Capacitance probe system suitable for supercritical water fluidized bed and use method thereof

A capacitive probe and water fluidized bed technology, which is applied in the sealing of engines, bulk chemical production, mechanical equipment, etc., can solve problems such as difficult use of capacitive probe systems, achieve safe and stable work, and solve measurement problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the present invention, the present invention will be described below in conjunction with the embodiments. These descriptions are only used to further explain the features and advantages of the present invention, and are not intended to limit the claims of the present invention.

[0036] In order to solve the application problem of the capacitance probe system in the supercritical water fluidized bed reactor, the present invention optimizes and improves on the basis of the traditional capacitance probe system, and develops a supercritical water fluidized bed reactor. The capacitance probe system and method can obtain detailed information such as local porosity in a supercritical water fluidized bed.

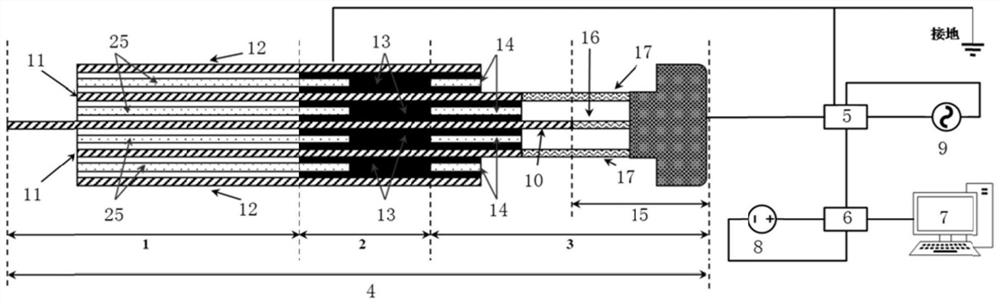

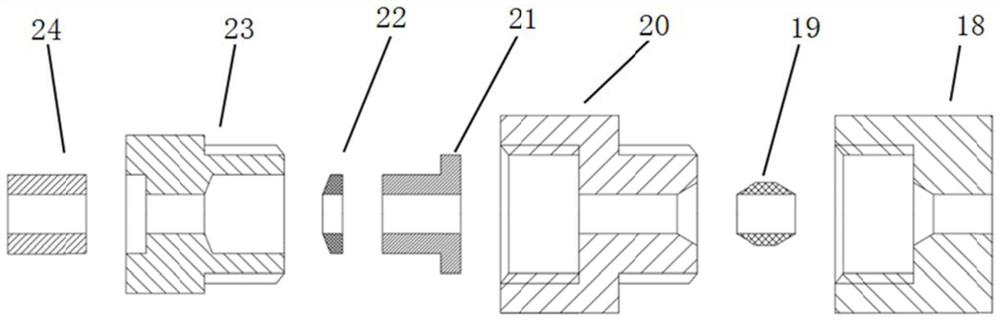

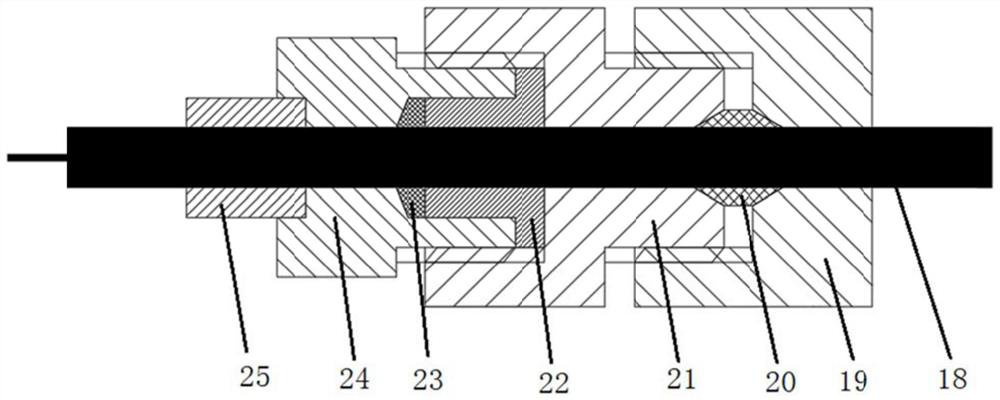

[0037]The present invention is applicable to a capacitance probe system of a supercritical water fluidized bed, including a capacitance probe sensor 4, a sealing device, a capacitance measurement amplifier 5, a data acquisition card 6, a DC pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com