Processing and bonding method of airborne rocket shell slideway

A rocket shell and bonding method technology, applied in the direction of connecting components, mechanical equipment, material gluing, etc., can solve the problems of high processing efficiency, low manufacturing cost, large quantity, etc., and achieve high bonding shear strength, high viscosity The effect of high bonding efficiency and high bonding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

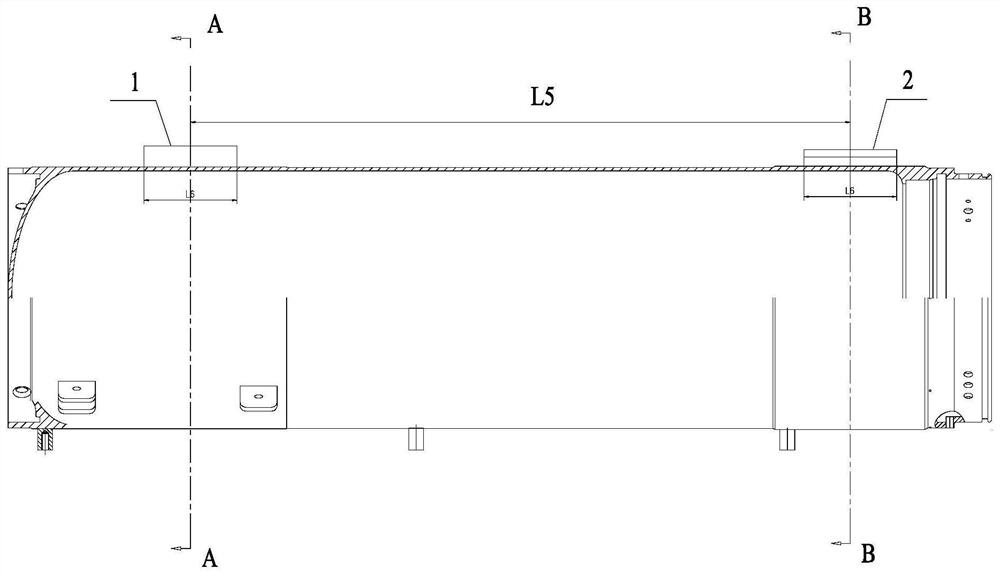

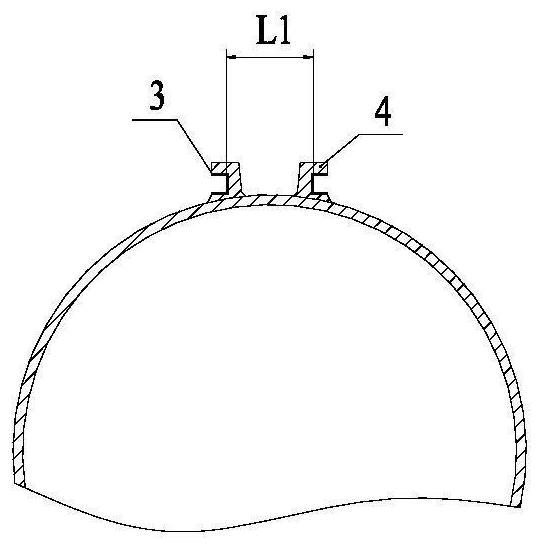

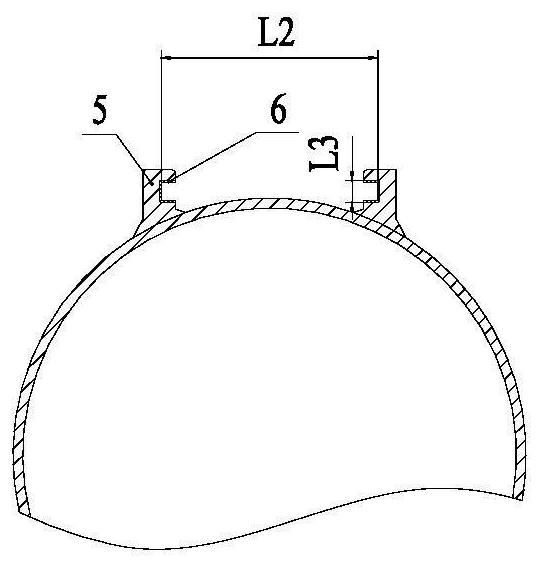

[0068] For a certain type of 30CrMnSiA low-alloy high-strength steel small shell, its outer diameter is 140mm, the shell length is 550mm, the distance L1 between the bottom of a pair of front slideway body guide grooves is 26mm, and the pair of rear slideway body guides The distance L2 between the groove bottoms is 62mm, the guide groove width L3 of the slideway body is 7mm, the groove width L4 of the slideway is 5mm, the center distance L5 from the front slideway body to the rear slideway body is 360mm, and the slideway body Length L6 is 50mm, and the processing and bonding method of airborne rocket shell slideway of the present invention are as follows:

[0069] 1) Processing of a pair of front slideway bodies and a pair of rear slideway bodies

[0070] The groove width of a pair of front slideway bodies and a pair of rear slideway body guide grooves is the same as L3, and the machining accuracy and deviation of L3 are L3(0, +0.02mm);

[0071] Machining of a pair of front c...

Embodiment 2

[0089] For a certain type of 30CrMnSiA low-alloy high-strength steel small shell, its outer diameter is 180mm, shell length is 850mm, the distance L1 between the bottom of a pair of front slideway body guide grooves is 36mm, and a pair of rear slideway body guides The distance L2 between the groove bottoms is 72mm, the guide groove width L3 of the slideway body is 9mm, the groove width L4 of the slideway is 7mm, the center distance L5 from the front slideway body to the rear slideway body is 560mm, and the slideway body Length L6 is 66mm, and the processing and bonding method of airborne rocket shell slideway of the present invention are as follows:

[0090] 1) Processing of a pair of front slideway bodies and a pair of rear slideway bodies

[0091] The groove width of a pair of front slideway bodies and a pair of rear slideway body guide grooves is the same as L3, and the machining accuracy and deviation of L3 are L3(0, +0.02mm);

[0092] Machining of a pair of front chute a...

Embodiment 3

[0110] For a certain type of 30Si2MnCrMoVE low-alloy high-strength steel small shell, its outer diameter is 220mm, the shell length is 1150mm, the distance L1 between the bottom of a pair of front slideway body guide grooves is 36mm, and the pair of rear slideway body guides The distance L2 between the groove bottoms is 72mm, the guide groove width L3 of the slideway body is 11mm, the groove width L4 of the slideway is 9mm, the center distance L5 from the front slideway body to the rear slideway body is 560mm, and the slideway body Length L6 is 80mm, and the processing and bonding method of airborne rocket shell slideway of the present invention are as follows:

[0111] 1) Processing of a pair of front slideway bodies and a pair of rear slideway bodies

[0112] The groove width of a pair of front slideway bodies and a pair of rear slideway body guide grooves is the same as L3, and the machining accuracy and deviation of L3 are L3(0, +0.02mm);

[0113] Machining of a pair of f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Adhesive shear strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com