Lost foam gluing mould

A technology of lost foam and mold, applied in the direction of casting molding equipment, etc., can solve the problems affecting the molding quality of castings, uneven glue application, etc., and achieve the effect of improving bonding precision and bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments.

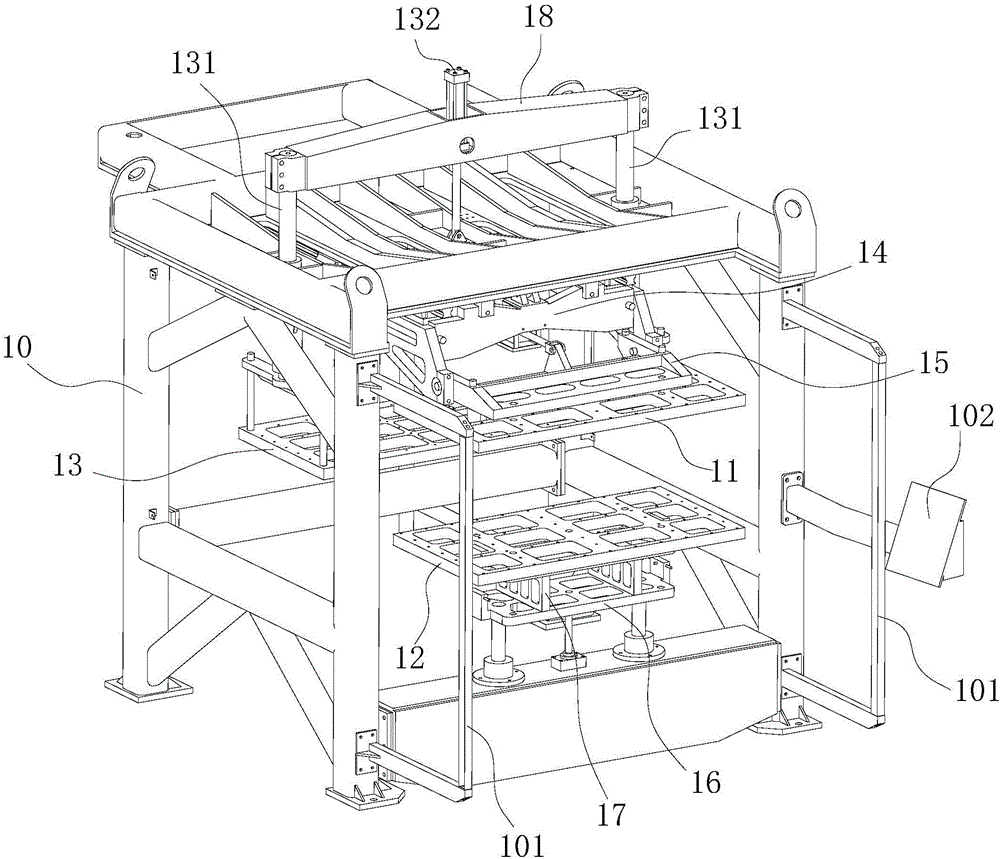

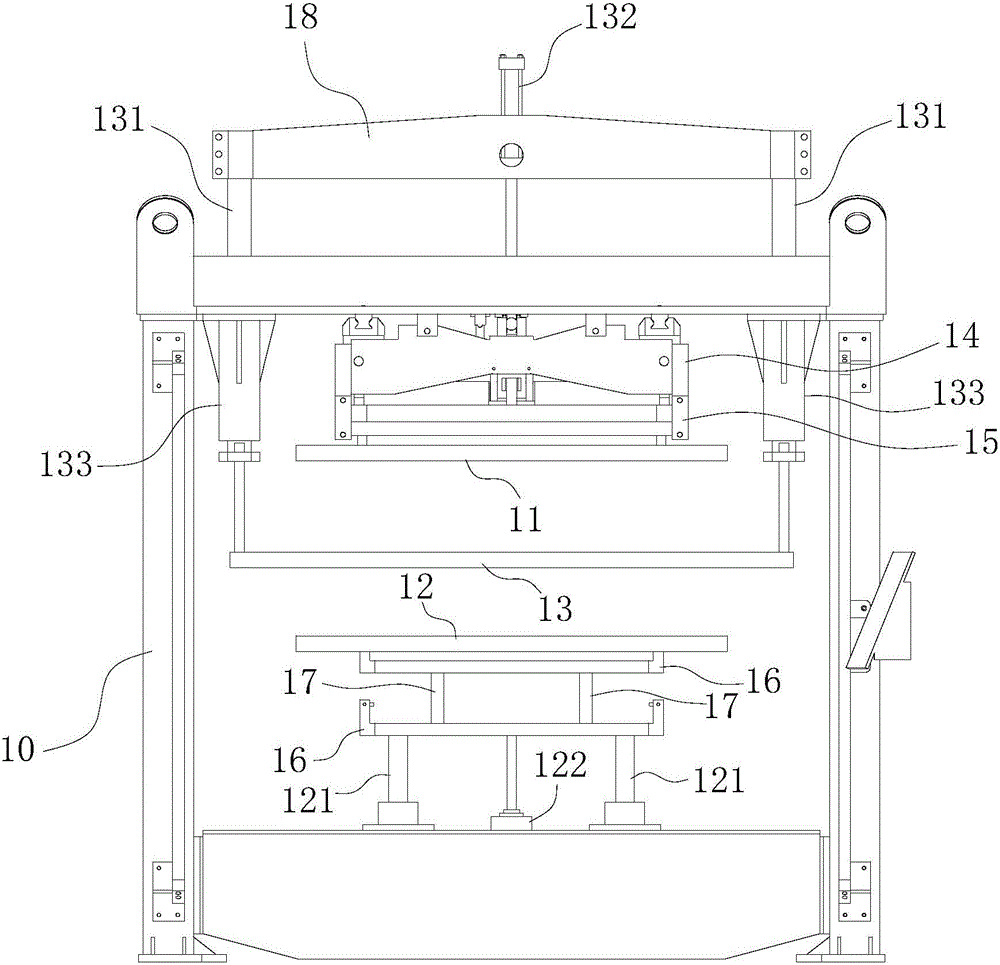

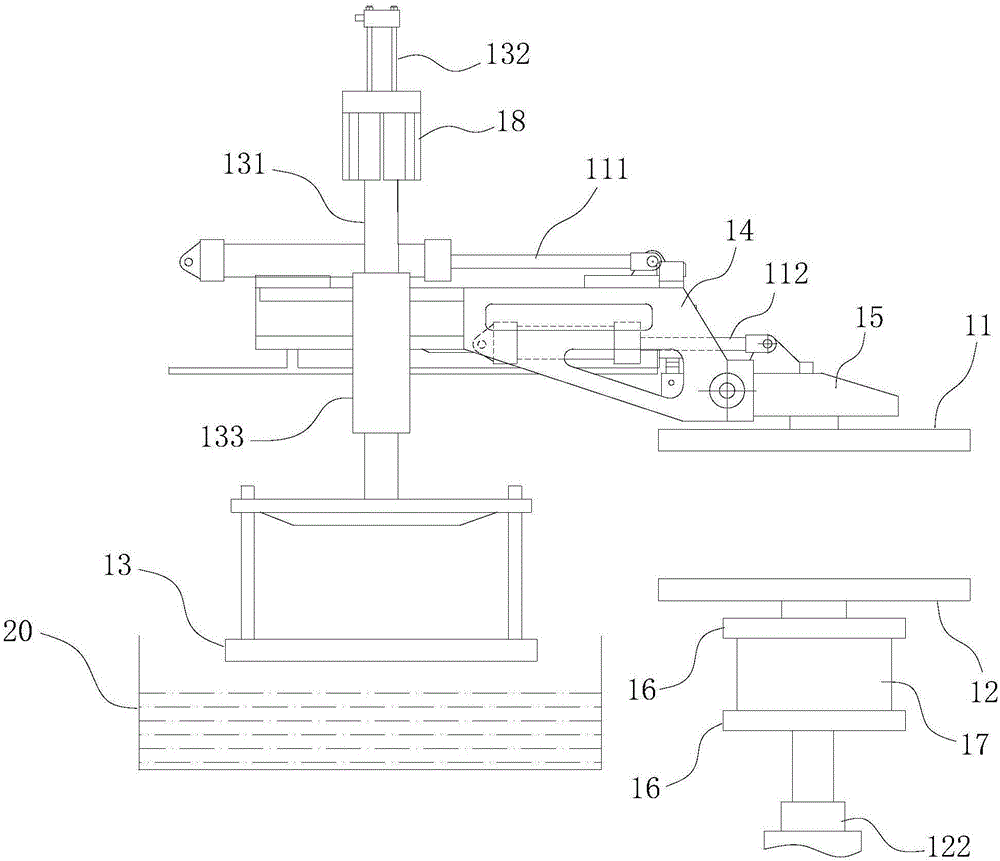

[0020] like Figure 1~4 As shown, a kind of lost foam gluing mold comprises an upper template 11 and a lower template 12 which are respectively used to fix the upper and lower halves of the lost foam to be glued on the frame 10, and is used for the upper half of the lost foam The die 13 with glue on the bottom; the upper template 11 and the lower template 12 are arranged in a vertically open and closed manner, and the die 13 is reciprocatingly arranged in the vertical direction, and the bottom of the die 13 is provided with a container for holding glue Glue pool 20, when the stamp 13 moves down, the upper surface of the stamp 13 can be submerged in the glue pool 20; the upper template 11 is reciprocatingly set along the horizontal direction, so that the upper template 11 can alternately run to the top or bottom of the stamp 13 Above the template 12, when the upper templa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com