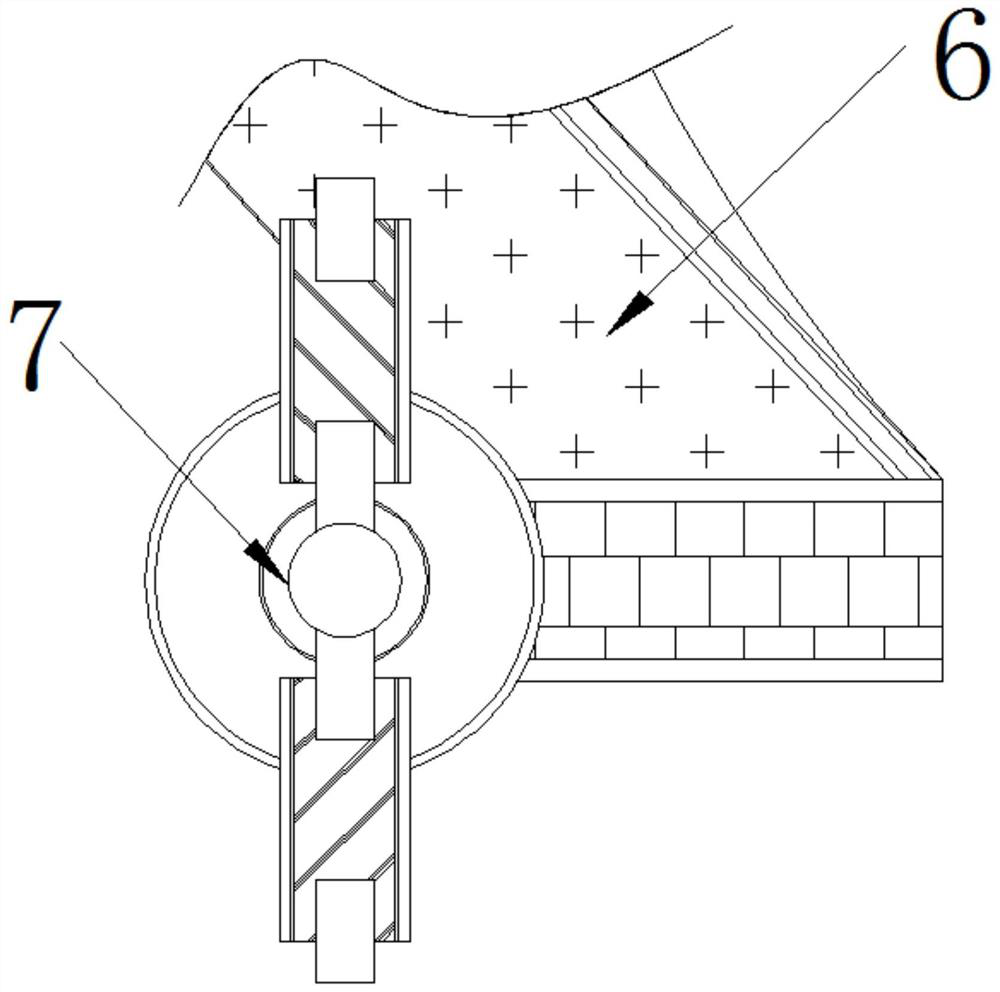

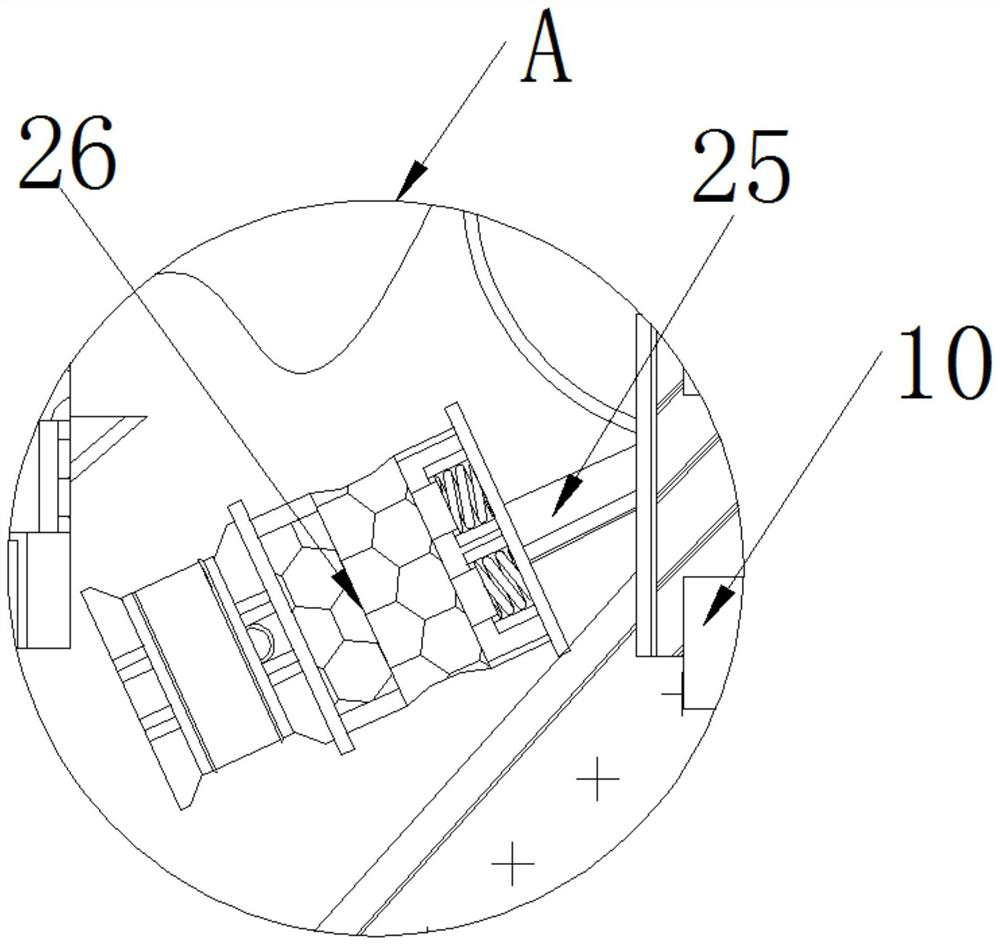

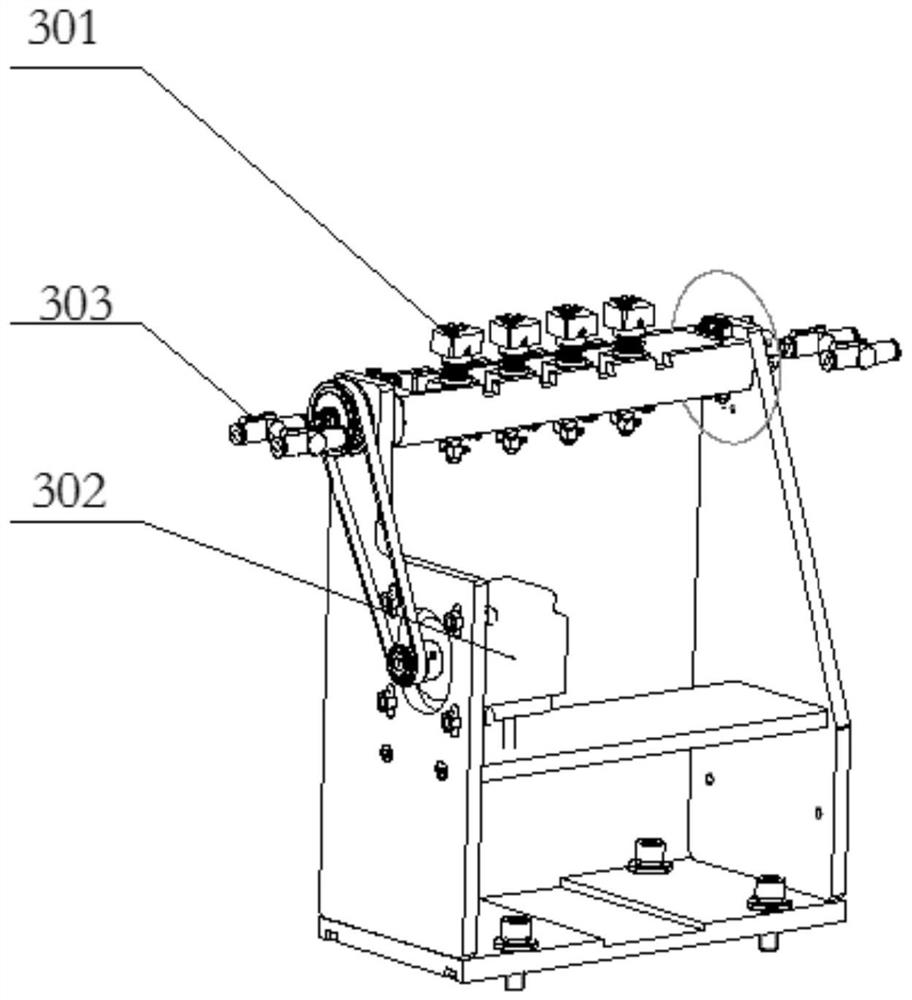

Corrugated paper production mechanism, four-layer corrugated board production line and production process thereof

PendingCN108515737AStable bondingSolve the unstable transmissionMechanical working/deformationProduction lineBonding process

The invention relates to a corrugated paper production mechanism, a four-layer corrugated paper board production line and a production process thereof. A corrugated paper production mechanism comprises a corrugated paper molding part. The corrugated paper molding part comprise a first corrugated roller, a second corrugated roller, a third corrugated roller, a fourth corrugated roller and a first glue painting mechanism, wherein the first corrugated roller and the second corrugated roller are used for molding first corrugated paper in a matched mode; the third corrugated roller and the fourth corrugated roller are used for molding second corrugated paper in a matched mode, and the first glue painting mechanism is used for painting glue on the second corrugated paper. The first corrugated roller is arranged between the fourth corrugated roller and the second corrugated roller, and the first corrugated roller and the fourth corrugated roller are matched to form a bonding passage, the bonding passage is bound by the first corrugated paper molded by the first corrugated roll and the second corrugated roller and the second corrugated paper molded by the third corrugated roller and the fourth corrugated roller. The tip a of the first corrugated paper and the tip b of the second corrugated paper are bonded in a tip-to-tip mode to form double-layer corrugated paper under the action of addendums of the first and fourth corrugated rolls separately. The corrugated paper production mechanism, the four-layer corrugated paper board production line and the production process thereof solvesthe problems that a layer of bottom paper needs to be clamped between two pieces of corrugated paper, the paper consumption is large, and the strength of the corrugated paper is low due to the fact that a tip-to-tip mode is difficult to achieve in the corrugated paper bonding process are solved.

Owner:王慧明

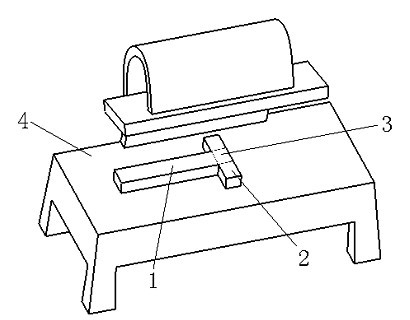

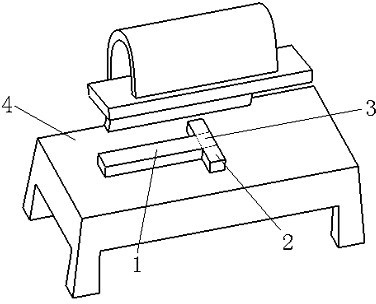

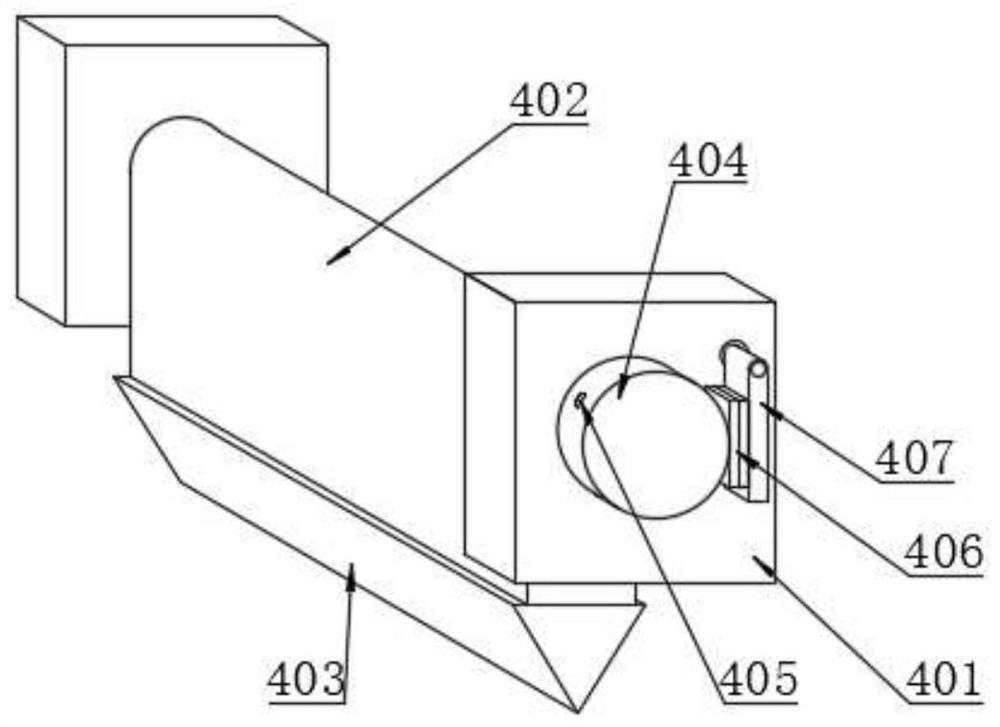

Lost foam gluing mould

InactiveCN106424550AHigh bonding precisionImprove bonding efficiencyFoundry moulding apparatusReciprocating motionEngineering

The invention belongs to auxiliary tools in the technical field of engine casting, and particularly relates to a lost foam gluing mould. The lost foam gluing mould comprises an upper mould plate and a lower mould plate which are arranged on a rack, and a die used for gluing the bottom of an upper half body of a lost foam; the upper mould plate and the lower mould plate are arranged in the vertical direction in an openable mode; the die is arranged in the vertical direction in a reciprocating motion mode; a glue pool used for containing glue is arranged below the die; when the die moves downwards, the upper surface of the die can sink into the glue pool; the upper mould plate is arranged in the horizontal direction in a reciprocating motion mode so that the upper mould plate can move to the position above the die or the lower mould plate alternately; and when the upper mould plate moves to the position above the die and the die moves upwards, glue on the upper surface of the die can be printed on the bottom of the upper half body of the lost foam. The lost foam is automatically glued through the die, the upper body and the lower body of the lost foam are pressed to be glued into a whole through the upper mould plate and the lower mould plate, and the gluing precision and efficiency of the lost foam are greatly improved.

Owner:ANHUI QUANCHAI ENGINE

Bonding tooling for upper glass components that can be adjusted in size in any direction

ActiveCN105538187BImprove bonding efficiencyHigh bonding precisionWork holdersBonding processEngineering

The invention relates to a bonding tool for mounting a part on a glass assembly and capable of adjusting dimensions in any direction. The bonding tool is characterized in that the tool comprises a rack body, glass panel limiting structures, support limiting structures and pressure maintaining blocks; the rack body is provided with a table board and an upper mounting plate; the glass panel limiting structures are used for limiting glass panels; the support limiting structures are used for limiting buckle supports; the pressure maintaining blocks are located above the glass panel limiting structures, and are driven by pressure maintaining cylinders mounted on the upper mounting plate to vertically move up and down; and the down pressing of the pressure maintaining blocks enables the glass panels to be tightly pressed on the bonding faces of the buckle supports to conduct pressure maintaining. In the bonding process, the relative position relation of the buckle supports and the glass panels is kept unchanged through the limiting of the glass panel limiting structures to the glass panels and the restraint of the support limiting structures to the buckle supports, and the bonding precision is high; the pressure maintaining blocks are driven by the action of the pressure maintaining cylinders to press the glass panels to the bonding faces, coated with glue, of the buckle supports and conduct pressure maintaining for a certain time, so that the buckle supports and the glass panels are firmly fixed.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

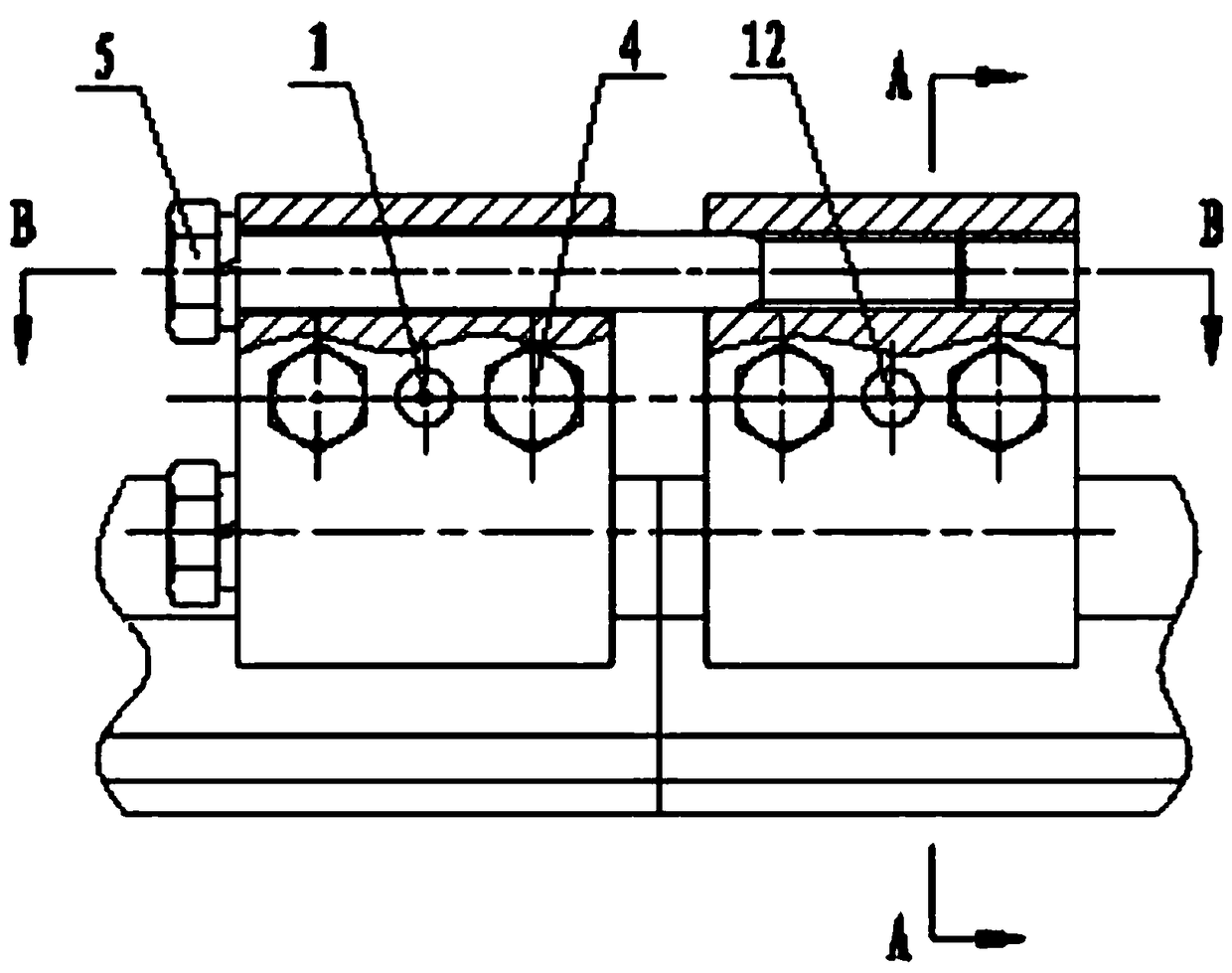

Bonding device and process for core disc air gap cushion block of shunt reactor

InactiveCN107068383AGuaranteed Bonding Tolerance RangeGuaranteed performanceMagnetic core manufactureProcess equipmentShunt reactor

The present invention involves a parallel anti -electrocomputer iron -hearted cake gas gap pad adhesion device and process, which belongs to the technology field of parallel anti -electronics technology production equipment.The technical solution is: the bonding template of the air gap pad (5) is a circular structure, and the gap pad bonding template (5) has a positioning tube (6) below the central part, and the bonding template of the air gap pad (5) Multiple holes (12) are arranged around the circular direction of the positioning tube; the bonding template of the gas gap pad (5) is pressed on the iron heart cake (4), and the positioning tube is as the phenolic paper tube in the center of the iron cake (4)Cooperate; multiple air gap pads (9) are located in multiple holes (12) on the bonding template (5) on the gas gap pad, respectively, and contact the iron heart cake; the pressure plate (10) is pressed on multiple gasOn the gap pad, the pressure plate and the support platform (1) are connected by fastening bolt (7).The invention has a simple structure and high adhesion accuracy. It can ensure the bonding tolerance range of the gas gap pads of the iron heart cake and ensure the performance of the parallel electrical antibody.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL +3

FPC automatic pasting machine

The invention provides an FPC automatic pasting machine. The FPC automatic pasting machine comprises a bearing device, an overturning device, a pasting device, a transferring device and a positioningdevice. The bearing device is configured to bear FPCs and products. The overturning device comprises a first receiving mechanism, an overturning mechanism and a first drive mechanism, the first receiving mechanism is configured to bear the FPCs, the first receiving mechanism is arranged on the overturning mechanism, the first drive mechanism is connected with the overturning mechanism, the first drive mechanism is configured to drive the overturning mechanism to be overturned, and the pasting surfaces of the FPCs are opposite to the to-be-pasted surfaces of the products. The pasting device isconfigured to paste the FPCs on the products. The transferring device is configured to transfer the FPCs on the bearing device to the overturning device and transferring the FPCs on the overturning device to the pasting device. The positioning device comprises a position acquisition mechanism and a deviation correction mechanism. The position acquisition mechanism is configured to acquire positioninformation of the FPCs and the products, and the deviation correction mechanism corrects the positions of the FPCs and the products according to the position information. The FPCs can be automatically pasted through the overturning mechanism, and the pasting precision of the FPCs can be improved through the positioning device.

Owner:GOERTEK INC

Heating bonding clamp

InactiveCN108942752AGood adhesionAccurate positional relationshipWork holdersFastening meansEngineeringMechanical engineering

The invention relates to a heating bonding clamp which comprises a table face. A bonding structure is arranged on at least one side of the table face. The heating bonding clamp is characterized in that each bonding structure comprises a bearing block, a locating structure, a mounting plate, a pressing block and a heating device; the bearing blocks are fixed to the table face so as to allow the inner surface of the front end face of a fume collection hood to be placed thereon; the locating structures are arranged on the bearing blocks to be used for locating the front end face of the fume collecting hood and face stickers; the mounting plates are fixed to the upper portion of the table face; the pressing blocks are located above the bearing block and are driven by pressing air cylinders mounted on the mounting plates to move up and down; and the heating devices are arranged in the bearing blocks and used for supporting the bearing blocks for heating. Through the arrangement of the heating devices in the bearing blocks, even though in the environment that the temperature is low, initial bonding force of double-face pressure-sensitive adhesive can be ensured, and the problem that theinitial bonding force of the double-face pressure-sensitive adhesive is low to influence reliability due to the low air temperature in winter is solved; and the heating bonding clamp is a bonding toolwhich is reasonable in structural design and can precisely and firmly bond the face stickers to the fume collecting hood, and the heating bonding clamp has the advantages of being high in bonding efficiency and precision, low in number of procedures and convenient to operate.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Bonding device for unframed oil seal

PendingCN108591472AQuality improvementHigh structural size matchingEngine sealsBonding processEngineering

The invention discloses a bonding device for an unframed oil seal. The bonding device comprises first connecting pieces, second connecting pieces, a first pressing plate, a second pressing plate, a third pressing plate and a fourth pressing plate. The first pressing plate and the second pressing plate are connected through the first connecting pieces. The third pressing plate and the fourth pressing plate are connected through the first connecting pieces. The first pressing plate and the fourth pressing plate are connected through the second connecting pieces, and a gap for operating is reserved between the first pressing plate and the fourth pressing plate. The second pressing plate and the third pressing plate are connected through the second connecting pieces, and a gap for operating isreserved between the second pressing plate and the third pressing plate so that the gap width can be adjusted when the pretightening force of the second connecting pieces is adjusted. According to the bonding device for the unframed oil seal, the special cutting and bonding device is designed according to the structure characteristics of the unframed oil seal, a cutting datum plane is provided inthe cutting process, and therefore the cutting stability is higher and the cutting face quality is better; and in the bonding process of the oil seal, the pressing plates at the two sides of the oilseal are not dismantled, and the consistency and stability of the oil seal in the cutting and bonding processes are guaranteed.

Owner:CHONGQING GEARBOX

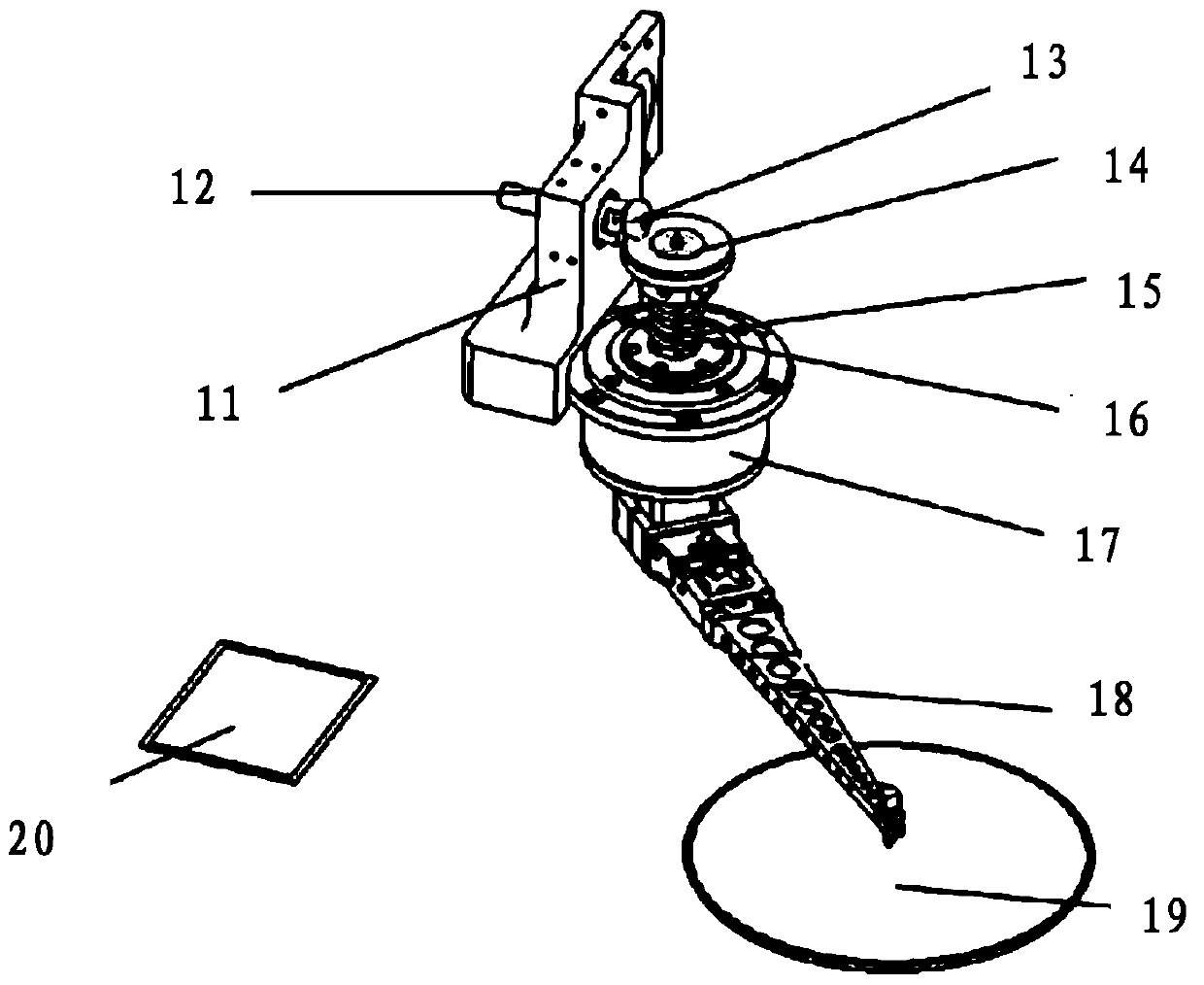

Stickup device of support plate

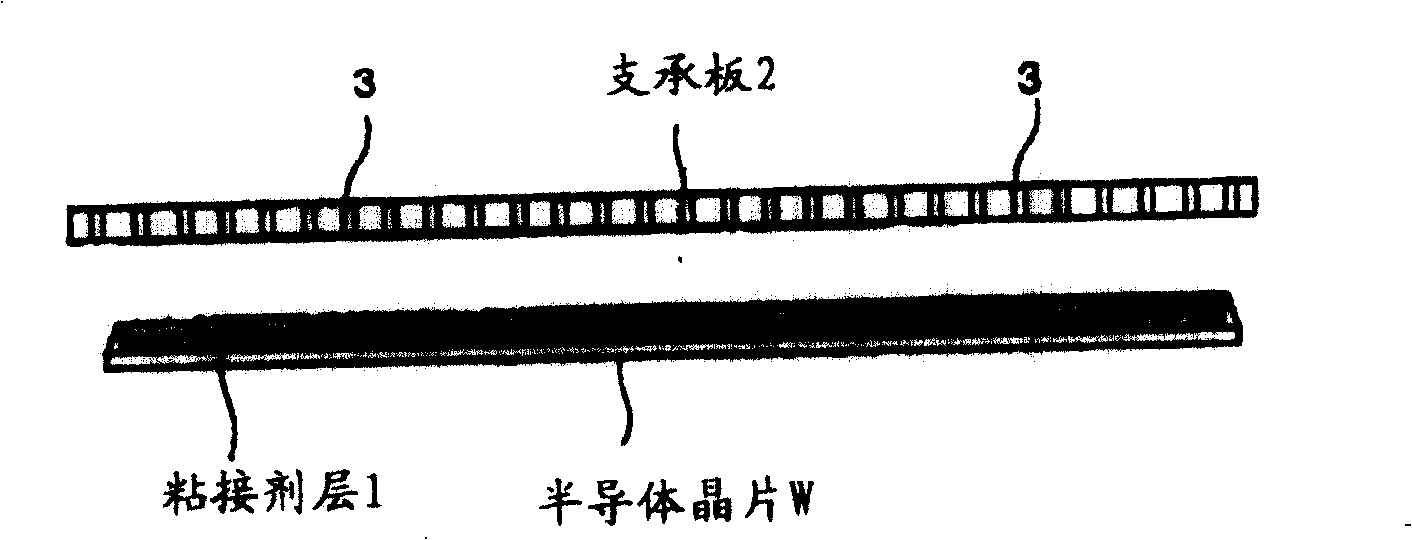

ActiveCN100454481CInhibitionHigh bonding precisionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

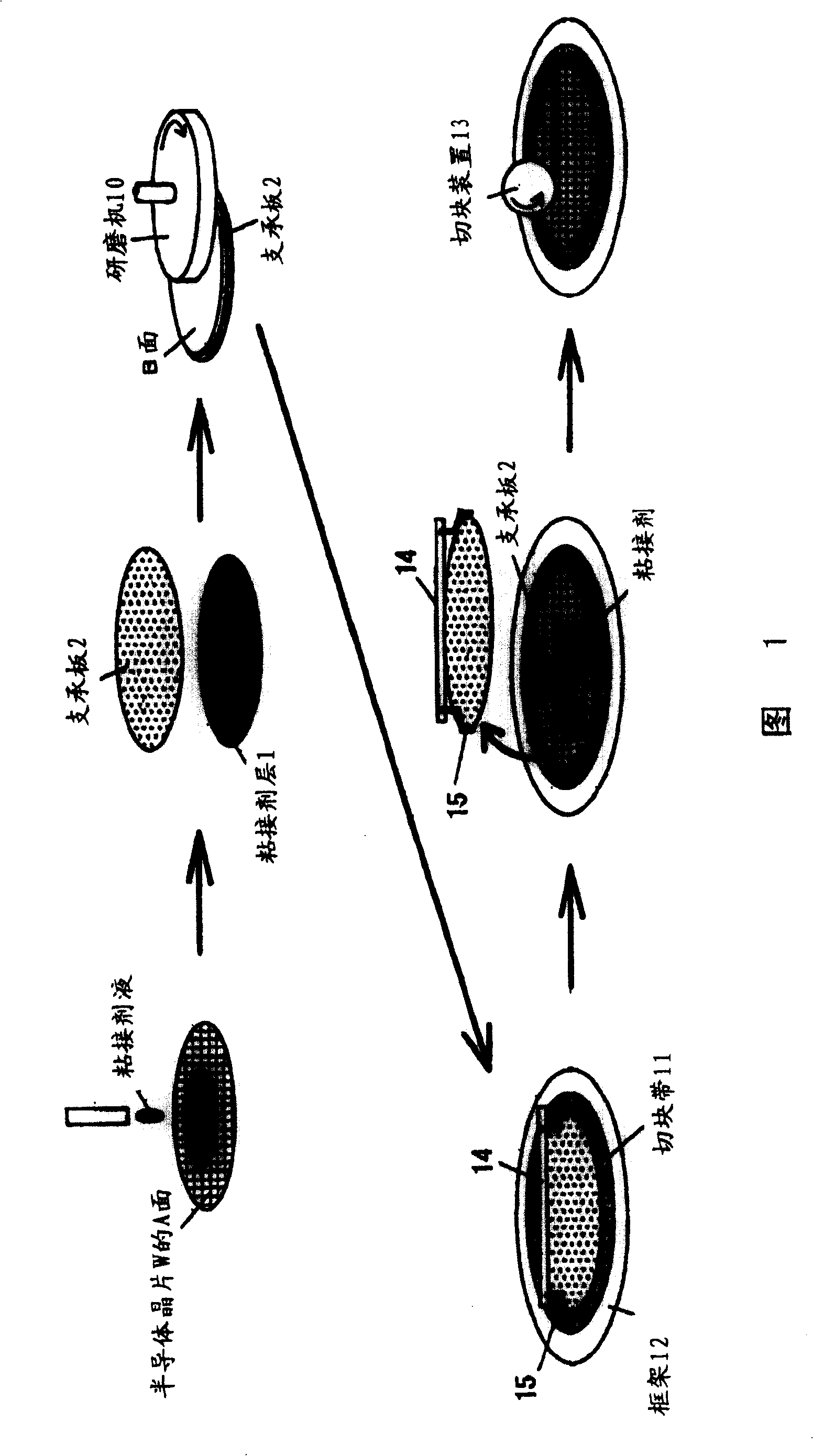

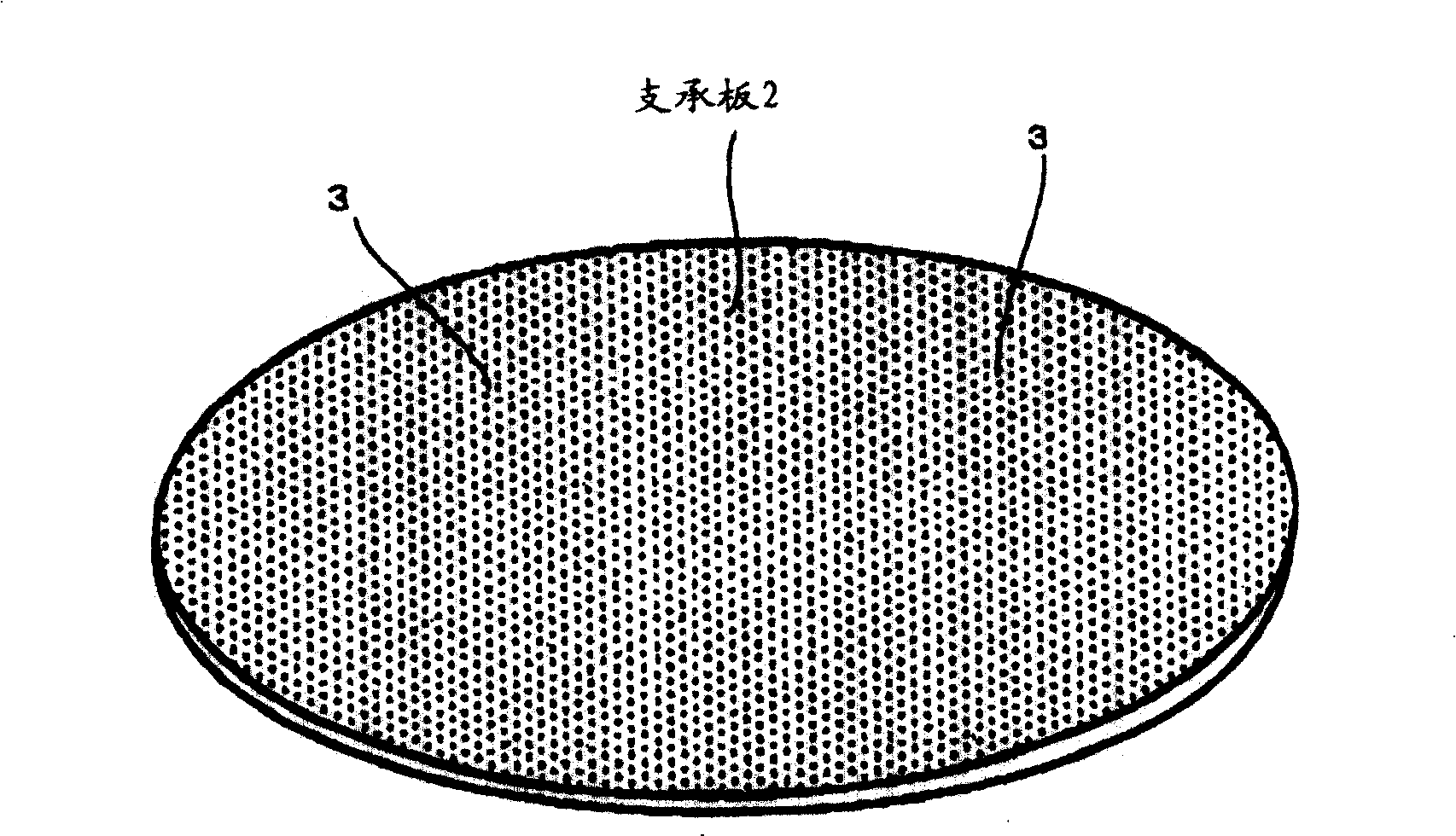

To provide an adhering apparatus for pressure-bonding a support plate while easily removing the gas held between a substrate such as semiconductor wafer or the like and the support plate. A pressure reducing chamber 50 is connected with an evacuation apparatus via a pipe 51, allows formation of a carrying-in / out aperture 52 at its one side surface, and opens or closes this aperture 52 with a shutter 53. This shutter 53 is moved upward and downward with a cylinder unit 54 and when it is pushed with a pusher 55 from a side at the lifted position, a seal provided at the internal side surface of the shutter 53 is placed in close contact with the circumference of the aperture 52 to seal the inside of the chamber 50. When the pusher 55 is moved backward and the shutter 53 is moved downward, the aperture 52 is opened and a laminate of the wafer W and support plate 2 is carried in and out using a transferring apparatus under the above state. Within the chamber 50, a holding base 56 and a pressuring plate 57 are arranged for pressure-bonding the laminate.

Owner:艾美柯技术株式会社 +1

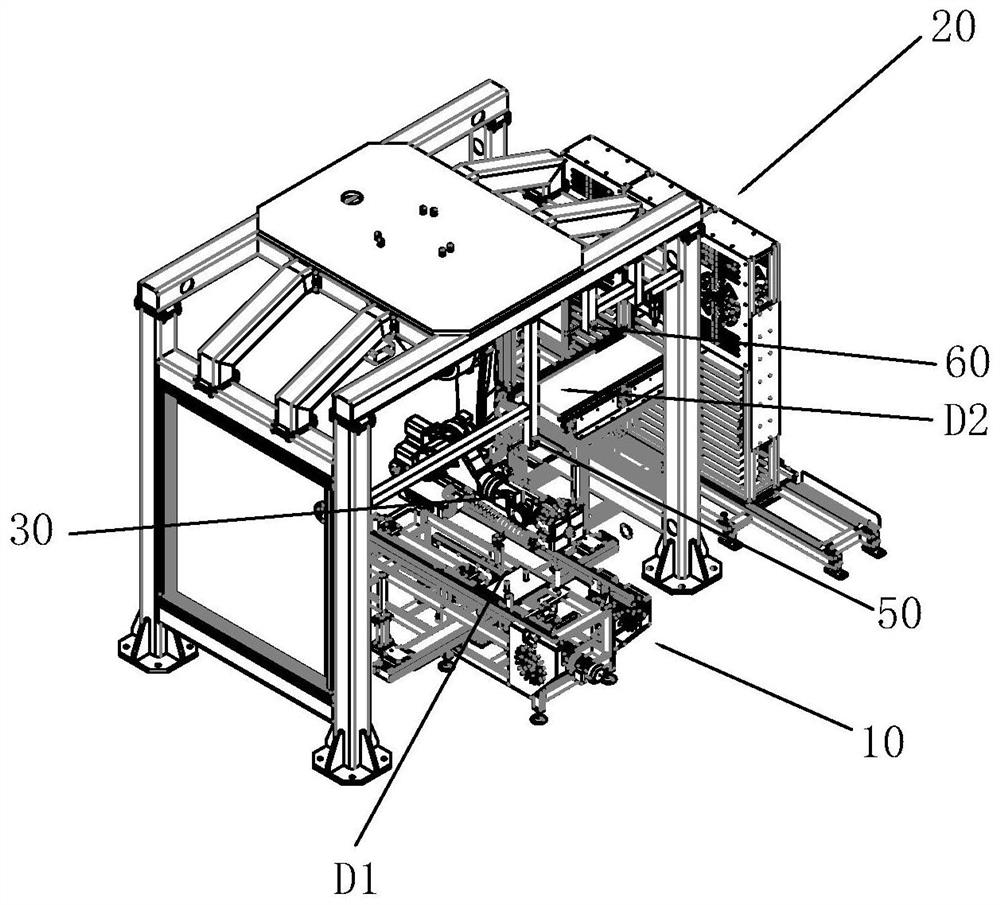

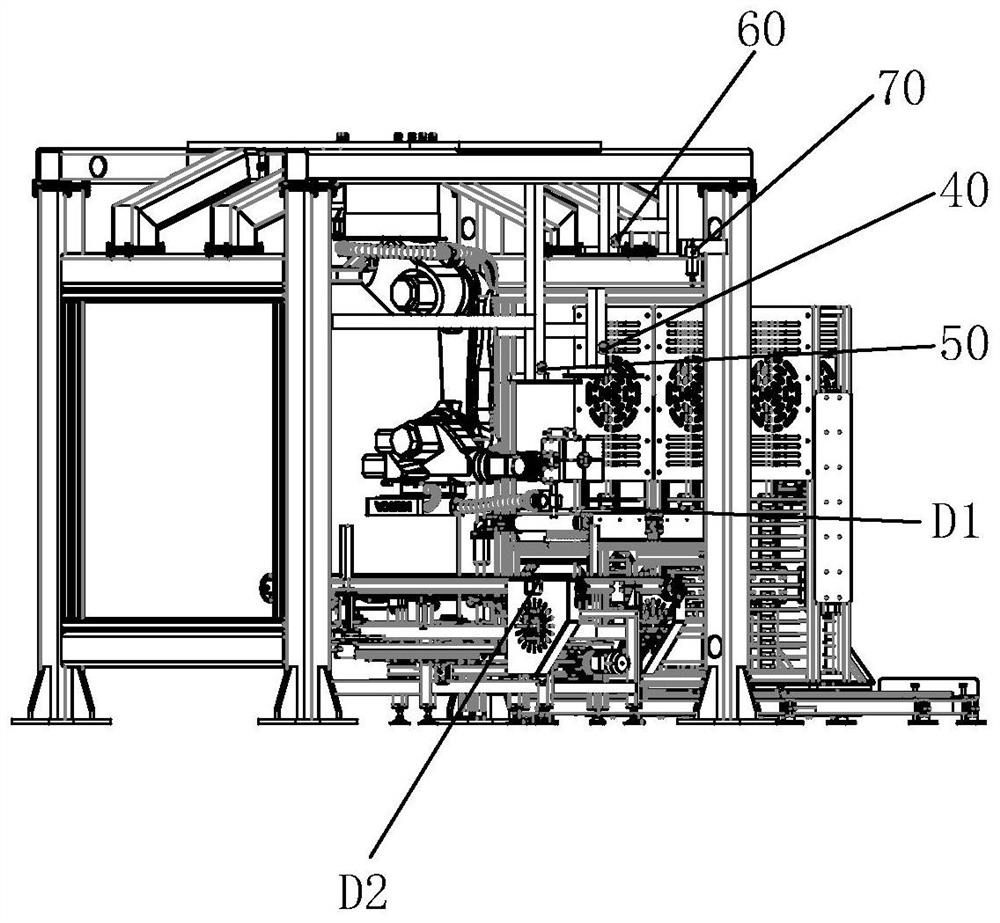

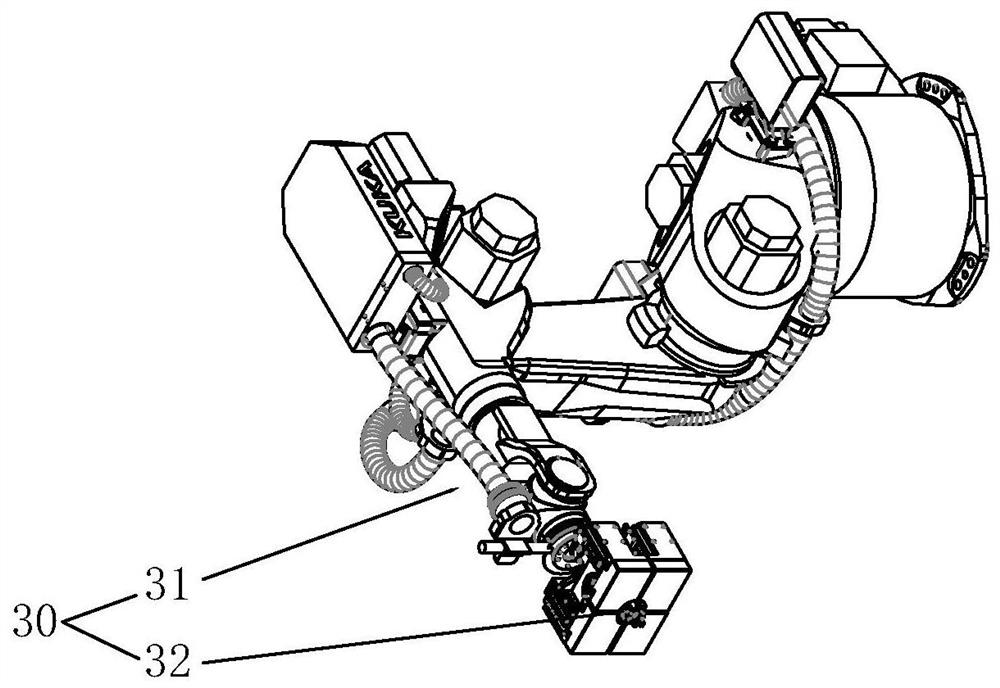

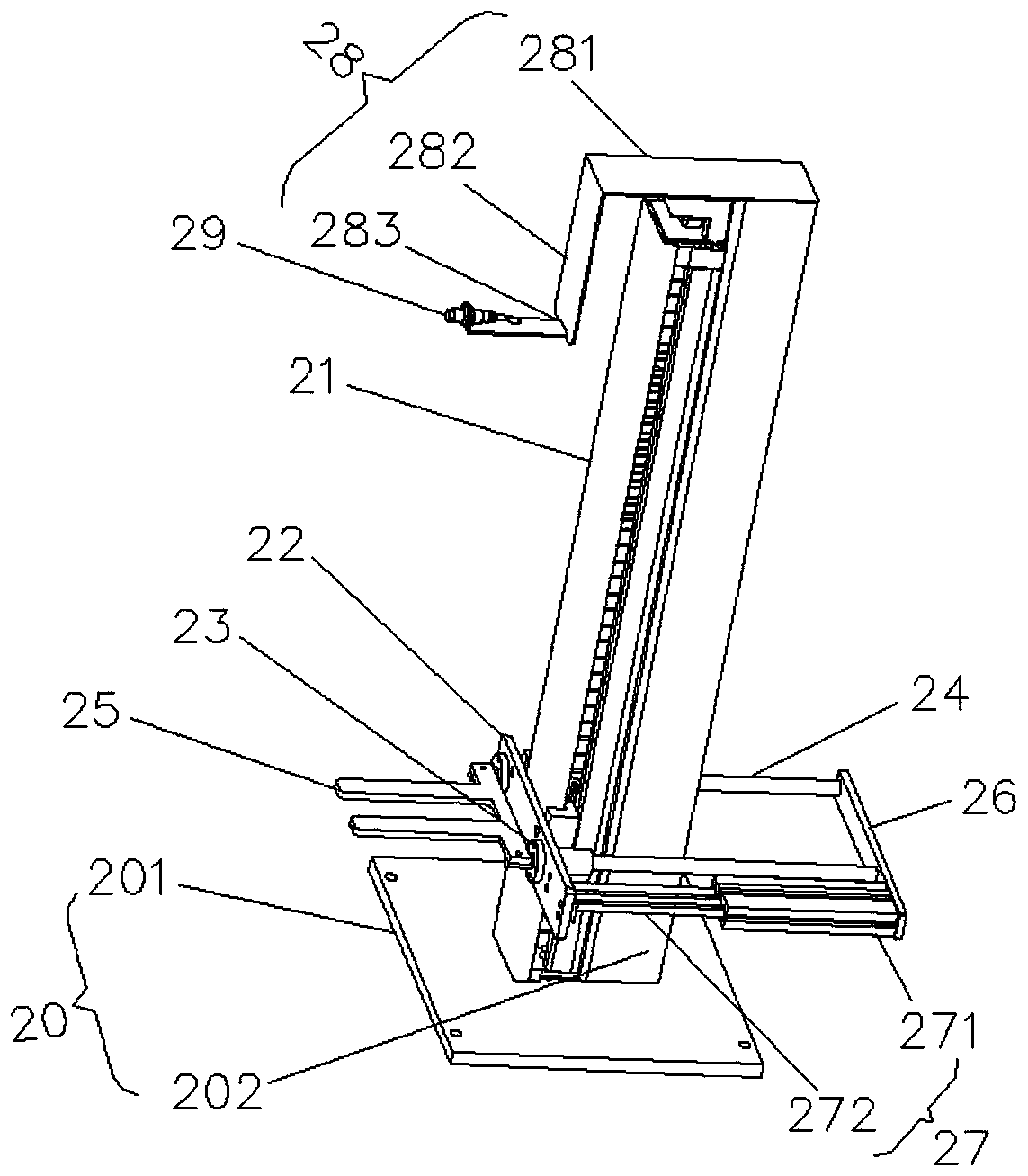

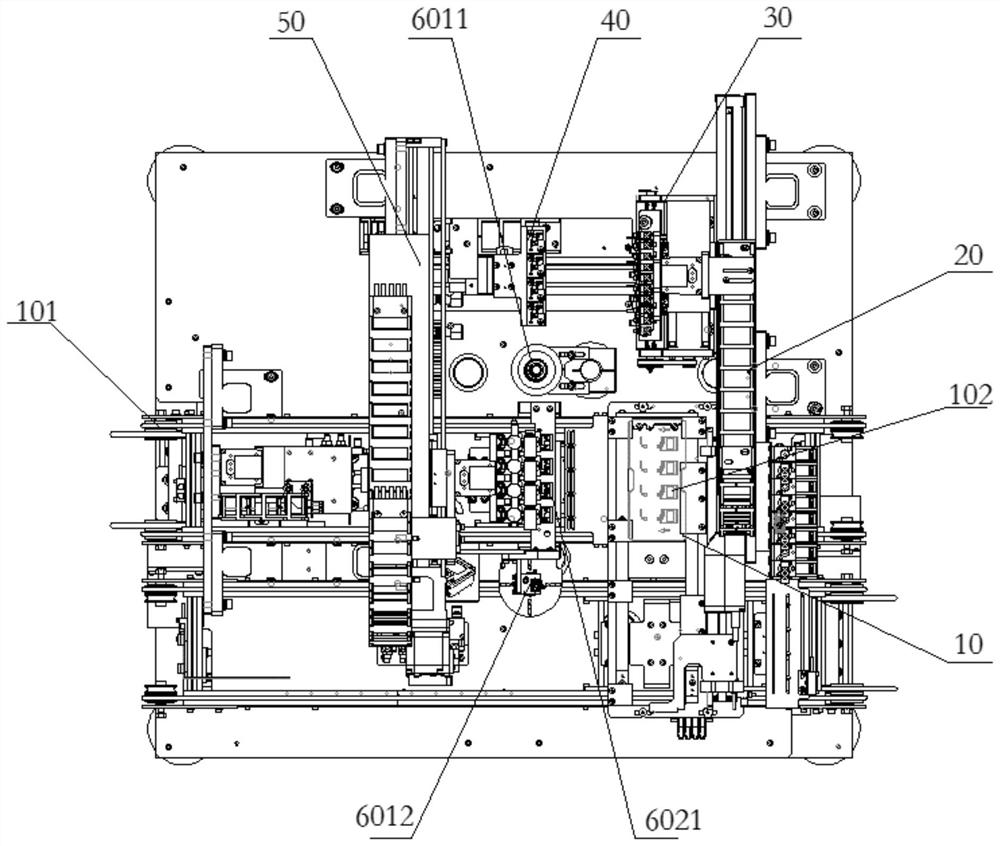

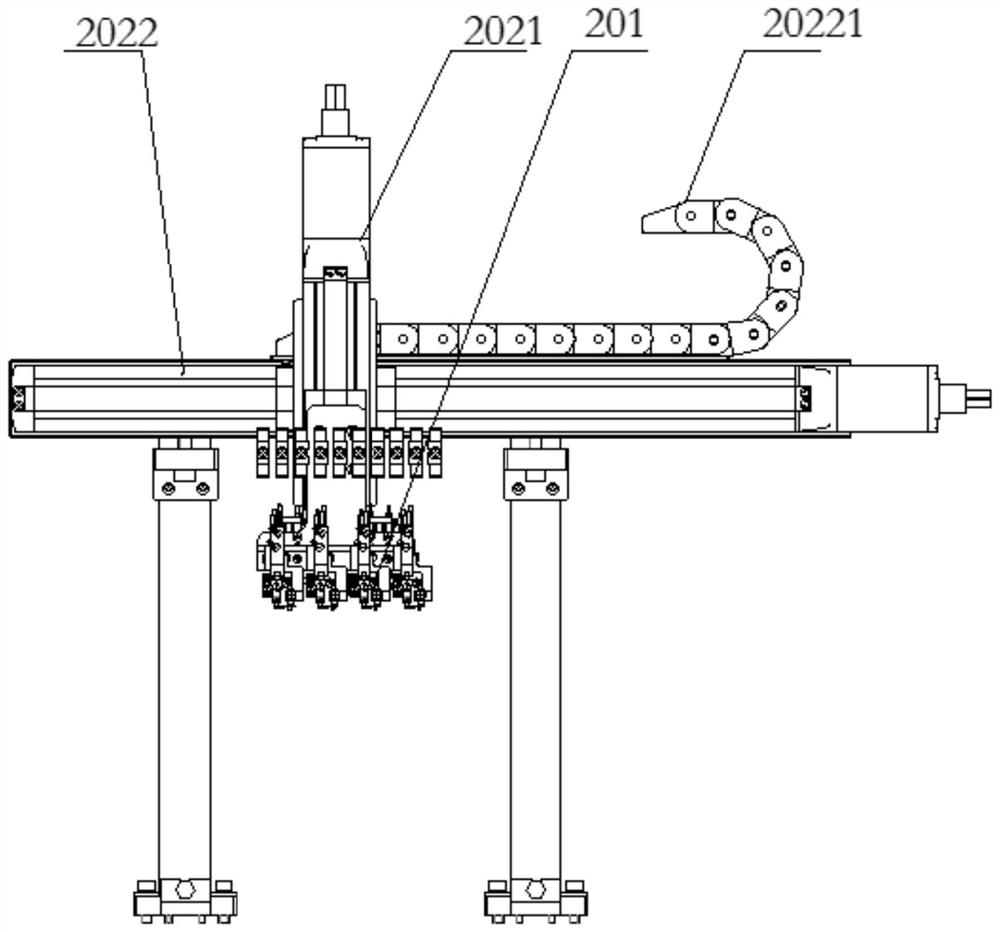

Support bonding equipment and bonding method

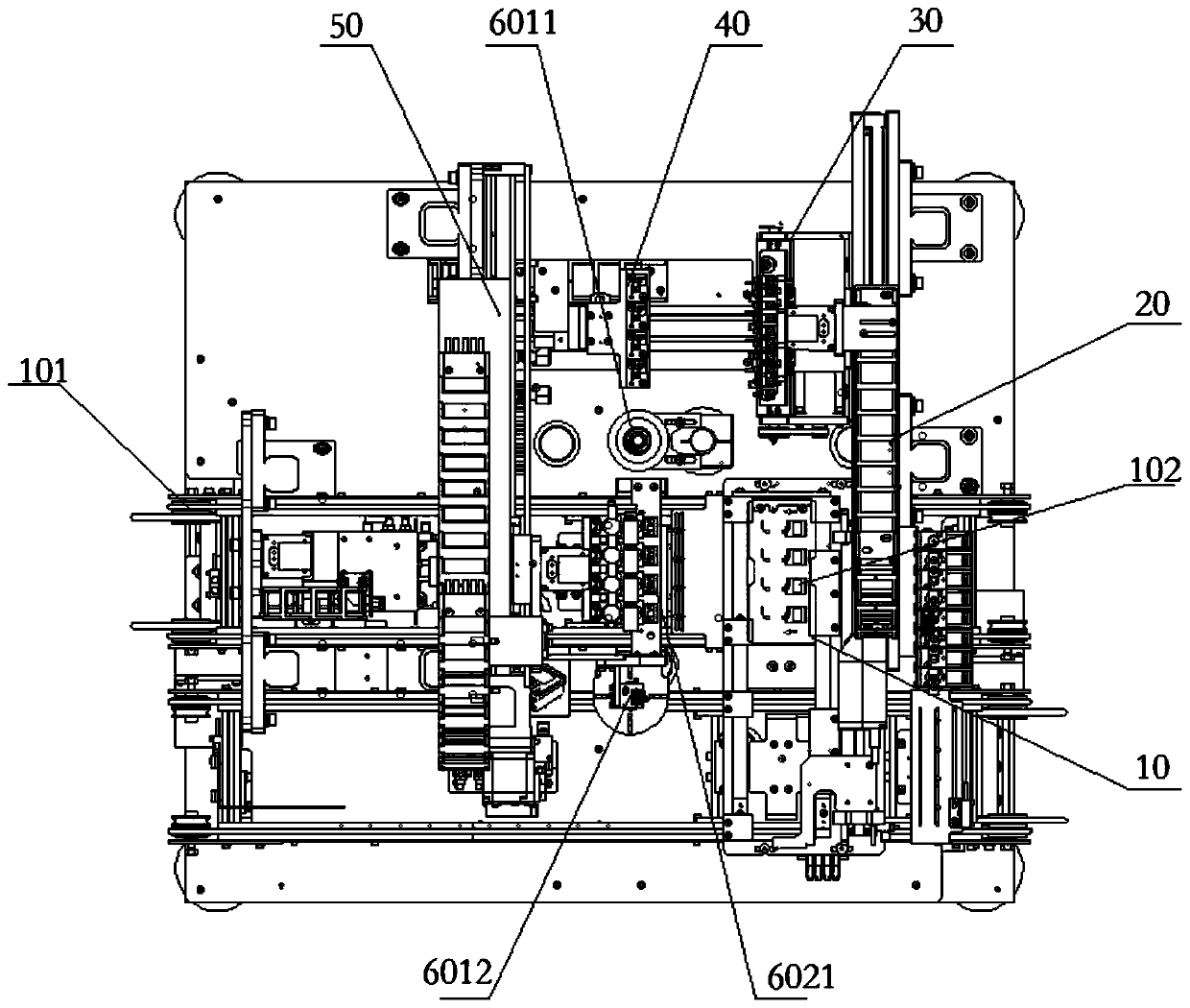

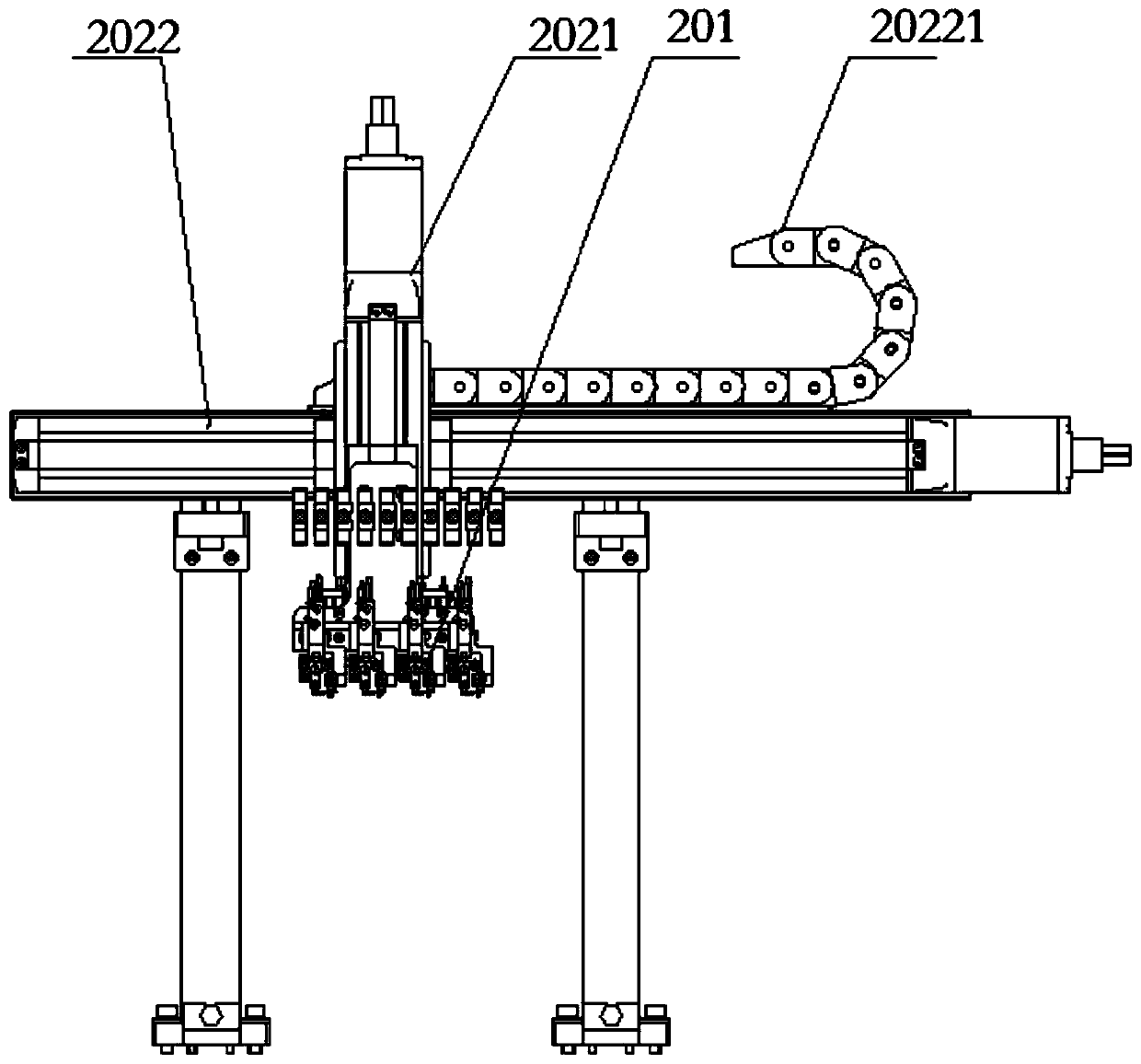

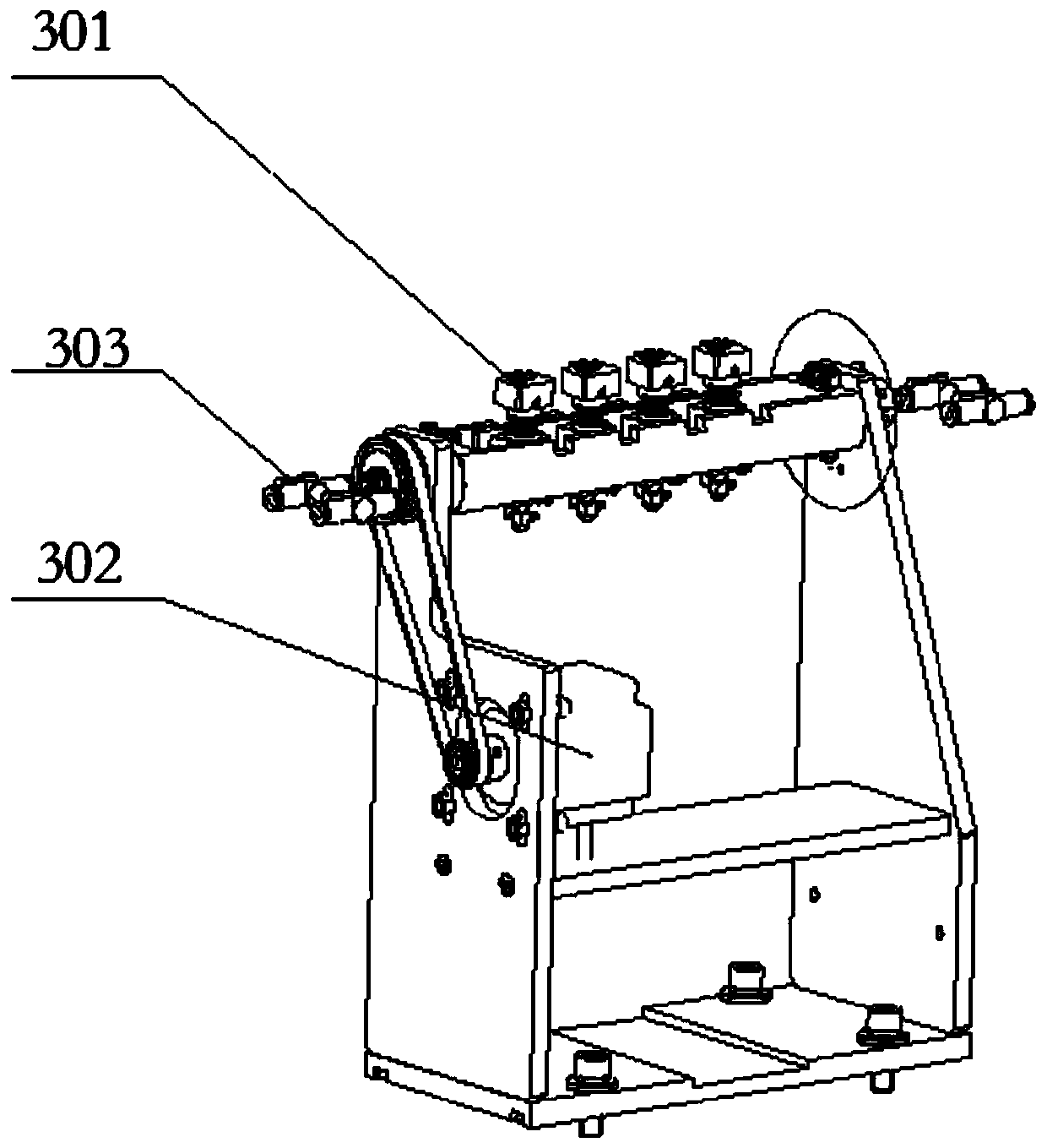

ActiveCN111908112ASolve the cumbersome replacementIncrease productivityConveyorsMaterial gluingStructural engineeringManipulator

The invention discloses support bonding equipment. The support bonding equipment comprises a glass plate conveying device, a support conveying device, a clamping device, and a control device, whereinthe glass plate conveying device is used for conveying a glass plate to a first position, the support conveying device is used for conveying a support to a second position, the clamping device can bemoved to the second position to clamp the support and paste the support to a preset area on the surface of the glass plate located at the first position, a column body is arranged on the surface, opposite to the bonding surface of the support, of the support, the clamping device comprises a manipulator, and a clamping mechanism, the clamping mechanism is connected to the working end of the manipulator and is provided with at least one pair of mouth parts which can be close to each other, and grooves corresponding to the peripheral shape of the column body are formed in the opposite surfaces ofthe two mouth parts. The support bonding equipment has the advantages that the cost is reduced, the production efficiency is high, and the support bonding equipment is suitable for alternate production occasions for pasting different types of supports.

Owner:FUJIAN WANDA AUTOMOBILE GLASS IND

Embedded Part Bonding Fixtures

ActiveCN109249319BMake sure to dryReliable contactMaterial gluingWork holdersFront edgeManufacturing engineering

The invention relates to an embedded part bonding fixture, which comprises a table board; a bonding structure, wherein the bonding structure comprises a decorative strip positioning structure; a pressing plate assembly arranged above the table board; a vertical driving structure used for driving the pressing plate assembly to move up and down perpendicular to the table board; a front positioning block used for positioning the front edge of a glass panel; a left positioning block and a right positioning block, which are respectively used for positioning the left edge and rear edge of the glasspanel; a rear positioning block used for positioning the rear edge of the glass panel; a front pushing block arranged on the table board and is driven by a front driving structure to slide back and forth, wherein the front pushing block is used for pushing the glass panel backwards and embedding the rear part of the glass panel into a clamping groove part of the decorative strip. The device can automatically embed the glass panel into the clamping groove part of the decorative strip with a U-shaped cross section, and can perform well pressure maintaining on the glass panel in the clamping groove part so as to ensure the automation of the process of bonding the decorative strip with the U-shaped cross section to the glass panel.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Device and method for adhesive bonding of membrane shell

ActiveCN110861310ATo achieve the bonding effectImprove controllabilityDomestic articlesAdhesive glueAir compressor

The invention discloses a device and a method for adhesive bonding of a membrane shell, and relates to the technical field of membrane separation. The device comprises a supporting frame, a supportingplate is fixedly connected to the top of the supporting frame, a supporting block is fixedly connected to the bottom of the supporting frame, fixing boxes are fixedly connected to the two sides of the top of the supporting plate, air compressors are fixedly connected to the tops of the two fixing boxes, and fixing plates are fixedly connected between the top and the bottom of the inner wall of the fixing boxes. According to the device and method for adhesive bonding of the membrane shell, the adhesive bonding work is carried out manually by means of a machine, the adhesive bonding effect canbe achieved through one person, the controllability is high, the adhesive bonding qualification rate is improved, the adhesive bonding error is reduced, the adhesive bonding precision is improved, thelabor cost is reduced, the practicability is high, mechanical adhesive bonding replaces manual adhesive bonding, the working efficiency is improved, the production speed is increased, the operation is convenient, the adhesive bonding can be performed immediately after the gluing work is completed, the glue drying is prevented, and the effect is lost.

Owner:XINJIANG DELAND

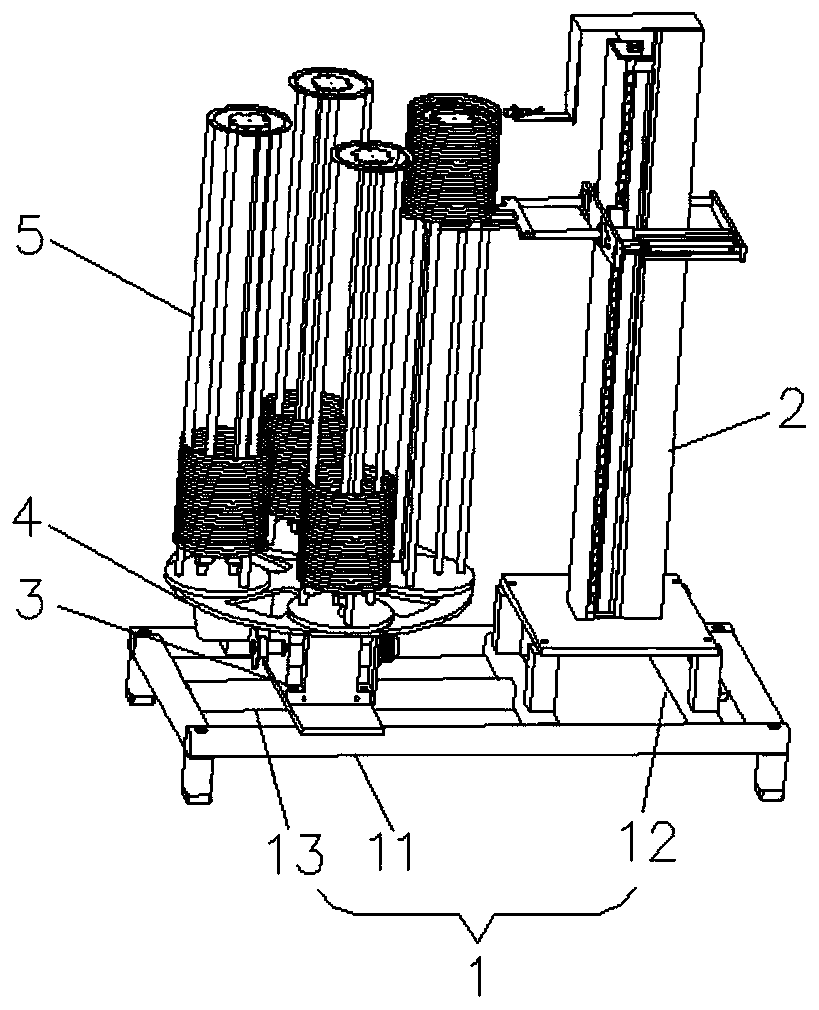

Disc core material storage and feeding device

PendingCN109969805AAchieve storageImprove supply efficiencyConveyorsDe-stacking articlesEngineeringMaterial storage

The invention discloses a disc core material storage and feeding device. The device comprises a support, a disc core feeding device, a driving assembly, a rotating part and a disc core storage device,wherein the disc core feeding device and the driving assembly are fixed on the support, the driving assembly is provided with a plurality of stations, the rotating part is fixed at the upper end of the driving assembly, the disc core storage device is fixedly arranged on the rotating part, and the disc core storage device and the disc core feeding device are arranged in parallel. Under the linkage cooperation of the disc core storage device and the disc core feeding device, a disc core is driven to rise wholly, so that storage and automatic feeding of the disc core are realized, the bonding precision is improved, and the labor cost is saved; and meanwhile, disc storage assemblies with two sizes are arranged, so that the device can be suitable for storage and automatic feeding of the disccores with different sizes, and the supply efficiency is improved.

Owner:深圳市沃尔热缩有限公司 +1

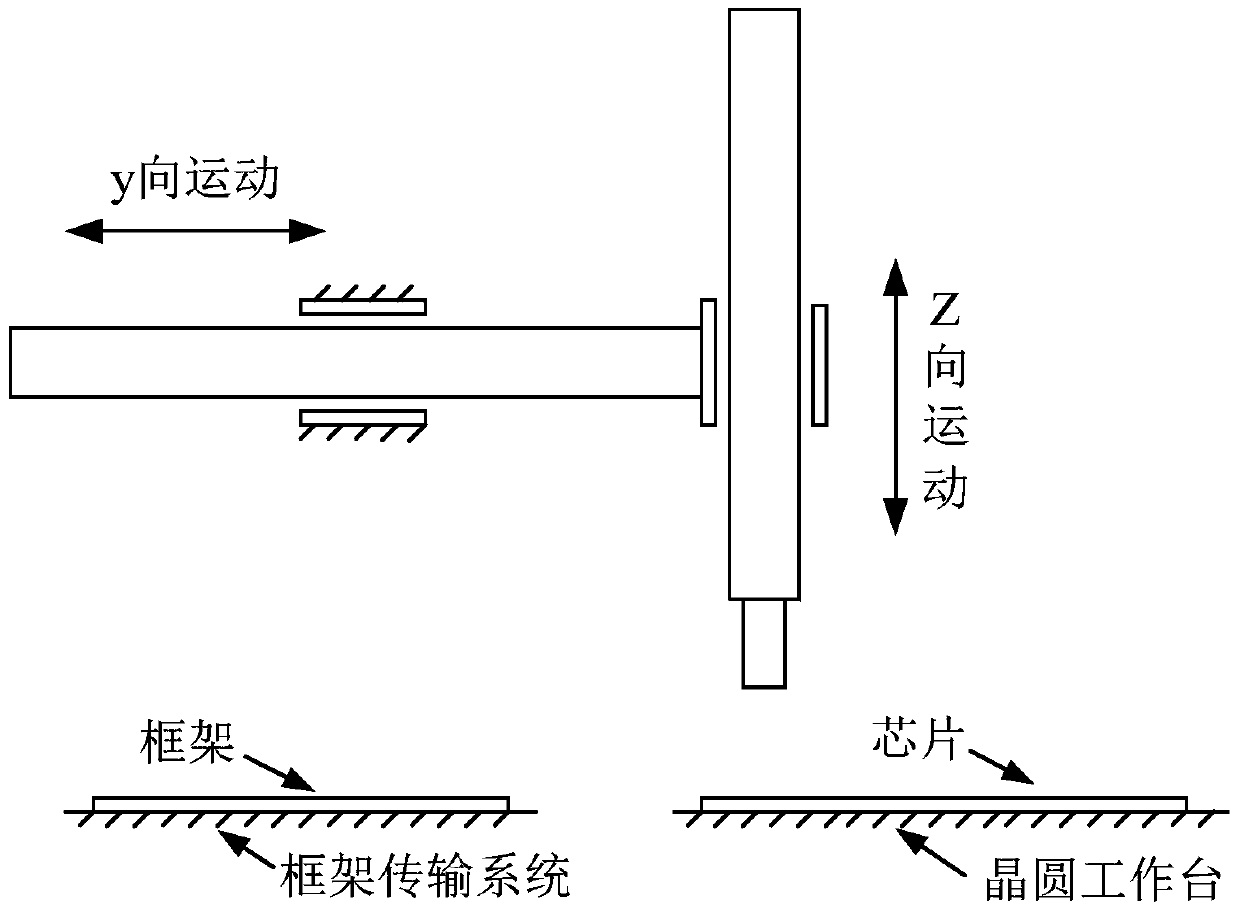

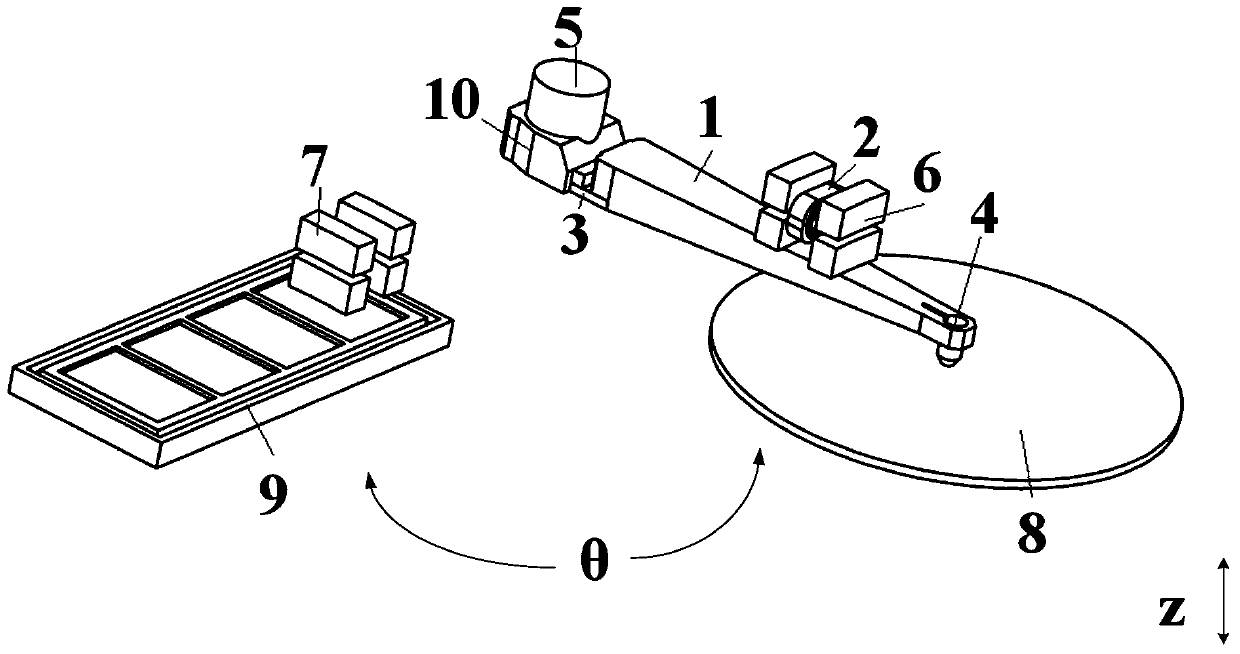

A chip feeding mechanism and chip bonder

InactiveCN105789101BIncrease stiffnessHigh speedSemiconductor/solid-state device manufacturingConveyor partsMachine buildingReciprocating motion

Owner:CETC BEIJING ELECTRONICS EQUIP

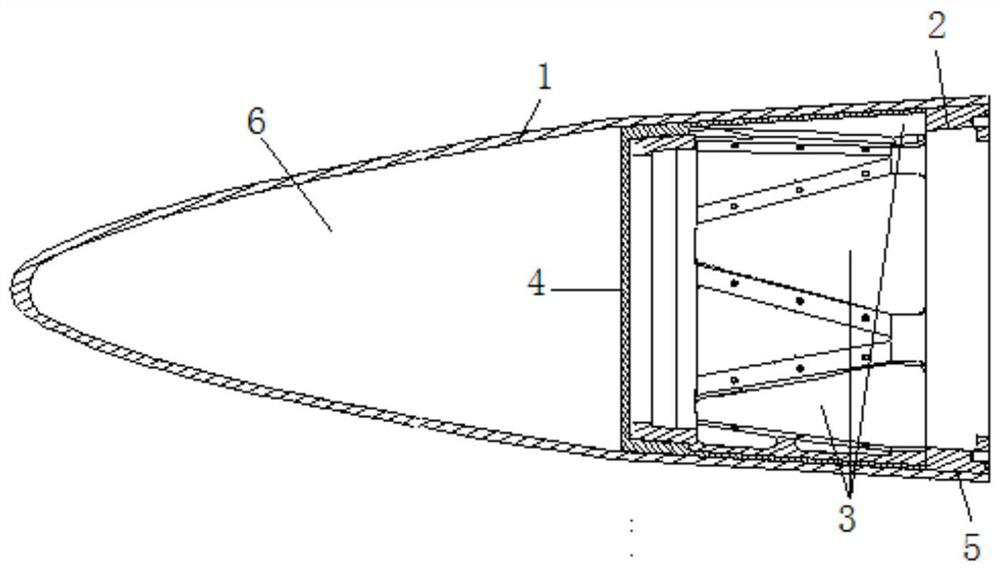

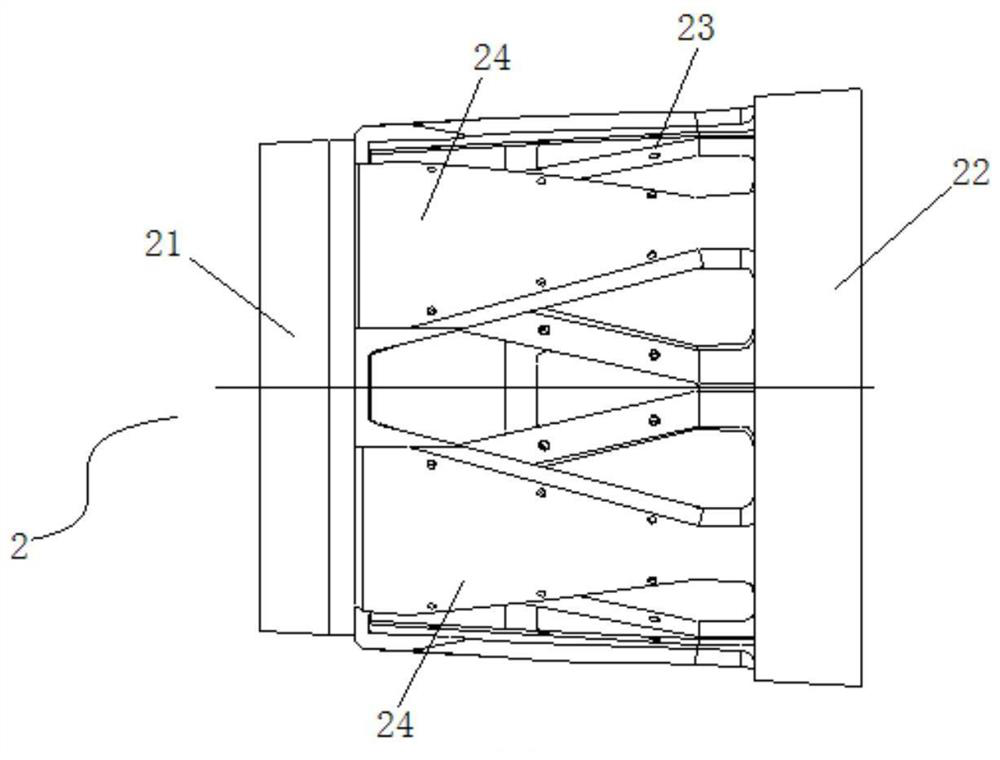

Conformal Active and Passive Radar Seeker Radome and Forming Method

ActiveCN108183303BSave spaceImprove Guidance AccuracyAntenna arraysAntenna supports/mountingsInterior spacePassive radar

The invention discloses a conformal active and passive radar guide head antenna cover. The conformal active and passive radar guide head antenna cover comprises a cover body, and further comprises a connecting ring assembly internally arranged in a cavity of the cover body, a plurality of conformal passive antennas arranged on the connecting ring assembly and an aerogel heat-insulating layer linked between the connecting ring assembly and the inner wall of the cover body, wherein the outer molded surfaces of the passive antennas are consistent with the inner molded surface of the cover body. The invention further provides a forming method for the antenna cover. The passive antennas and the antenna cover are designed in a conformal mode, and the passive antennas are peripherally and uniformly distributed on the connecting ring assembly inside the antenna cover, so that the homing angle range is great, the interior space of a guide head cabin is reduced, and guidance precision is improved; and the aerogel heat-insulating layer is adopted for insulating heat for the conformal passive antennas, so that normal use of antennas is guaranteed; and the conformal passive antennas are mountedon the connecting ring assembly, so that the structure is stable, and mounting is convenient.

Owner:湖北三江航天江北机械工程有限公司

Ultrasonic bonding method for J-shaped ruler

InactiveCN102615825AImprove structural strengthReduce measurement errorUltrasonic weldingUltrasonic bonding

The invention discloses an ultrasonic bonding method for a J-shaped ruler. One end of a main ruler of the J-shaped ruler is connected to the middle of an auxiliary ruler of the J-shaped ruler in a J-shaped manner; and under the condition that pressure of 2.0 to 6.5 Mpa is applied to a joint of the main ruler of the J-shaped ruler and the auxiliary ruler of the J-shaped ruler, the joint is welded by ultrasonic welding equipment and then hardened. According to a theory that the ultrasonic welding equipment welds a thermoplastic material, the J-shaped ruler is bonded under the condition of no toxicity and no harmfulness; furthermore, the method has the advantages of high bonding speed and high bonding precision; and therefore, the structural strength of the J-shaped ruler is effectively improved, and the measurement error of the J-shaped ruler is reduced.

Owner:南昌航天文化科技有限公司

A device for producing paper cones for smart speakers

ActiveCN112911493BAvoid affecting the assembly pressHigh bonding precisionElectrical transducersAdhesiveElectric machine

The invention discloses a device for producing intelligent speaker paper cones, which relates to the technical field of production of speaker paper cones, comprising: a base, a box cover is fixedly connected to the top of the base, a conveyor belt is slidably connected to the inside of the base, and the conveyor belt Extend outward through both sides of the box cover, and the top of the inner cavity of the box cover is provided with a pressing mechanism body, and one side of the inner cavity of the box cover is provided with a glue injection mechanism. In this scheme, by setting the glue injection mechanism, the discharge frequency of the piston can be adjusted by adjusting the rotation frequency of the rear motor, and the extension of the electric push rod can drive the connecting rod to move downward to adjust the movement stroke of the piston. The main body of the paper cone after glue injection It can be scraped upwards with the scraper. After the scraper is scraped, the excess adhesive can be scraped into the bottom overflow groove, and then the excess adhesive can be scraped and discharged by the scraper to avoid excessive glue injection. It affects the assembly and pressing, improves the bonding accuracy after pressing and assembling, and meets the overall production needs.

Owner:嵊州市锦声电子有限公司

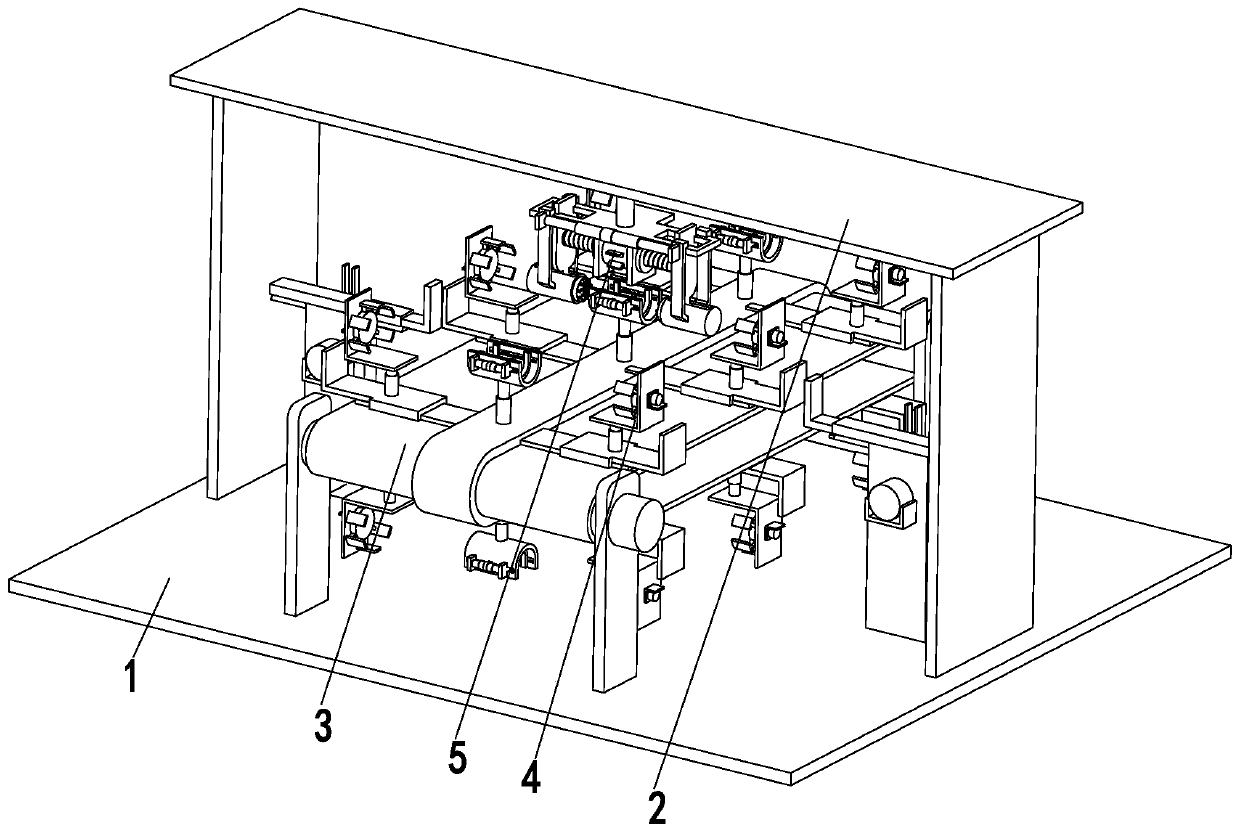

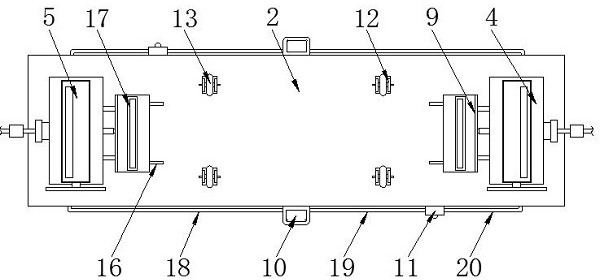

A kind of power transformer porcelain sleeve production bonding equipment

ActiveCN109119244BIncrease labor costImprove work efficiencyCoils manufactureTransformerBonding process

The invention relates to manufacture bonding equipment for a porcelain sleeve of a power transformer, the equipment includes a bottom plate, a mounting rack, conveyor, fixed device and bonding device,the conveyor is installed in the middle of the bottom plate, the fixed device is uniformly installed on the conveyor, an upper end of the fixed device is provided with the mounting rack, the mountingrack is mounted on the bottom plate, and the bonding device is mounted on the lower end of the mounting rack. The fixed device comprises a mounting ring, a linear slide rail, a sliding rack, a No. 1fixing mechanism and a No. 2 fixing mechanism, and the No. 1 fixing mechanism comprises a No. 1 regulating cylinder, a bearing bracket, a clamping plate, a bidirectional regulating cylinder and a mounting seat. The invention can solve the problems of poor stability, high labor cost, low working efficiency and easy occurrence of uneven bonding in the bonding process of the porcelain sleeve of tan existing transformer, can realize the function of automatic bonding of the porcelain sleeve of the transformer, and has the advantages of high stability, low labor cost, high working efficiency and high bonding precision.

Owner:WENZHOU HAILAN IND DESIGN

A device and method for bonding membrane shells

ActiveCN110861310BTo achieve the bonding effectImprove controllabilityDomestic articlesClassical mechanicsAdhesive glue

The invention discloses a device and method for bonding membrane shells, comprising a support frame, the top of the support frame is fixedly connected with a support plate, and the bottom of the support frame is fixedly connected with a support block, and the top of the support plate is fixedly connected with a support plate. Both sides are fixedly connected with a fixed box, and the tops of the two fixed boxes are fixedly connected with an air compressor, and a fixed plate is fixedly connected between the top and bottom of the inner wall of the fixed box. The invention relates to the technical field of membrane separation. The device and method for bonding membrane shells are mechanically assisted in manual bonding, and the bonding effect can be achieved through one-person operation, with high controllability, improved bonding pass rate, reduced bonding error, and improved bonding accuracy. , reduced labor costs, high practicability, mechanical bonding instead of manual bonding, improves work efficiency, speeds up production, and is easy to operate. It can be bonded immediately after the glue application is completed to prevent the glue from drying out and losing its effect. .

Owner:XINJIANG DELAND

Building decorative board bonding equipment capable of automatically improving bonding precision

PendingCN113914586AHigh bonding precisionGood adhesionBuilding constructionsConstruction engineeringPulley

The invention relates to the technical field of buildings, and discloses building decorative board bonding equipment capable of automatically improving bonding precision. The building decorative board bonding equipment comprises a bonding main body seat and a mounting mechanism, wherein the bonding main body seat comprises a supporting seat; the inside of the supporting seat is movably connected with a first placing plate; the inside of the supporting seat is fixedly connected with a sliding track; the mounting mechanism comprises a mounting plate; the surface of the mounting plate is rotatably connected with a driving plate; the other side of the mounting plate is movably connected with a pulley seat; the building decorative board bonding equipment further comprises a bonding mechanism; the bonding mechanism comprises a first driving rod; the outer surface of the first driving rod is rotatably connected with a rotating rod; one end of the rotating rod is movably connected with a moving wheel; the outer surface of the moving wheel is fixedly connected with a supporting shaft; and the outer surface of the supporting shaft is fixedly connected with a first convex seat. The bonding distance of decorative boards can be reduced, the bonding precision is improved, intelligence is high, and convenience is brought to use of building decorative boards in the future.

Owner:徐蕾莹

Bonding tool for bonding glass panels to fume hoods

The invention relates to an adhering tool for adhering a glass panel to an exhaust fume collecting hood. The adhering tool comprises a support, and an adhering structure is at least arranged on one side of the support. The adhering tool is characterized in that the adhering structure comprises an upper bearing board, a lower bearing board, two positioning air cylinders, an upper installation board and compression blocks, wherein locating detents are installed on piston rods of the positioning air cylinders and provided with horizontal arms and inclined arms; first positioning blocks are fixed to the horizontal arms; second positioning blocks are fixed to the ends of the inclined arms on at least one side; the upper installation board is fixed above the support; the upper installation board and a top board of the support are spaced vertically; the compression blocks are located over the upper bearing board and driven by a compression air cylinder to vertically and perpendicularly move; the compression blocks press downwards to compress the glass panel to the front end face of the exhaust fume collecting hood for pressure maintaining. The adhering tool has the advantages that structural design is reasonable, the glass panel adheres to the exhaust fume collecting hood accurately and firmly, the binding efficiency and precision are high, a few procedures are needed, and operation is convenient.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Processing and bonding method of airborne rocket shell slideway

The invention discloses a processing and bonding method of an airborne rocket shell slideway. The processing and bonding method comprises a pair of front slideways and a pair of rear slideways. Each front slideway comprises a front slideway body and a front sliding groove. Each rear slideway comprises a rear slideway body and a rear sliding groove. The processing of the pair of front slideway bodies and the pair of rear slideway bodies, the processing of the pair of front sliding grooves and the pair of rear sliding grooves, the manufacturing of samples and parts and the bonding and curing ofthe parts and the samples are achieved. A high-shear-strength adhesive and an optimized curing parameter are selected, an efficient bonding surface treatment method is adopted, a high-precision integral bonding special positioning and clamping device and reasonable bonding part size precision design and processing are adopted, the bonding effects of high bonding shearing strength, high bonding precision and high bonding efficiency are obtained, and the bonding shearing strength is improved from 26 MPa to at least 40 MPa. The device not only can be used for processing and high-strength bondingof the airborne rocket shell slideway, but also can be used for processing and high-strength bonding of other similar product parts.

Owner:湖北三江航天江北机械工程有限公司

A fpc automatic bonding machine

ActiveCN110886751BRealize automatic bondingHigh bonding precisionMaterial gluingEmbedded systemElectrical mechanism

The present invention provides an FPC automatic bonding machine, comprising: a carrying device configured to carry FPC and products; a turning device including a first feeding mechanism, a turning mechanism and a first driving mechanism, and the first feeding mechanism is configured as The FPC is carried, the first feeding mechanism is arranged on the flipping mechanism, the first driving mechanism is connected with the flipping mechanism, and the first driving mechanism is configured to drive the flipping mechanism to flip, so that the bonding surface of the FPC is opposite to the surface to be bonded of the product; a connecting device configured to bond the FPC to the product; a transferring device configured to transfer the FPC on the carrier device to the flipping device and the FPC on the flipping device to the bonding device; the positioning device, including position acquisition A mechanism and a deviation correction mechanism; the position acquisition mechanism is configured to acquire position information of the FPC and the product, and the deviation correction mechanism corrects the position of the FPC and the product according to the position information. The turning mechanism can realize automatic bonding of FPC, and the positioning device can improve the bonding accuracy of FPC.

Owner:GOERTEK INC

Embedded part bonding fixture

ActiveCN109249319AHigh bonding efficiency and precisionBonding requires less processMaterial gluingWork holdersEngineeringAutomation

The invention relates to an embedded part bonding fixture, which comprises a table board; a bonding structure, wherein the bonding structure comprises a decorative strip positioning structure; a pressing plate assembly arranged above the table board; a vertical driving structure used for driving the pressing plate assembly to move up and down perpendicular to the table board; a front positioning block used for positioning the front edge of a glass panel; a left positioning block and a right positioning block, which are respectively used for positioning the left edge and rear edge of the glasspanel; a rear positioning block used for positioning the rear edge of the glass panel; a front pushing block arranged on the table board and is driven by a front driving structure to slide back and forth, wherein the front pushing block is used for pushing the glass panel backwards and embedding the rear part of the glass panel into a clamping groove part of the decorative strip. The device can automatically embed the glass panel into the clamping groove part of the decorative strip with a U-shaped cross section, and can perform well pressure maintaining on the glass panel in the clamping groove part so as to ensure the automation of the process of bonding the decorative strip with the U-shaped cross section to the glass panel.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com