Ultrasonic bonding method for J-shaped ruler

A bonding method and ultrasonic welding technology, applied in the field of T-square ultrasonic bonding, can solve the problems of T-square cracking, adhesion precision error, and weak adhesion structure, so as to improve structural strength, reduce measurement error, The effect of fast bonding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

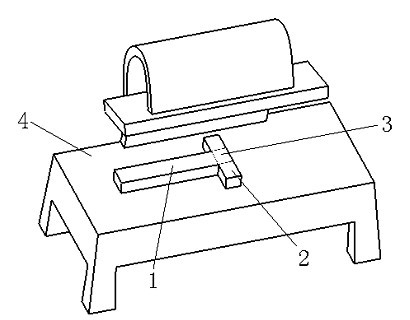

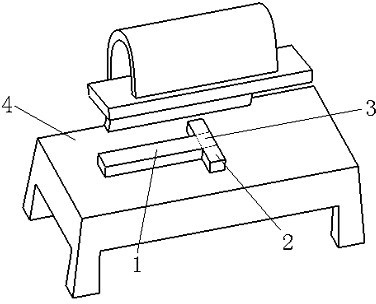

[0008] Such as figure 1 As shown, the present invention is realized in this way, one end of the main chi 1 of the T-shaped ruler is connected in a T-shape with the middle part of the auxiliary chi 2 of the T-shaped ruler, and 2.0 ~ 6.5 Under the condition of Mpa pressure, the connecting part 3 is welded by ultrasonic welding equipment 4, and the connecting part 3 is hardened after welding.

[0009] In an embodiment, one end of the main ruler 1 of the T-square is connected to the middle part of the auxiliary ruler 2 in a T-shape, and under the condition that a pressure of 4.0 Mpa is applied to the connecting part 3 of the main ruler 1 of the T-square and the auxiliary ruler 2 of the T-square, the connecting part 3 Welded by ultrasonic welding equipment 4, the joint part 3 is hardened after welding, and the T-square welding is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com