Building decorative board bonding equipment capable of automatically improving bonding precision

An architectural decoration and bonding technology, applied in the direction of construction and building structure, can solve problems such as affecting the use of architectural decorative panels, affecting the bonding accuracy of panels, and large bonding distance, and achieves high intelligence, convenient operation, and reduced cost. The effect of small bonding distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

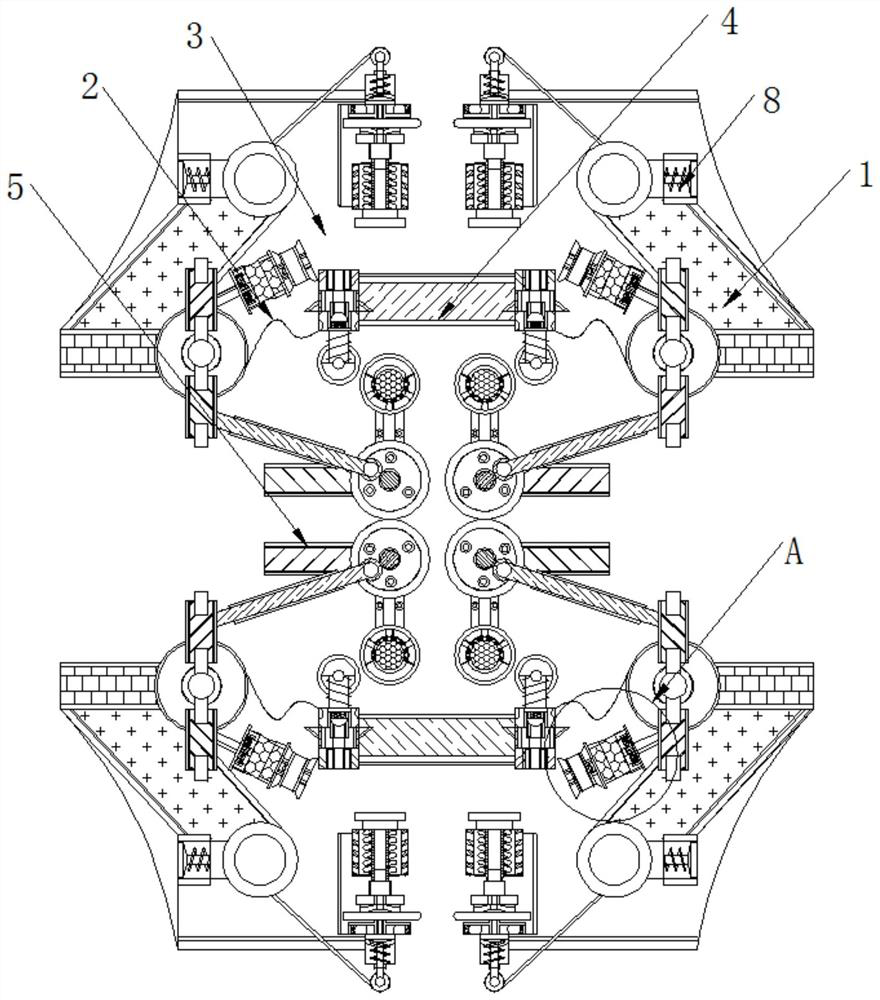

[0021] as attached figure 1 to attach Figure 4 Shown:

[0022] A building decoration plate bonding equipment that can automatically improve the bonding accuracy, including a bonding main body seat 1 and an installation mechanism 2, the bonding main body seat 1 includes a support seat 3, and a first placement plate 4 is movably connected inside the support seat 3 , the inside of the support seat 3 is fixedly connected with a sliding track 5 .

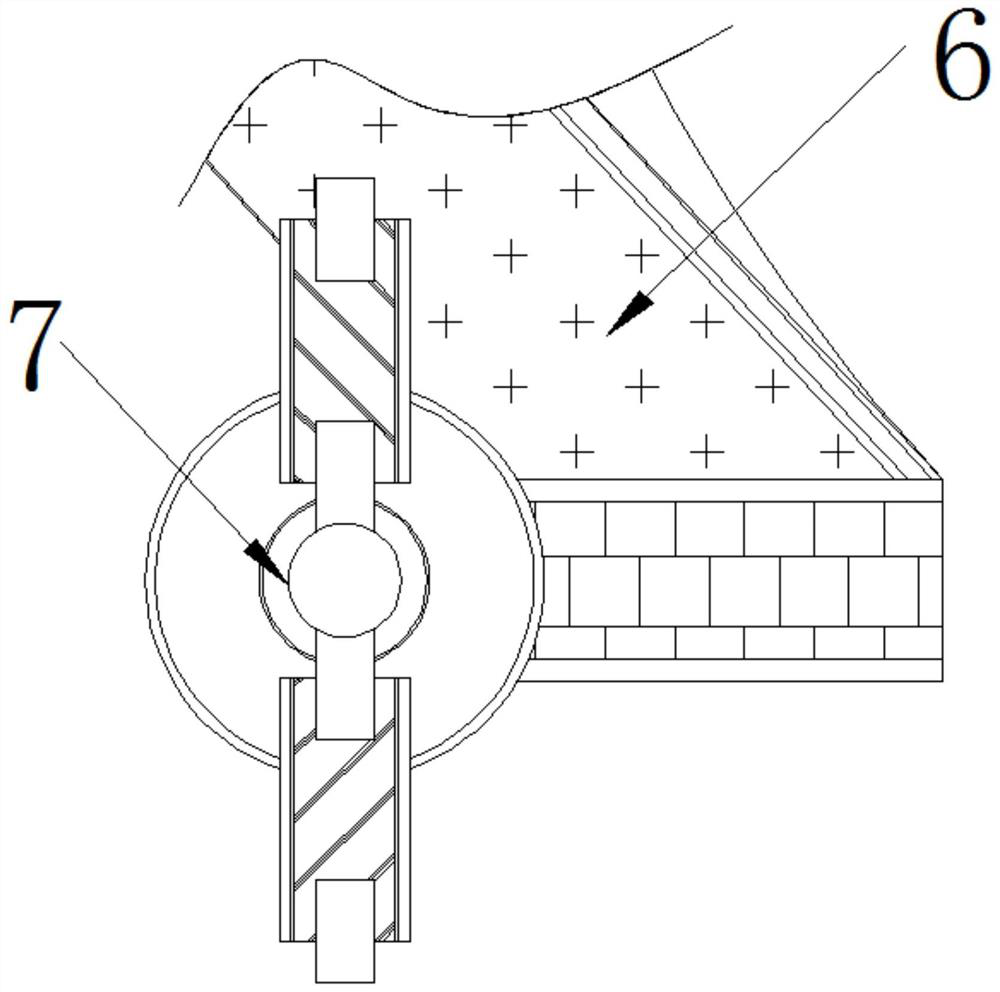

[0023] The mounting mechanism 2 includes a mounting plate 6 , the surface of the mounting plate 6 is rotatably connected with a drive disc 7 , and the other side of the mounting plate 6 is movably connected with a pulley seat 8 .

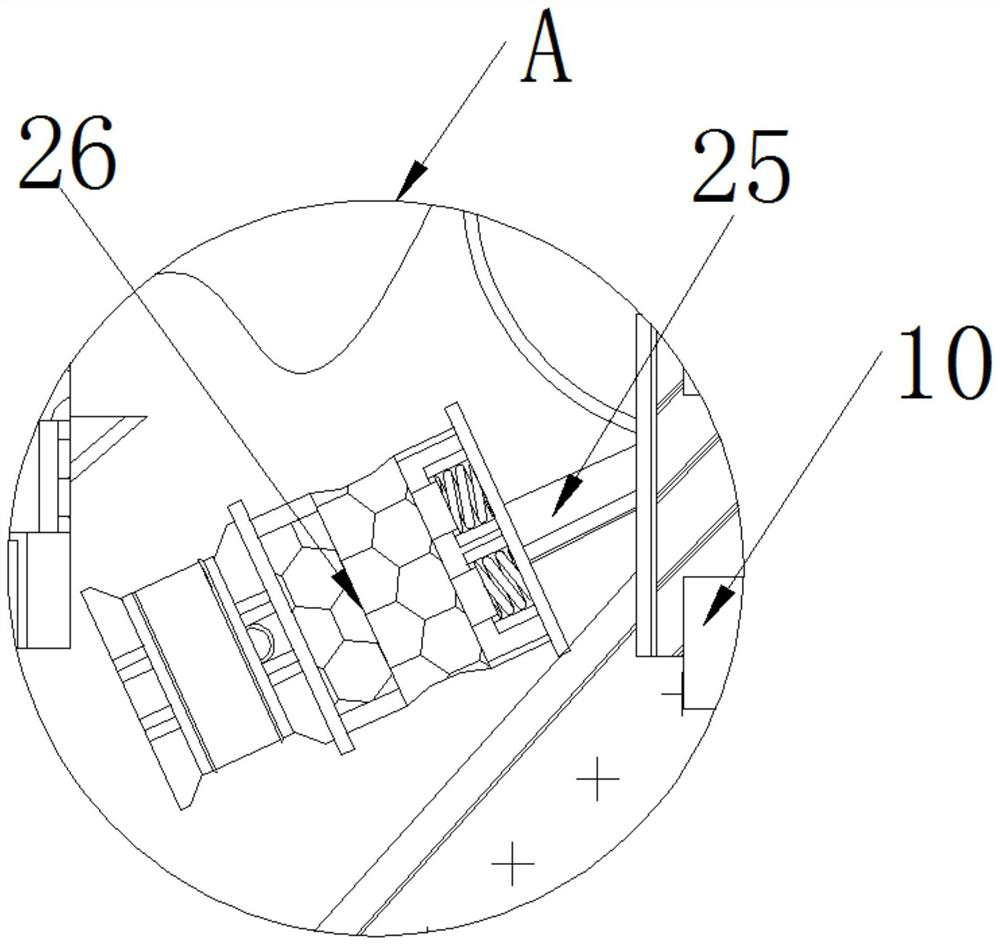

[0024] Further, a bonding mechanism 9 is also included, and the bonding mechanism 9 includes a first driving rod 10, the outer surface of the first driving rod 10 is rotatably connected with a rotating rod 11, and one end of the rotating rod 11 is movably connected with a moving wheel 12, and the moving whe...

specific Embodiment approach 2

[0026] as attached Figure 4 to attach Figure 5 Shown:

[0027] A building decoration plate bonding equipment that can automatically improve the bonding accuracy, including a bonding main body seat 1 and an installation mechanism 2, the bonding main body seat 1 includes a support seat 3, and a first placement plate 4 is movably connected inside the support seat 3 , the inside of the support seat 3 is fixedly connected with a sliding track 5 .

[0028] Further, it also includes an adjustment mechanism 18, the adjustment mechanism 18 includes a second drive rod 19, the outer surface of the second drive rod 19 is movably connected with a connecting rope 20, and the other end of the connecting rope 20 is movably connected with an extension seat 21, and the extension seat 21 The inner side of the extension seat 21 is movably connected with an extension spring 22, the side surface of the extension seat 21 is movably connected with an adjustment seat 23, the lower surface of the a...

specific Embodiment approach 3

[0030] as attached figure 1 to attach Figure 5 Shown:

[0031] A building decoration plate bonding equipment that can automatically improve the bonding accuracy, including a bonding main body seat 1 and an installation mechanism 2, the bonding main body seat 1 includes a support seat 3, and a first placement plate 4 is movably connected inside the support seat 3 , the inside of the support seat 3 is fixedly connected with a sliding track 5 .

[0032] The mounting mechanism 2 includes a mounting plate 6, the surface of the mounting plate 6 is rotatably connected with a drive disc 7, the other side of the mounting plate 6 is movably connected with a pulley seat 8, and the bonding mechanism 9 includes a first driving rod 10, the first driving rod 10 The outer surface of the rotating rod 11 is rotatably connected with a rotating rod 11, and one end of the rotating rod 11 is movably connected with a moving wheel 12, the outer surface of the moving wheel 12 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com